3

481#Wdj#Rq#1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111#93

491

49041

44

45

48

49

4:

4:

4;

4<

53

53

54

55

56

57

5:

5;

5<

63

64

65

66

67

69

85

8;

9:

9:

9;

9<

:3

:4

4905041

4905051

4906041

4906051

1. SPECTIFICATIONS ................................................................................................................ 4

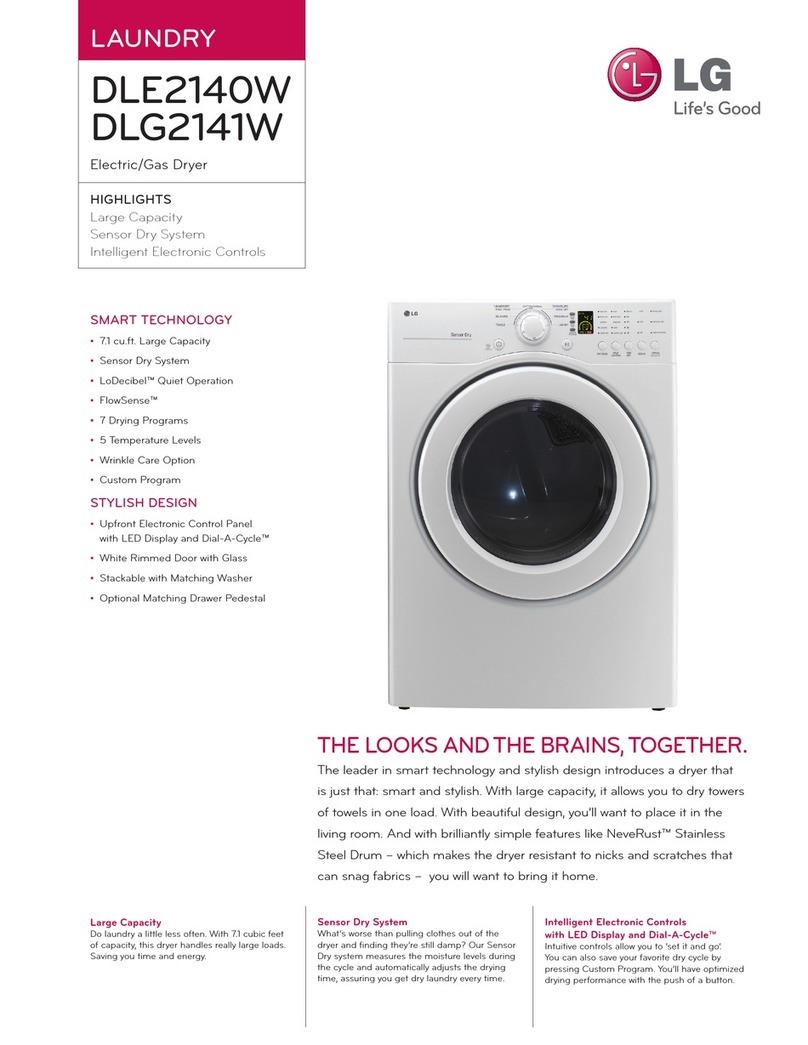

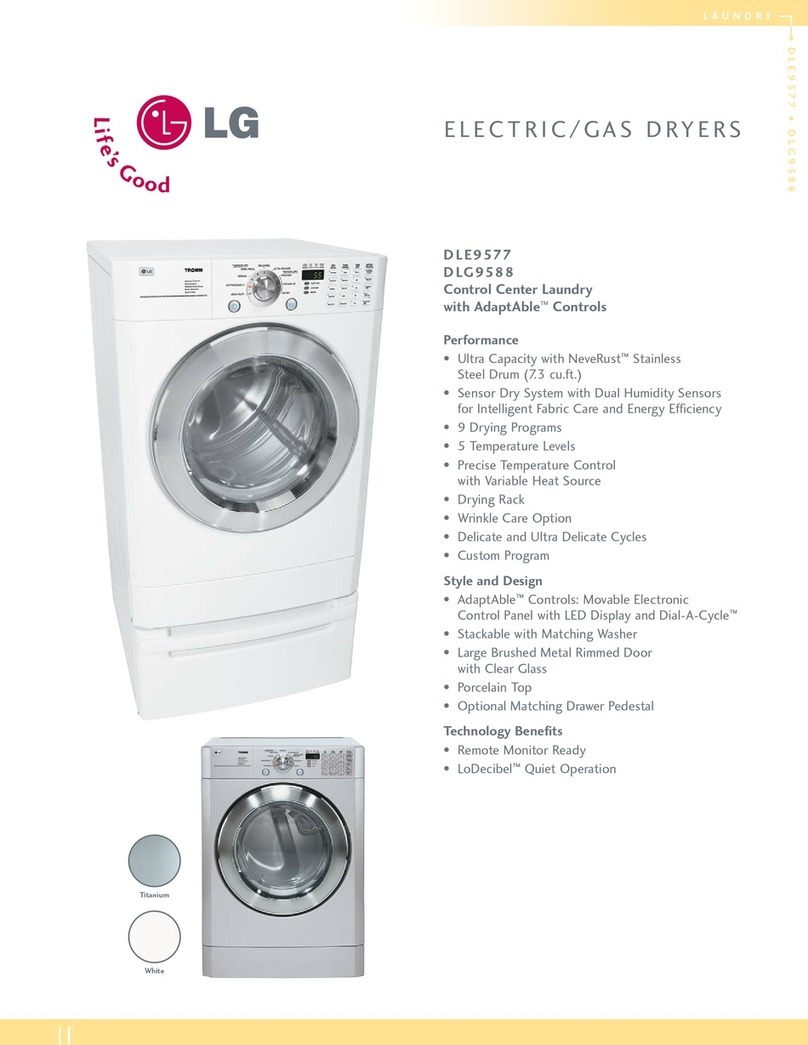

2. FEATURES AND BENEFITS ...................................................................................................6

