- 7 - LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only or training and service purposes

ADJUSTMENT INSTRUCTION

1. Application

This spec. sheet is applied to all o the PD01A chassis.

2. Sp cification

[Caution: Th modul k ping condition]

- The module keeping condition: The normal temperature

condition(more than 15 °C)

--> Immediately the line supply.

- The module keeping condition: 0 °C

--> The module must be kept or more than 2 hours at the

normal temperature.

- The module keeping condition: -20 °C

--> The module must be kept or more than 3 hours at the

normal temperature.

- The case o Gu-mi actory at the winter season.

--> The module must be kept or more than 5 minutes at

the heating zone(40 °C ~ 45 °C).

(1) The adjustment is according to the order which is

designated and which must be ollowed, according to the

plan which can be changed only on agreeing.

(2) I there is no speci ic designation, the adjustment must be

per ormed in the circumstance o 25 °C ± 5 °C o

temperature and 65 % ± 10 % o relative humidity.

(3) The input voltage o the set must keep 100 V ~ 240 V,

50 / 60 Hz.

(4) Input signal Unit: Product Speci ication Standard.

(5) The set must be operated or about 5 minutes prior to the

adjustment.

OA ter turning on RGB Full Window pattern in HEAT-RUN

Mode, the receiver must be operated.

OEnter into HEAT-RUN MODE

1) Press the ‘POWER ON’ button on R/C or adjustment.

2) Press the ‘ADJ’ button on R/C and enter EZ ADJUST

Select “7. Test Pattern” by using D/E(CH +/-) and press

ENTER(V)

Select “White” by using F/G(VOL +/-) and press

ENTER(V)

- Set heat run should be activated without a signal generator.

- Single color patterns (RED / BLUE / GREEN) o HEAT RUN

MODE are used to check a plasma panel.

- Caution: I you turn on a still screen more than 20 minutes

(Especially digital pattern, cross hatch pattern), an a ter

image may be made in the black level part o the screen.

[Caution]

- Use ‘power on’ button o a service R/C to power on TV set.

- Do not connect any external input cable i there is no any

speci ics.

3. Updat S/W using Auto Download

through th USB

Caution: S/W version o USB ile (xxx.epk) must be bigger than

one which is downloaded previously.

(1) Insert the USB stick to the USB socket

(2) A downloaded ile in USB stick will be detected

automatically.

(3) I S/W version o USB ile (xxx.epk) is bigger than one

which is downloaded previously, the message, “Copying

iles rom memory”, will appear.

(4) I an update procedure was completed, TV set will be

turned o and on automatically.

(5) I TV set is turned on, check an updated version.

* I a downloaded version is more bigger than one o which

TV set had, TV set can lost channel data. In this case,

you have to scan channels again.

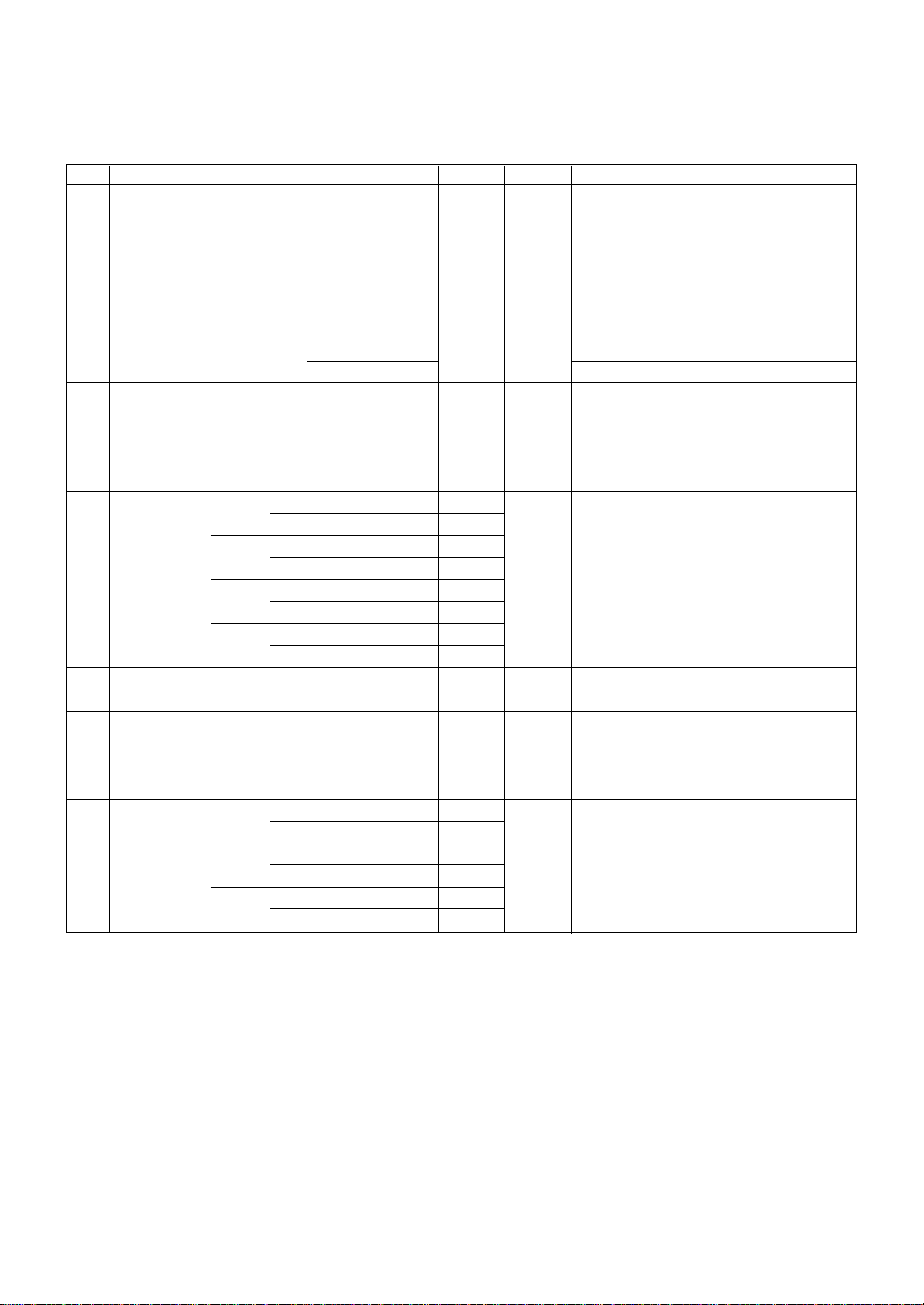

4. Aft r Downloading S/W, Adjust

TOOL OPTION

(1) Push “IN-START” button on a service R/C.

(2) Select “Tool Option 1” and Push “OK” button.

(3) Put the number o a below table in order o a su ix o the

“Tool Option(X)”.

(Each model has a di erent number.)