CONTENTS

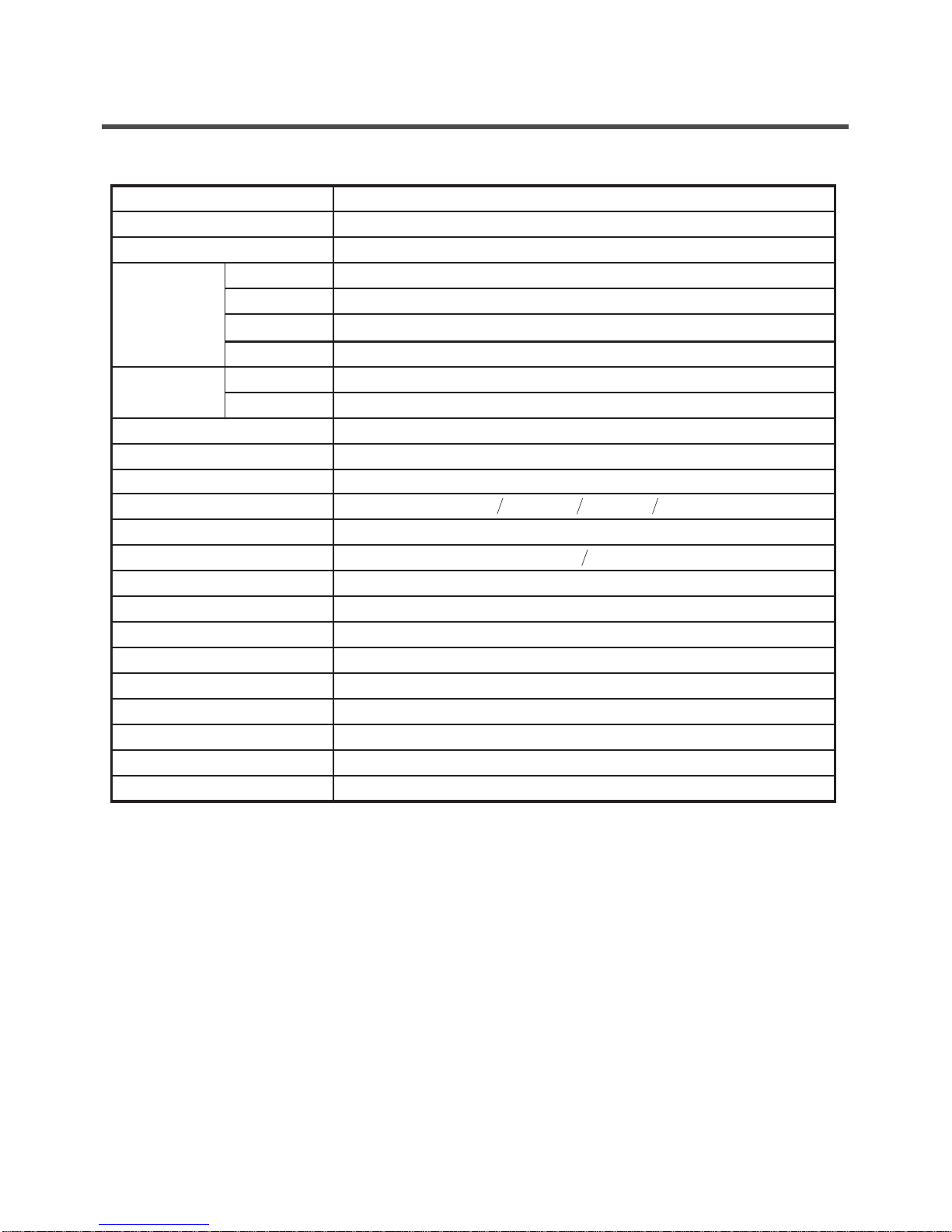

1. SPECIFICATIONS .........................................................................................................................3

