TKR Group 83 30 5 A69 930 User manual

83 30 5 A69 930

R1-22.08-V1

Testing box for HV adapter cable sets GEN3/4/5

Translation of the original owner‘s manual

2

?

Owner‘s manual,

digital

Europe

Worldwide

www.tkr-service.comOwner‘s Manual USB-Stick

Owner‘s manual,

digital

Europe

Worldwide

3

1. Safety

1.1 General instructions 4

1.2 Explanation of symbols 5

1.3 Labelling 6

1.4 Scope of supply 6

1.5 Safety instructions 7

2. Technical Data

2.1 Technical Data 8

2.2 Device components 9

3. Installation

3.1 Intended use 10

3.2 Working with the tool - basic principles 10

3.3 Commissioning and safe handling 11

4. Application

4.1 Operation and use 12

4.1.1 Testing before use 12

4.1 Operation and use 13

4.1.2 With two-pole voltage tester 13

4.1 Operation and use 14

4.1.2 With multimeter 14

4.1 Operation and use 15

4.1.3 Sources of faults 15

4.2 Putting out of operation and storage 15

5. Maintenance

5.1 Troubleshooting 16

5.2 Regular checking and maintenance 16

5.3 Spare parts and accessories 16

6. Service

6.1 Disposal 18

6.2 Warranty and Service 18

6.3 EU Declaration of Conformity /

Declaration of Conformity 19

This owner‘s manual is protected by copyright. Any use beyond the restrictions imposed by copyright legislation undertaken without the permission of the manufacturer

is illegal and punishable by law. This also applies to the extraction of individual illustrations and use of texts as excerpts.

4

6.3

1.1 General instructions

State-of-the-art

This tool is state-of-the-art technology. To ensure that the equip-

ment operates safely, it must be operated in a proper and safety-

conscious manner.

Technical changes

In the interests of quality assurance, we reserve the unrestricted

right to carry out technical changes as a result of further techno-

logical developments and product improvements without prior

notication.

Reading the owner's manual

Before using the tool, make sure you read the owner's

manual carefully and understand it. This manual

must always be available where the product is used.

Handling

All the actions necessary to ensure correct operation are descri-

bed in the owner's manual. Any working methods other than

those approved by the manufacturer are prohibited.

Faults

If faults occur, the operator may only eliminate those faults

through their own actions where the corresponding remedy is

described.

Warranty

The manufacturer accepts no liability for damage or injury cau-

sed by improper repair or the use of third-party replacement

parts.

No warranty will be provided for damage caused to the device

due to the tool being used incorrectly.

Environment

Make sure that the tool is set up in a work area which is free from

sources of heat (max. 50°C / 122 °F), corrosive liquids, greases or

oils.

Declaration of Conformity

The tool has been manufactured in accordance with

international guidelines. The relevant declaration of

conformity (CE, UKCA, CB) is included with this ow-

ner’s manual.

Risk of damage to the tool

The tool must only be used as described in the ins-

truction manual. It is expressly forbidden to misuse

the tool or to use it for any other purpose. Please

make sure that you and your sta handle the tool

correctly.

Risk of injury

In addition to the owner's manual and the binding

provisions of the accident prevention regulations

which apply in the country and at the place of use,

you must also comply with the general (accepted)

rules for safe and professional working.

Electrician

Only trained and instructed personnel are authorized to carry

out the repair / maintenance work on the vehicles and vehicle

components concerned.

5

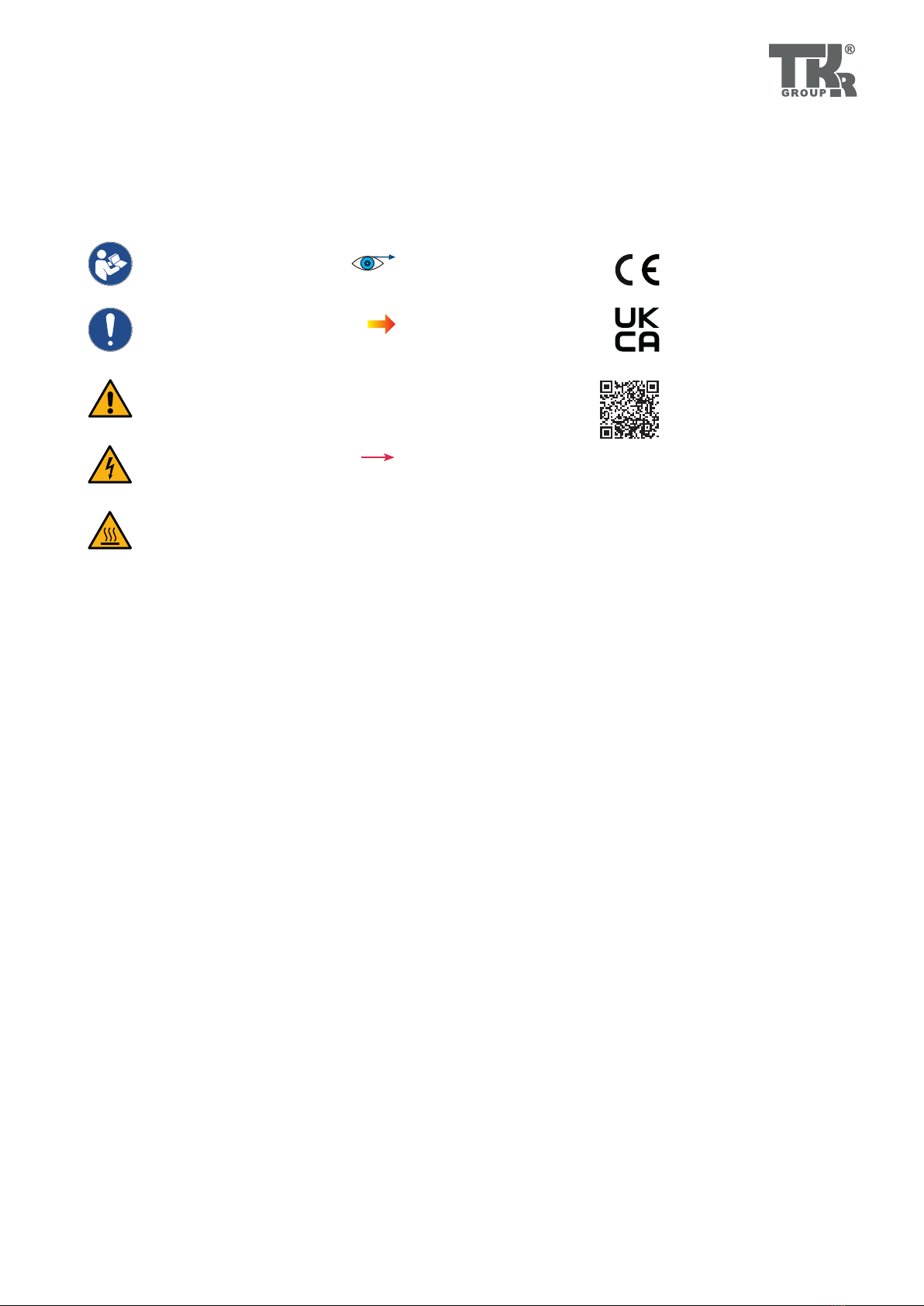

x.x

1.2 Explanation of symbols

Some chapters in this instruction manual use internationally recognised warning symbols, warning notes and general in-

struction symbols.

The individual symbols are explained below. Follow all the instructions and safety rules.

Follow the manual

Follow the general

instructions

Warning!

General source of danger

High voltage!

Danger to life!

Warning!

Hot surface

Please note

the following...

Arrow to clarify

compression

For more information,

see chapter …

Arrow showing direction

CE-mark

UK Conformity Assessment

Product certicate

https://www.tkrgroup.com/

83305A69930-cert.htm

6

A

B

B

D

C

G

JIH

EF

A

B

C

D

E

1.3 Labelling

Fig. 1 Fig. 2

Fig. 1

Testing box: labelling, top

A Three stickers (Warning!, High voltage!,

Follow owner‘s manual!)

B Designation of measurement points

C Warranty seal

D Seal with reference to trained personnel

Fig. 2

Testing box: labelling, bottom

E Manufacturer’s label and part number

F Item number and serial number

G Connection diagram

H Company address

I CE-mark, UKCA-mark, disposal

J Voltage and protection class

1.4 Scope of supply

A Testing box

B 2 x Reducing adapter 2 / 4 mm

D Owner’s manual

D USB stick

E Case

7

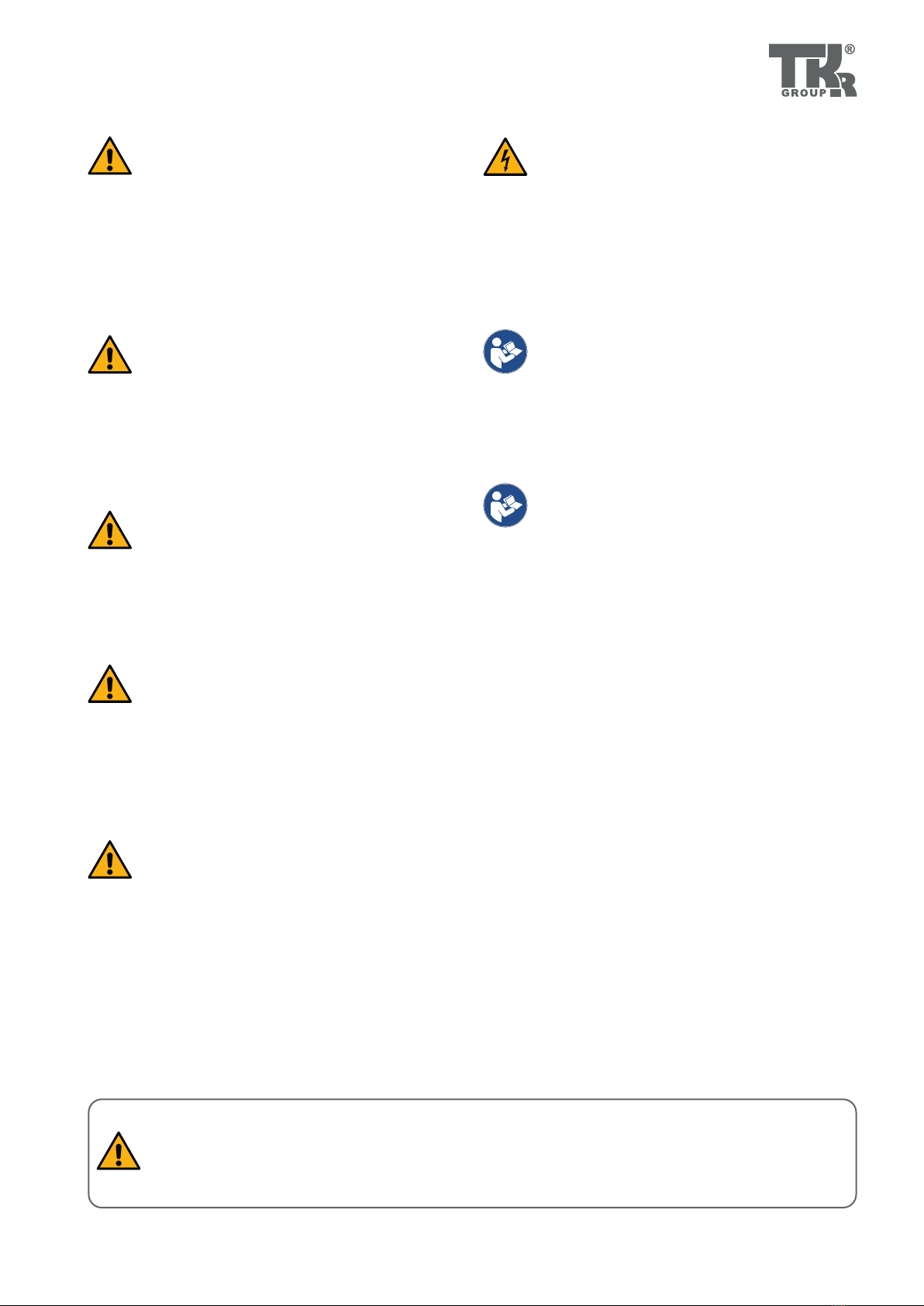

1.5 Safety instructions

If any abnormality is identied, the tool must not be used.

Please contact Service ( 6.2).

CAUTION

If used with the wrong accessories, this may

cause material damage and bodily injury.

Not using original tools and original accessories will

result in a high risk to safety. Only original accessories

may be used.

The manufacturer cannot accept any liability for con-

versions or modications to the tool.

CAUTION

Trip hazard

Laying supply cables carelessly can lead to accidents

through tripping, twisting of the ankle or falls or may

even damage the cables.

Lay all supply cables so that they cannot be damaged

and nobody can trip over them.

CAUTION

Risk of material damage and bodily injury

You must read and understand the safety instruc-

tions before carrying out the repair.

Not reading the instructions may result in serious

bodily injury.

CAUTION

Risk of material damage and bodily injury

Only technical personnel who have received inst-

ruction are authorized to operate this tool. The tool

must not be lent to untrained persons. Ensure that

the tool is only operated by trained personnel who

are instructed in its use!

CAUTION

Risk of damage to the tool

Not handling the tool properly can lead to damage to

the tool. Never throw the tool or allow it to fall.

CAUTION

Risk of personal injury

In order to avoid receiving an electric shock, make

sure that this tool is not connected to a power source

before carrying out any conguration, cleaning or

maintenance work on it. Just switching o the tool or

pressing the disconnecting button does not reduce

the risk.

Ensure that the owner's manual is made availa-

ble to the operating personnel.

Each operator must carefully read and understand

this owner's manual before using the tool for the rst

time. This owner's manual must always be available

where the product is used.

Follow the applicable national regulations for

the prevention of accidents.

In addition to the owner's manual and the binding

provisions of the accident prevention regulations

which apply in the country of use, you must also

comply with the general, accepted rules for safe and

professional working.

