~

~~

IIJ'~

r-

--~

--------------~

----

----------------------------------------

-

LEYBOLD

SECTION

1

INTRODUCTION

This

manual

contains

all

of the information

that

you

need

to

safely

install,

start,

operate, maintain, troubleshoot,

and

order

parts

for

your

OF-lOOO

oil

filtering

system.

The

OF-IOOO

oil

filtering

system extends

the

life

of

the

vacuum

oil

and

of

the

vacuum

pump

by

removing contaminants

and

heat

from

the

oil.

It

can

be

used

with

TRIVAC

"A"

pumps.

With

minor

modifications,

you

can

also

use

it

with E

and

OK

series

rotary

piston

pumps

(see

Appendix A).

Aluminum

oxide,

particulate,

Fullers

Earth

and

hydroph

ilic

filtering

elements

are

available

for

use

in

the

OF-1000

. See S

ection

3

for

a

detailed

description

of

the

OF-1000

and

Sectio

n

3.3

for

information

on

selecting

the

correct

filter

element fo r your

application.

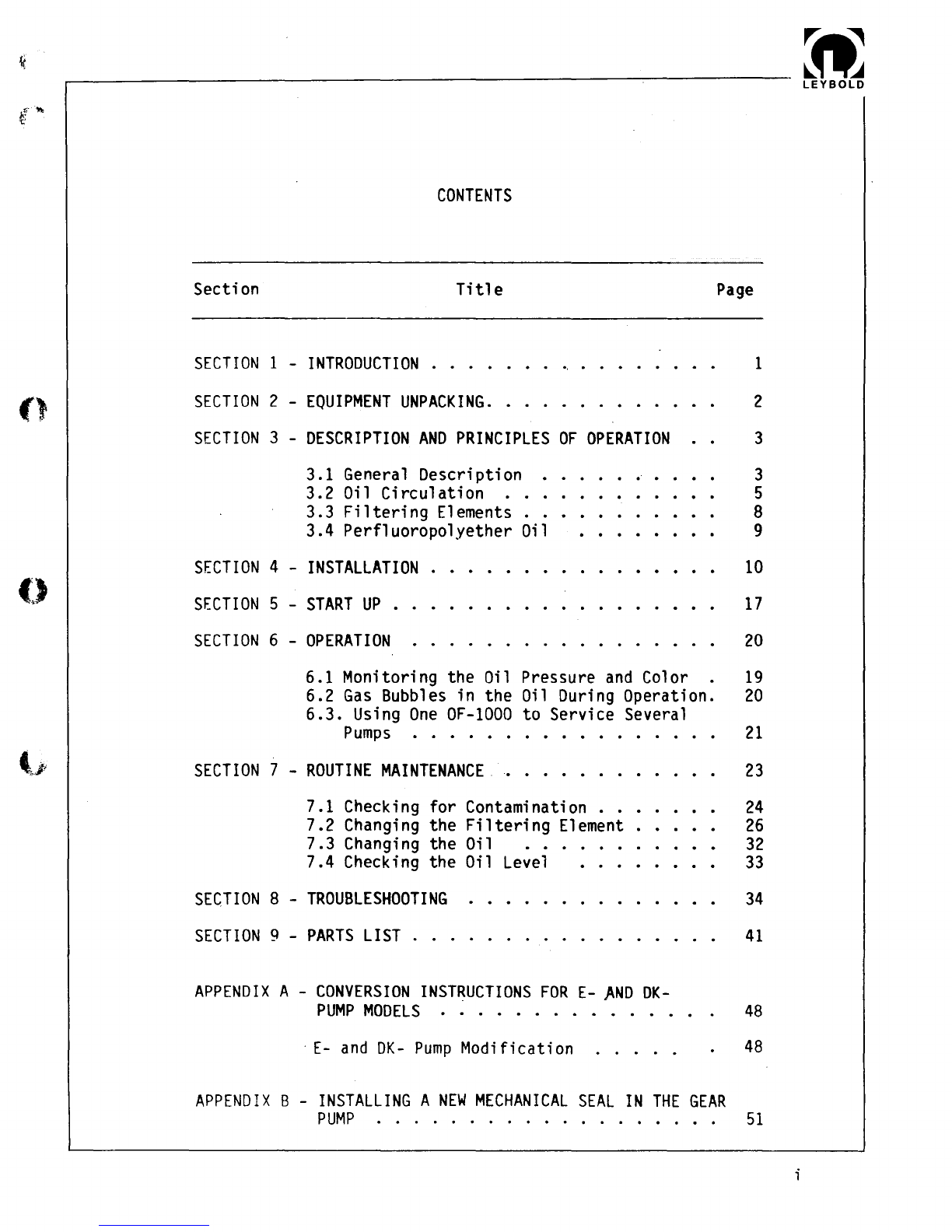

There are

two

model

s of the

OF-lOOO:

1) a

single-canister

housing

model

and

2)

a dual-canis

ter

model. There are three versions of each

of

these

two

models: 1) a

st

andard version,

2)

a version prepared for

perfluoropolyether

oil,

and

3)

a coated

corrosive-series

version prepared

for

perfluoropolyether

oil.

The

coated version

is

referred

to

as the

OF-IOOOC.

Unless otherwise noted,

all

references

to

the

OF-1000

in

this

manual

apply to

all

three

versions of the oil

filtering

system.

Check

the nameplate

on

the

OF-1000

pan

to determine

which

version

you

have.

The

following

lists

the

part

number

for each version.

Single-Canis

ter

Model

Standard V

ersi

on

Version Prepared for Perf1uoropo1yether

OF-IOOOC

Coated Version Prepared for

Perflu

cr

opo

1

yether

Dual-Canister

Model

Standard V

ersi

on

Version Prepared for Perf1uoropolyether

OF-IOOOC

Coated Version Prepared for

P

erfluor

opo

1

yether

Part

Number

898550

898551

898561

Part

Number

898552

898553

898554

The

top of the

cove

r nut

is

painted

brown

on

the

OF-1000C

versions to

make

it

easy to

identify

.

"WARNING

" statements are used in

this

manual

to prevent injury to

personnel ;

"CAUTION

" statements are used to prevent

damage

to equipment;

"NOTES"

contain hel pful information.

1