- 3 - LGE Internal Use OnlyCopyright©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

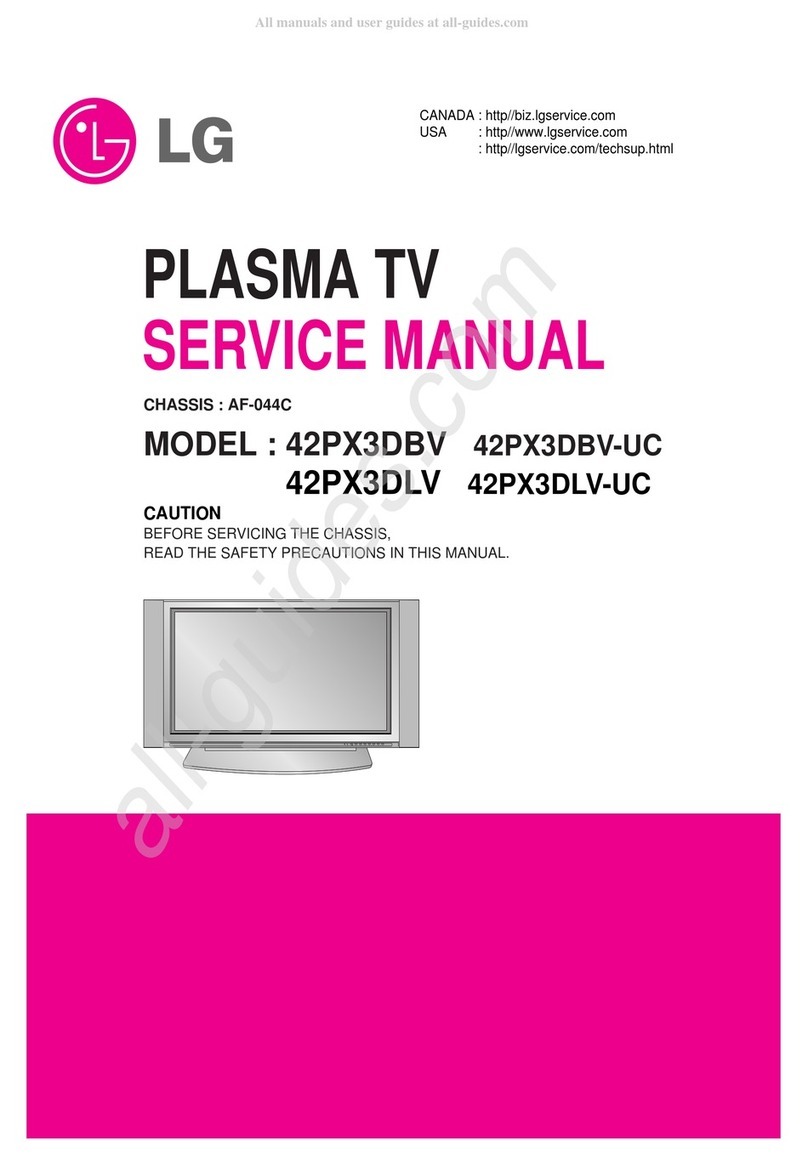

PRECAUÇÕES DE SEGURANÇA

ADVERTÊNCIA : Antes de reparar este chassis., leia as “ PRECAUÇÕES DE RADIAÇÃO POR RAIO X “, “ INSTRUÇÕES

DE SEGURANÇA “ e “ AVISO SOBRE SEGURANÇA DE PRODUTOS “.

Muitas partes elétricas e mecânicas neste chassis, tem características relacionadas com a segurança. Estas características

frequentemente não são verificadas nas inspeções visuais e a proteção que proporcionam contra a RADIAÇÃO DE RAIO “ X “ nem

sempre se obtem utilizando componente com maior potência ou de maior isolação. As peças que têm essas características de

segurança são identificadas por uma marca [ ] impressa sobre o diagrama esquemático e a marca [ ★] impressa na lista de

partes elétricas. Antes de substituir algum destes componentes, leia cuidadosamente este manual. O uso de peças de reposição que

não tenham as mesmas características de segurança, como especificado na lista de material de reposição, pode gerar Radiação de

Raios “X”.

1. Quando o receptor está em operação, são geradas tensões

potencialmente altas em torno de 25-29 kV. Operar o receptor

fora de seu gabinete ou com a tampa traseira removida pode

causar perigo de choque elétrico.

(1) Ninguém deverá tentar reparar o aparelho sem estar

familiarizado com as precauções que são necessárias

quando se trabalha com um equipamento de alta tensão.

(2) Sempre descarregue o anodo do cinescópio ao terra para

evitar o risco de choque elétrico antes de remover o conector

do anodo (chupeta de alta tensão).

(3) Descarregue completamente o potencial do cinescópio

antes de manuseá-lo. O cinescópio é de alto vácuo, e se

quebrar, os fragmentos de vidro são expelidos violentamente.

2. S e queimar algúm fusível deste receptor de televisão,

substitua-o por outro especificado na lista de peças elétricas.

3. Quando substituir placas de circuito impresso ou módulos, fixe

seus fios nos terminais antes de soldar.

4. Quando substituir uma resistência de potência (resistor de

película de óxido metálico) no painel de circuito impresso,

mantenha os seus terminais com 10mm de distância do

painel.

5. Mantenha os fios e cabos distantes de componentes de alta

potência e de alta temperatura.

