–9–

(1) The function of main control

1. Time Delay Safety Control

ƒU3min¡ƒ The compressor is ceased for 3 minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

ƒU3sec¡ƒ The indoor fan is ceased for 3 seconds to prevent relay noise.

(Protection of fan relay and micro chip)

ƒU30sec¡ƒThe 4-way valve is ceased for 30 sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode.

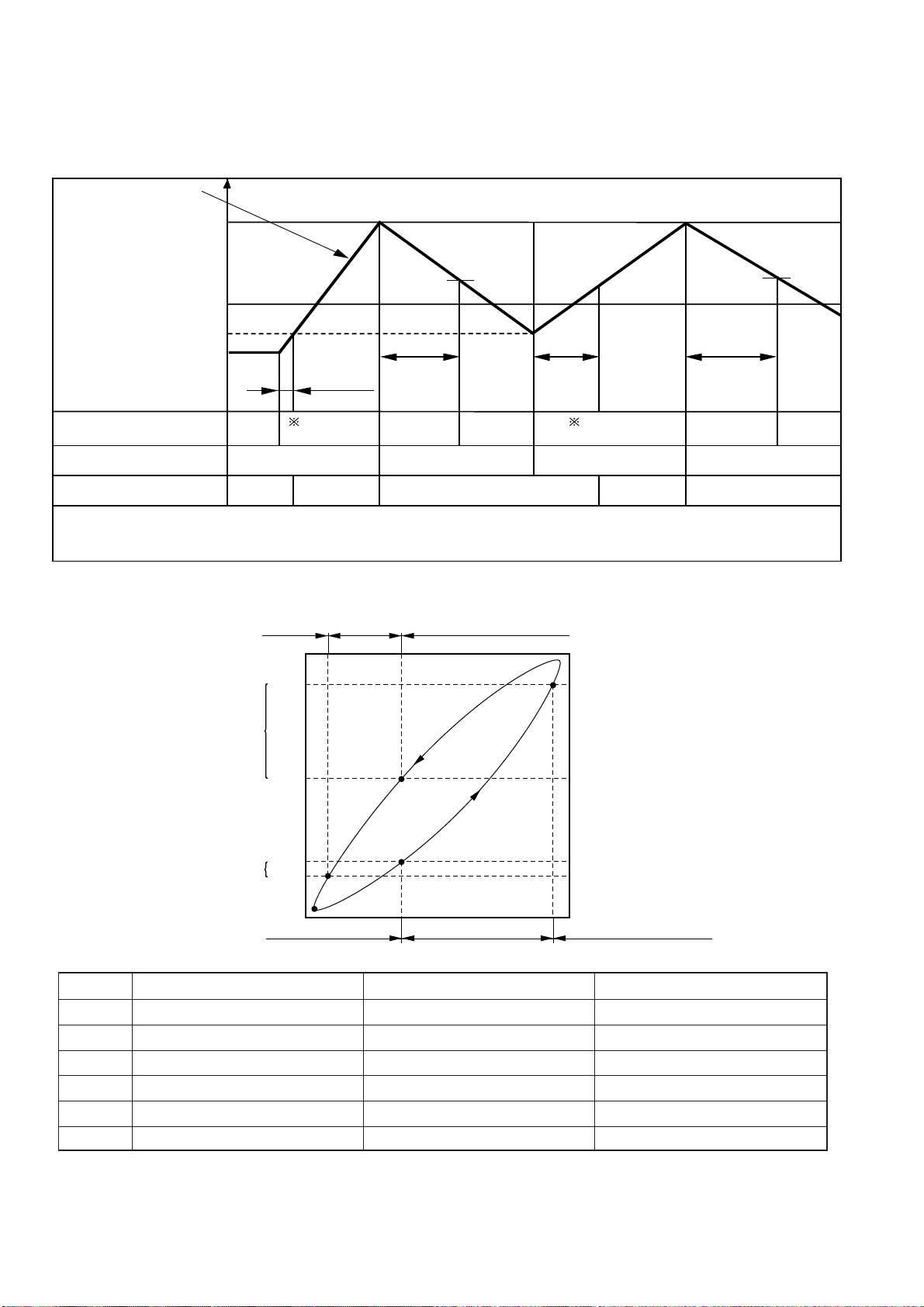

2. Airflow Direction Control

ƒUThis function is to swing the louver left and right automatically and to set it at the desired position.

