DELTA PRES SURE

FRESH AIR

DELTA PRES SURE

EX HAUST AIR

Figure 21

OPERATION

Recovery Wheel Mode

On a thermostat call for blower operation in heating,

cooling or continuous blower, the ERS media will rotate

between fresh air and exhaust air streams. Both the fresh

air blower and exhaust air blower will be operating.

Economizer/Power Exhaust Mode

On the activation of the economizer mode (closure of EH

and EH1 of logic module), the ERS unit will shutdown for

approximately60secondstoallowtheERS mediatopivot

out of the air stream. After this delay timer has been

satisfied,theexhaustairblowerwilloperate.TheERS unit

will act as a power exhaust unit.

This mode will continue until economizer has been

deactivated.Theexhaustairblowerwill shut downandthe

delay timer will be activated. During this time period the

ERS mediawillpivotback intotheairstream.Whentiming

is complete the unit will operate in the Recovery Wheel

Mode.

Then if economizer continues to close the ERS will

shutdown when the "N" terminal is deactivated, thus

allowing rooftop unit to run in night set back mode.

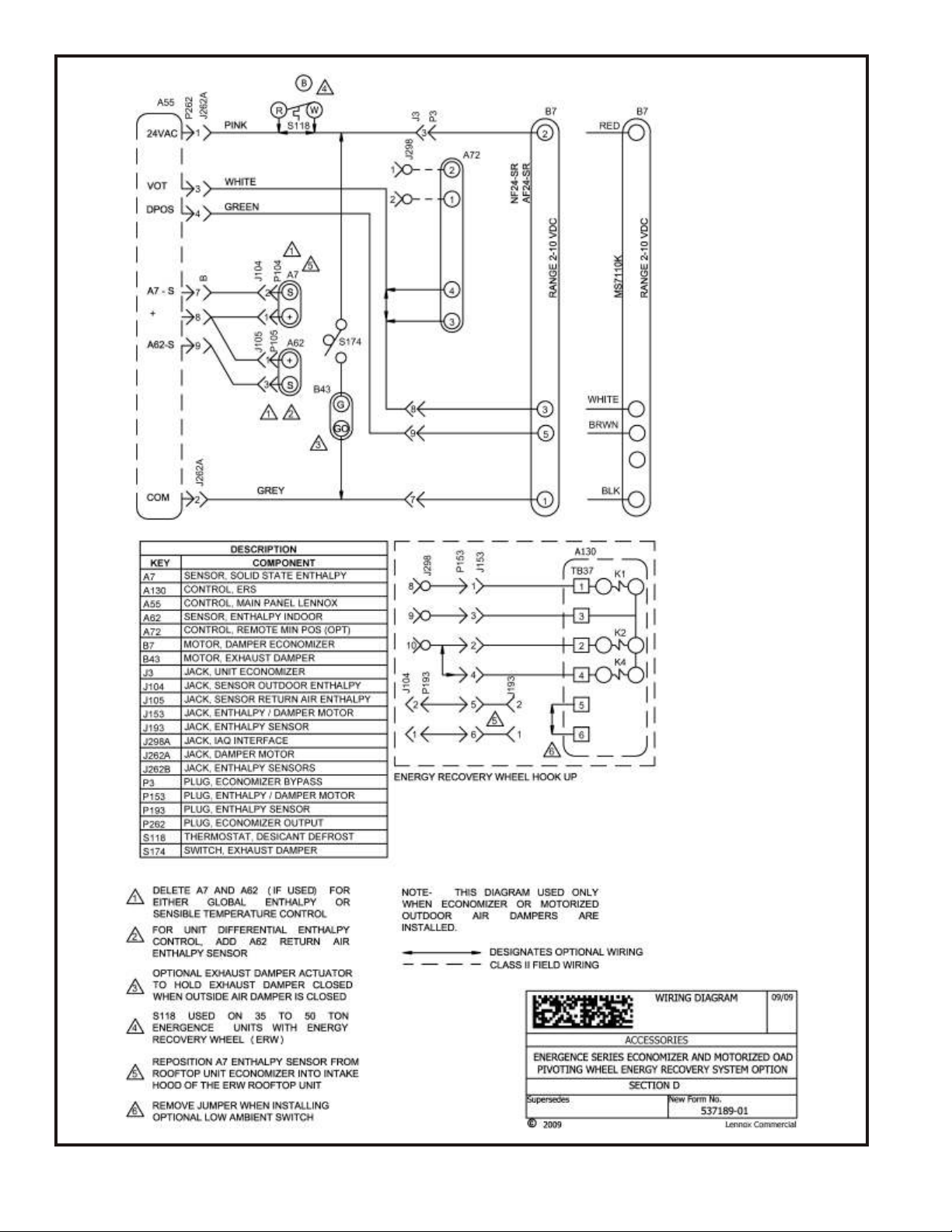

1. Disconnect ERS main power.

Note: If Low ambient kit S26 is used the jumper

between TB37-5 and TB37-6 should be removed.

Alsoifsystemcheck outisbeingconductedatlow

ambient temperatures, jumper low ambient

switch.

2. Open rooftop unit blower access panel and locate

TB1. Jumper terminals 6 (24v) and 3 (G) to energize

rooftop unit blower. Refer to manufacturers

instructions when an electronic thermostat or other

energy management system is used.

3. Remove ERS control access panel and install jumper

at low voltage terminal strip between TB37-1 and

TB37-2.

4. Restore power to ERS unit. The recovery wheel will

pivot out of the air stream, fresh air blower dampers

will open, and after a delay, the exhaust blower will

operate.

5. Remove jumper from ERS control board TB37-1 and

TB37-2. The recovery wheel will pivot into the air

stream, the fresh air blower dampers will close, and

after a delay, the fresh air blower and exhaust air

blower will operate.