8

120.7

180

76.3

HV–

SCR

HV+

HV–

SCR

HV+

HV–

SCR

HV+

HV+

SCR

HV–

Art. Nr. 77-001070

HV–

SCR

HV+

47 kΩ

47 kΩ

77-001104

47 kΩ

47 kΩ

HV–

SCR

HV+

77-001105

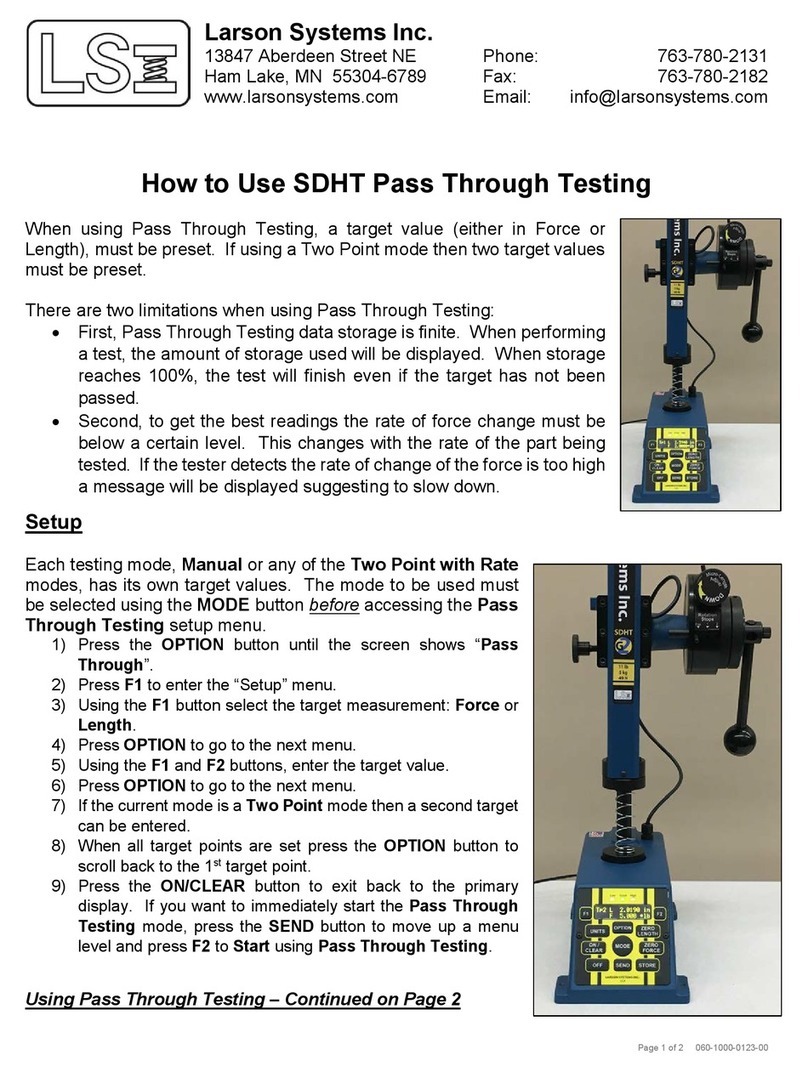

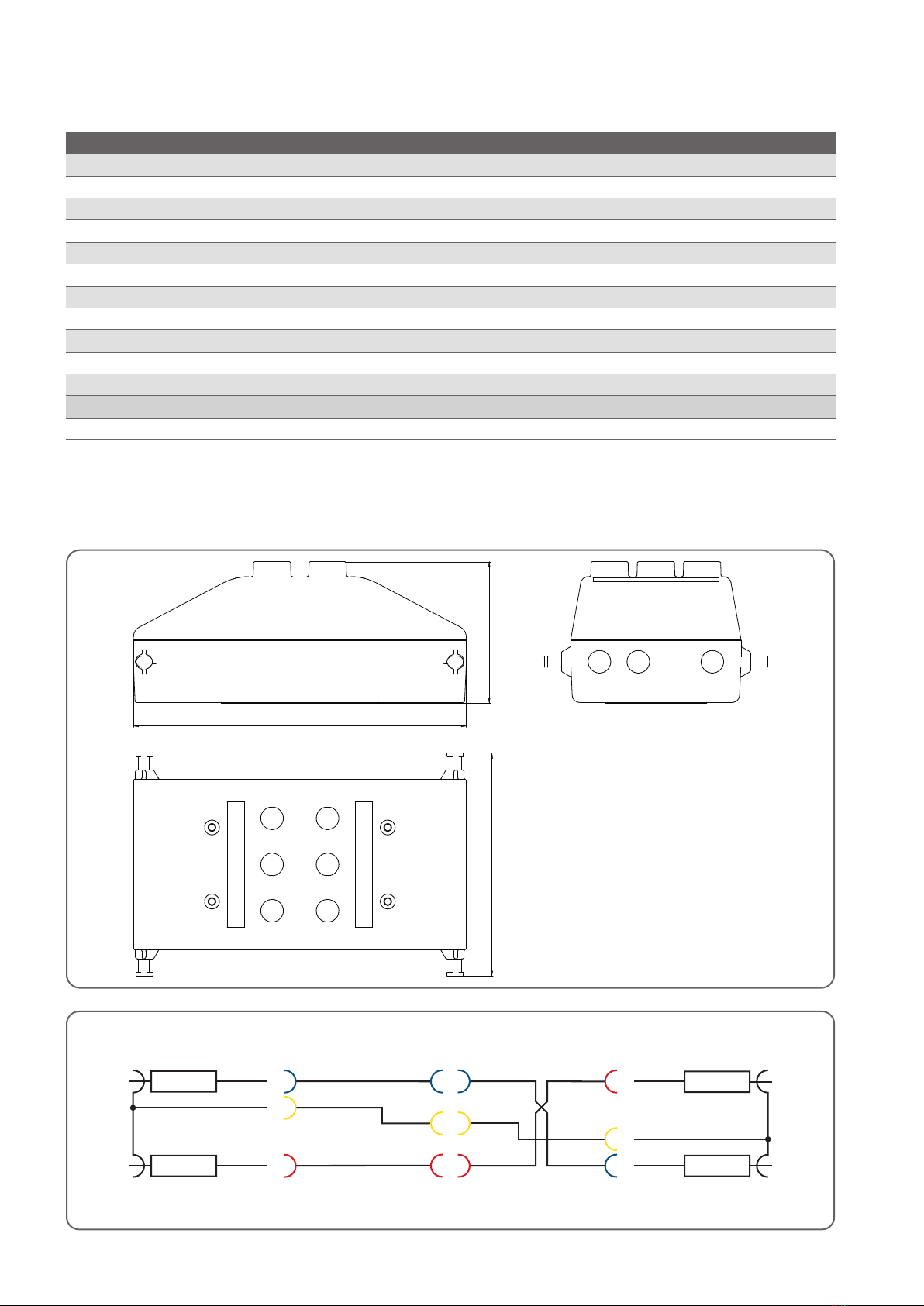

2.1 Technical Data

Adapter end Adapter endHV Adapter

Connection diagram

83 30 5 A69 930

Type of device Measurement

Conguration Hand held

Supply connection None (passive)

