LG ELECTRIC AND GAS DRYER DLE 5977W User manual

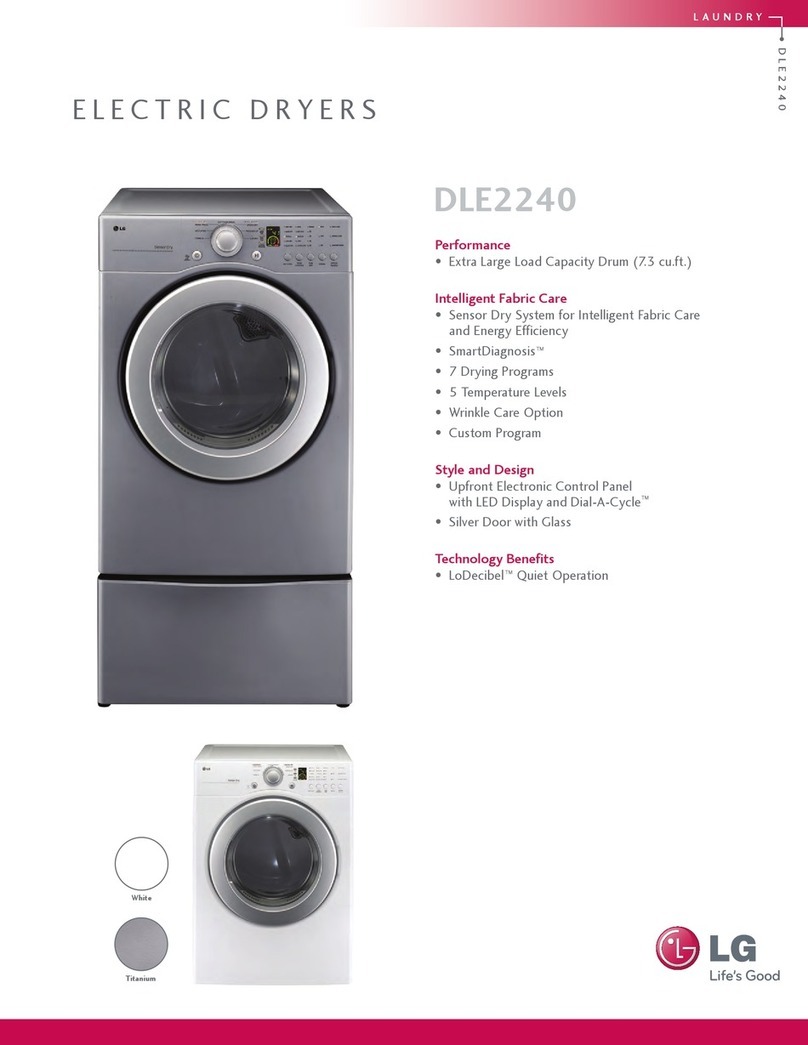

Other LG Dryer manuals

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual