©Copyright 2017 Liberty Pumps Inc. All rights reserved 3

3Installation Instructions

1. Excavation: Excavate the hole for the basin as small as possible, with a minimum base diameter of 38”. Never place the basin in

direct contact with rocks or other sharp objects. Place enough fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone at

the bottom of the excavation to create a minimum of 12 inches stone or gravel after compaction. Do not use sand or native soil as

backfill*. Properly compact underneath the basin to provide a solid, level base that can support the weight of the filled basin. If a

concrete pad will be used under the basin, the compacted stone sub-base can be reduced to 6 inches.

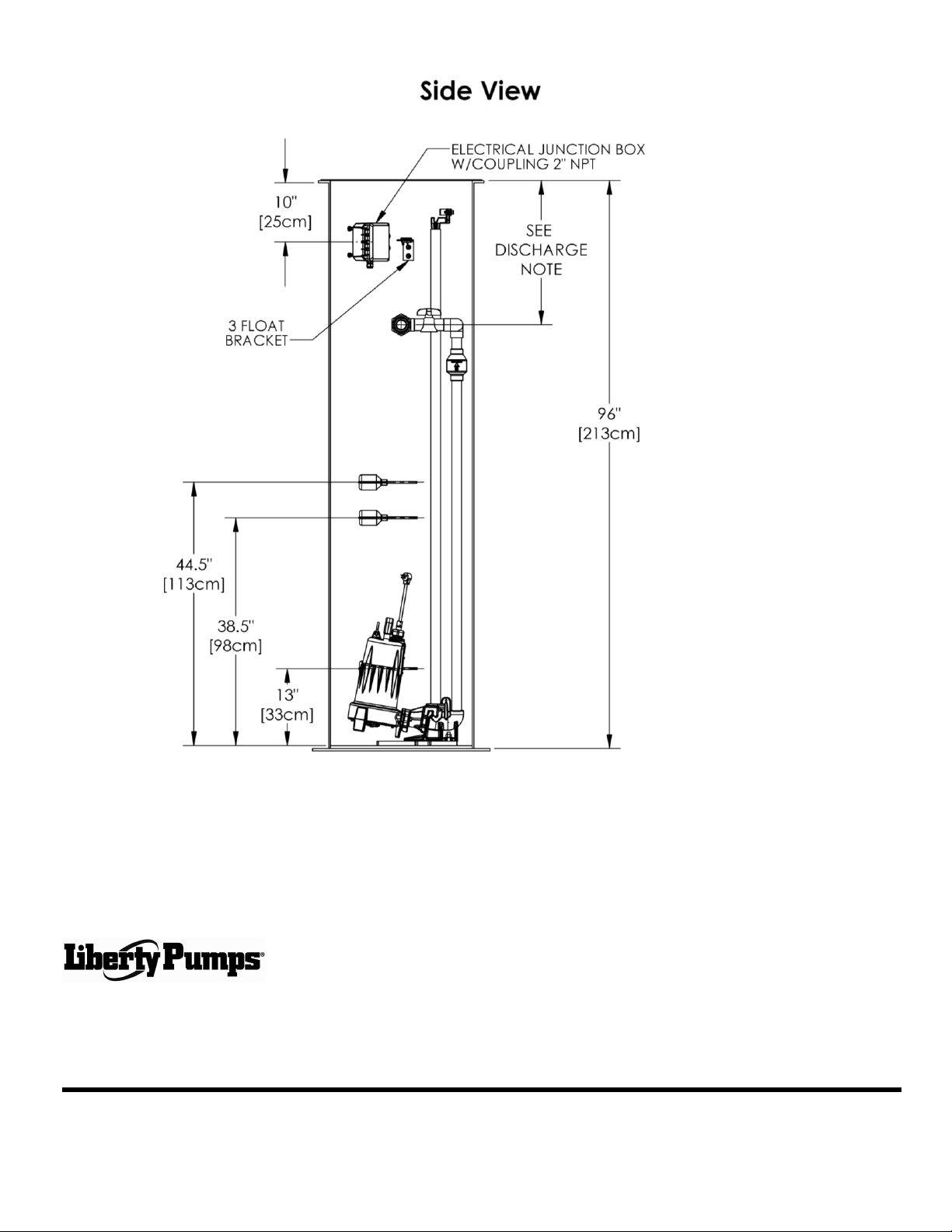

2. Connections & Backfill: Pour enough concrete over and around the anti-floatation flange to anchor the basin and prevent

upward movement. Connect 1¼” schedule 80 PVC pipe to the pump discharge. Do not reduce the size of the discharge piping,

and do not increase the discharge piping to larger than 2”. The remainder of the discharge line should be as short as possible with

a minimum number of turns. Connect the inlet line to the 4” fiberglass inlet hub with a rubber donut (Liberty #6112000). Connect

the electrical coupling to 2” electrical conduit and run the power and float cords through the conduit to the control panel. The

remaining backfill should be only fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone. Do not use sand or native soil

as backfill*. Do Not exert heavy pressure or run heavy equipment over the backfill material, as it may cause tank collapse.

*Other backfill options may be available –consult the factory for special instructions relative to your situation.

3. Venting: The fiberglass basin provided with the system

must be completely sealed and properly vented in order to

meet health and plumbing code requirements. The system

is designed to be vented through the inlet to an existing

building vent stack. In order to accomplish this, there must

be no traps between the system inlet and the nearest

building vent stack connection. See Figure A for an

example. If this is not possible or desirable in your

application, a vent flange or grommet can be installed in a

hole cut into the solid fiberglass cover.

