Features of refrigerant (R600a)

• Achromatic and odor less gas.

• Flammable gas and the ignition (explosion) at 494°C.

• Upper/lower explosion limit: 1.8%~8.4%/Vol.

Features of the R600a refrigerator

•

Charging of 60% refrigerant compared with a R134a model

•

The suction pressure is below 1bar (abs) during the operation.

• Because of its low suction pressure, the external air may

flow in the cycle system when the refrigerant leak, and it

causes malfunction in the compressor.

• The displacement of compressor using R600a must be at

least 1.7 times larger than that of R134a.

• Any type of dryer is applicable (XH-5, 7, 9).

• The EVAPORATOR or any other cycle part that has

welding joint is hidden in the foam. (If not hidden inside,

the whole electric parts must be tested with the

LEAKAGE TEST according to the IEC Standard.)

• The compressor has label of the refrigerant R600a.

• Only the SVC man must have an access to the system.

Installation place

• Must be well ventilated.

• Must be 20 m3or larger.

• Must be no-smoking area.

• No ignitable factors must be present.

Utilities

• Refrigerant cylinder (MAX NET 300g)

• Manometer

• Vacuum pump (600

L

/min)

• Piercing Clamp

• Quick coupler

• Hoses (5m-1EA, 1m-3EA)

• LOKRING

• Portable Leakage detector (3g/year↓)

• Nitrogen cylinder (for leakage test)

• Concentration gauge

Make sure before Servicing

• Refrigerant

Confirm the refrigerant by checking Name Plate and the label

on the compressor, after opening the COVER ASSY,

BACK-M/C.

• If the refrigerant is R600a, you must not weld or apply a

heat source.

