LEROY-SOMER [ Installation and maintenance |

________

4803 en-2011.12/ b

LSA 42.3 - 4 POLES

ALTERNATORS

CONTENTS

1 - RECEIPT

............................................................................................................................

4

1.1- Standards and safety measures

................................................................................

...4

1.2 - Inspection

.......................................................................................................

4

1.3 - Identification

................................................................

....4

1.4-Storag e

..........................................................................................

4

1.5-Application s

..................................................................................................................

4

1.6 - Contraindications to use

...............................................................................................

4

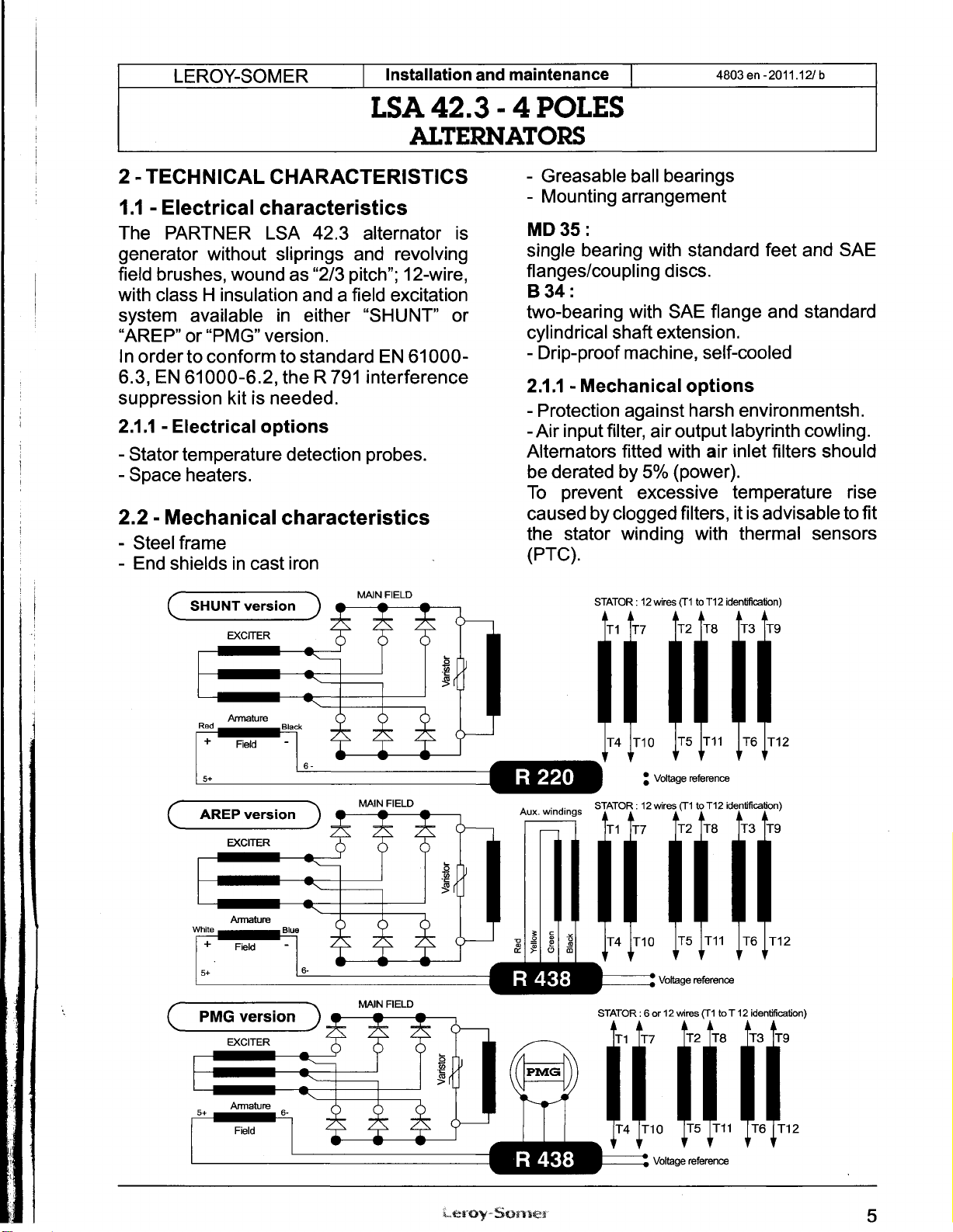

2 -TECHNICAL CHARACTERISTICS

....................................................................................

5

2.1 - Electrical c aracteristics

...............................................................................................

5

2.2 - Mec anical c aracteristics

...........................................................................................

5

3 - INSTALLATION

..................................................................................................................

6

3.1 -Assembly

......................................................................................................................

6

3.2 - C ecks prior to first use

................................................................................................

7

3.3 - Terminal connection diagrams

...................................................................

7

3.4 - Commissioning

..................

10

3.5 - Setting up

....................................................................

10

4 - SERVICING - MAINTENANCE

...................................................................

11

4.1 - Safety measures

.........................................................................................................

11

4.2 - Routine maintenance

..................................................................................................

11

4.3 - Fault detection

..................

.........................................................................................

11

4.4 - Mec anical defects

....................................................................................................

12

4.5 - Electrical faults

...........................................................................................................

12

4.6 - Dismantling, reassembly

............................................................................................

14

4.7 - Installation & maintenance of t e PMG...

....................................................................

16

4.8 - Table of c aracteristics

...............................................................................................

16

5 - SPARE PARTS

............................................................................................

18

5.1 - First maintenance parts

..............................................................................................

18

5.2 - Tec nical support Service

...........................................................................................

18

5.3 - Exploded views, parts list and tig tening torque

.........................................................

19

EC declaration of incorporation

.........................................................................................

22