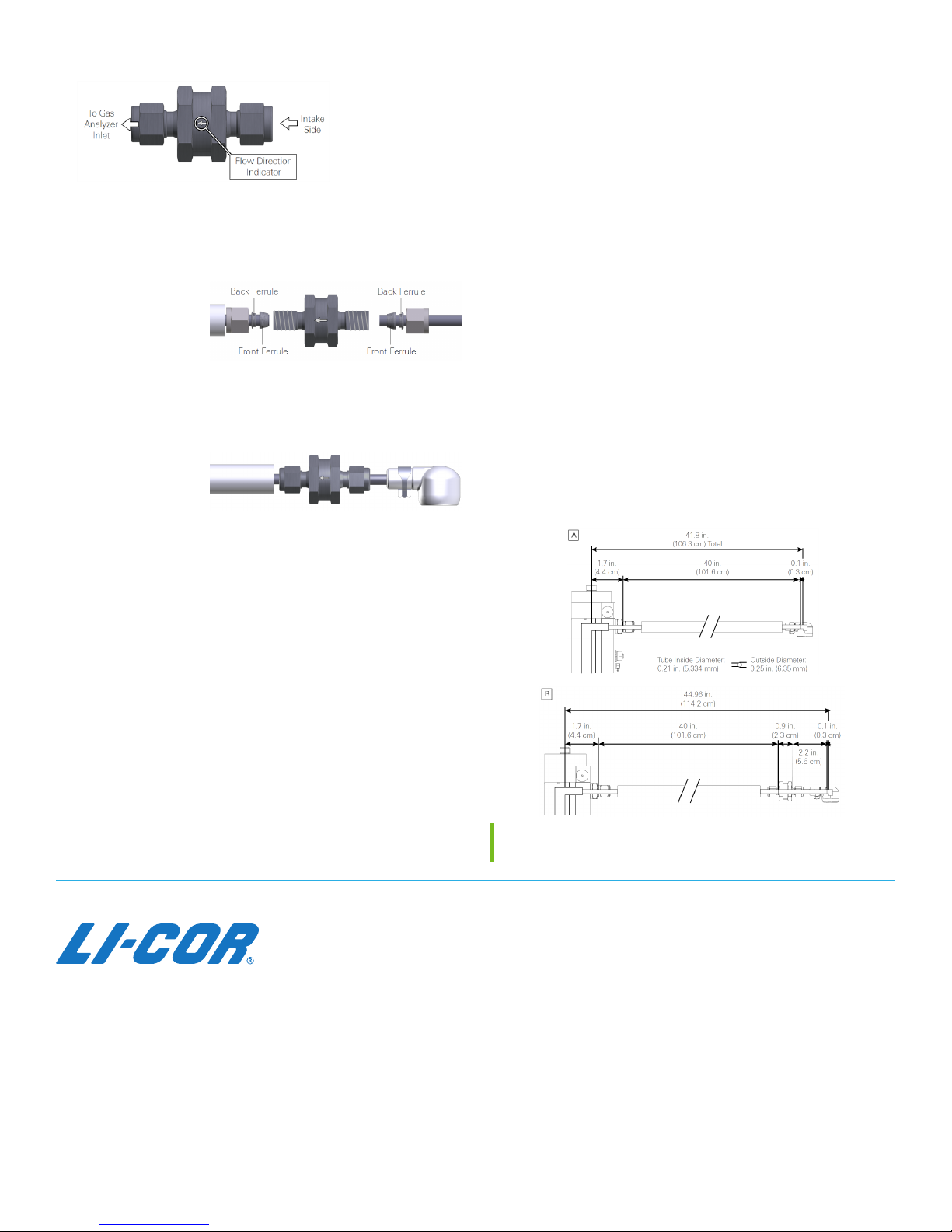

LI-7200 Intake Cap and Dust Filter

This document describes the intake cap and dust filter for

the LI-7200. The intake cap (part number 9972-072) is

designed to minimize water vapor and CO2frequency atten-

uation. The dust filter (part number 9972-073) helps prevent

dust and pollen from entering the LI-7200 optical cell.

Installing the Intake Cap

The intake cap kit includes the following components:

Intake Cap (includes screen and hose clamp).

Spare screen, retaining ring, and hose clamp.

The intake cap attaches to the standard ¼" diameter intake

tube (part number 9972-053) and heated intake tube. To

install the intake cap:

1If necessary, remove the old cap and all of its com-

ponents from the intake tube.

2Place one hose clamp over

the intake tube and slide

the new intake cap over

the stainless steel intake tube until it stops.

The intake tube should extend ~1

inch (2.54 cm) into the cap.

3Using a pliers, grasp the hose

clamp to expand it. Slide it over

the inlet cap as shown and release it.

Note: Do not expand the hose clamp more than necessary.

Doing so can permanently deform the clamp.

Cleaning the Intake Cap and Screen

To clean the cap and screen, remove the intake cap assembly

and back-flush it with compressed air or water. You can

immerse the intake cap assembly in boiling water for a few

minutes or soak it in an ultrasonic water bath. Usually, you

should not have to remove the screen from the cap. If you

do need to remove the screen:

1Insert a small screwdriver between the screen and

intake cap.

Use caution to avoid damaging the cap and deforming

the screen.

2Carefully pull the screen

out of the cap.

3Assembly is the reverse of

removal.

Be sure the screen is seated

fully in the cap.

Dust Filter

The dust filter (part number 9972-073) is a Swagelok® 2-

micron filter that will reduce the amount of dust that enters

the gas analyzer optical cell. Under normal conditions, the

filter should extend the amount of time that can pass before

you need to clean the optical cell. Use the filter in envir-

onments that have airborne dust and pollen that can con-

taminate the optical cell.

Important: The filter does not completely eliminate the

need to regularly clean the optics. Regular cleaning is

required in order to prevent measurement drift that can

occur when certain kinds of contaminants accumulate on

the cell windows.

The filter will increase the power requirements of your

system. As the filter becomes dirty, the flow module

will use more power to maintain the same flow rate.

The filter may affect H2O frequency response, espe-

cially when it is dirty. (This can be addressed with addi-

tional frequency response corrections.)

The effectiveness of the filter depends upon the site

conditions, overall level of dust in the air, and the char-

acteristics of the dust (fine vs. coarse dust particles).

The dust filter includes:

Swagelok filter with two compression fittings.

Two inch (5.08 cm) by ¼ inch stainless steel intake

tube extension.

Installing the Dust Filter

The dust filter installs between the end of the intake tube

and the intake cap. To install it:

Installation Guide

1