4. Control Panel:

Risk of Electric shock: This pump is

supplied with a grounding conductor. To reduce the risk of

electric shock, be certain that it is connected only to a

properly grounded earth wire. All electrical circuitry should

be installed in accordance with the National Electric Code

(NEC) and all applicable local codes or ordinances.

The control panel that is an integral part

of this complete unit is supplied with its own separate

Installation/Operation/Maintenance manual. Ensure that

you have received this manual, and that you read and

understand it prior to installing this unit. Your familiarity with

the control panel manual is critical.

Per UPC code, a separate 115V branch circuit should be

installed for the alarm circuit. We do not recommend

splitting the incoming pump power circuit to power the

control circuit.

Connect the grinder pump leads and the float switch leads

to the control panel in accordance with the instructions

included with those units.

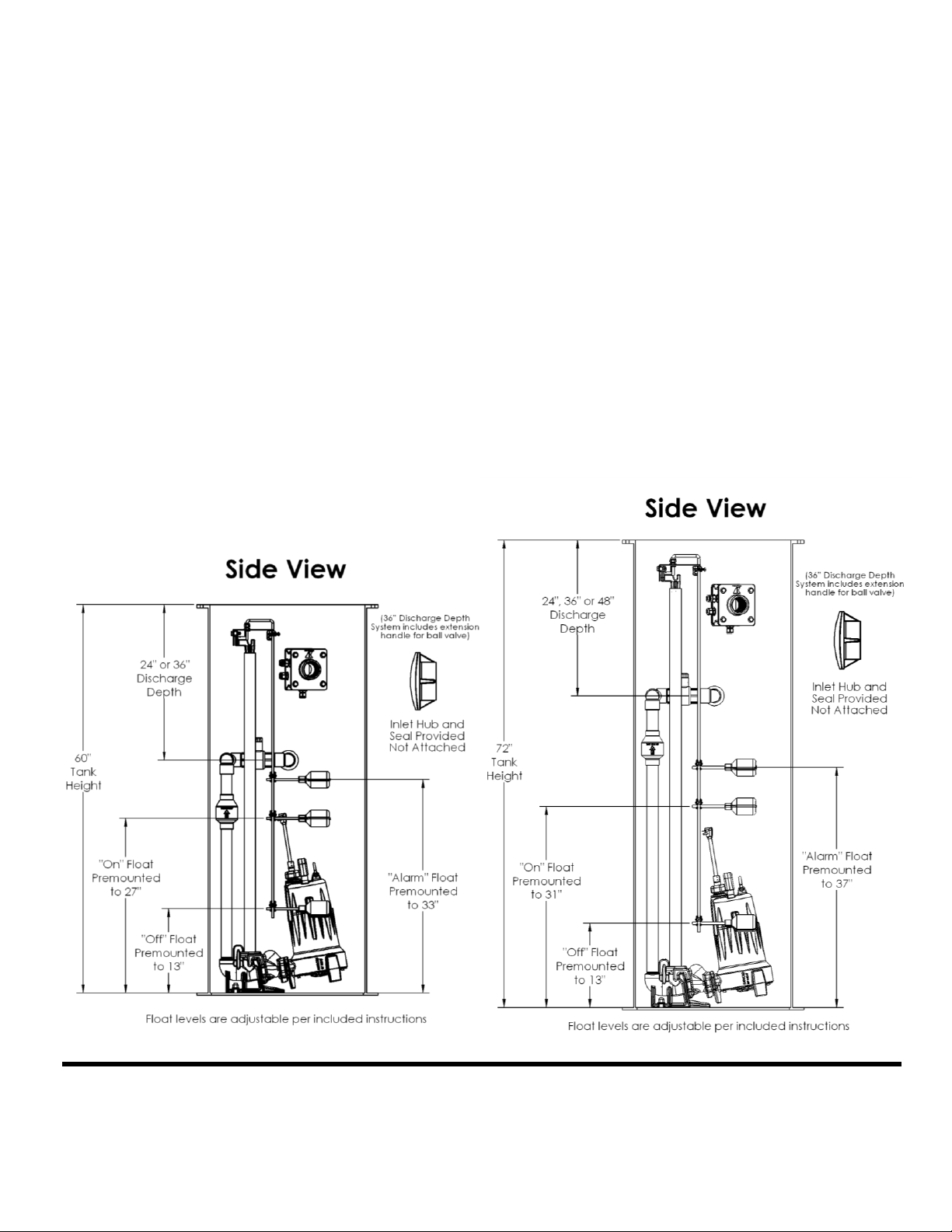

5. Float Switches:

The float switches are pre-mounted on a quick tree. For

quick tree removal, loosen the cord nut, locking clamp, and

pull the tree straight out of the tank. The pump cycle is pre-

set at the factory at 14” for 2460LSG (approximately 28

gallons), 18” for 2472LSG (approximately 35 gallons), 20”

for 2484LSG (approximately 39 gallons), and 24” for the

2496LSG (approximately 47 gallons). The pump cycle can

be adjusted by loosening the cord clamp and moving the

“on” float up or down. We do not recommend adjustments

of more than 3” in either direction – please call the factory if

you need to adjust the pump cycle beyond this

recommended level.

6. Testing and Startup: Follow the testing and startup

procedures found in the LSG / LSGX Series and control

panel manuals.