2

CONTENTS

1. SPECIFICATIONS ............................................................................................................................. 3

2. FEATURES & TECHNICAL EXPLANATION ..................................................................................... 4

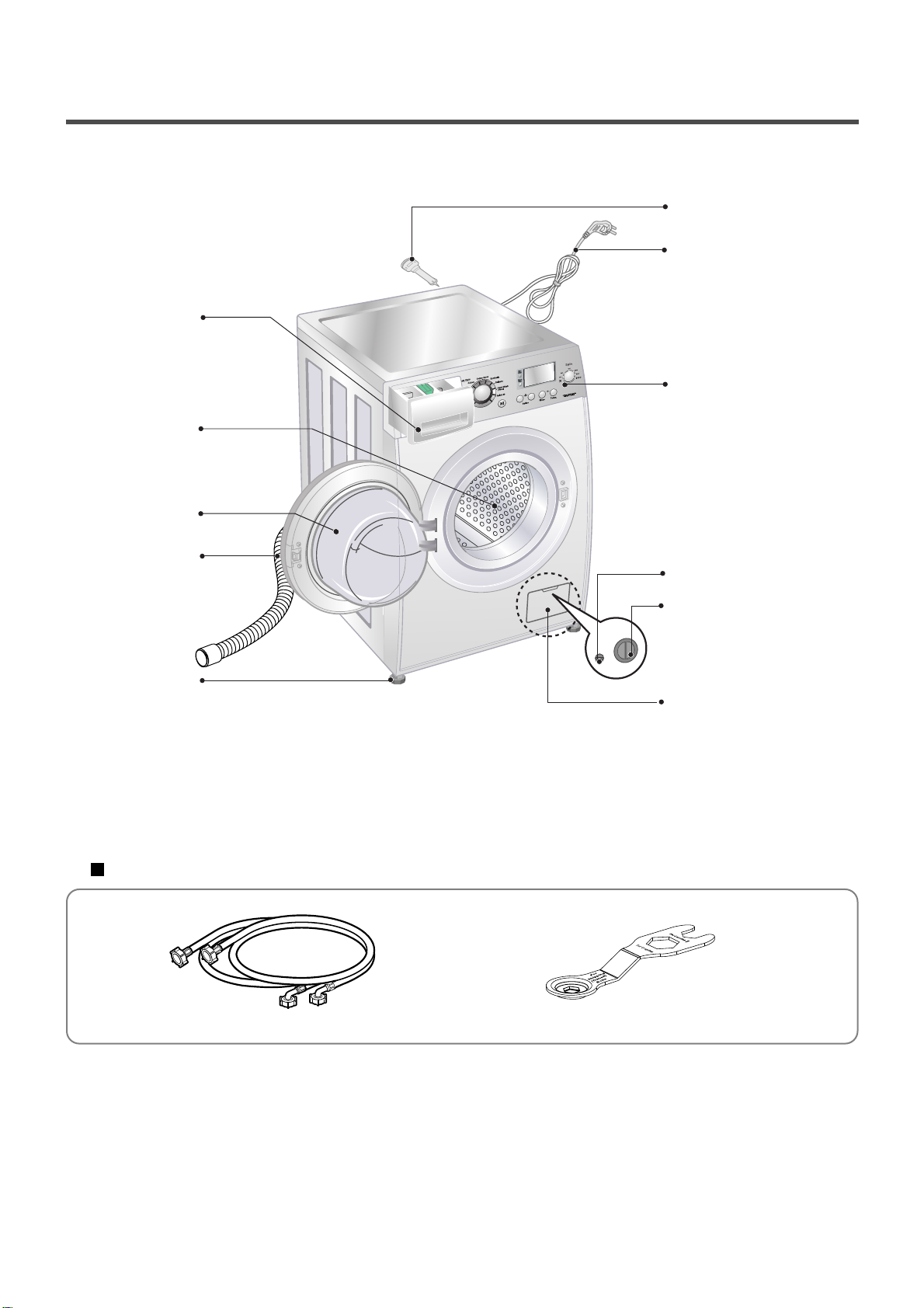

3. PARTS IDENTIFICATION ................................................................................................................. 6

