Lennox FLATAIR KFC Series User manual

Other Lennox Fan manuals

Lennox

Lennox EvenHeater ECB29EH User manual

Lennox

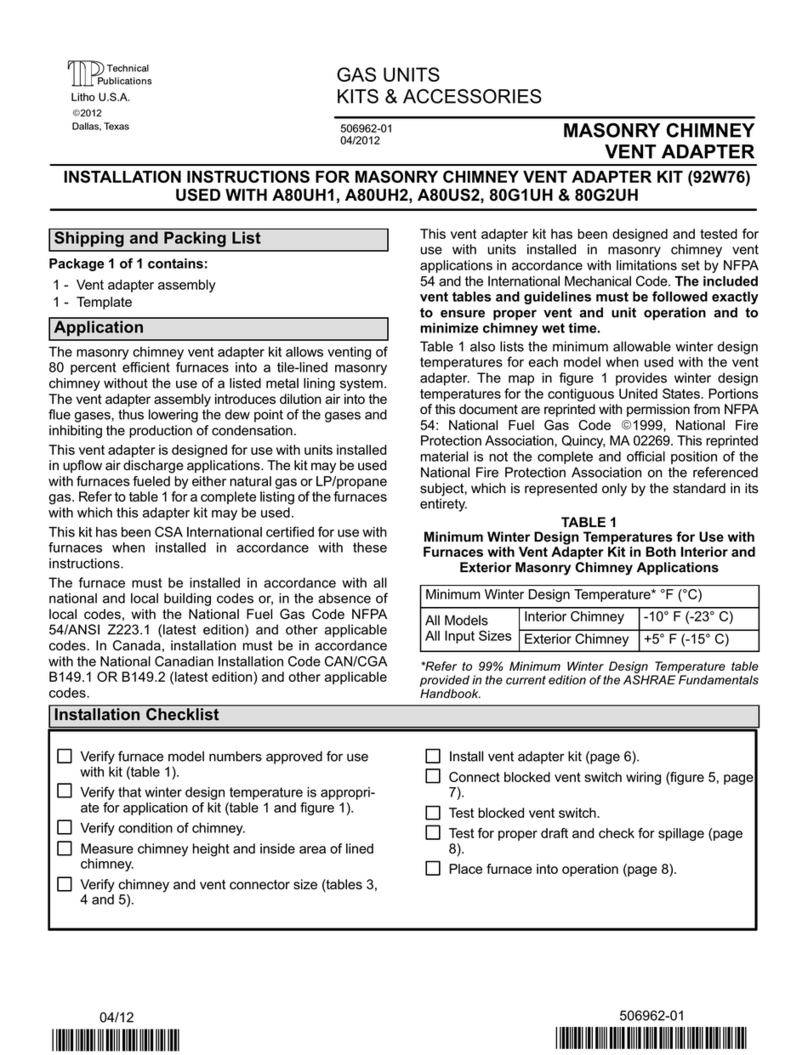

Lennox 92W76 User manual

Lennox

Lennox LPVK-110 User manual

Lennox

Lennox 18M7901 User manual

Lennox

Lennox KG Series User manual

Lennox

Lennox ELS SERIES Installation and operation manual

Lennox

Lennox Enlight LGT Series User manual

Lennox

Lennox ARIA EC Series User guide

Lennox

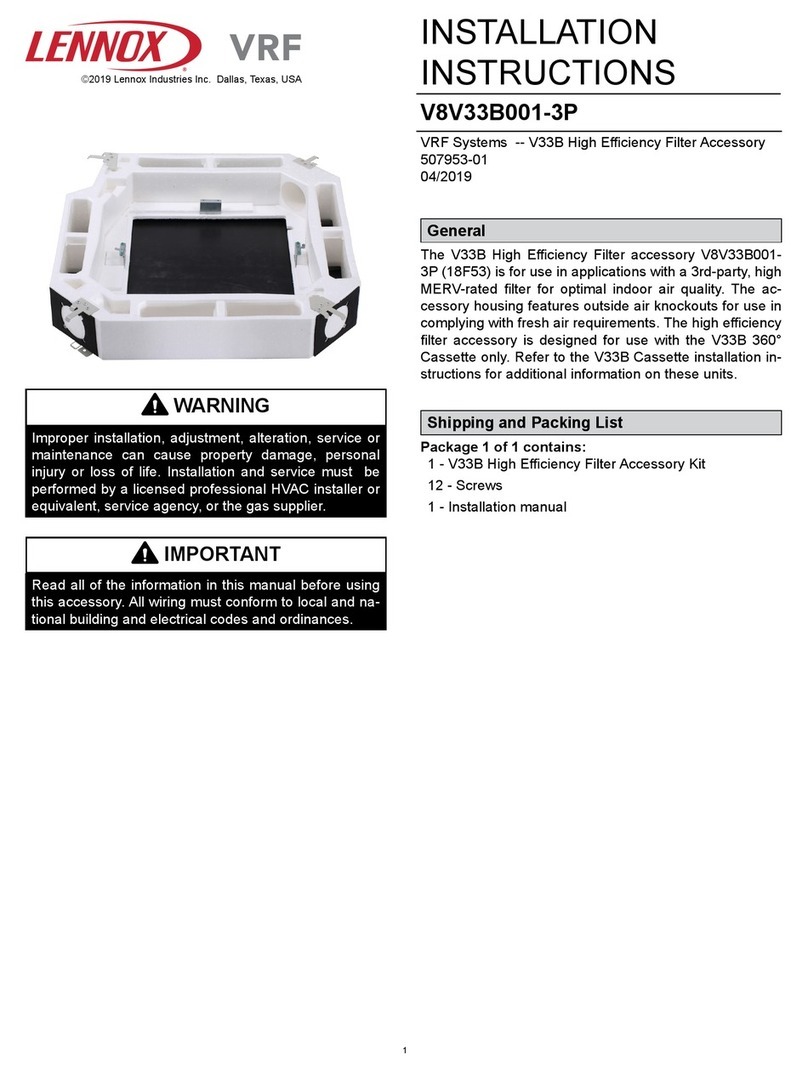

Lennox V8V33B001-3P User manual

Lennox

Lennox EDA User manual

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions