- 10 - LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only or training and service purposes

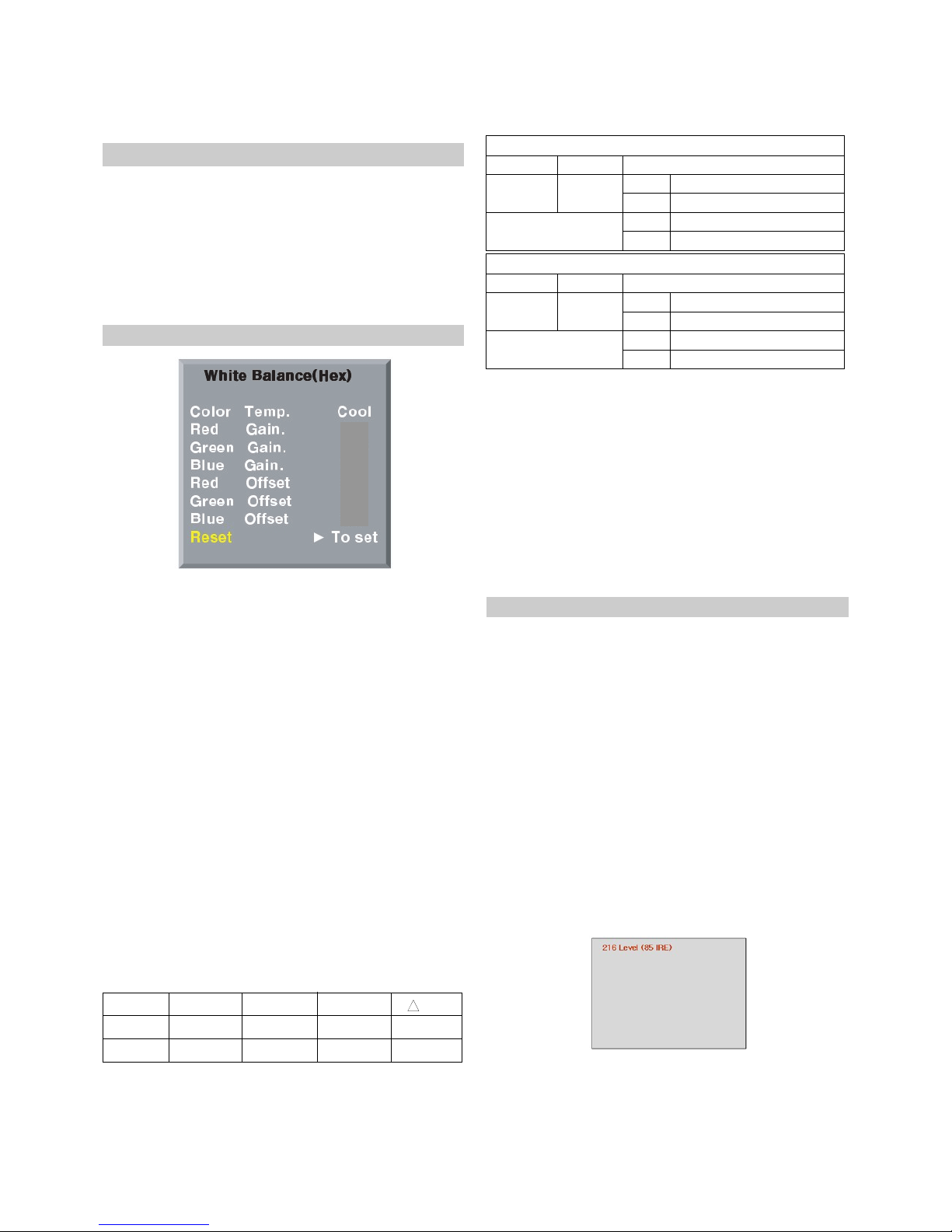

11. hite Balance

* Notice

- Do the white balance adjustment under the 10LUX

- Be ore white balance, press the In-start key 2times and do

the reset like Fig.6

- Use the Torino inner pattern(216 gray pattern)

- To enter White-balance mode,press the IN-START key

2times.

11-1. Test Equipment

(1) Color Analyzer (CA-100),CA-210.

* Note : hen using the Color Analyzer with PDP,

recommend the CA-100 more than CA-210.

If CA-100 can not available, it is also good th use

the CA-210

(2) PC( or communication through RS-232C)

-> UART Baud rate : 115200.

(3) Pattern Generator(MSPG-925FA etc.)

11-2. Color Temperature & Color

Coordinates Setting

(1) When adjusting the Color Temperature o PDP, Color

Analyzer CA-210(Matrix should be corrected through

CH10 o CS-1000) should be used. When CA-210 have

used, it don’t need to it the CH10.

(2) Adjust the Color Temperature based below adjustment

color coordinates.

(3) Even i CH9 o CA-210 is corrected with Matrix, there may

be many character o Module and Filter.

(4) There ore Re er to the below Color Coordinates Target.

But, in case o WCG module, use the CH12 o CA-210.