Ambient temperature (operation) 5 °C to 45 °C / 41 °F to 113 °F

Ambient temperature (storage) -20 °C to +60 °C, to -4 °F +140 °F

Maximum application height 2000 m

Ambient humidity To 95 % (non-condensing)

Protection class IP 20

Measurement category CAT I*

Maximum measurement voltage (Umax) 1000 V DC

Impedance 47 kΩ HV +, 47 kΩ HV -

Weight 0.5 kg

Dimensions (W x H x D) 180 x 76.3 x 120.7 mm

* Measurements on electrical circuits which are not directly connected to the mains (e.g. battery operation and passenger car electrical circuits)

Fig. 1

Fig. 2

9

1

2

3

3

4

4

5

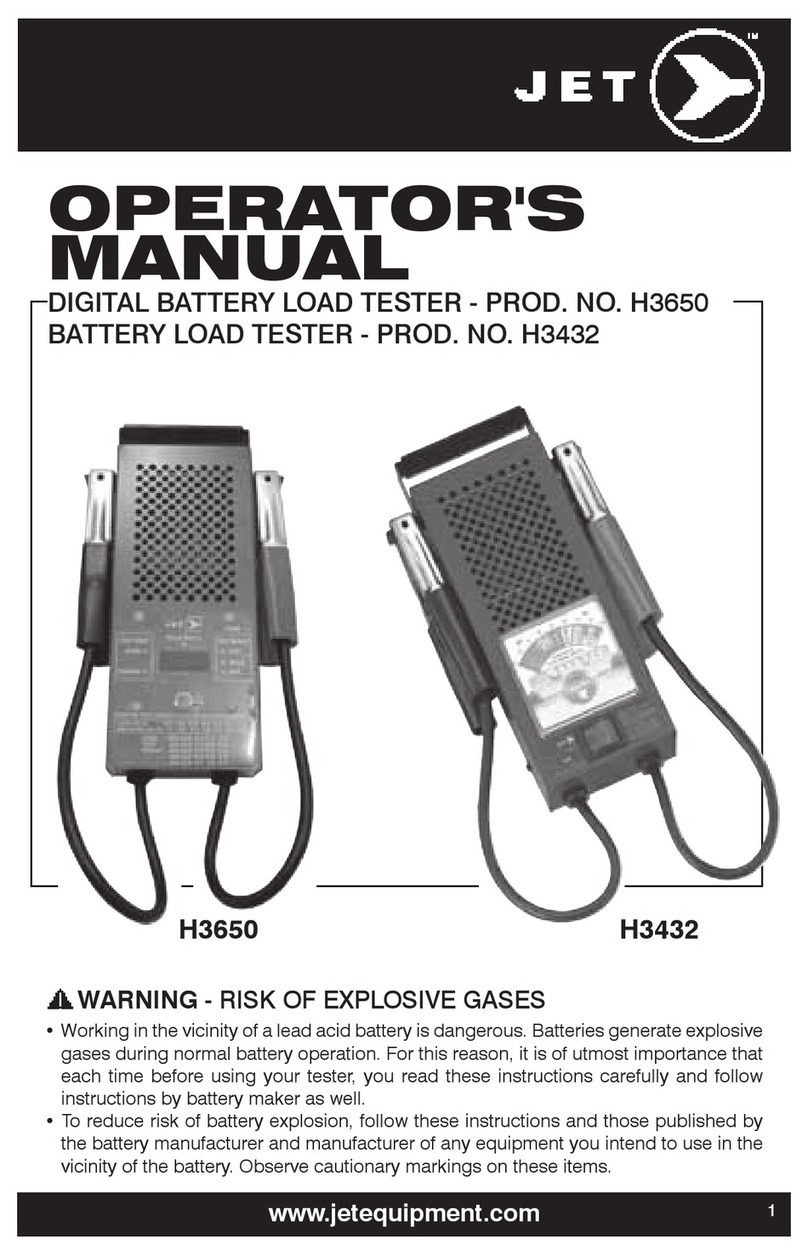

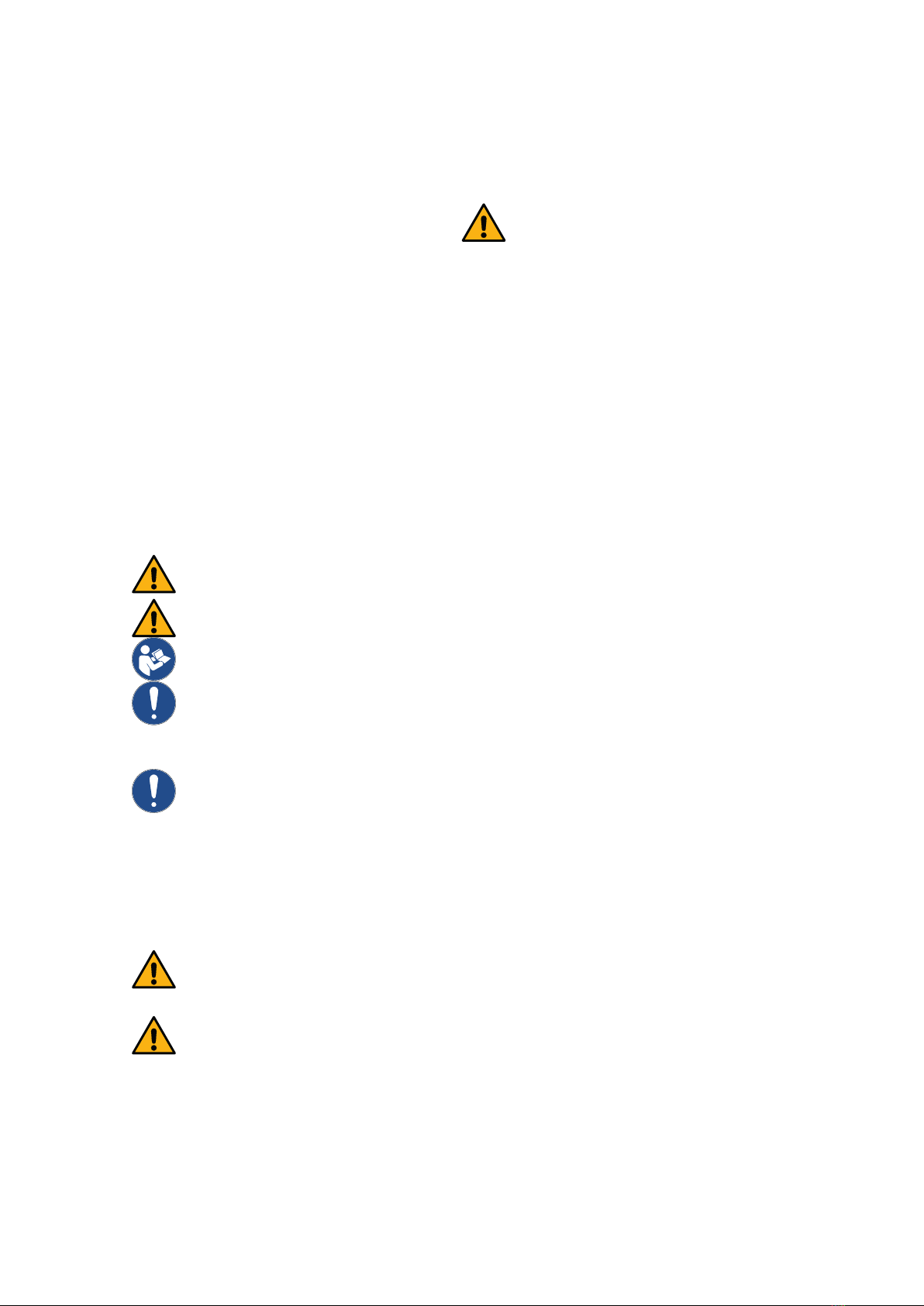

2.2 Device components

Voltage supply

No additional voltage supply is needed.

Climate conditions

Storage temperature: -40 °C to +60 °C / -40°F to +140 °F

Operating temperature: +5°C to +45 °C / +41 °F to +113 °F

Environmental humidity: up to 95% (not dew-forming)

Protection: IP20, CAT I, Degree of contamination 2

Climate class: 3K3

Fig. 1

[1] Testing box

[2] Annular contact sockets, 4 mm

[3] Labelling of annular contact sockets

[4] Plug connector Testing box (socket)

Fig. 1

Fig. 2

[5] Reducing adapter

Fig. 2

10

3.1 Intended use

The testing box is used in workshops to make sure there is no live

voltage or insulation defects on HV motor vehicle on-board elec-

trical systems. Dierent types of plug connectors are therefore

included in the scope of supply for connection to the dierent

HV components.

A trained user can use suitable testing and measurement inst-

ruments to check the voltage or use guided troubleshooting to

nd faults on the HV system.

As a rule, never work on live parts of the electrical system or

equipment. Before starting work, live parts must therefore be

de-energised and this state checked and guaranteed for the

duration of the work.

The testing and measurement instruments used

must be approved and must be suitable for the

voltage being measured (label on the instrument

at least CAT I and the max. operating voltage pre-

sent, e.g. CAT I 1000 V).

3.2 Working with the tool - basic principles

Risk of injury

It is vitally important that you make sure that you are handling the tool correctly.