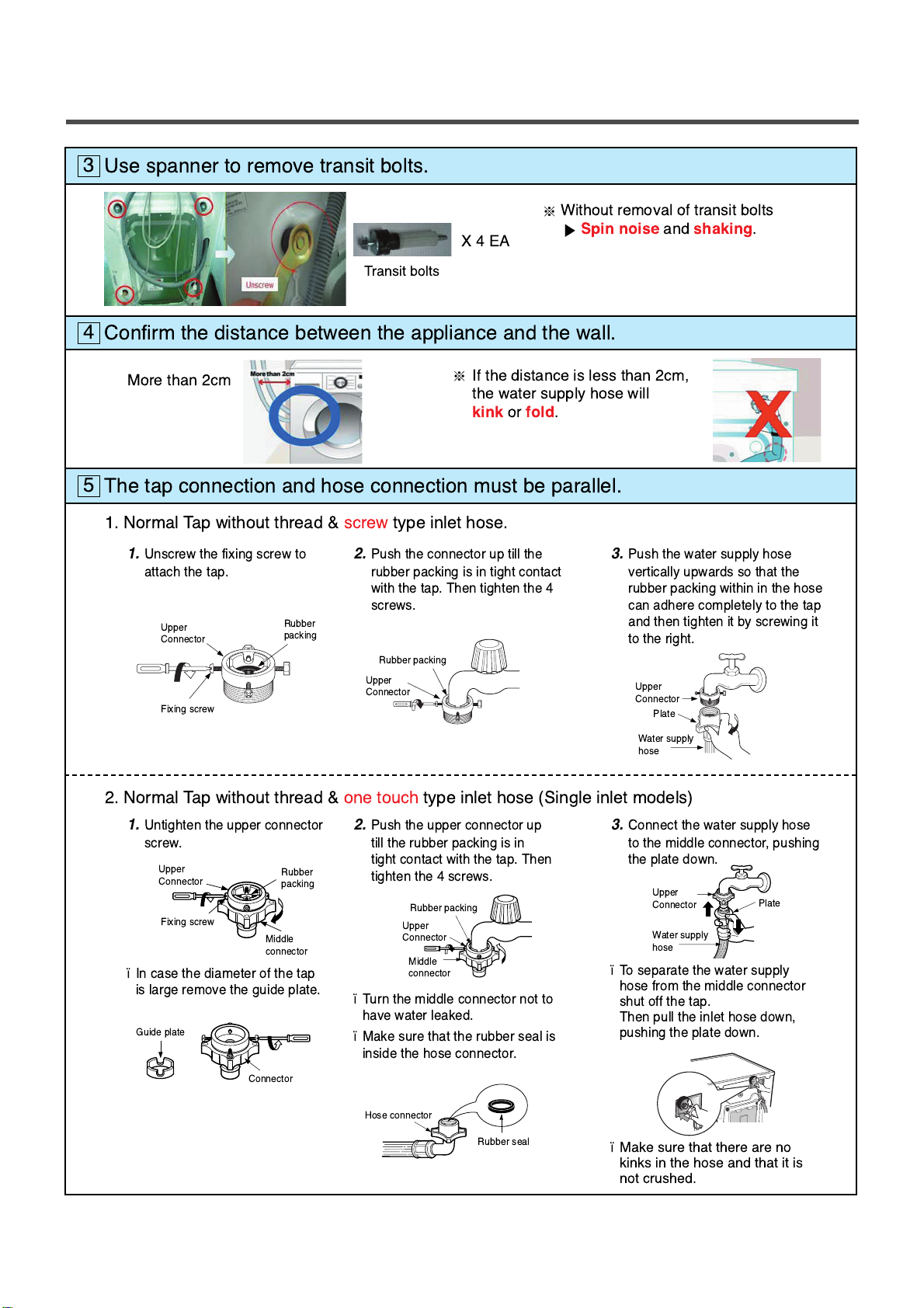

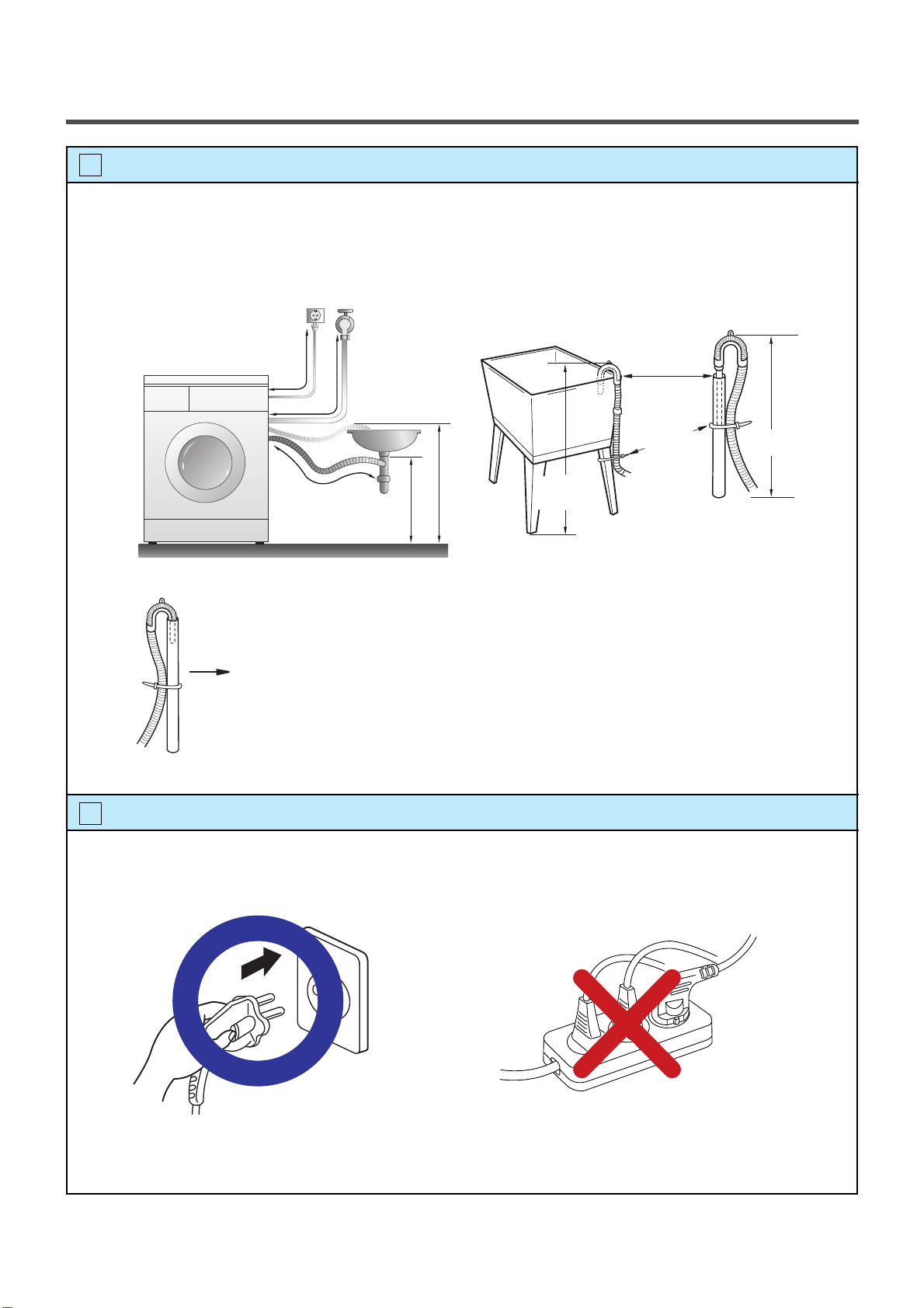

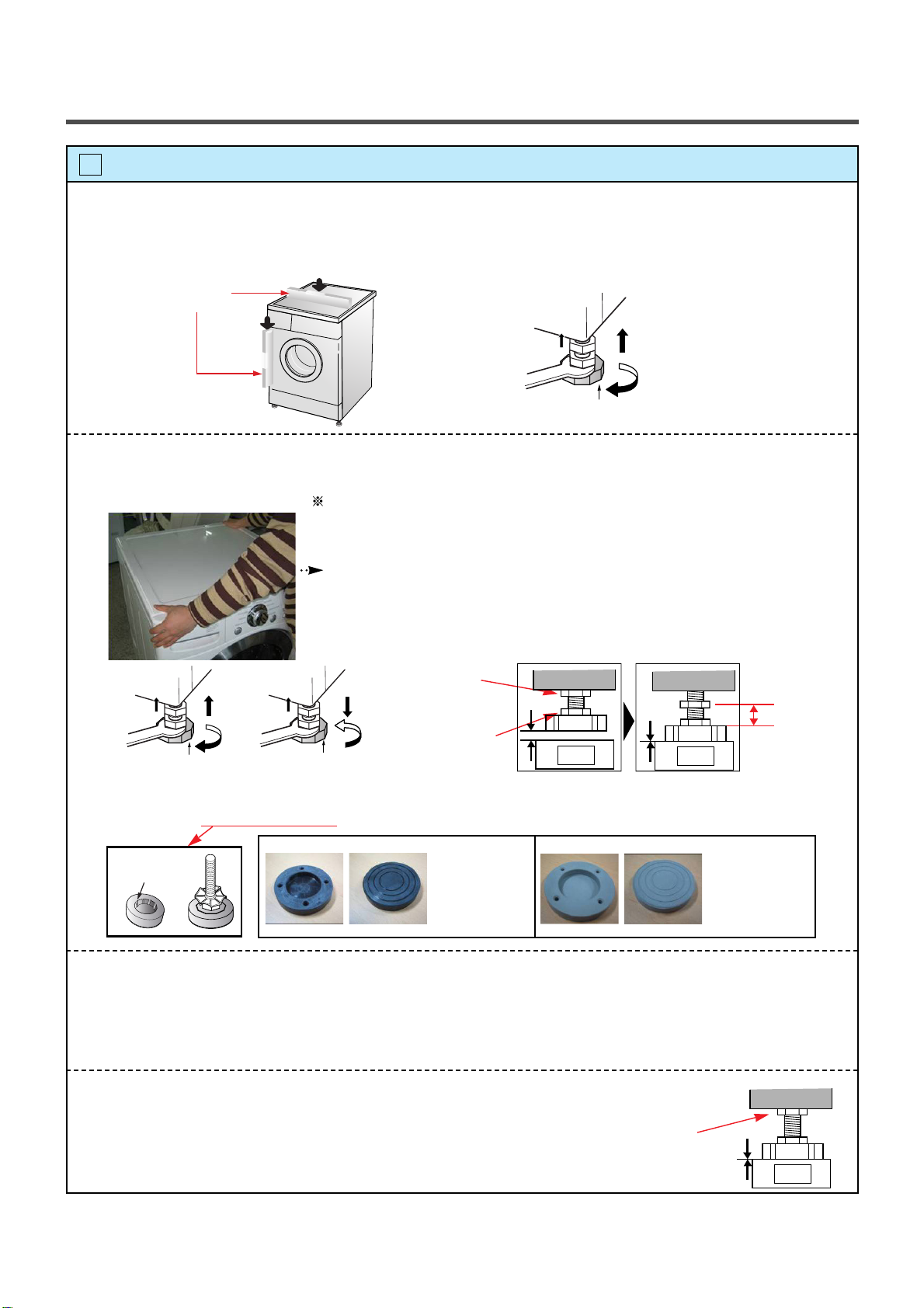

4. INSTALLATION .................................................................................................................................. 7

5. OPERATION ................................................................................................................................... 12

6. WIRING DIAGRAM / PCB LAYOUT ................................................................................................ 14

7. TROUBLESHOOTING......................................................................................................................19

7-1.BEFORE PERFORMING SERVICE ......................................................................................... 19

7-2.LOAD TEST MODE .................................................................................................................. 19

7-3.HOW TO CHECK THE WATER LEVEL FREQUENCY ............................................................ 20

7-4.

HOW TO CHECK THE TEMPERATURE OF EACH THERMISTOR AT OPERATING CONDITION

...... 20

7-5.ERROR DISPLAY ..................................................................................................................... 21

7-6.TROUBLESHOOTING WITH ERROR ..................................................................................... 23