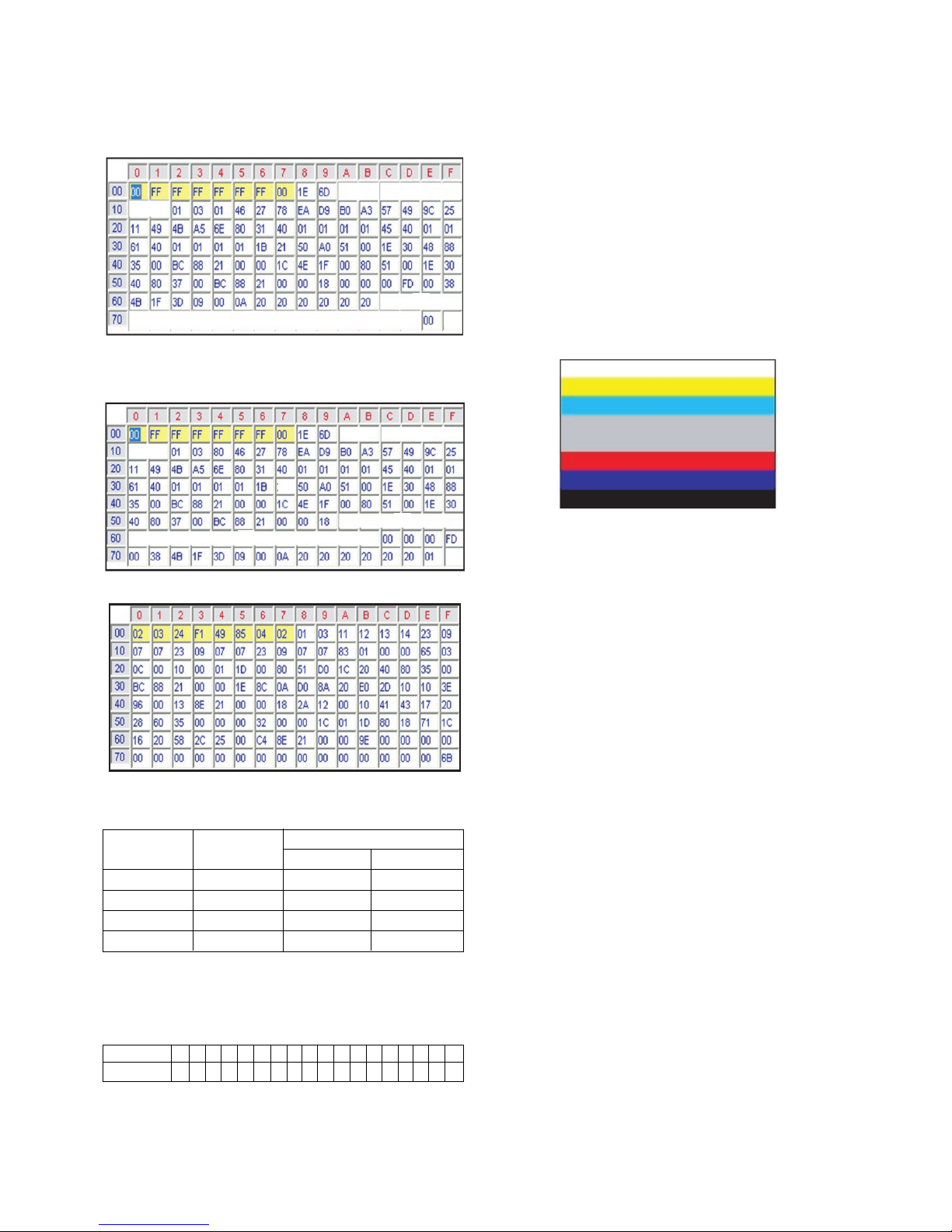

W Target Value CA-210(CH10), CA-100

( R/G/B gain and R/G/B o set De ault values are di erent in

according to using module)

W

Target Value o Brightness, Color Coordinates, Color Temperature

11-3 .Manual white Balance (INNER Pattern)

(For White Balance, Adjust twice, Cool and Warm)

(1)

Execute CA-100, CA-210(10CH) or CA-100 Zero Calibration.

