9

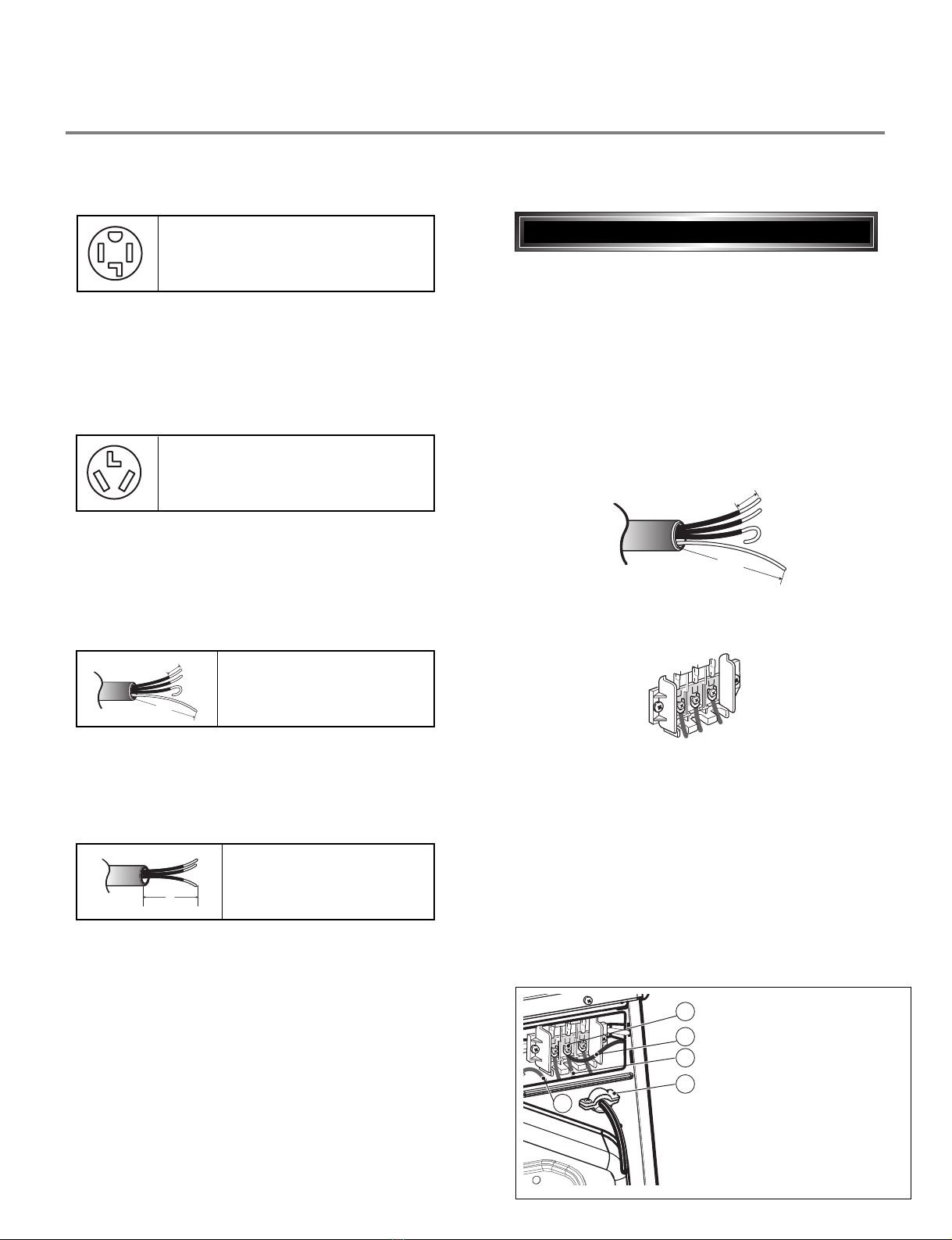

Use the instructions at this section if your home has

a 3-wire receptacle (NEMA type 10-30R) and you

will be using a UL listed, 120/240 volt minimum,

30 amp, dryer power supply cord.

Review the following options to determine the appropriate electrical connection

for your home:

If this type is available at your home. you will be

connecting to a fused disconnect or circuit breaker

box

Important : use 4-wire connection in the places such

as mobile homes and areas where 3-wire connections

is not available.

Prepare minimum 5ft(1.52m) of length in order for

dryer to be replaced.

First, peel 5 inch (12.7cm) of covering material from

end. Make a 5 inch of ground wire bared. After cutting

1

1

/2inch (3.8cm) from 3 other wires. peel insulation

back 1inch (2.5cm). Make ends of 3 wires a hook

shape.

Then, put the hooked shape end of the wire under the

screw of the terminal block(hooked end facing rightward)

and pinch the hook together and screw tightly.

Use the instructions at this section if your home has

a 4-wire receptacle (NEMA type 14-30R) and you

will be using a UL listed, 120/240 volt minimum,

30 amp, dryer power supply cord.

If this type is available at your home. you will be

connecting to a fused disconnect or circuit breaker

box

1. Connect neutral wire(white) of power cord to center

terminal block screw.

2. Connect red and black wire to the left and right

terminal block screws.

3. Connect ground wire(green) of power cord to external

ground screw and move neutral ground wire of

appliance and connect it to center screw.

4. Make sure that the strain relief screw is tightened.

and be sure that all terminal block nuts are on tight and

power cord is in right position.