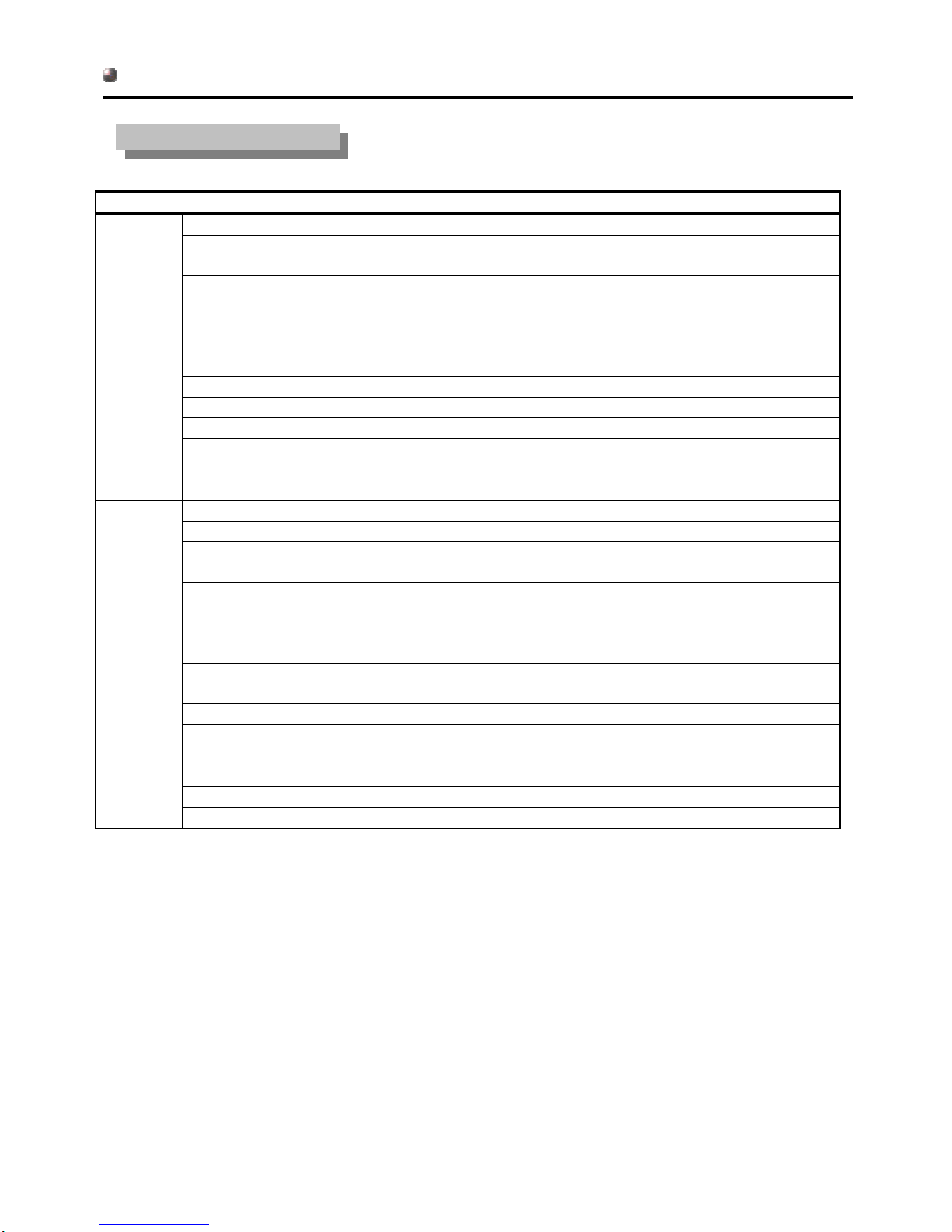

ABSTRACT OF PRODUCT

- 3 -

WARNING

INSTALL THE PRINTER ON A FLAT, STABLE SURFACE

The printer may cause an injury if it falls or is dropped.

MAINTAIN GOOD VENTILATION

Ventilation slots are provided to keep the printer from overheating. Covering the slots may cause

fire. To allow adequate air circulation, place the printer at least 10cm from any walls.

DO NOT PUT ANY OBJECT EXCEPT LEUCO CARD INTO THE PRINTER

Do not put any solid objects except LEUCO card or liquids such as water into the printer. In case

of an accident, unplug your printer immediately and contact your dealer. Using the printer with any

object inside except LEUCO card may cause fire, electric shock or damage.

DO NOT TURN OFF THE POWER WHILE OPERATING LEUCO CARD

Turn off the power while operating LEUCO card may cause damage.

DO NOT USE THE PRINTER NEAR WATER

Do not use where water may be splashed or split onto the monitor as it may cause fire or electric

shock.

STOP OPERATING THE PRINTER WHEN YOU SENSE TROUBLE

If you notice any abnormal phenomena such as smoke, strange sounds or fumes, unplug your printer

immediately and contact your dealer. Using the printer with any object except LEUCO card inside may

cause fire, electric shock or damage.

NEVER REMOVE THE CABINET OR PRINTER UNIT

Removing the cabinet or printer unit may expose you to the danger of fire or electric shock.

OPERATE UNDER THE SPECIFIED POWER SUPPLY

Be sure to operate the monitor only with the specified power supply. Use of an incorrect voltage

will cause malfunction and may cause fire or electric shock.

CAUTION

DO NOT TOUCH MOTOR OR THERMAL PRINT HEAD

Motor or thermal print head become high temperature while printer working. it may cause an injury

if it touches directly.

DO NOT CONNECT THE POWER CONNECTOR OR COMMUNICATION CONNECTOR WHEN POWER SWITCH CONDITION IS ON.

DO NOT DISCONNECT THE POWER CONNECTOR OR COMMUNICATION CONNECTOR WHEN POWER SWITCH CONDITION IS ON.

FOR YOUR SAFETY