Chapter 6. BUFFER MEMORY CONFIGURATION AND FUNCTION

6.1 Buffer Memory Configuration ···········································································································6 -1

6.1.1 G3F-DA4V / G3F-DA4I ···············································································································6 -1

6.1.2 G4F-DA1A ································································································································6 -2

6.2 Buffer MemoryFunction······················································································································6 -3

6.2.1 Available ChannelSpecification ·······························································································6 -3

6.2.2 DataInput Type Specification·······································································································6 -3

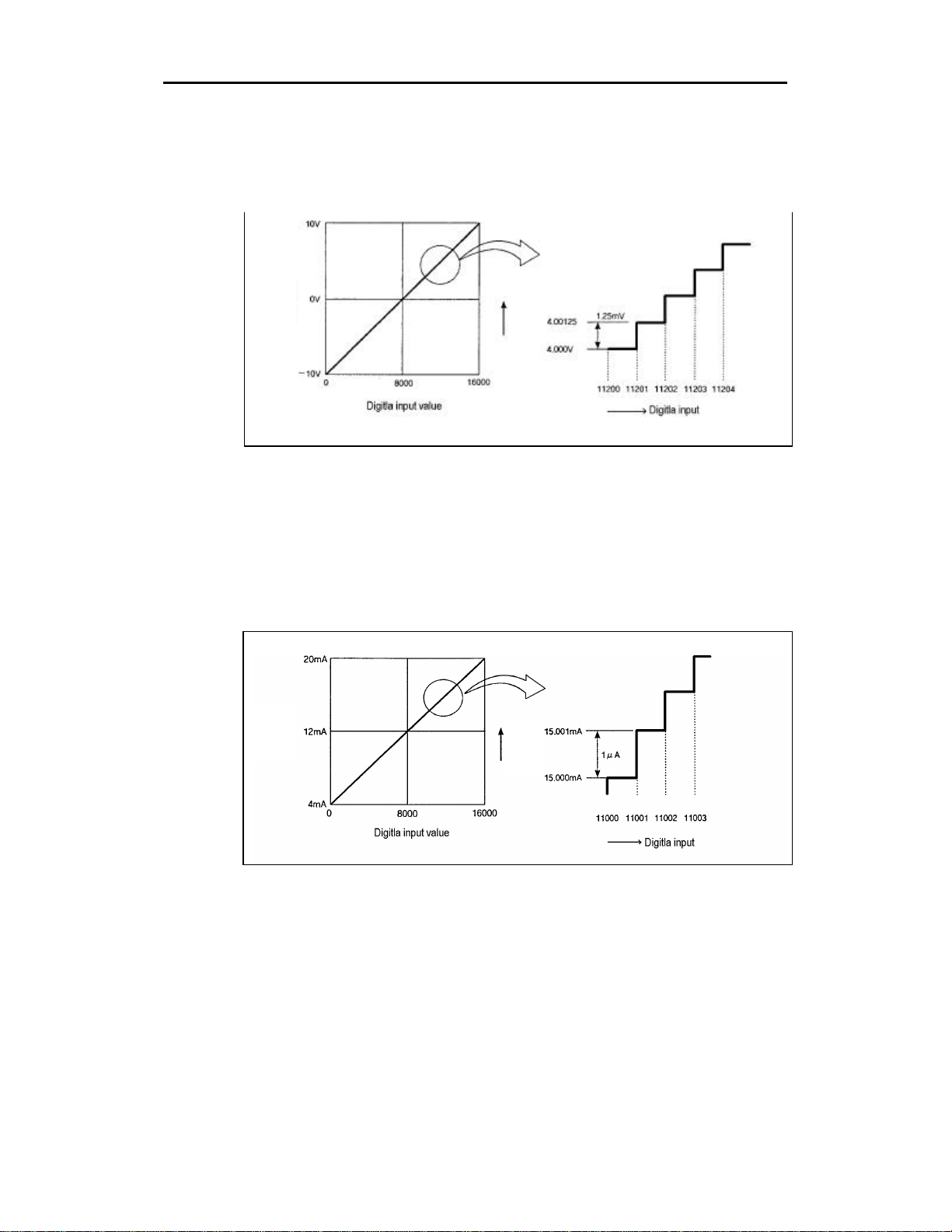

6.2.3 Digital Input ·································································································································6 -4

6.2.4 Specification of CPUModule's Stop Conditionor Disabled Channel's OutputCondition············6 -4

6.2.5 SET DataSpecification ···············································································································6 -5

6.2.6 ChannelOperation Data Area······································································································6 -5

Chapter 7. SPECIALMODULECOMMAND(BUFFER MEMORYREAD/WRITE)

7.1 Local Command···································································································································7 -1

7.1.1 BufferMemory Read-GET, GETP Command ············································································7 -1

7.1.2 Buffer Memory Write-PUT, PUTP Command ··········································································7 -2

7.2 Remote Command································································································································7 -3

7.2.1 Buffer Memory Read-RGET ······································································································7 -3

7.2.2 BufferMemory Write-RPUT ····································································································7 –4

Chapter 8. MK PROGRAMMING

8.1 Basic Programming ·························································································································8 -1

8.1.1 G3F-DA4V / G3F-DA4I ················································································································8 -1

8.1.2 G4F-DA1A ································································································································8 -2

8.2 Application Programming ···············································································································8 -3

8.2.1 Programming for Controlling InverterSpeed with 5 Step Analog Output Voltage·······················8 -3

8.2.2 Programming for Displaying of D/A Conversions which is Set byDigital Switch ····················8 -5

8.2.3 Programming for Mounting D/A Conversion Module on RemoteI/O Station ····························8 -7

Chapter 9. TROUBLESHOOTING

9.1 Error Code Indicated by RUN LED Flickering···················································································9 -1

9.2 Troubleshooting Procedure················································································································9 -1

9.2.1 RUNLEDFlickering ····················································································································9 -1

9.2.2 RUNLEDOff ····························································································································9 -2

9.2.3 SuddenD/A OutputValue Change·······························································································9 -3