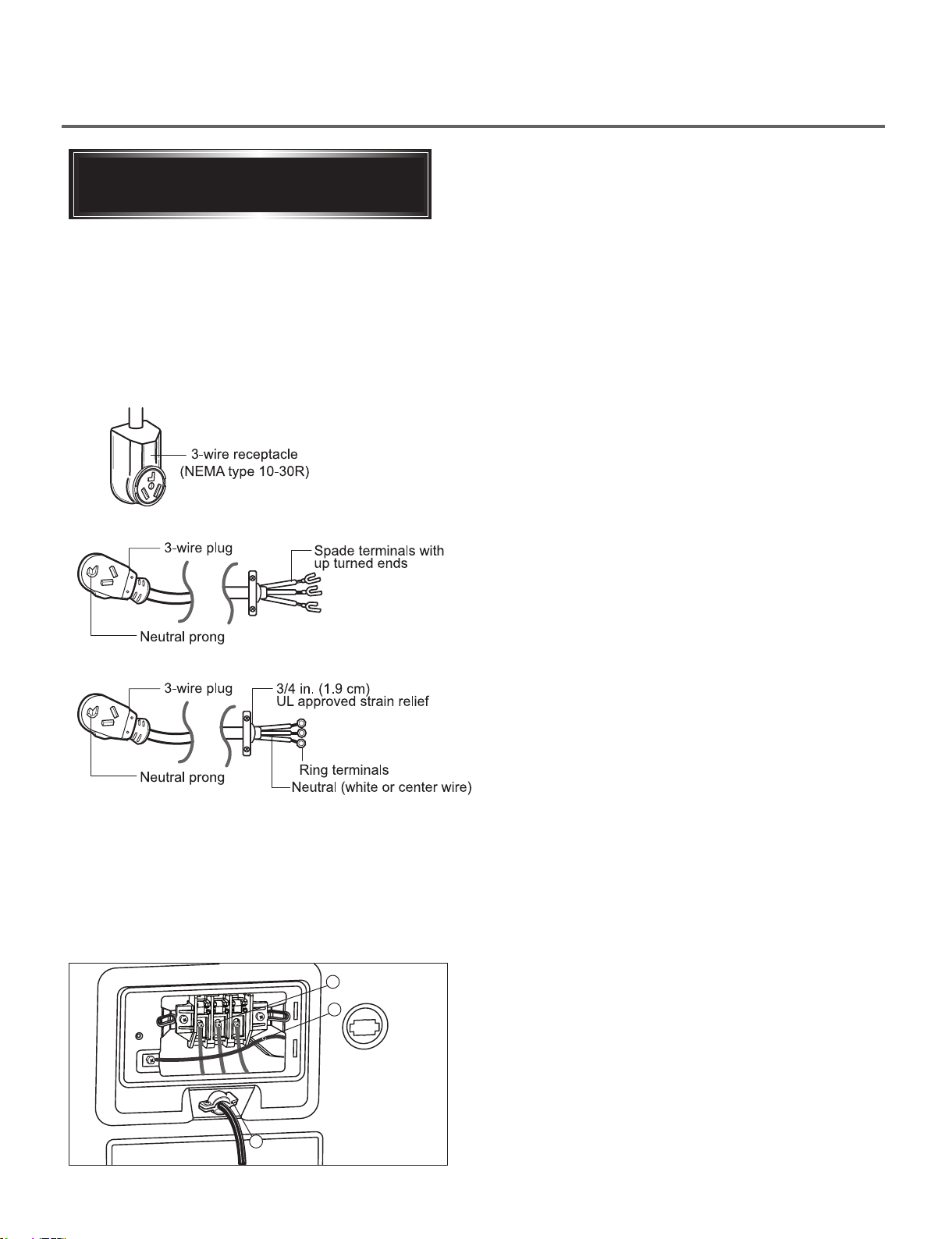

3. INSTALLATION INSTRUCTIONS ............................................................................................6