It is expressly forbidden to misuse the tool or to use it for any other purpose.

The tool must only be used as described in the instruction manual.

Warranty

The manufacturer accepts no liability for damage or injury caused by improper repair or

the use of third-party replacement parts.

No warranty will be provided for damage caused to the device due to the tool being used

incorrectly.

Environment

The tool may only be used in a work area which is free of sources of heat (max.

45 °C / 113°F), corrosive liquids, greases and oils.

Leave to acclimatise before starting.

Avoid the formation of condensation.

Make sure that the area is well ventilated to avoid the build-up of explosive

vapours.

Declaration of Conformity

The tool has been manufactured and tested in accordance with the European directives.

The Declaration of Conformity is included with this owner's manual.

6.3

11

3.3 Commissioning and safe handling

Check the HV Adapter Set for any damage every

time before using it.

Always carry out a visual inspection of the spring

contacts before use.

A self-test must always be carried out on the tool

to make sure that it is in perfect working order

before using it.

HV– to HV– Resistance 94 kΩ, Tolerance 1 %

HV+ to HV+ Resistance 94 kΩ, Tolerance 1 %

SCR to SCR Resistance 0 Ω

HV+ to HV– Resistance > 10MΩ

HV– to HV+ Resistance > 10MΩ

HV+ to SCR Resistance > 10 MΩ

HV– to SCR Resistance > 10 MΩ

Fig. 1 Fig. 3

Check the measurement instrument for damage

and check operation before carrying out any

measurement.

Before using the HV Adapter Set, check whether

the relevant thermal sticker on the adapter ends

is in order.

3.3.5

Fig. 1

Plug the connector together.

Fig. 2

Test set-up for self-test

During the self-test, all the plugs and sockets must be connected

to each other and the adapter ends plugged into the HV Adapter

and locked.

Fig. 2

Fig. 3

Test set-up for resistance tests

Now carry out the following resistance tests with a suitable

measurement instrument and compare the results with the table

below:

If the measurement values shown above do not

appear during the self-test, the HV adapter set

must not be used!