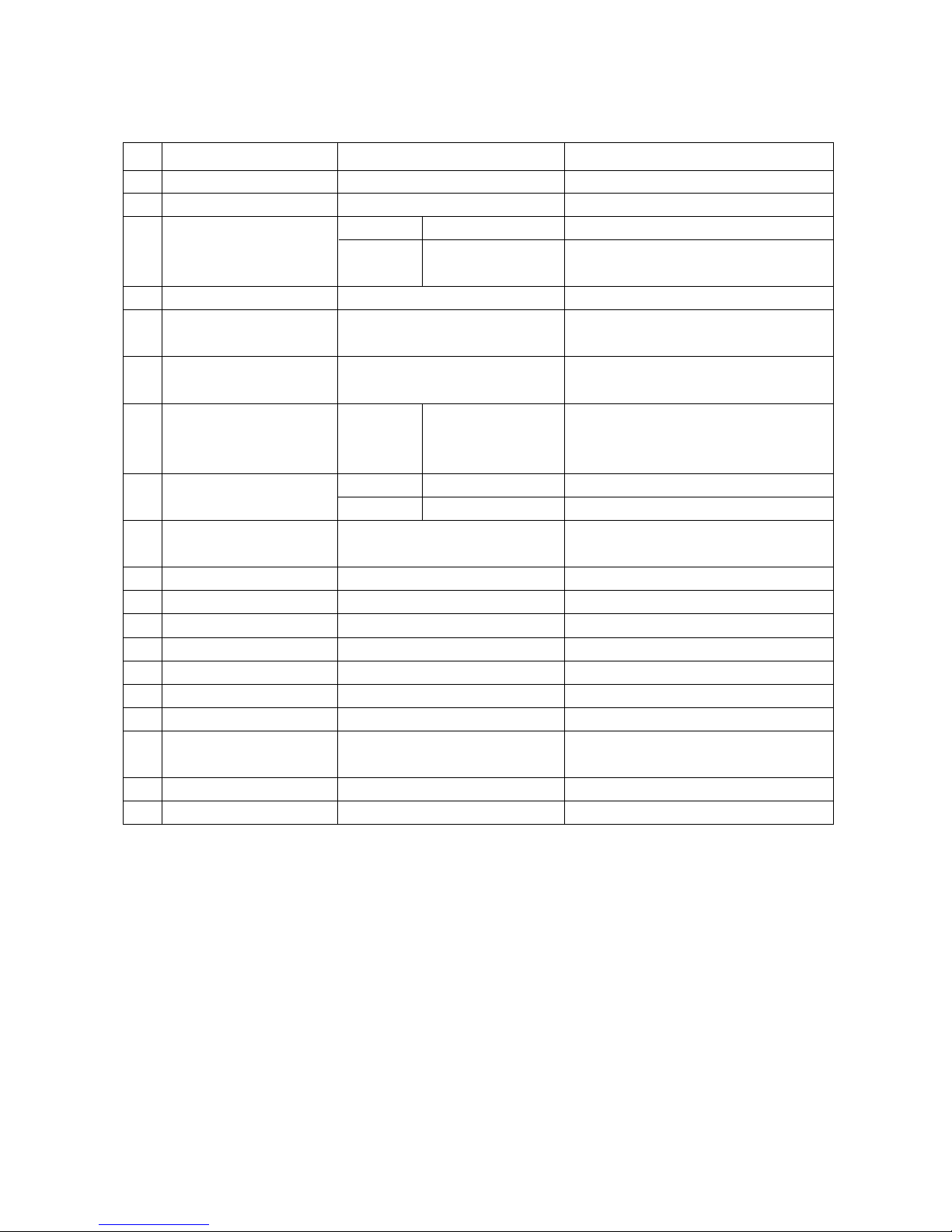

(2) Use torino inner pattern as below Fig.7, Supply 216Level

(85 IRE) ull screen pattern

(3) Enter the White Balance adjustment mode by pressing the

INSTART key twice(White Balance) on R/C.

(4) Stick sensor to center o the screen and select each items

(Red/Green/Blue Gain and O set) using D/E (CH+/-) key

on R/C.

(5) Adjust with R / G / B Gain using F/G(VOL+/-) key on R/C.

(6) Adjust it until color coordination becomes as below.

W Color Temperature : Cool, Medium, Warm

(1) One o R/G.B Gain should be ixed at 80 and adjust two

Gain Value with decreasing the De ault values rom 80

1) When R Gain is Fixed at De ault value(80)

- Adjust G gain and B gain with decreasing De ault values

rom 80

2) When B Gain is Fixed at De ault value(80)

- Adjust R gain and G gain with decreasing De ault values

rom 80

3) When G Gain is Fixed at De ault value(80)

- Adjust R gain and B gain with decreasing De ault values

rom 80

(2) R/G/B Gain and R/G/B O set De ault Value.

- Red Gain : 80

- Green Gain : 80

- Blue Gain : 80

(Fig.6)

- Be ore White-balance, the AV ADC should be done.

- System control RS-232 Host should be “PC“ or adjustment.

- A ter All adjustment is completed, Please push “Instop” Key.

Temp x

0.276±0.002

0.313±0.002

0.283±0.002

0.329±0.002

+0.000

+0.003

11,000K

6,500K

COOL

WARM

CSM y uv

High Light

High Light

60 ± 20cd/m2(42XGA)

Cool X: 0.276±0.002, Y: 0.283±0.002

Normal X: 0.313±0.002, Y: 0.329±0.002

Cool 11,000±500K

Warm 6,500K±500K

Brightness

Color

-Coordinate

Desired result (216 Gray)

(Fig.7)

Color Temperature

High Light

High Light

50 ± 20cd/m2(80% o non-high altitude)

Cool X: 0.276±0.002, Y: 0.283±0.002

Normal X: 0.313±0.002, Y: 0.329±0.002

Cool 11,000±500K

Warm 6,500K±500K

Brightness

Color

-Coordinate

Desired result or high altitude(216 Gray)

Color Temperature