• IE (Water Inlet Error) .............................................................................................................. 23

• UE (Unbalanced Error) ........................................................................................................... 24

• OE (Water Outlet Error) .......................................................................................................... 25

• FE (Over Flow Error) .............................................................................................................. 27

• PE (Pressure Sensor S/W Error) ............................................................................................ 28

• dE (Door open Error) .............................................................................................................. 29

• tE (Thermistor (Heating) Error) ............................................................................................... 30

• LE (Motor Lock Error) ............................................................................................................. 31

8. TROUBLESHOOTING OTHER ...................................................................................................... 33

• No power ................................................................................................................................ 33

• Vibration & Noise during spin ................................................................................................. 34

• Detergent & Softener does not flow in .................................................................................... 35

• Water Leak ............................................................................................................................. 36

9. PART INSPECTION ........................................................................................................................ 38

9-1.FILTER ASSEMBLY (LINE FILTER) ......................................................................................... 38

9-2.DOOR LOCK SWITCH ASSEMBLY ......................................................................................... 39

9-3.STATOR ASSEMBLY ............................................................................................................... 41

9-4.

PUMP MOTOR ASSEMBLY

....................................................................................................... 44

9-5.INLET VALVE ASSEMBLY .......................................................................................................45

10. DISASSEMBLY INSTRUCTIONS .................................................................................................. 46

11. EXPLODED VIEW AND PART LIST .............................................................................................. 54