12

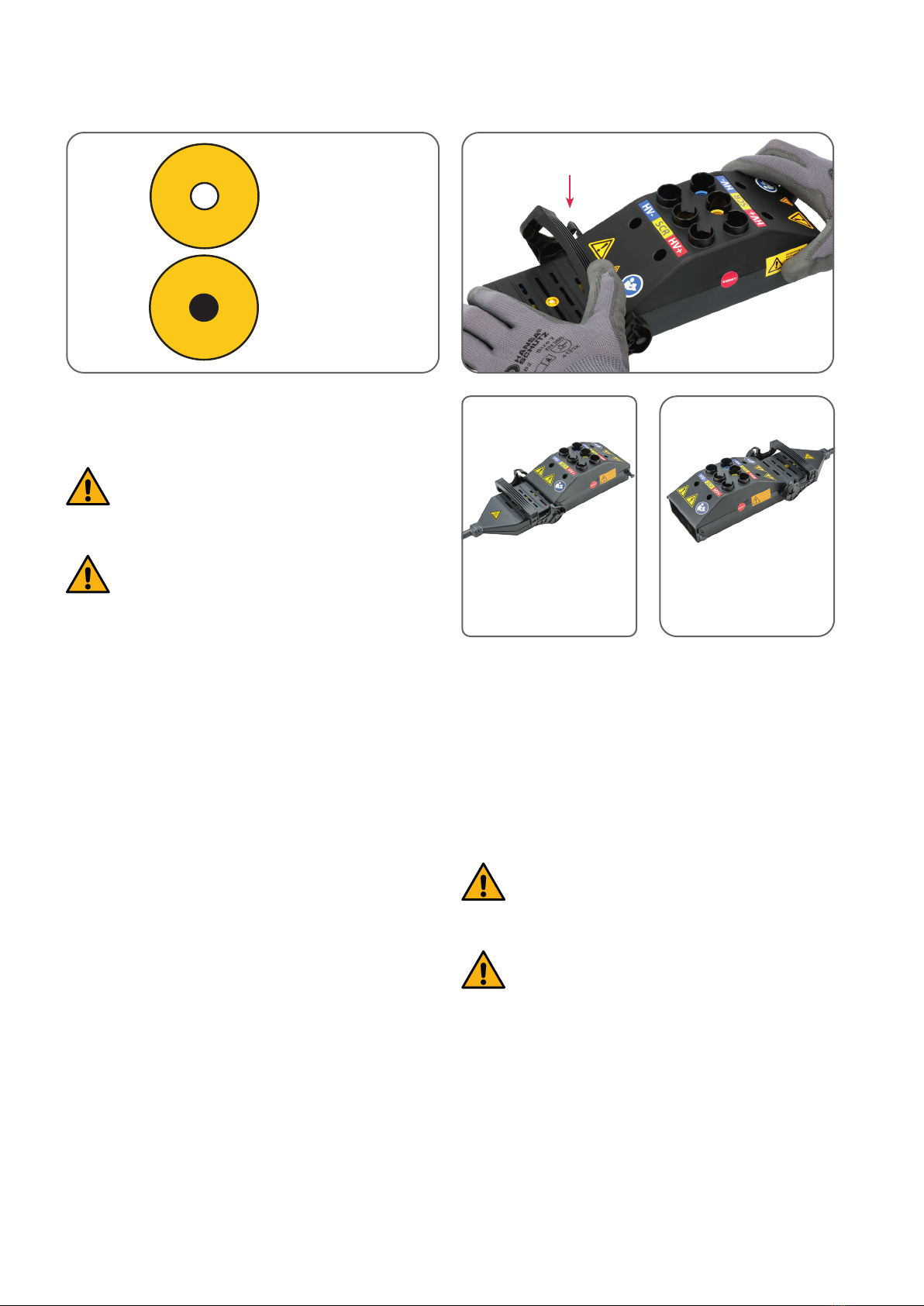

°

0

8

F

1

8

C

2

°

°

0

8

F

1

8

C

2

°

7

3

Fig. 1

Thermal sticker: Testing before use

Before using the HV Adapter Set, check whether

the relevant thermal sticker on the adapter ends

is in order (white dot in the centre).

If the dot in the centre of the thermal sticker has

gone black, the temperature has exceeded 82 °C

/ 180 °F and the adapter must not be used!

Fig. 2–4

Connecting HV components

Connect each adapter cable needed to the testing box and se-

cure it with the clamp.

Now connect the corresponding pin / socket housing of the

adapter cable to the HV components.

When connecting two HV components, never

connect the HV+ and HV- connections to the op-

posing HV+ and HV- connections.

If there is bridging or short circuiting, the adap-

ter cables must be changed immediately.

Connection to HV components

with pin or socket contact

Connection to HV components

with pin or socket contact

Fig. 1

4.1 Operation and use

4.1.1 Testing before use

Fig. 2

Fig. 3 Fig. 4

13

Fig. 5

Checking to make sure there is no live voltage with two-

pole voltage tester

The supplied reducing adapters are used depending on the

diameter of the test connections (2 mm /4 mm) of the testing /

measurement instrument used and are plugged into the corre-

sponding measurement sockets.

Never use two-pole voltage testers with 2 mm

test connections without the reducing adapters.

The voltage tester used must be approved and

must be suitable for the voltage being tested.

Suitable testing / measurement instruments

must be used to make sure there is no live voltage

when testing with the HV Adapter Set!

(Label on the testing / measurement instrument

at least CAT I and the max. operating voltage pre-

sent, e.g. CAT I 400 V)

Check the testing / measurement instrument for

damage and check operation before carrying out

any measurement.

Check the testing / measurement instrument with a known vol-

tage source to make sure it is operating properly.

Fig. 6, 7

Testing:

Voltage tester across HV+ and HV-

Voltage tester across HV+ and SCR

Voltage tester across HV- and SCR

The voltage tester may only display voltages below 60 V during

the tests.

If there are deviations, the procedure must be repea-

ted with a multimeter.

During the testing procedures, make sure that

you only select the measurement sockets on the

side of the adapter end plugged in!

The connections with the same designation are

not connected to one another!

If the voltage is higher than 60 V DC, the entire

HV system must be regarded as DANGEROUSLY

ACTIVE.

You must not continue working on live HV com-

ponents!

Note that the deviation is greater when using

testing / measurement instruments with a lower

internal resistance.

A voltage tester usually has an internal resistance of 200 kΩ.

When the voltage which appears is 60 V, the

actual voltage is approx. 88 V.

Internal resistance Deviation

5 MΩ approx. 2 %

1 MΩ approx. 9 %

200 kΩ approx. 32 %

Fig. 5 Fig. 6 Fig. 7

4.1.3

4.1.4

4.1 Operation and use

4.1.2 With two-pole voltage tester

14

4.1 Operation and use

4.1.2 With multimeter

Fig. 1

Preparation test/measurement instrument

The testing / measurement instruments used

must be approved and must be suitable for the

voltage being tested.

The test leads used must be touch protected and

approved and must be suitable for the voltage

being tested.

Suitable testing / measurement instruments

must be used to make sure there is no live voltage

when testing with the HV Adapter Set!

(Label on the testing / measurement instrument

at least CAT I and the max. operating voltage pre-

sent, e.g. CAT I 1000 V)

Check the testing / measurement instrument for

damage and check operation before carrying out

any testing procedures.

Set the testing / measurement instrument to a suitable DC volta-

ge measurement range. Switch o the automatic measurement

range switching.

Check the testing / measurement instrument with a known vol-

tage source to make sure it is operating properly.

Fig. 2

Checking to make sure there is no live voltage

The testing / measurement instrument must be

set to DC voltage and the automatic measure-

ment range change-over must be switched o.

During the testing procedures, only select the

measurement sockets on the side of the adapter

end plugged in!

Connections with the same designation are not

connected to one another!

If the voltage is higher than 60 V DC, the entire

HV system must be regarded as DANGEROUSLY

ACTIVE.

Be aware of possible errors in the voltage check

due to the voltage drop across the internal resis-

tance.

You must not continue to work on live HV compo-

nents!

To test potentials against the screen (SCR), rst use suitable test

leads to connect the COM port of the testing / measurement ins-

trument to the SCR (screen) connection of the HV Adapter Set.

Connect the (V) connection of the testing / measurement ins-

trument to the HV+ or HV- connection being measured. The

resulting voltage can now be read on the meter.

To test voltages across HV+ and HV-, connect the COM port of

the testing / measurement instrument to the HV- connection of

the HV Adapter Set and the (V) connection of the testing / mea-

surement instrument to the HV+ connection of the HV Adapter

Set.

The voltage of each testing procedure must be zero.

Fig. 1 Fig. 2

15

4.1 Operation and use

4.1.3 Sources of faults

Testing results/testing errors

The HV Adapter Set contains two 47 kΩ resistors in each adapter

connection plug in the HV+ line and the HV- line.

These resistors cause a voltage drop during the voltage testing

which depends on the internal resistance of the testing / measu-

rement instrument used. This voltage drop causes the reading

on the testing / measurement instrument to be lower than the

actual voltage.

On a standard testing / measurement instrument with an in-

ternal resistance of 10 MΩ (10,000 kΩ), the voltage drop in the

HV adapter is approx. 1 % of the actual voltage. In this case, the

measured voltage is 1% less than the actually available voltage.

Internal resistance Deviation

5 MΩ approx. 2 %

1 MΩ approx. 9 %

200 kΩ approx. 32 %

Note that the deviation is greater when using

testing / measurement instruments with a lower

internal resistance.