6. Este receptor deve operar em redes de 100 a 240 V AC.

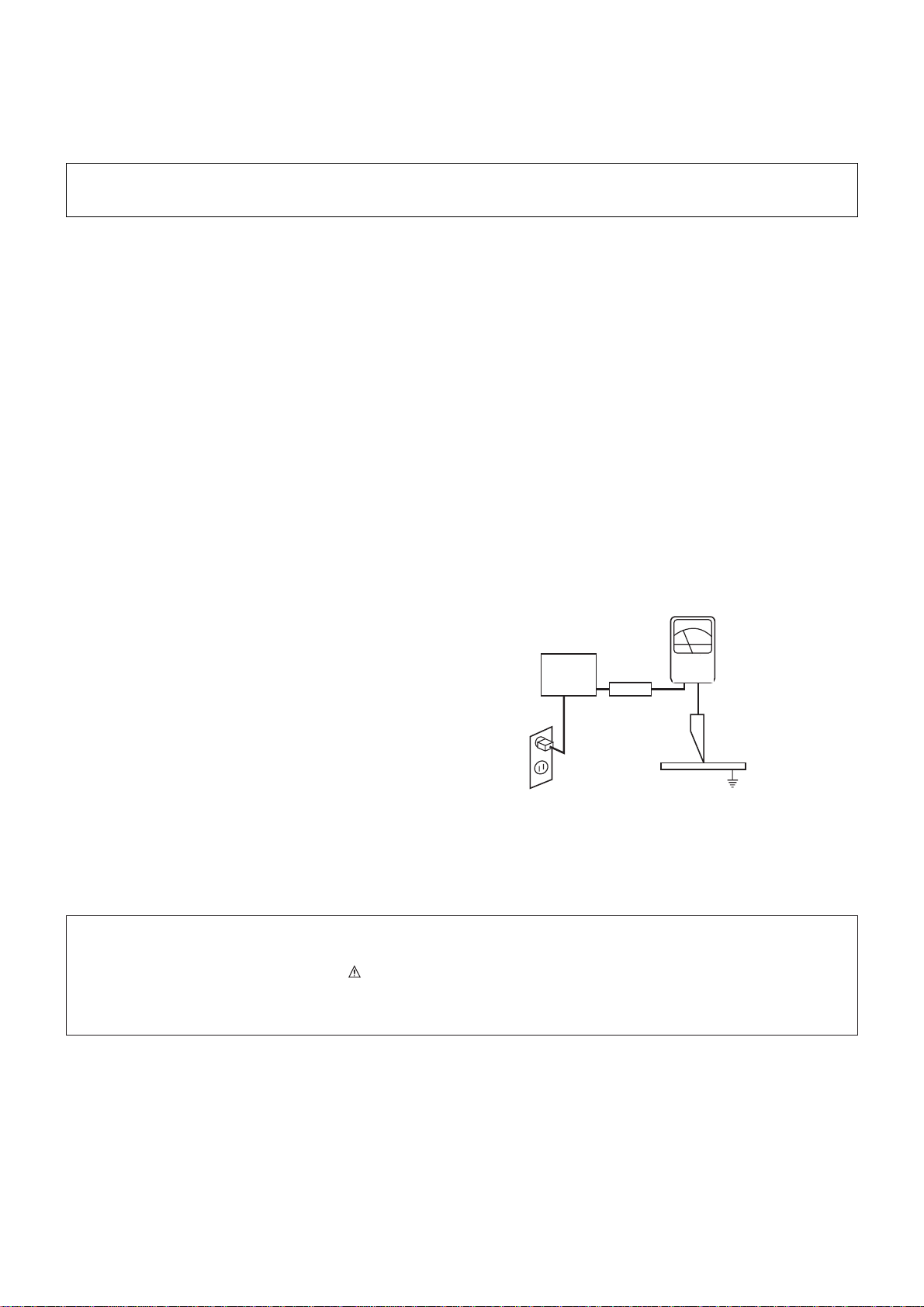

7. Antes de devolver este aparelho ao cliente, faça uma

verificação de fuga de corrente sobre as partes metálicas

expostas do gabinete, tais com antenas, terminais, cabeças

de parafusos, tampas de metal, alavancas de controle, etc., e

certifique-se de que o aparelho funciona sem perigo de

choque elétrico. Ligue o cabo de rede do aparelho

diretamente a uma tomada de força de 100-240 V AC. Não

utilize um transformador de isolação durante este teste.

Utilize um voltímetro de no mínimo 1KW por Volt de

sensibilidade, da forma que se segue.

Quando a unidade estiver conectada ao AC, pulse o

comutador primeiramente em “ON” (ligado) e em seguida em

“OFF” (desligado), meça desde um ponto de terra conhecido

(tal como um terminal de terra central da rede elétrica) a

todas as partes metálicas expostas do televisor ( antenas,

teclas metálicas, capas metálicas, alavancas de controle,

etc..) especialmente qualquer parte metálica que possa

oferecer um caminho ao chassis. Nenhuma medição de

corrente elétrica deve exceder 0,5 mA. Repita a prova

mudando a posição do pluque de rede na tomada AC.

Qualquer medição que não esteja dentro dos limites aqui

especificados, representam risco potencial de choque elé

trico que deve ser sanado antes que o aparelho retorne ao

cliente.

INSTRUÇÕES DE SEGURANÇA

AVISO SOBRE SEGURANÇA DE PRODUTO