6Power Station LV101

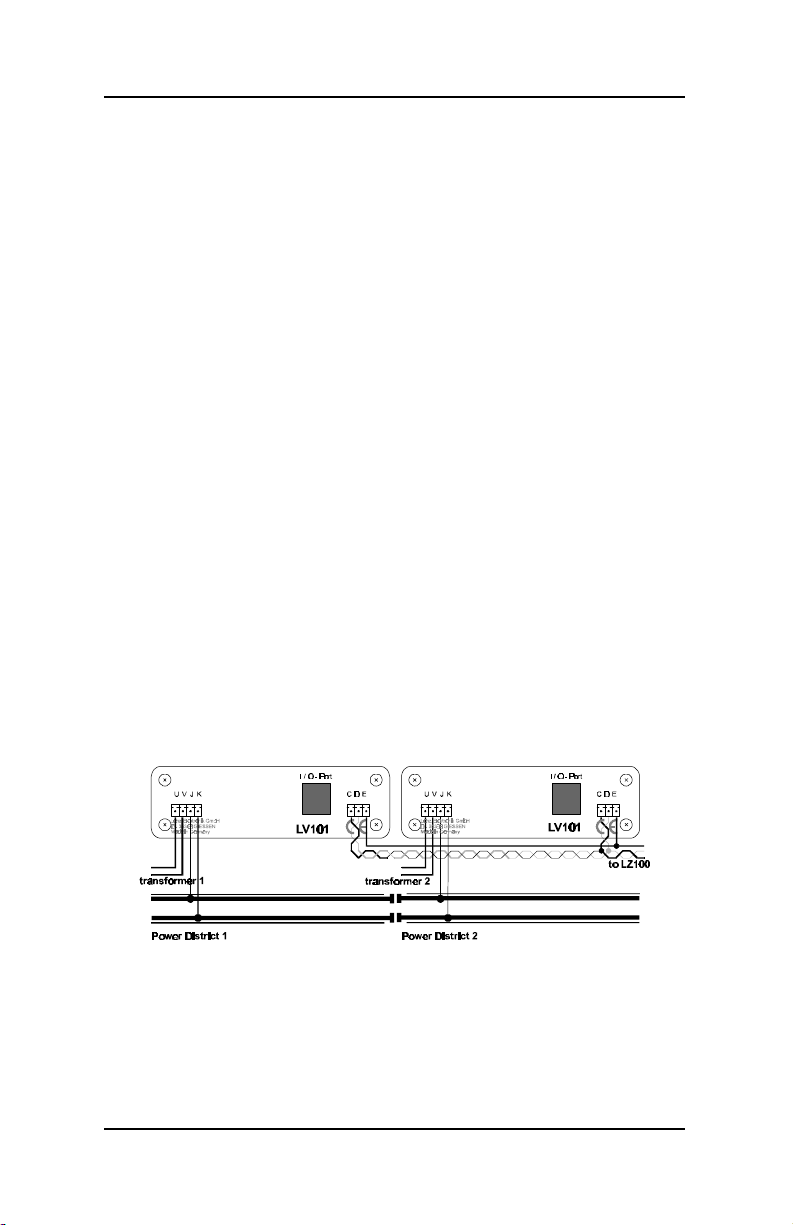

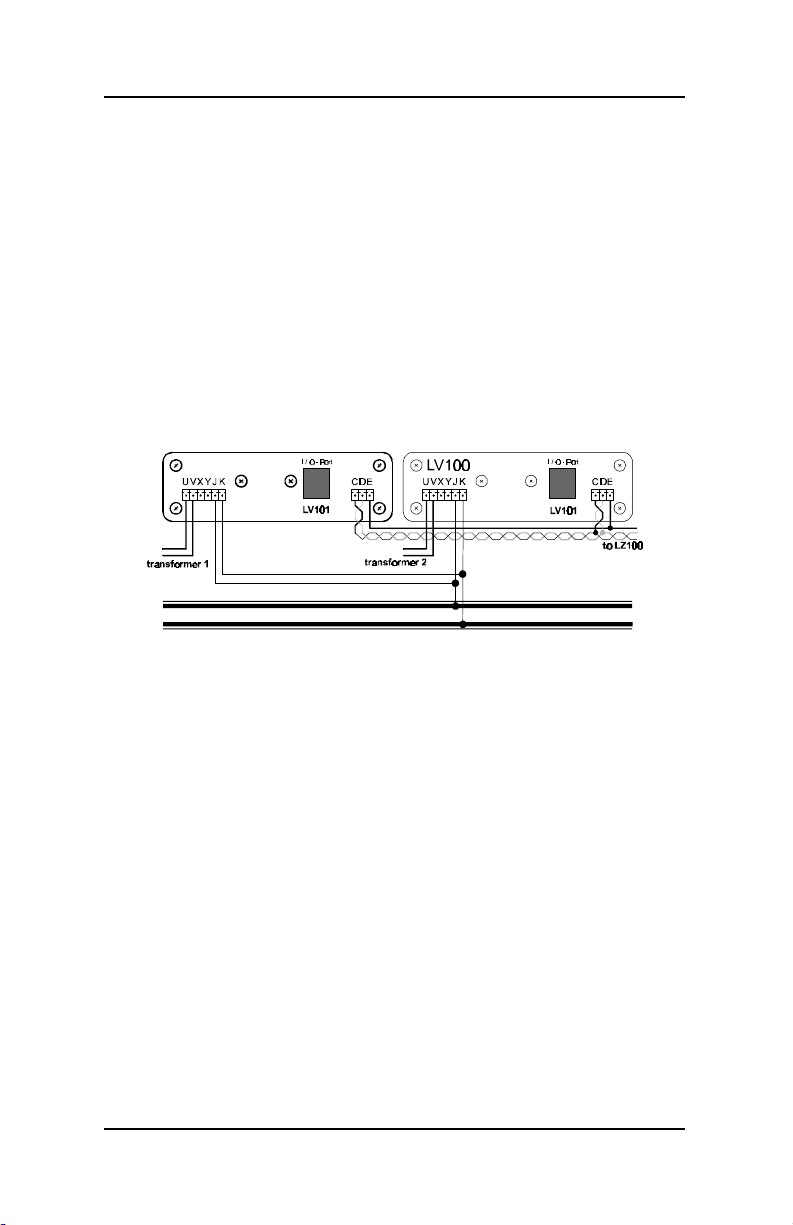

When such a locomotive bridges the gap between isolated

power stations, the locomotive will stall. The solution to this

problem is to provide a common wire between all the power

stations. All systems of command control need to have a such a

common provided, if offset pickup locomotives are to be

operated.

Lenz has chosen to leave the option of the location of the

common up to the individual operator. The LV101 is completely

opto-isolated. This allows you to use one of the rails (called

common rail) for your common. Common rail wiring is also

compatible with many existing signaling systems. While

common rail is the preferred place for a common, you may

rather connect all the power station Uor Vwires together. This is

called common power supply wiring.

Caution: If you decide to install a common, it is important that

you only have a single common. Multiple commons (such as

common rail and common transformer) should be avoided.

Mixing Digital and Analog Operations

Conventional and digital track sections must be consistently

separated from each other by using isolating tracks or isolating

rail connectors between the digital and conventional (DC=) track

sections (double gapping).

At the gap dividing digital from analog operation, you must take

steps to prevent interference between the 2 systems when a

locomotive crosses the gap. One approach is to use a Digital

Circuit Breaker such as the LT130. If a locomotive bridges the

insulated gap, the module immediately interrupts the analog

power supply.

Warning:

Mixed digital/analog operations using both rails and catenary

(overhead wire) is not allowed. In this mode of operation, if the

locomotive is on the track in the wrong direction (for instance

after going through a loop), the built-in locomotive decoder could

be destroyed by excessive voltage! We suggest you operate

with current pickup from the rails (wheel pickups), since that

contact is more reliable (and thereby the transmission of the

digital signals to the locomotive decoder) than with catenary.