In the event of misuse, the resistors integrated in

the adapter ends heat up!

Example:

If the internal resistance of the testing / measurement instrument

is 200 kΩ and the measured voltage is 60V, the actual voltage

across the HV accumulator is approximately 88 V.

4.2 Putting out of operation and storage

Check the tool for any damage before and after each use.

Make sure that the tool is stored in a dry and warm place.

Avoid contamination.

Clean all parts carefully before storing. Store the tool in the case.

16

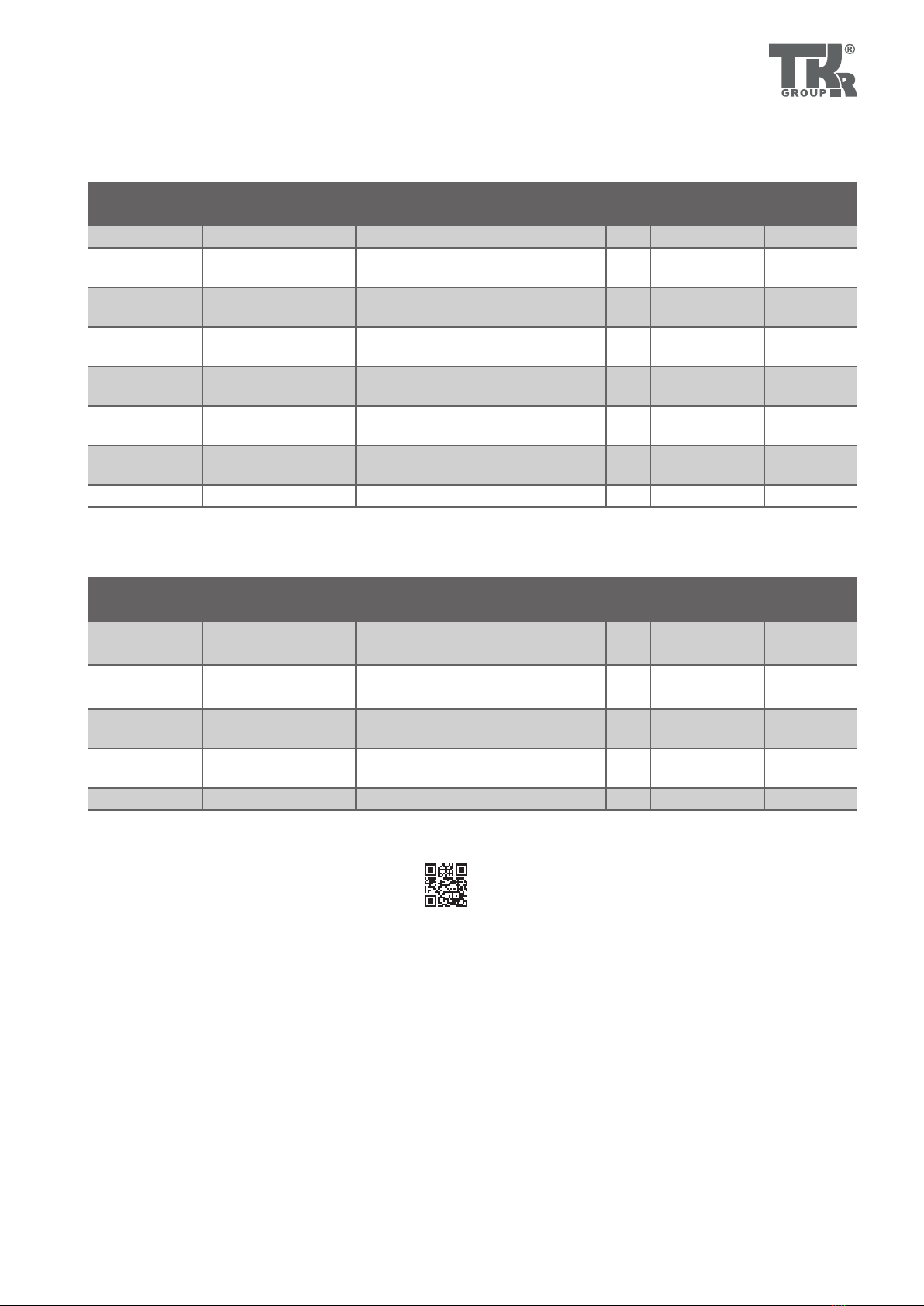

5.2 Regular checking and maintenance

5.3 Spare parts and accessories

Cleaning

Apart from occasional cleaning with a dry, lint-free cloth, the

Testing boxt is maintenance-free.

5.1 Troubleshooting

Malfunction Problem Remedy Chapter

The measurement values specied are

not measured during the self-test.

There is a fault in the adapter cable (e.g.

due to incorrect use). Change adapter cables. 3.3

The colour of the thermal sticker has

changed from white to black in the

center.

The integrated resistors have heated up

due to incorrect use. Change adapter cables. 3.4

Service

Do not carry out any service activities on this device.

Spare parts for Testing box 83 30 5 A69 930

BMW

Item no.

TKR

Item no. Designation Pcs. Set Partial refe-

rence path

83 30 5 A69 930 Testing box for HV adapter cable sets

GEN3/4/5 1 83 30 5 A69 930 BMW

99-000439 Adapter XA 2/4 2 83 30 5 A69 930 TKR

DOK-BMW-10000013 Owner's Manual 1 83 30 5 A69 930 TKR

WZK-BMW-10000007 Case 1 83 30 5 A69 930 TKR

Spare parts for Adaptor Cable (Set) GEN5, Connector system Kostal KS22, 83 30 5 A55 B86

BMW

Item no.

TKR

Item no. Designation Pcs. Set Partial refe-

rence path

83 30 5 A55 B86 Adaptor cable (Set) Kostal KS22 1 83 30 5 A55 B86 BMW

BGR-BMW-10000136 Adaptor cable Socket housing

Kostal KS22 1 83 30 5 A55 B86 TKR

BGR-BMW-10000137 Adaptor cable Pin housing

Kostal KS22 1 83 30 5 A55 B86 TKR

DOK-BMW-10000015 Owner's Manual 1 83 30 5 A55 B86 TKR

Spare parts for Adaptor Cable (Set) GEN5, Connector system Rosenberger HVS240, 83 30 5 A44 4A2

BMW

Item no.

TKR

Item no. Designation Pcs. Set Partial refe-

rence path

83 30 5 A44 4A2 Adaptor cable (Set) 1 83 30 5 A44 4A2 BMW

BGR-BMW-10000126 Adaptor cable Socket housing Rosenber-

ger HVS240 1 83 30 5 A44 4A2 TKR

BGR-BMW-10000127 Adaptor cable Pin housing

Rosenberger HVS24 1 83 30 5 A44 4A2 TKR

DOK-BMW-10000006 Owner's Manual 1 83 30 5 A44 4A2 TKR

17

Spare parts for existing HV Adaptor Set GEN5, Connector system Rosenberger HVS420 and Hirschmann HPS40-2,

83 30 5 A33 FD8

BMW

Item no.

