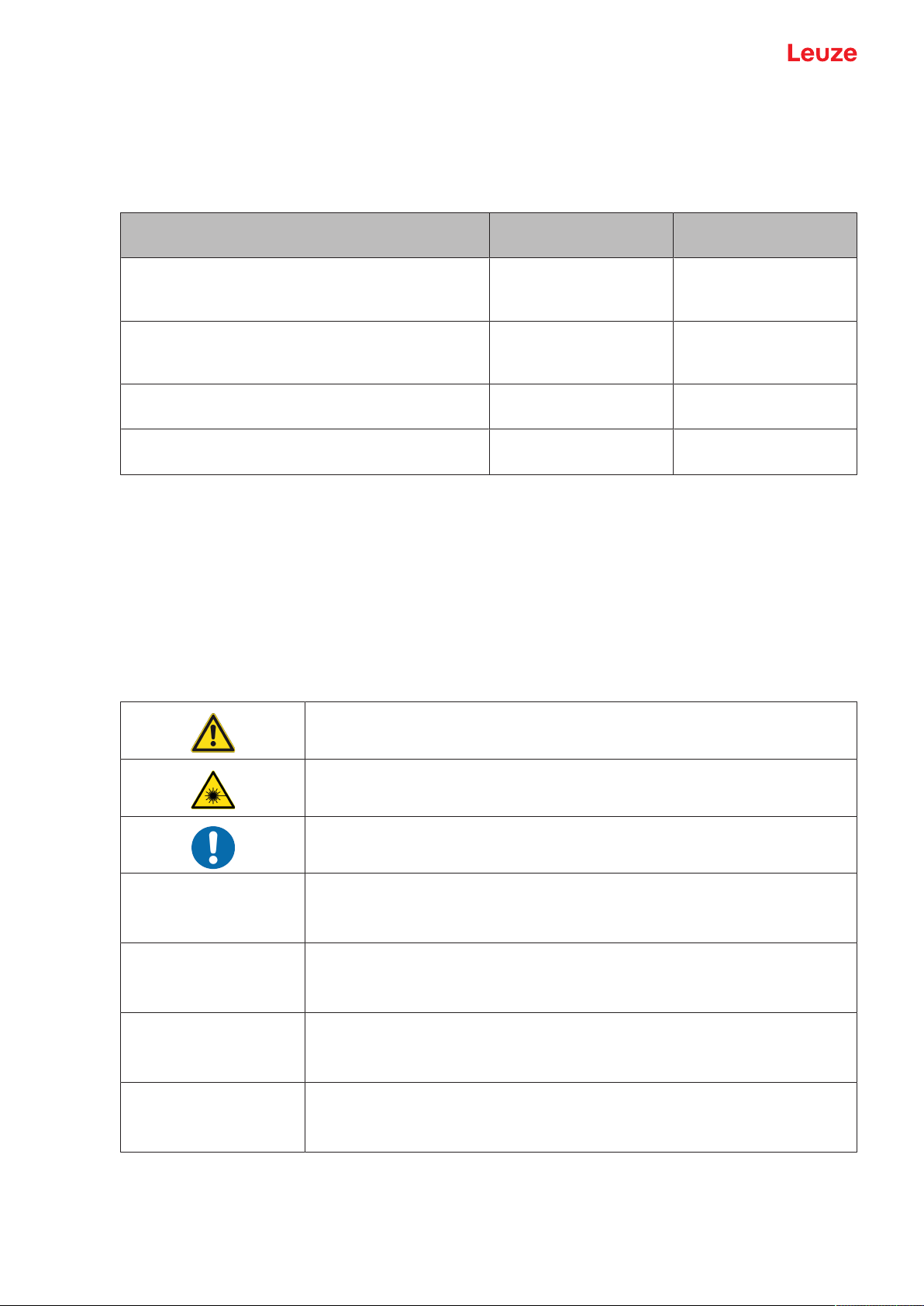

Table of contents

Leuze electronic GmbH + Co. KG RSL 420P 4

5 Functions.............................................................................................................34

5.1 Authorization concept of safety sensor.................................................................................34

5.2 Function modes of safety sensor..........................................................................................35

5.2.1 One protective function .....................................................................................................36

5.3 Selectable resolution for hand, leg and body detection ........................................................ 36

5.4 Speed-dependent protective function for vehicles................................................................36

5.5 Response time......................................................................................................................36

5.6 Configurable start-up behavior ............................................................................................. 37

5.6.1 Automatic start/restart .......................................................................................................37

5.6.2 Start interlock/automatic restart.........................................................................................37

5.6.3 Start/restart interlock (RES) ..............................................................................................38

5.7 Field pair changeover ........................................................................................................... 38

5.7.1 Fixed selection of one field pair.........................................................................................39

5.7.2 Changeover of five field pairs in changeover mode Overlapped monitoring..................... 39

5.7.3 Changeover of ten field pairs in changeover mode Fixed changeover moment ...............40

5.8 Monitoring of field pair changeover....................................................................................... 42

5.9 Reference contour monitoring .............................................................................................. 42

5.10 Field pair monitoring ............................................................................................................. 42

5.11 Signaling functions................................................................................................................ 42

6 Applications ........................................................................................................43

6.1 Stationary danger zone guarding.......................................................................................... 43

6.2 Stationary point of operation guarding.................................................................................. 43

6.3 Mobile danger zone guarding ............................................................................................... 44

6.4 Danger zone safeguarding on side-tracking skates.............................................................. 46

7 Mounting..............................................................................................................47

7.1 Basic infos............................................................................................................................. 47

7.1.1 Calculation of safety distanceS ........................................................................................47

7.1.2 Suitable mounting locations ..............................................................................................48

7.1.3 Mounting the safety sensor ...............................................................................................48

7.1.4 Mounting examples ...........................................................................................................51

7.1.5 Information on protective field dimensioning .....................................................................53

7.2 Stationary danger zone guarding.......................................................................................... 56

7.3 Stationary point of operation guarding.................................................................................. 59

7.4 Mobile danger zone guarding on AGVs................................................................................ 60

7.4.1 Minimum distanceD..........................................................................................................61

7.4.2 Protective field dimensions................................................................................................62

7.5 Mobile side guarding on AGVs ............................................................................................. 63

7.6 Mounting accessories ........................................................................................................... 63

7.6.1 Mounting system ...............................................................................................................63

7.6.2 Loop guard ........................................................................................................................64

8 Electrical connection..........................................................................................65

8.1 Electrical supply.................................................................................................................... 66

8.2 Interfaces .............................................................................................................................. 66

8.3 Connection unit CU400P-3M12 ............................................................................................ 66

8.4 Connection unit CU400P-4M12 ............................................................................................ 68

8.5 Connection unit CU400P-AIDA............................................................................................. 69

8.6 Connection unit CU400P-AIDA-OF ...................................................................................... 71

8.7 Cable lengths according to the operating voltage................................................................. 73