2. FEATURES & TECHNICAL EXPLANATION ................................................................................ 4

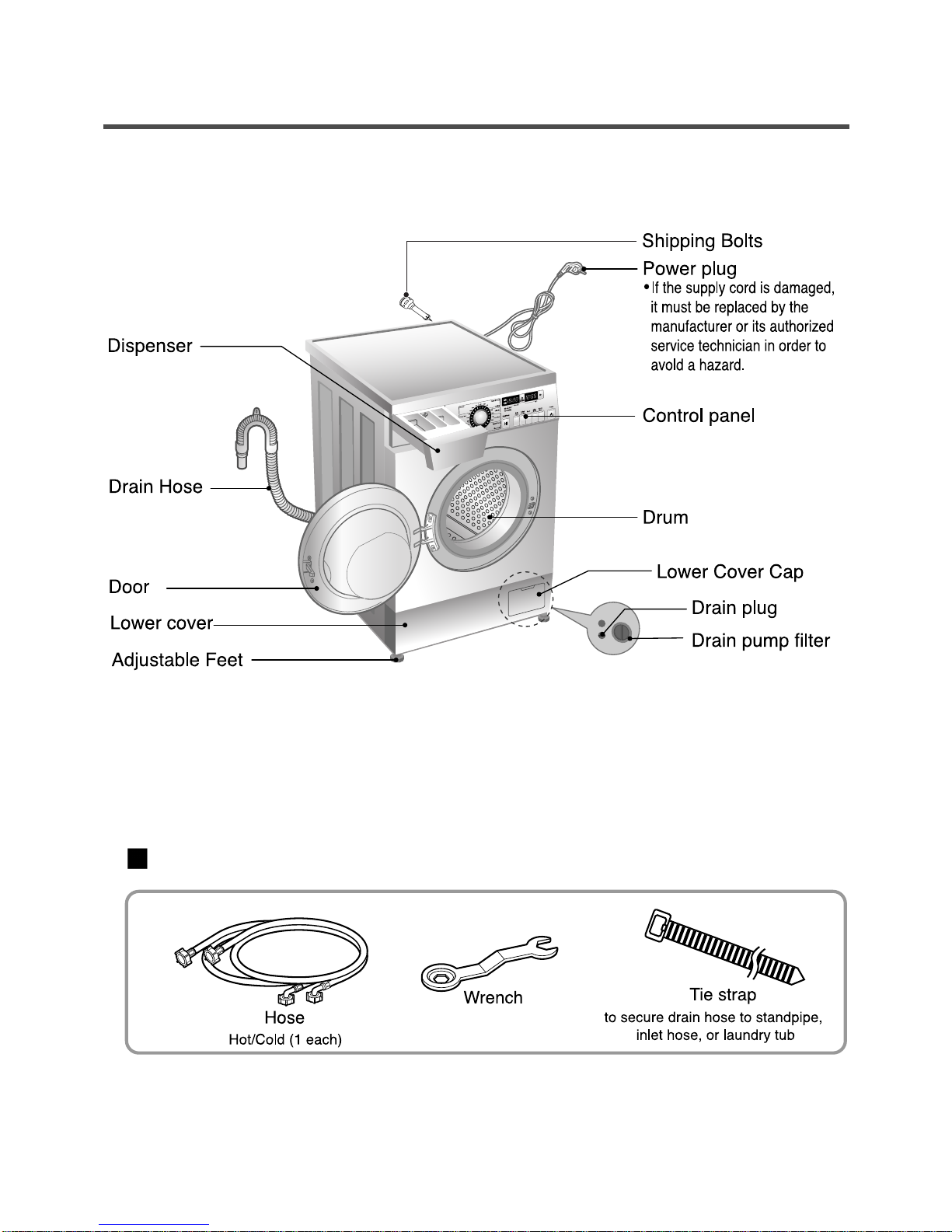

3. PARTS IDENTIFICATION ............................................................................................................ 6

