Attaching the Tubing and Air Filter

IMPORTANT: Clamping the tubing to the hose barbs and air filter as described

below is very important. The tubing will initially seal without hose clamps, but

in our experience, leaks will develop slowly over time. Note, too, that the Tygon

tubing should not be draped over support stands or other equipment, as it can

soften in sunlight and warm weather, causing it to kink, resulting in flow restric-

tion.

There is a 16’ length of ½” I.D. Tygon tubing in the spares kit that is used for air

flow between the LI-7200/RS sensor head and the 7200-101 Flow Module. We

recommend that you always attach the air filter in-line between the LI-7200/RS

sensor head and the 7200-101 AIR IN port. Follow these steps to attach the Tygon

tubing and air filter:

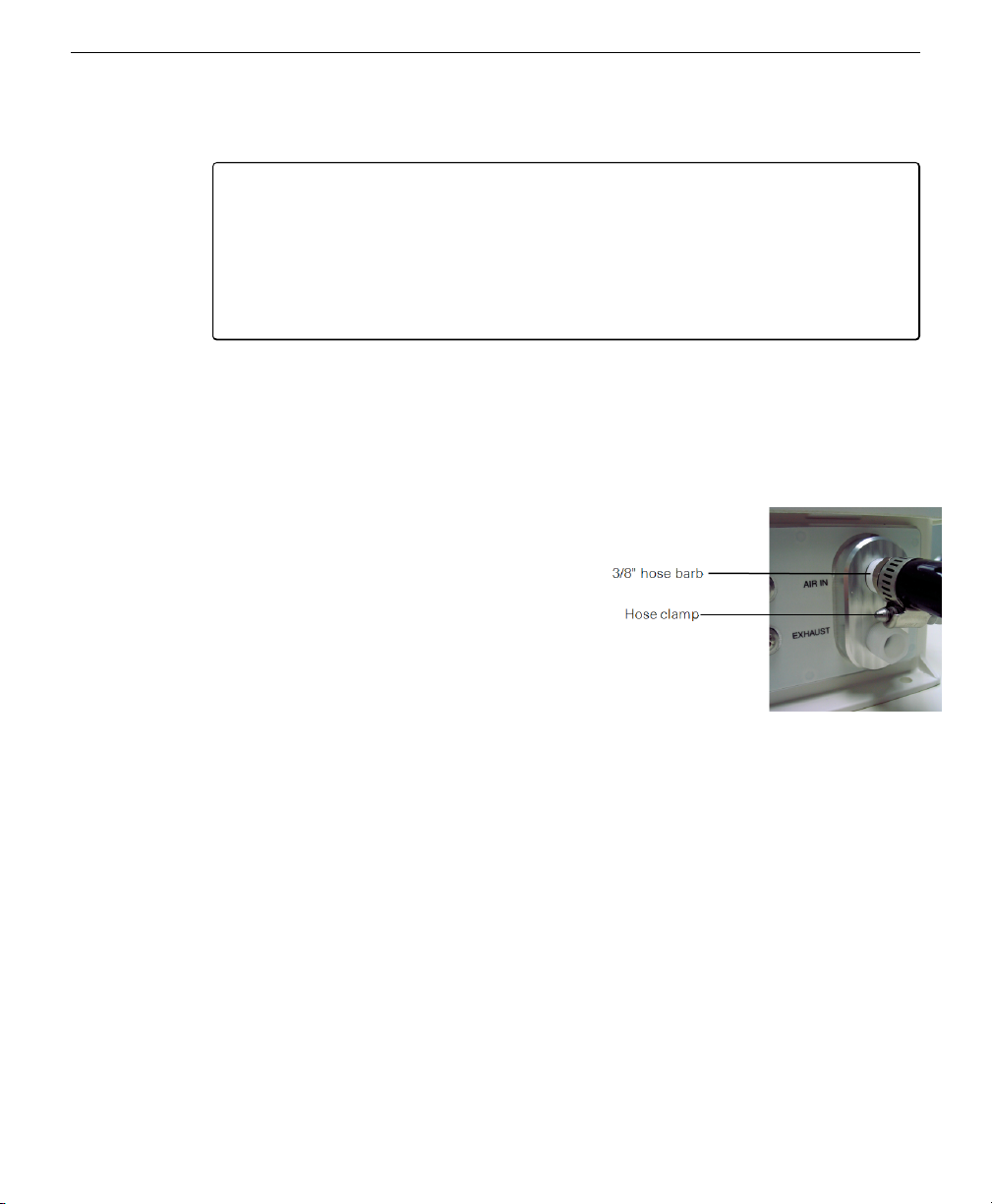

Figure 1-2. Thread the exhaust fitting

into the EXHAUST port and hand

tighten. Thread the 3/8” hose barb into

the AIR IN port.

1Remove the red shipping plugs from the

EXHAUST and AIR IN ports.

Screw the white exhaust fitting into the

EXHAUST port on the 7200-101 front

panel. Tighten with an open end wrench;

this fitting serves to hold a small filter

screen in place inside the port.

2Locate the 3/8” nickel plated hose barb in the

spares kit (part number 300-11179).

Thread the hose barb into the AIR IN port.

Tighten with an open end wrench.

3Cut a 4” section from the length of Tygon tubing.

Place a hose clamp over this section of

tubing, and push onto the hose barb. Tighten the hose clamp. TIP: Use a pair of pli-

ers to tighten the hose clamp initially; after you have tightened the clamp once,

you’ll be able to tighten the thumb screw by hand.

4Place another hose clamp over the short section of tubing, and push the tubing onto the air filter.

Note the orientation of the filter; the arrow on the body of the filter must face toward

the instrument.

Section 1. Overview of the 7200-101 Flow Module

1-3Attaching the Tubing and Air Filter