TKR

Item no. Designation Pcs. Set Partial refe-

rence path

83 30 5 A33 FD8 HV Adaptor Set GEN5 1 83 30 5 A33 FD8 BMW

83 30 5 A2F 674 Adaptor cable set,

Rosenberger HVS420 1 83 30 5 A2F 674 BMW

BGR-BMW-10000122 Adaptor cable socket housing,

Rosenberger HVS420 1 83 30 5 A2F 674 TKR

BGR-BMW-10000123 Adaptor cable pin housing,

Rosenberger HVS420 1 83 30 5 A2F 674 TKR

83 30 5 A2F 675 Adaptor cable set,

Hirschmann HPS40-2 1 83 30 5 A2F 675 BMW

BGR-BMW-10000124 Adaptor cable socket housing,

Hirschmann HPS40-2 1 83 30 5 A2F 675 TKR

BGR-BMW-10000125 Adaptor cable pin housing,

Hirschmann HPS40-2 1 83 30 5 A2F 675 TKR

DOK-BMW-10000004 Owner's Manual 1 83 30 5 A33 FD8 TKR

Spare parts for existing HV Adaptor Set GEN3/4, Connector system Kostal PLK 14.5 and Hirschmann HPS40-1,

83 30 2 449 661

BMW

Item no.

TKR

Item no. Designation Pcs. Set Partial refe-

rence path

BGR-BMW-10000067 Adapter cable pin housing,

Kostal PLK 14.5 1 83 30 2 449 661 TKR

BGR-BMW-10000068 Adapter cable socket housing,

Kostal PLK 14.5 1 83 30 2 449 661 TKR

BGR-BMW-10000069 Adapter cable pin housing,

Hirschmann HPS40-1 1 83 30 2 449 661 TKR

BGR-BMW-10000070 Adapter cable socket housing,

Hirschmann HPS40-1 1 83 30 2 449 661 TKR

DOK-BMW-10000009 Owner's Manual 1 83 30 2 449 661 TKR

Other languages, accessories and spare parts:

www.tkr-service.com

18

6.2 Warranty and Service

Tools from TKR Spezialwerkzeuge GmbH come with a 24 month warranty against material and manufacturing defects.

Otherwise, the statutory conditions governing warranty periods and our General Terms and Conditions of Sale and Supply

apply.

High voltage components are not included.

The warranty begins on the date of delivery, as specied on the invoice or delivery note.

The warranty shall be valid for the user / customer provided that the tool is obtained from an authorized sales outlet and

is used as described in the instructions and for the purposes for which it was designed.

The warranty shall be invalidated if the tool is used for any purposes other than those for which it was designed.

Furthermore, the warranty shall be invalidated if the tool is not used as described in the owner's manual.

In the event of a defect or fault, TKR Spezialwerkzeuge GmbH shall only repair or replace faulty parts at its own discretion.

Service address TKR Spezialwerkzeuge GmbH

Service

Am Waldesrand 9–11

D-58285 Gevelsberg (Germany)

Online-Service www.tkrgroup.com/service

Other language versions, assistance with use and information

Visit our Customer Service area.

Devices and machinery and components of devices and machinery must be disposed of in compliance with the

laws, regulations and other stipulations of the country in which they are located.

We recommend using specialist licensed companies for disposal.

The modules and units have been developed to be environmentally compatible and suitable for recycling. According to

the EU Directive 2002/96/EC, these parts must be taken to authorized collection points.

Batteries and rechargeable batteries - including button cells - do not belong in the residual waste bin, but must be dispo-

sed of properly.

The manufacturer does not promise to take back modules and components of electrical equipment or electrical equip-

ment in its entirety or batteries at no cost.

6.1 Disposal

19

6.3 EU Konformitätserklärung6.3 EU Declaration of Conformity /

Declaration of Conformity

EU Declaration of Conformity

For the purposes of the low voltage directive

2014/35/EU

Manufacturer: TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

58285 Gevelsberg, Germany

Person authorised to compile

the technical documentation: Thorsten Weyland

Type of tool: Testing box for HV adapter cable sets

Type designation: 83 30 5 A69 930

Developed and constructed in accordance with

the standards and guidelines listed by

TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

58285 Gevelsberg (Germany)

Harmonised standards used: EN 61010-031:2016

Serial number range: 00001–10000

Low voltage directive: 2014/35/EU

As manufacturer, we declare: The products marked accordingly fulfill the

requirements of the directive and standards listed.

Gevelsberg, 28.03.2022 Thorsten Weyland

Technical Manager

EU Declaration of Conformity

In compliance with the low voltage directive 2014/35/EU

Tool type: Testing box for HV adapter cable sets

Type designation: 83 30 5 A69 930

Serial number range: 0001–1000

Has been developed and designed in compliance with

thestandardsanddirectivesspeciedbelowby

Manufacturer TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

DE-58285 Gevelsberg

Person authorised to compile

the technical documents: Thorsten Weyland

Harmonised standards used: EN 61010- 1:2010/A1:2019/AC:2019-04

EN 61010-1:2010/A1:2019

EN IEC 63000:2018

Directives: Low voltage directive 2014/35/EU

RoHS 2011/65/ EU

As manufacturer, we declare: The products marked accordingly fulfil the requirements

of the directive and standards listed.

Town and date: Gevelsberg, 28.03.2022

Signature:

Thorsten Weyland

Technical Director

21

EU Declaration of Conformity

For the purposes of the low voltage directive

2014/35/EU

Manufacturer: TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

58285 Gevelsberg, Germany

Person authorised to compile

the technical documentation: Thorsten Weyland

Type of tool: Testing box for HV adapter cable sets

Type designation: 83 30 5 A69 930

Developed and constructed in accordance with

the standards and guidelines listed by

TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

58285 Gevelsberg (Germany)

Harmonised standards used: EN 61010-031:2016

Serial number range: 00001–10000

Low voltage directive: 2014/35/EU

As manufacturer, we declare: The products marked accordingly fulfill the

requirements of the directive and standards listed.

Gevelsberg, 28.03.2022 Thorsten Weyland

Technical Manager

Declaration of Conformity

Tool type: Testing box for HV adapter cable sets

Type designation: 83 30 5 A69 930

Serial number range: 0001–1000

The product is developed and constructed in accordance

with the UK legislation and designated standards by

Manufacturer TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

DE-58285 Gevelsberg

Person authorised to compile

the technical documents: Thorsten Weyland

Applicable UK legislation: Electrical Equipment (Safety) Regulations 2016

The Restriction of the Use of Certain Hazardous

Substances in Electrical and Electronic Equipments

Regulations 2012

UK Designated Standards: EN 61010- 1:2010/A1:2019/AC:2019-04

EN 61010-1:2010/A1:2019

EN IEC 63000:2018

As manufacturer, we declare: The products marked accordingly fulfil the requirements

of the directive and standards listed.

Town and date: Gevelsberg, 28.03.2022

Signature:

Thorsten Weyland

Technical Director

Table of contents

Other TKR Group Test Equipment manuals