SYSTEM CHECK

PAGE 7

MAINTENANCE

Motor Maintenance

All motors use prelubricated sealed bearings; no further

lubrication is necessary.

Mechanical Inspection

Make visual inspection of dampers, linkage assemblies

and ERS rotating bearings during routine maintenance.

Filters should be checked periodically and cleaned when

necessary. Filter is located in fresh air hoods. DO NOT

replace permanent filters with throwaway type filters.

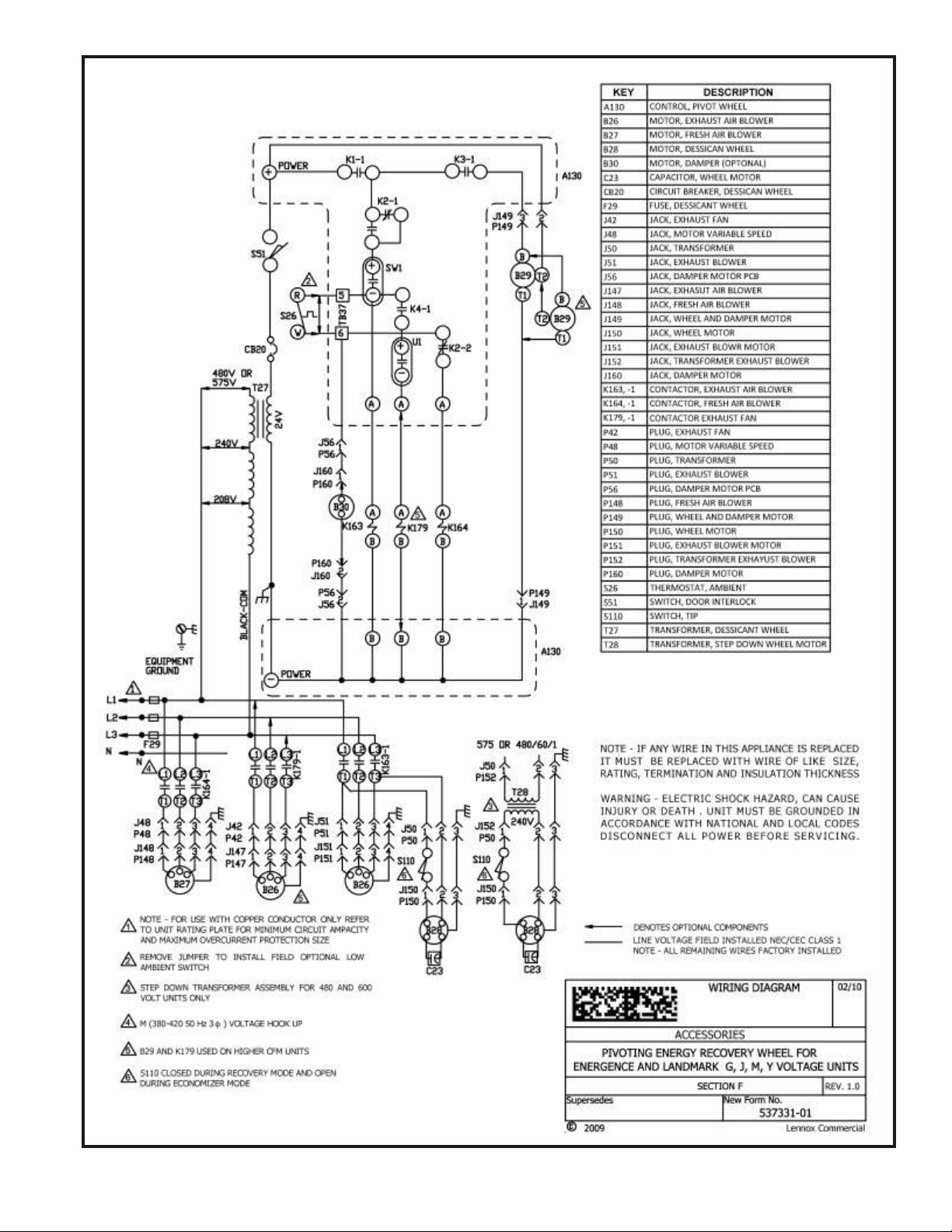

Energy Wheel Maintenance

Four pie-shaped energy recovery wheel segments are

seated on stops between the stainless steel spring

retainers, secured to the hub and rim of wheel. Annual

inspection of the self cleaning wheel is recommended.

With power disconnected, remove ERS access panels

(rear)andunplug(J150&P150).Refertowiringdiagramin

this instruction manual. Each segment is secured in place

by a stainless steel spring retainer located on wheel rim.

Removeoneendof thestainlesssteelspringretainerfrom

the slot in the wheel rim and remove. Do the same on the

next retainer. Remove segment and wash with water

and/or mild detergent. Replace segment by reversing the

above procedure. See Fig ure 22. Discoloration and

staining of ERS segment does not affect its performance.

Only excessive buildup of foreign material need be

removed. If the segment appears excessively dirty, it

should be cleaned to ensure maximum operating

efficiency. Thoroughly spray plastic surface with

household cleaner such as Fantasticor equivalent

middledetergent and gently rinse with warm water usinga

soft brush to remove heavier accumulation. Shake excess

water from segment and replace in reverse of removal

instructions.

6. Disconnect main power to unit before making

adjustment to economizer and/or ERS unit.

7. Remove all jumpers and replace ERS control access

cover.

8. Set thermostat to normal operating position.

9. Restore power to unit.

HUB

SEGMENT

FIGURE 22

SPOKE

SEGMENT RETAINER CATCH

WHEEL RIM

SEGMENT RETAINER