- 7 - LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Object

These instructions are applied all of the PLASMA TV,

PD82A Chassis.

2. Note

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100-240V~,

50/60Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment.

OAfter RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

OEnter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

* Set is activated HEAT-RUN without signal generator in

this mode.

* Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

3.

ADC Calibration

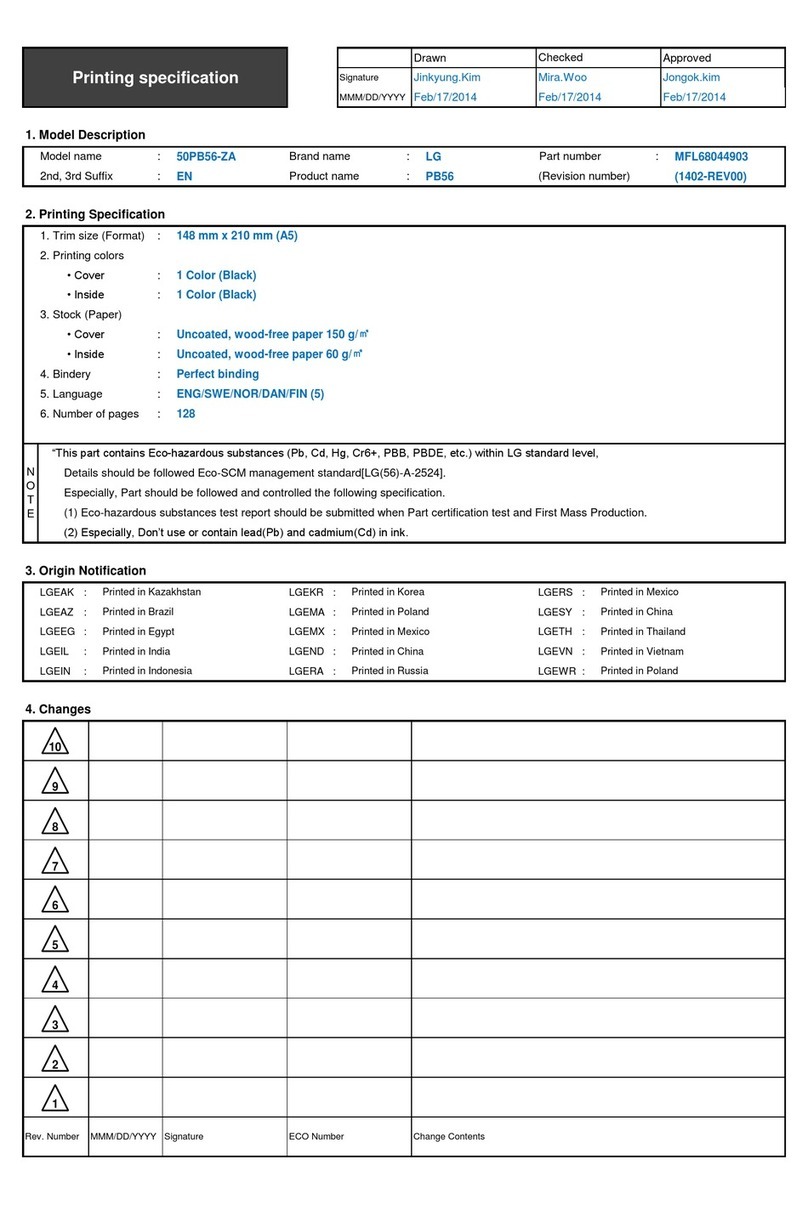

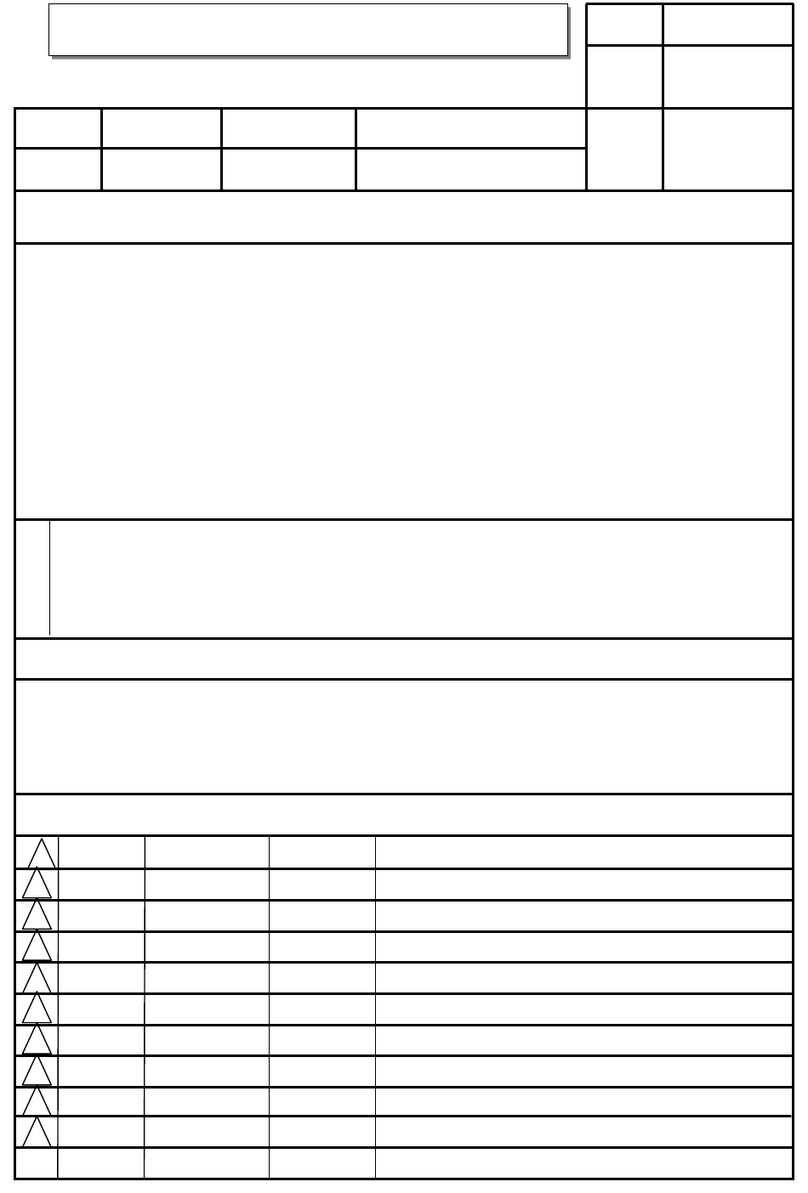

V Auto adjustment Map(RS-232C)

- Baud : 115200bps, RS232 Host : PC, Echo : none.

4. Adjustment of AV Color Balance

4-1.

Standard Equipment

: 802F Pattern Generatorr. Master Pattern Generator(MSPG-

925, etc) or same product.

4-2. Required Equipment

O Remote controller for adjustment.

O MSPG-925FS Pattern Generator. (Which has Video Signal:

7 Color Bar Pattern shown in Fig.1)

-> Model: 202 / Pattern: 65 EC and FC model use PAL-

BGDHI(composite signal)

(1) Input the Video Signal: 7 Color Bar signal into AV3.

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment.

(4) Press the G(Vol. +) key to operate the set, then it

becomes automatically.

5. Adjustment of Component

5-1.

Standard Equipment

: 802F Pattern Generatorr. Master Pattern Generator(MSPG-

925, etc) or same product.

5-2. Required Equipment

O Remote controller for adjustment.

O MSPG-925FS Pattern Generator. (Which has Video Signal:

7 Color Bar Pattern shown in Fig.2)

-> Model: 202 / Pattern: 65 EC and FC model use PAL-

BGDHI(composite signal)

(1) Input the Component 720p/50Hz 7 color Bar

Pattern(MSPG-925FS model : 215, Pattern : 65) signal into

Component.

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment.

(4) Press the G(Vol. +) key to operate the set, then it

becomes automatically.

