5

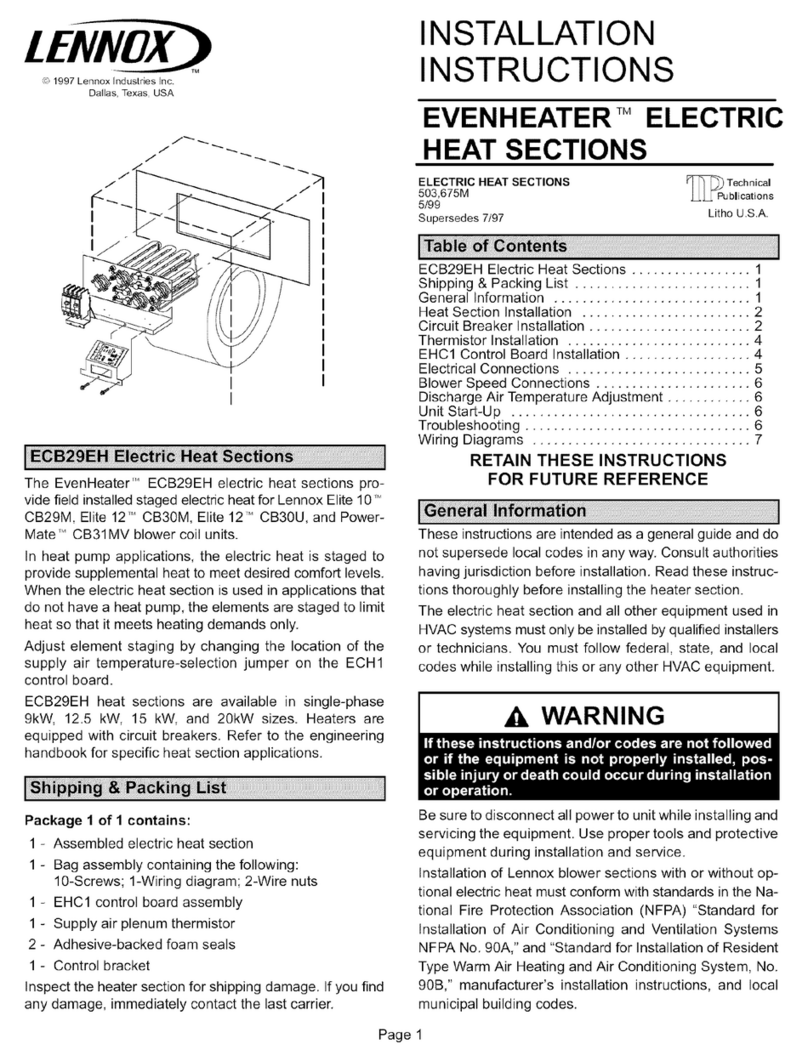

1.5. Decision Tree

Upflow/Horizontal

NOTE − AIR HANDLER REQUIRES

FIELD-FABRICATED TRANSITION

BETWEEN BLOWER OUTLET AND

EDA COIL.

[If

furnace]

Select

indoor

coil

MUST BE

TXV ONLY

Select EDA

Zoning

application?

START

Must use one of

these variable speed

indoor units:

CBA25UHV, CBA27UHE, CBA38MV, CBX27UH,

CBWMV, EL296UHV, EL296DFV,

ML296UHV, ML296DFV

SL280UHV, SL280UHNV, SL280DFV,

SL297UHNV, SLP98UHV, SLP98DFV ONLY!!

*Must use one of

these outdoor units:

YES NO YES

Is

selection a

certified AHRI rated

system (https://www.

ahridirectory.org)

Downflow

NOTE - REQUIRES ADDITIONAL

FIELD-FABRICATED SUPPORT

FRAME AND TRANSITION; SEE

INSTALLATION SUPPLEMENT,

“Installing Humiditrol®Unit in

Downflow Configuration”.

Upflow/

Horizontal Downflow

How

installed

?

YES

INSTALL SYSTEM

Order Humiditrol®Zoning

Accessory (HZA) Kit (39W67)

REFER TO INSTALLATION INSTRUCTION,

“Installing The Humiditrol®Enhanced

Dehumidification Accessory (EDA) In A

Harmony III™ Zoning System Using The

Humiditrol®Zoning Accessory”

Application

Not Approved

DO NOT

INSTALL!

NO

Harmony

III™ Zoning

System

?

YES

Select Piping Kit

NO

Select different equipment

X = PREFERRED MATCH-UP

A = ALLOWED FOR PHYSICAL MATCH-UP TO INDOOR COIL

Capacity

HUMIDITROL®EDA MODEL

EDA-024B

(94M41)

EDA-036C

(94M42)

EDA-060D

(94M43)

-018 XA

-024 XA

-030 XA

-036 XA

-042 X

-048 X

-060 X

*Not applicable to variable-capacity outdoor units!

13ACXN, 14ACX, 16ACX, EL16XC1, ML14XC1,

SL18XC1, SSB, TSAH4, TSAS4, XC13N, XC14,

XC16, XC21 ONLY!

14HPX, 16HPX, EL15XP1, EL16XP1, ML14XP1,

ML16XP1, SL18XP1, SPB, TPAH4, XP14,

XP16, XP21 ONLY!

Capacity Type Outdoor Unit Model Piping Kit

018 AC 13ACXN, 14ACX, EL16XC1, ML14XC1, XC13N, XC14 98M62

HP 14HPX, EL15XP1, EL16XP1, ML14XP1, ML16XP1, XP14 98M22

024 AC 13ACXN, 14ACX, EL16XC1, ML14XC1, SL18XC1, XC13N, XC14, XC21 98M62

16ACX, XC16 98M22

XC21 94M44

HP 16HPX, SL18XP1, XP16, XP21 94M44

14HPX, EL15XP1, ML14XP1, XP14 98M62

EL16XP1, ML16XP1 98M22

030 AC 13ACXN, 14ACX, 16ACX, EL16XC1, ML14XC1, SL18XC1, XC13N, XC14 98M62

HP 14HPX, EL15XP1, ML14XP1 98M62

EL16XP1, ML16XP1, SL18XP1 98M22

036 AC 13ACXN, 14ACX, 16ACX, EL16XC1, ML14XC1, SL18XC1, SSB, TSAH4, TSAS4,

XC13N, XC14, XC16

98M62

XC21 94M44

HP 14HPX, 16HPX, EL15XP1, ML14XP1, SPB, TPAH4, XP14, XP16, XP21 94M44

EL16XP1, ML16XP1, SL18XP1 98M22

042 AC 13ACXN, 14ACX, EL16XC1, ML14XC1, SL18XC1, TSAH4, TSAS4, XC13N, XC14 98M62

HP 14HPX, TPAH4, XP14 94M44

EL15XP1, EL16XP1, ML14XP1, ML16XP1, SL18XP1 98M22

048 AC 13ACXN, 14ACX, 16ACX, EL16XC1, ML14XC1, SL18XC1, SSB, TSAH4, TSAS4,

XC13N, XC14, XC16

98M62

XC21 94M44

HP XP21 94M44

14HPX, 16HPX, EL15XP1, EL16XP1, ML14XP1, ML16XP1, SL18XP1, SPB,

TPAH4, XP14, XP16

98M22

060 AC 13ACXN, TSAS4, XC13N 98M62

14ACX, 16ACX, EL16XC1, ML14XC1, SL18XC1, SSB, TSAH4, XC14, XC16 98M22

XC21 94M44

HP 16HPX, EL15XP1, EL16XP1, ML14XP1, ML16XP1, SPB, XP16 98M22

14HPX, SL18XP1, TPAH4, XP14, XP21 94M44

iComfort®

E30, M30 or

ComfortSense®

7500?

NO

YES

Figure 1. Decision Tree