4-1 COMPRESSOR

4-1-1 Role

The compressor inhales low temperature and low pressure

gas evaporated from Evaporator of the Refrigerator, and

condenses this gas to high temperature and high pressure

gas, and then plays delivering role to Condenser.

4-1-2 Composition

The Compressor is Composed of Compressor Apparatus

compressing gas, Compressor Motor moving Compressor

Apparatus and Case protecting Compressor Apparatus

and Motor. There are PTC-Starter, and Over Load

Protector (OLP) in the Compressor outside.

On the other

hand, because the Compressor consists of 1/1000mm processing

precision components and is sealed after producing without dust

or humidity, deal and repair with care.

4-1-3 Note to Use

(1) Be careful not to allow over-voltage and over-current.

(2) No Strike

If applying forcible power or strike (dropping or careless

dealing), poor operation and noise may occur.

(3) Use proper electric components appropriate to the

Compressor.

(4) Note to Keep Compressor.

If Compressor gets wet in the rain and rust in the pin of

Hermetic Terminal, poor operation and poor contact

may cause.

(5) Be careful that dust, humidity, and flux due to welding

don't inflow in Compressor inside in replacing

Compressor. Dust, humidity, and flux due to welding

which inflows to Cylinder may cause lock and noise.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is no-contact

semiconductor starting device which uses ceramic

material and the material consists of BaTiO3.

(2) The higher the temperature is, the higher resistance

value becomes . These features are used as starting

device of Motor.

4-2-2 Role of PTC-Starter

(1) PTC is attached to Hermetic Compressor used for

Refrigerator, Show Case and starts Motor.

(2) Compressor for household refrigerator applies single-

phase induction Motor.

For normal operation of single-phase induction motor, in

the starting operation flows in both main coil and sub-

coil. After the starting is over, the current is cut off in

subcoil. The proper features of PTC play the above all

roles. So, PTC is used as a starting device of motor.

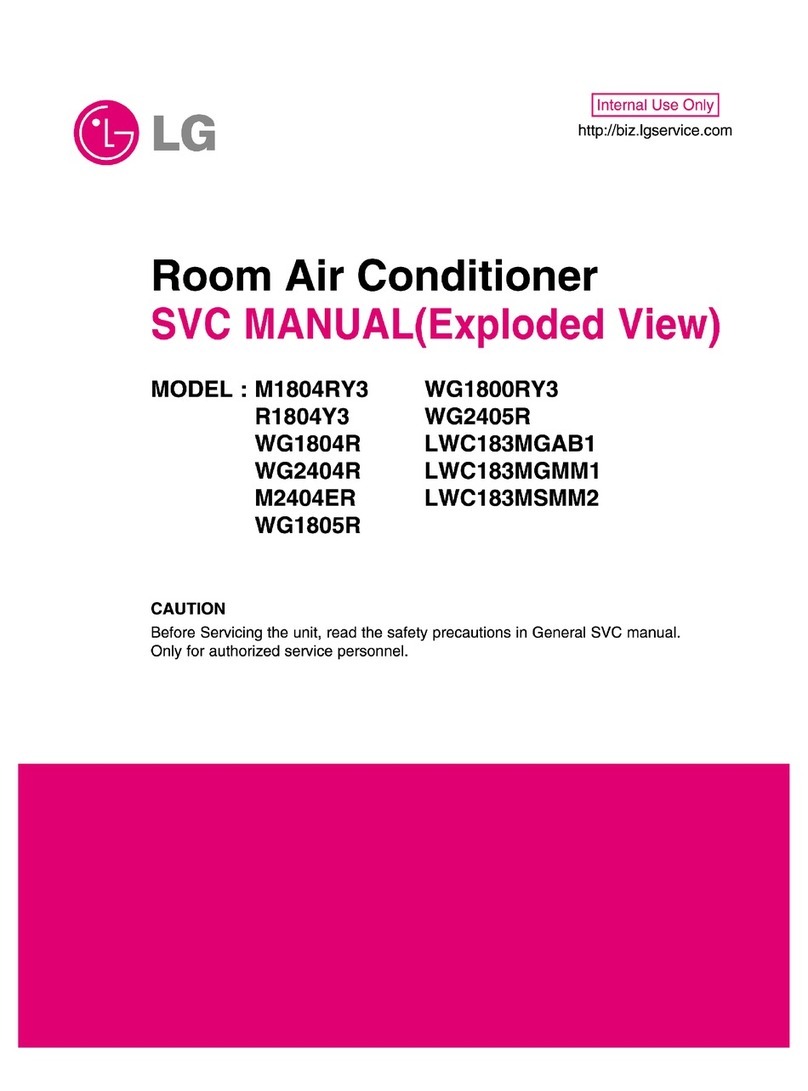

4-2-3 PTC-Applied Circuit Diagram

According to Starting Method of Motor

4-2-4 Motor Restarting and PTC Cooling

(1) For restarting after power off during normal

Compressor Motor operation, plug the power cord after

5 min. for pressure balance of Refrigerating Cycle and

PTC cooling.

(2) During normal operation of Compressor Motor, PTC

elements generate heat continuously. Therefore,

if PTC isn't cooled for a while after power off, Motor

can't operate again.

4-2-5 Relation of PTC-Starter and OLP

(1) If power off during operation of Compressor and power

on before PTC is cooled, (instant shut-off within 2 min.

or reconnect a power plug due to misconnecting),

PTC isn't cooled and a resistance value grows. As a

result, current can't flow to the sub-coil and Motor can't

operate and OLP operates by flowing over current in

only main-coil.

(2) While the OLP repeats on and off operation about 3-5

times, PTC is cooled and Compressor Motor performs

normal operation.

If OLP doesn't operate when PTC is not cooled,

Compressor Motor is worn away and causes circuit-

short and fire. Therefore, use a proper fixed OLP

without fail.

4-2-6 Note to Use PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) No Strike

Don't apply a forcible power or strike.

(3) Keep apart from any liquid.

If liquid such as oil or water inflows into PTC,

PTC materials it may break due to insulation

breakdown of material itself.

(4) Don't change PTC at your convenience.

Don't disassemble PTC and mold. If damaging to

outside of PTC-starter, resistance value alters and poor

starting of compressor motor may cause.

(5) Use a properly fixed PTC.

4. ADJUSTMENT

- 8 -

OVERLOAD PROTECTOR

C

COMPRESSOR

PTC 5MOTOR

M

SM

S

6

3

HERMETIC

PTC STARTER TERMINAL

RSIR

Figure 17