(5) Auto-RGB OK means the adjustment is completed.

* Using ‘power on’ button off the control R/C, power on TV.

If you turn on a still screen more than 20 minutes, (Especially

digital pattern, cross hatch pattern) after image may be occur in

the black level part of the screen.

ADC adjust

Data Read

Default Write

Enter

Adjust Mode

ADC adjust

ADC Parameter

Digital Data

ADC Parameter

(Average)

Adjustment

Confirmation

Adjust Mode In

Adjust Mode Off

NO Item Remark

CMD1 CMD2

Data 0

A

A

A

A

A

A

A

D

D

D

D

D

D

D

0

0

0

0

0

0

0

1

2

3

4

9

0

9

Transfer 18Byte

(Input resolution Data)

To check ADC Adjusment

on Assembly line

When transger the ‘Mode

In’, Carry the command.

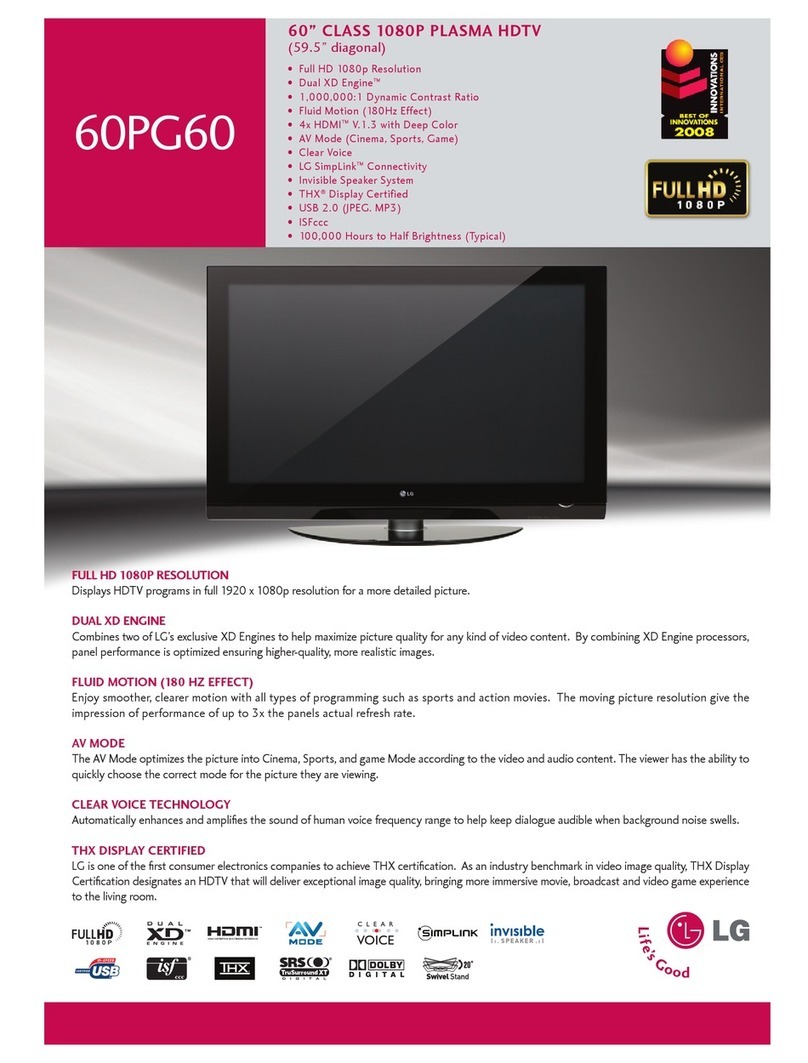

MSPG925FS

Component RGB-PCAVADC

Model : 3

(1024*768 60Hz)

Pattern : 65

7 Color Bar

Model:215(720P)

Pattern : 65

* 720P/50Hz

7 Color Bar

PAL

INPUT SELECT AV3

Model : 202

(PAL-BGDHI)

Pattern : 65

* PAL 7 Color Bar

(Fig.1) 7 color Bar signal

(Fig.2) 7 color Bar signal