ƒUThe procedure is as the following.

1st : Press the ON/OFF Button to operate the product.

2nd : Press the Airflow Direction Control Button to swing the louver left and right automatically.

(Remote controller)

3rd : Repress the Airflow Direction Control Button to set the louver as the desired position.

(Remote controller)

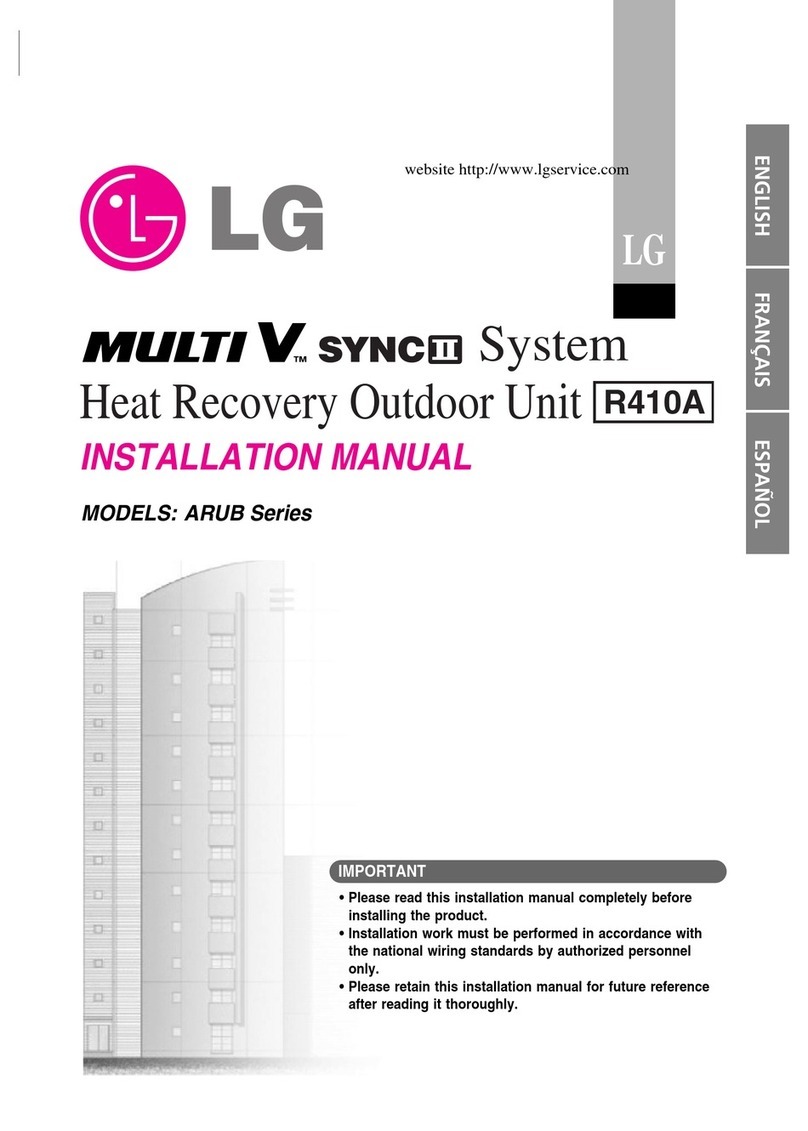

3. Cooling Mode Operation

ƒUWhen selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the

controller and the operation diagram is as following.

Operation Details

4. Off Timer Function

This function is to set the time of stopping the unit operation.

The procedure is as the following.

1st: Press the timer set button on the Remocon.

2nd: The buzzer sounds and then the display window shows the Off-Time to be set as

- The Off-Time is shifted as the following by each press.

- If you select ' ', the Off-Timer function will be cancelled.

- During Off-Timer Operation, if you repress the timer set button, the rest time will be displayed.