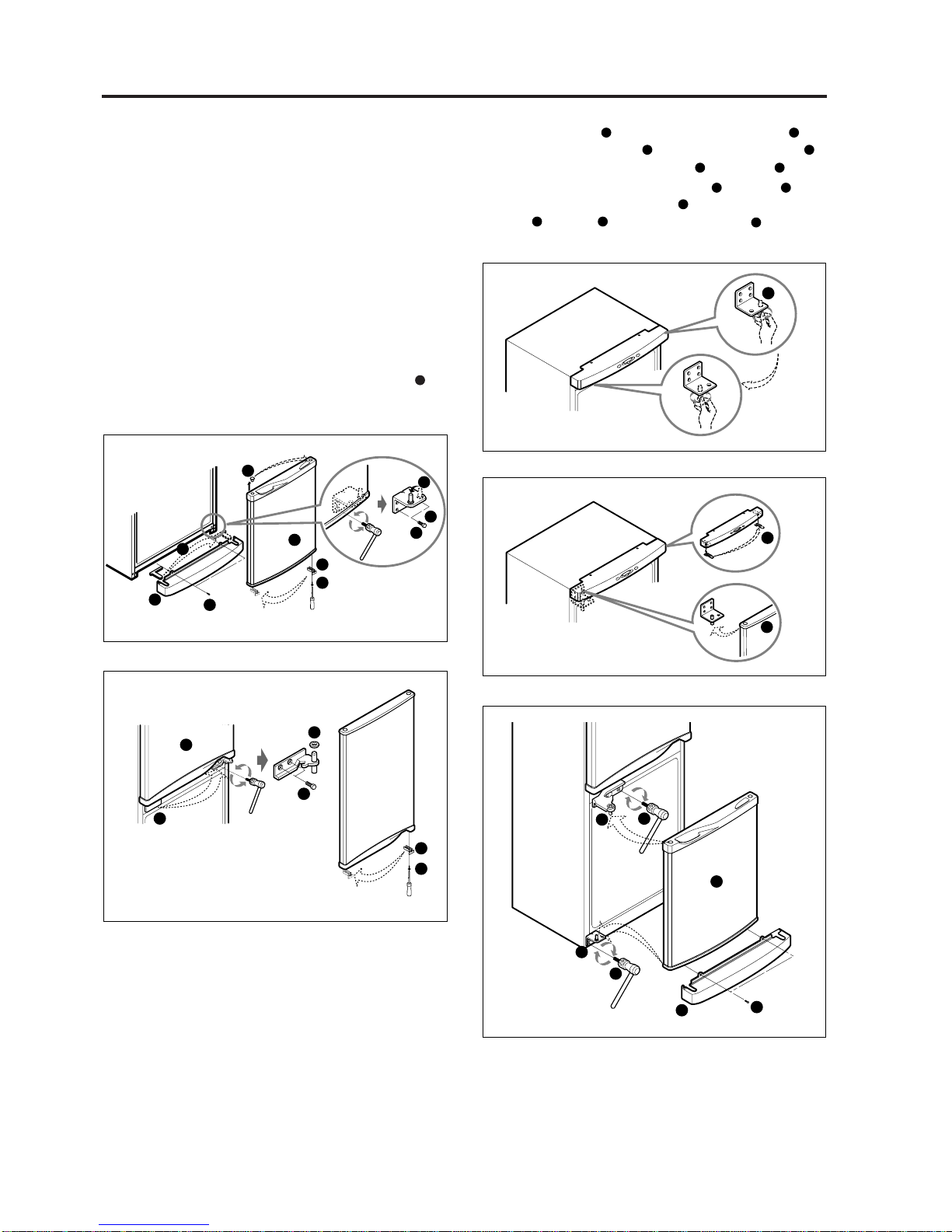

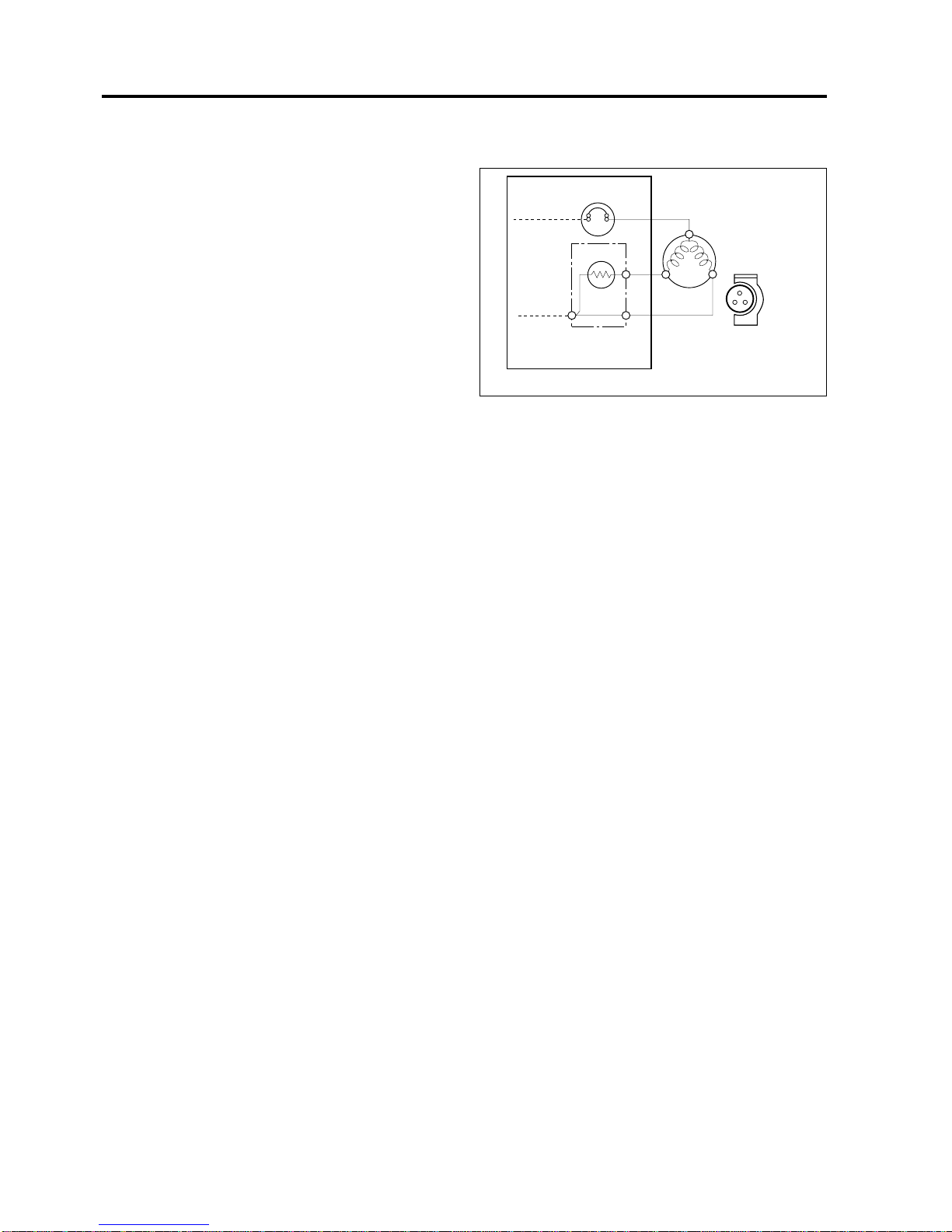

Air Recharging in Compressor

Before refilling the refrigerant, you must perform the test according

to Chapter 5 (TROUBLESHOOTING CHART). When the defects

are found, you must discharge the residual refrigerant (R600a) in

the outdoor. For discharging the refrigerant R600a, break the

narrow portion of tube extension by hand or with a pipe cutter as

shown in Figure 1. Leave it for 30min in outside to stabilize the

pressure with ambient. Then, check the pressure by piercing the

dryer part with piercing pliers. If the refrigerant is not completely

discharged, let the refrigerator alone for more 30min in outside.

Attach the service tube installed with a Schrader valve (one-way

valve) by using the LOKRING (Figure 2). Then, connect the

Schrader valve (one-way valve) to the pump that is connected to

the discharging hose leading to the outside. When discharging the

residual refrigerant, repeat 3 cycle that includes 3min of the pump

running->pump off->30sec of the compressor running.

After the refrigerant (R600a) is completely discharged, repair any

defective parts and replace the dryer. At any case you must use the

LOKRING for connecting or replacing any part in the cycle (No Fire,

No Welding). Connect the Schrader valve to pump with the coupler.

And then turn the pump on for vacuum state (Figure 3). Let the

pump run until the low-pressure gauge indicates the vacuum (gauge

pressure 0, absolute pressure -1atm or -760mmHg). Recommended

vacuum time is 30 min. Charge the N2gas in order to check for

leakage from welding points and the LOKRING. If leakages are