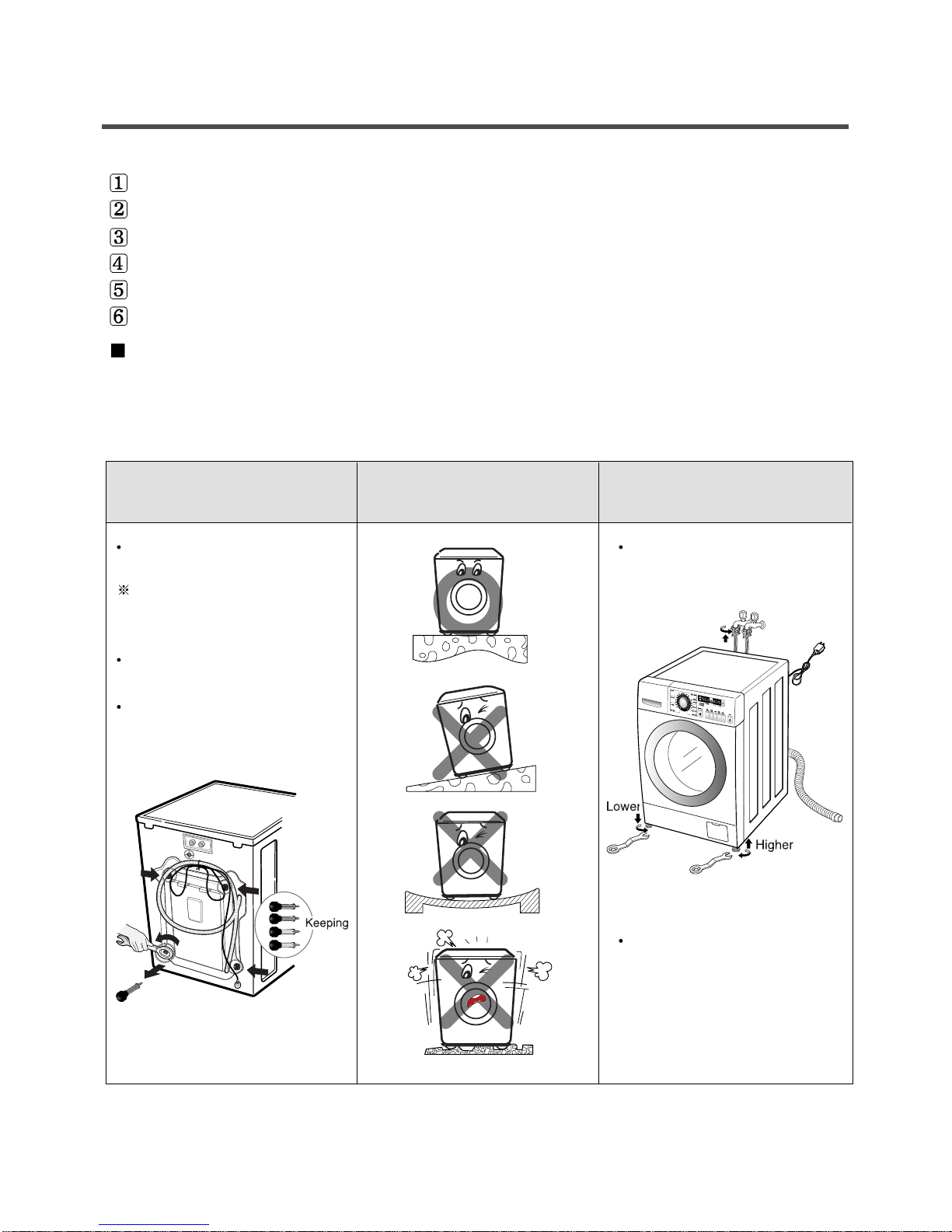

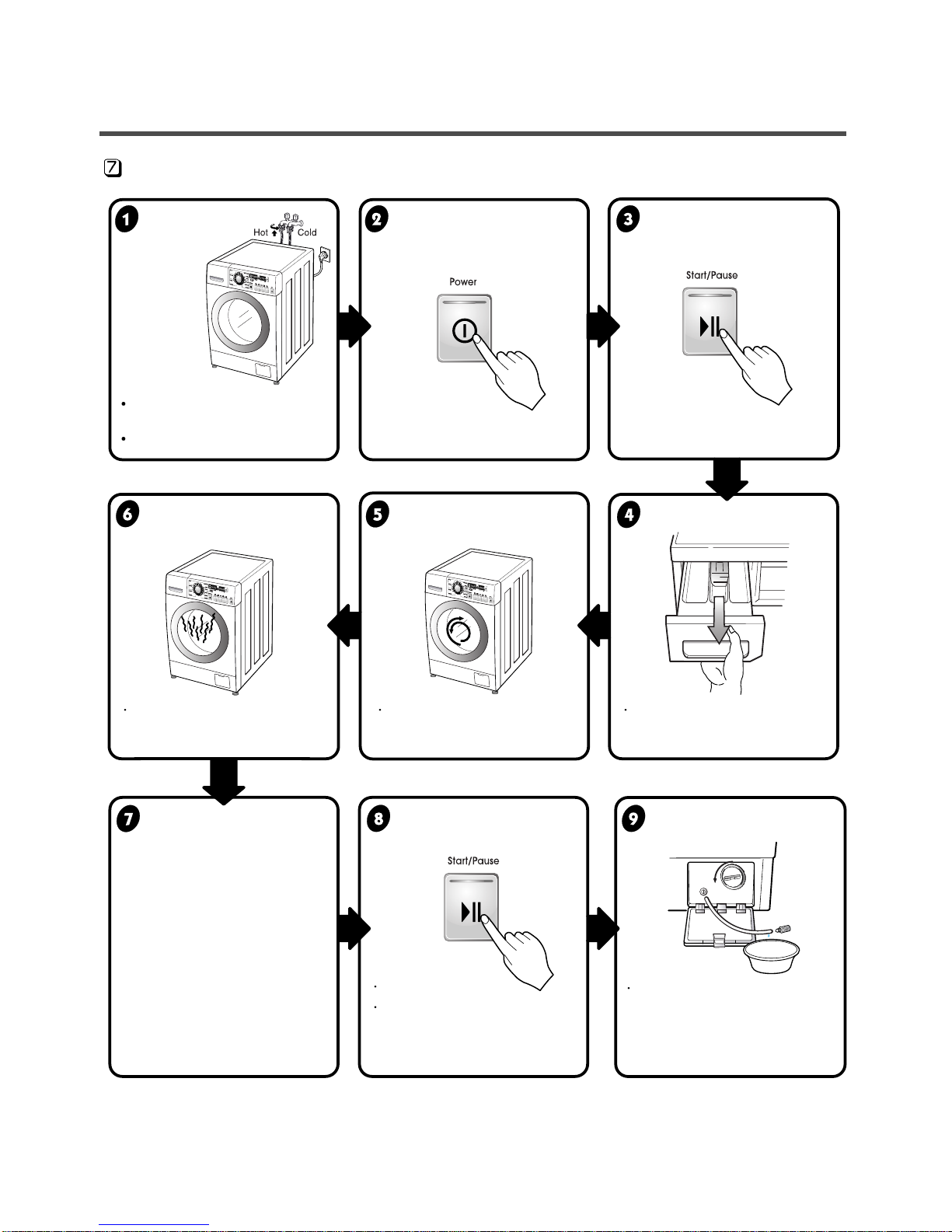

4. INSTALLATION & TEST ............................................................................................................... 7

5. OPERATION................................................................................................................................10

6. WIRING DIAGRAM/PROGRAM CHART.....................................................................................12

7. TROUBLESHOOTING.................................................................................................................13

7-1. BEFORE PERFORMING SERVICE...................................................................................13

7-2. QC TEST MODE.................................................................................................................13

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY......................................................13

7-4. ERROR DISPLAY...............................................................................................................14

8. ERROR DIAGNOSIS AND CHECKLIST.....................................................................................15

8-1. DIAGNOSIS AND SOLUTION FOR ABNORMAL OPERATION ........................................15

8-2. FAULT DIAGNOSIS AND TROUBLE SHOOTING .............................................................18

9. DISASSEMBLY INSTRUCTIONS ...............................................................................................25

10. EXPLODED VIEW.....................................................................................................................32

10-1. CABINET & CABINET COVER ASSEMBLY.....................................................................32

10-2. CONTROL PANEL & DISPENSER ASSEMBLY...............................................................33

10-3. DRUM & TUB ASSEMBLY................................................................................................34

2