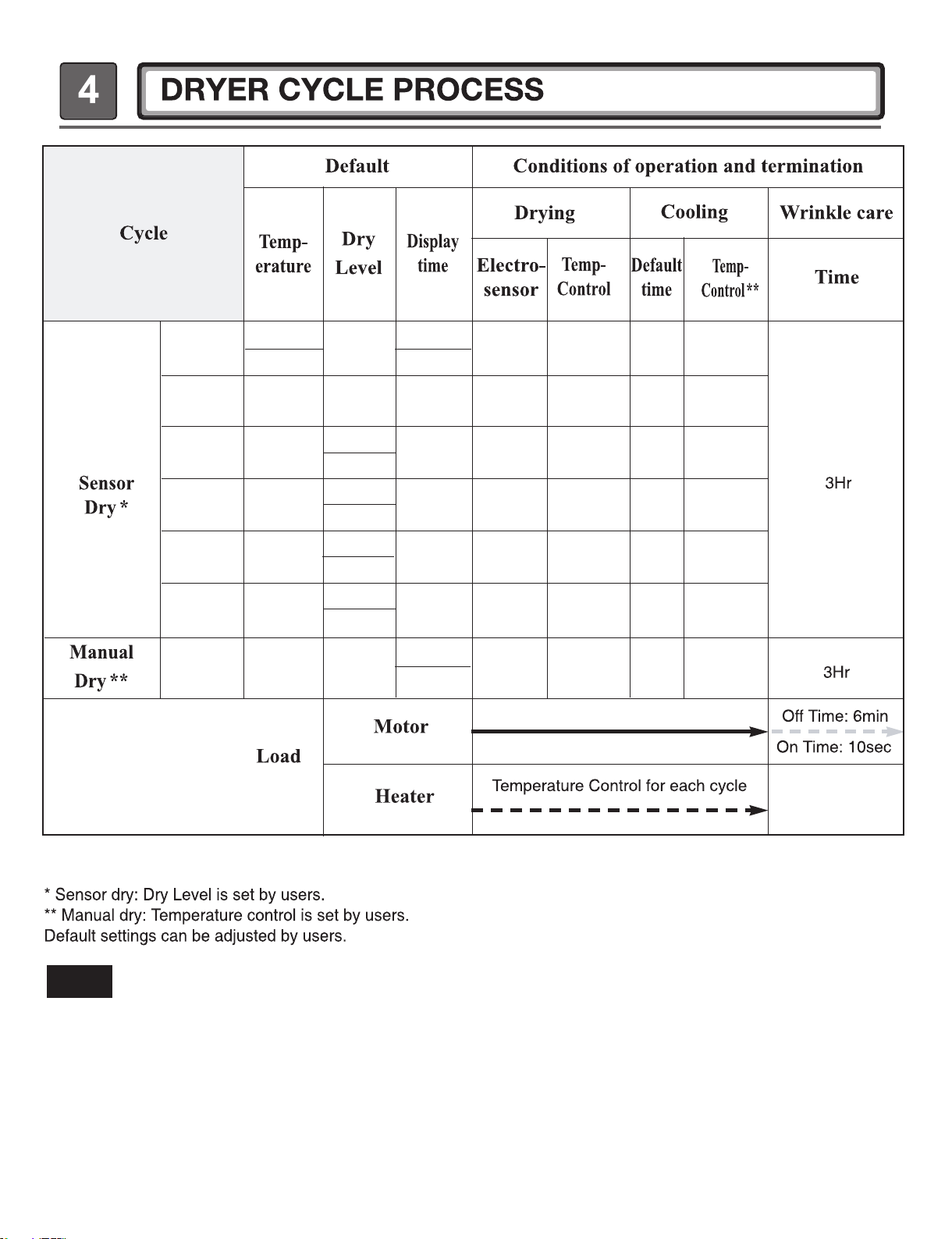

4. DRYER CYCLE PROCESS ...................................................................................................10

5. COMPONENT TESTING INFORMAITON .............................................................................11

6. MOTOR DIAGRAM AND SCHEMATIC ..................................................................................14

7. WIRING DIAGRAM ................................................................................................................15

8. FLOW SENSORFUNCTION .................................................................................................17

9. DIAGNOSTIC TEST ...............................................................................................................20

10-1. TEST 1 120 VAC ELECTRICAL SUPPLY ....................................................................21

10-2. TEST 2 THERMOSTOR TEST - MEASURE WITH POWER OFF ...............................24

10-3. TEST 3 MOTOR TEST..................................................................................................25

10-4. TEST 4 MOISTURE SENSOR ......................................................................................26

10-5. TEST 5 DOOR SWITCH TEST .....................................................................................27

10-6. TEST 6 HEATER SWITCH TEST - ELECTRIC TYPE ..................................................28

10-7. TEST 7 GAS VALVE TEST - GAS TYPE......................................................................29

10. CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS) ............................................30

11. DISASSEMBLY INSTRUCTIONS ........................................................................................32

12. REVERSING THE DOOR ....................................................................................................50

12. FASTENER CHART - SIZE AND POSITIONS ....................................................................57

12-1. DOOR..........................................................................................................................57

12-2. CABINET COVER .......................................................................................................58

13. EXPLODED VIEW ................................................................................................................59

13-1. CONTROL PANEL AND PLATE ASSEMBLY.............................................................59

13-2-1. CABINET AND DOOR ASSEMBLY : ELECTRIC TYPE..........................................60

13-2-2. CABINET AND DOOR ASSEMBLY : GAS TYPE ....................................................61

13-3-1. DRUM AND MOTOR ASSEMBLY : ELECTRIC TYPE ............................................62

13-3-2. DRUM AND MOTOR ASSEMBLY : GAS TYPE ......................................................63

Copyright © 2016 - 2017 LG Electronics Inc. All

rights reserved. Only training and service purposes.