found, repair the defects and repeat the vacuum process.

After the system is completely vacuumed, fill it with the refrigerant

R600a up to what has been specified at your refrigerator Name

Plate. The amount of refrigerant (R600a) must be precisely

measured within the error of ±2g by an electron scale (Figure 4).

If you use the manifold connected with both the refrigerant

(R600a) cylinder and the vacuum pump simultaneously,

make sure the pump valve is closed (Figure 5).

Connect the charging hose (that is connected to the refrigerant

(R600a) cylinder) to the Schrader valve installed on the service

tube. Then, charge the refrigerant (R600a) by controlling the

Throttle valve. When you do so, do not fully open the Throttle valve

because it may make damage to the compressor. Gradually charge

the refrigerant (R600a) by changing open and close the Throttle

Valve (5g at each time). The charging hose must use a one-way

valve to prevent the refrigerant refluence. Close the Schrader valve

cap after the refrigerant (R600a) is completely recharged.

After you completely recharge the refrigerant (R600a), perform the

leakage test by using a portable leakage detector or soapy water.

Test the low pressure (suction) parts in compressor off time and

high pressure parts in compressor on time. If the leakages are

found, restart from the refrigerant (R600a) discharging process and

repairs defects of leaks.

After the leakage test, check the temperature of each parts of the

cycle. Check with hands if the CONDENSER and the case (HOT-

LINE pipe) that is contacted to the door gasket are warm. Confirm

that frost is uniform distributed on the surface of the EVAPORATOR.