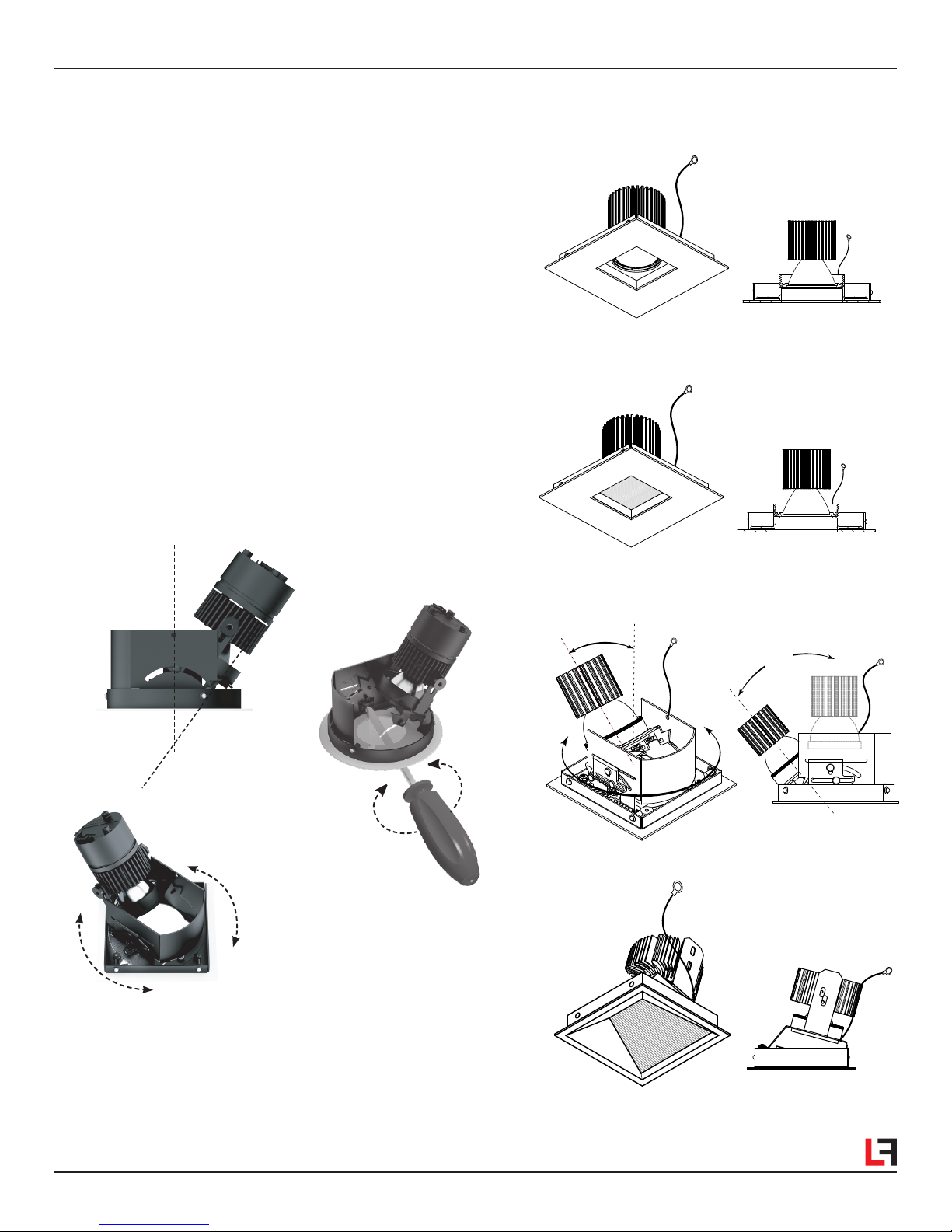

Butterfly Mounting (Commercial):

Step 1. Fixture comes equipped with Universal BUTTERFLY

MOUNTING BRACKETS and take common 1” or 1-1/2” Black

Iron or Galvanized MOUNTING CHANNELS (Supplied By Others).

Step 2. POSITION FIXTURE so the MOUNTING CHANNELS lie on

top of ceiling runners.

Step 3. Fasten MOUNTING CHANNELS securely to the ceiling

runners with wire tie downs.

Step 4. Secure MOUNTING CHANNELS to the UNIVERSAL

BUTTERFLY MOUNTING BRACKETS with wire tire downs.

Step 5. ADJUST ELEVATION OF FIXTURE so that the surface of

the PERFORATED HOUSING PLATE SITS FLUSH with the top of

the finished ceiling surface. Fine adjustments can be made by

loosening the two (2) 1/4” HEX SCREWS on both UNIVERSAL

BUTTERFLY MOUNTING BRACKETS and set accordingly Fig 1.

See FINE CEILING ADJUSTMENT

Fig 4

.

VF100 Series Mini and Small

SQUARE TRIMMED FIXTURE

INSTALLATION INSTRUCTIONS

* Risk of fire or electric shock.

* Disconnect all power before installing or servicing.

* Installation Instructions for qualified electricians only.

* Install per National Electrical Code and local regulations.

* Read Installation Instructions completely before installation.

* Failure to follow Installation Instructions may void warranties.

THIS PRODUCT MUST BE INSTALLED IN

ACCORDANCE WITH THE APPLICABLE

INSTALLATION CODE BY A PERSON

FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF THE PRODUCT AND THE

HAZARDS INVOLVED.

C US

®

Warnings:

It is IMPORTANT TO READ instruction sheet completely before installation

Joist Installation:

Includes Heavy-Duty L-Bars™ hanger bar system LF# LBARS4PK

Step 1. Extend HANGER BARS to fit between joist and

attach to joist or frame member using appropriate hardware for

material. See Fig 2, Detail 2A.

Step 2. ADJUST ELEVATION OF FIXTURE so that the surface of

the PERFORATED HOUSING PLATE SITS FLUSH with the top of

the finished ceiling surface. See Fig 1.

Step 3. Position housing horizontally by sliding on hanger bars.

Secure housing in position using wire tie downs. See Fig 2.

Pre-Installation Note: The trim and housing are packaged and shipped in separate cartons. Set the trim unit aside in a clean

and undamaging environment. The trim unit will be put in place after housing / ceiling installation. For joist installations or where wiring

access to housing is limited, it is advised to pre-wire the housing with leads before installation.

Alternate Mounting

Suspension Tabs

Mounting

Channel

(By others)

Universal Butterfly

Mounting Bracket

(2) 1/4” Hex Screw

Trim Collar

Perforated

Plaster Frame

Finished

Ceiling Surface

FIGURE 1

Hanger Bars

Detail 2A

Adjustable

Plaster Frame with

Breakaway Feature

Breakaway Plaster Frame Length

for Closer Edge Positioning