TFP (Turbulent Flow Precipitator) Technology removes health

threatening particles from the air far more effectively than most

other residential cleaners. It operates continuously at maximum

efficiency without the need for constant adjustment and cleanout.

Unlike some air cleaners, it introduces absolutely no ozone into

your home. It cleans the air throughout your home, benefiting all

the family, all the time. The TFP allows air to circulate freely,

without putting any extra load on your air distribution system.

Why do I need a TFP Air Cleaner?

The air in today's homes is 3 to 5 times more polluted than outdoor

air creating health problems such as asthma, allergies, headaches,

and fatigue for the home's occupants. The Lifebreath TFP Air

Cleaner will remove 99% of these polluting particles from your

home creating a clean and comfortable environment for you and

your family.

Will I notice a difference in the amount of dust in

my home?

We have received numerous testimonials from satisfied customers

attesting to the significant drop in dust found in the homes where a

TFP is installed.

Does the TFP generate harmful ozone?

The TFP series is an induced airflow system which requires no

electric charge.

Is the TFP a patented unique technology or just

another filter?

Airia Energy Systems hold the patent for this TFP technology.

The TFP series are the only one of its kind.

How much maintenance is involved? How often do

the filters need to be replaced?

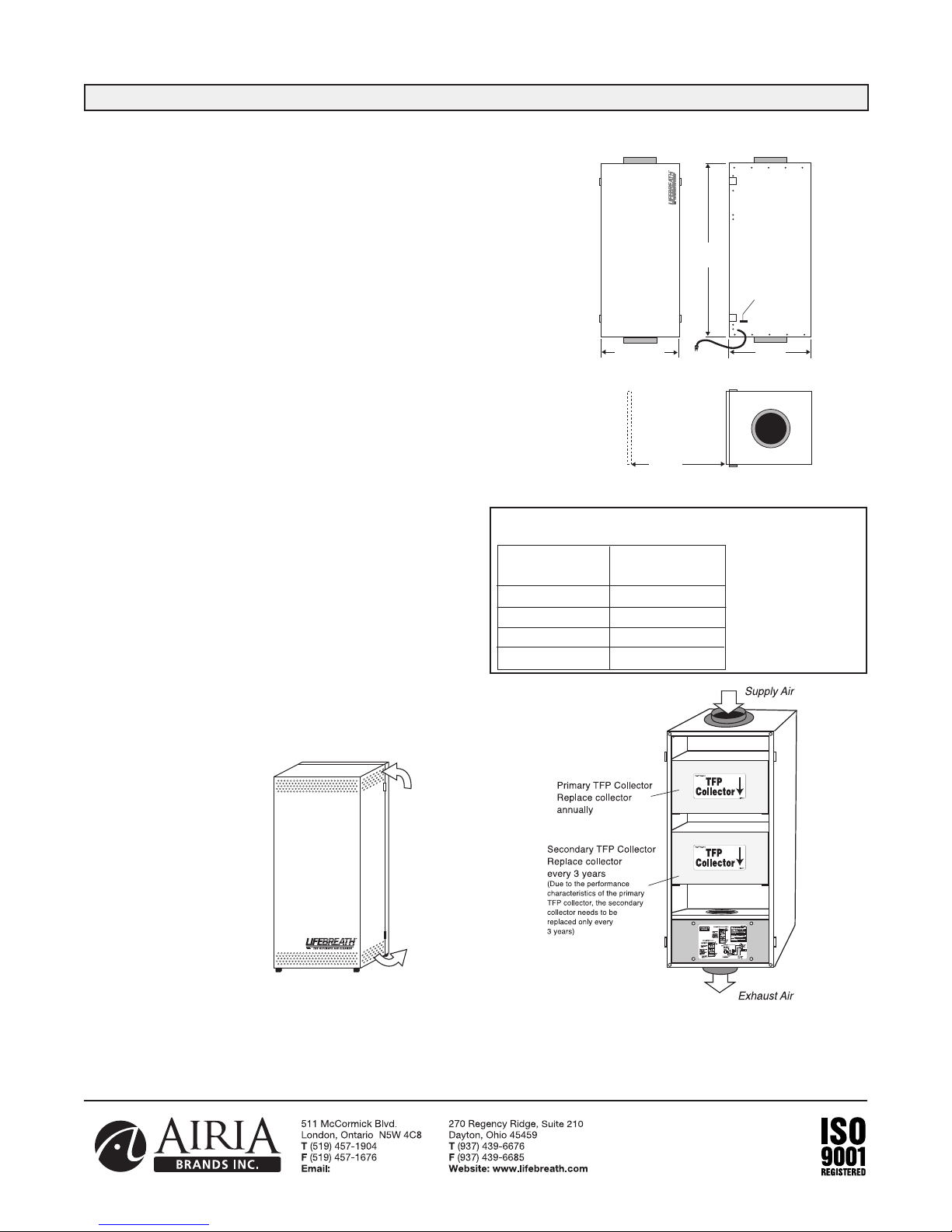

As tested under average household dust loading, the TFP should

be inspected annually. Typically the primary collector should be

replaced annually and the secondary collector should be replaced

every 2 years.

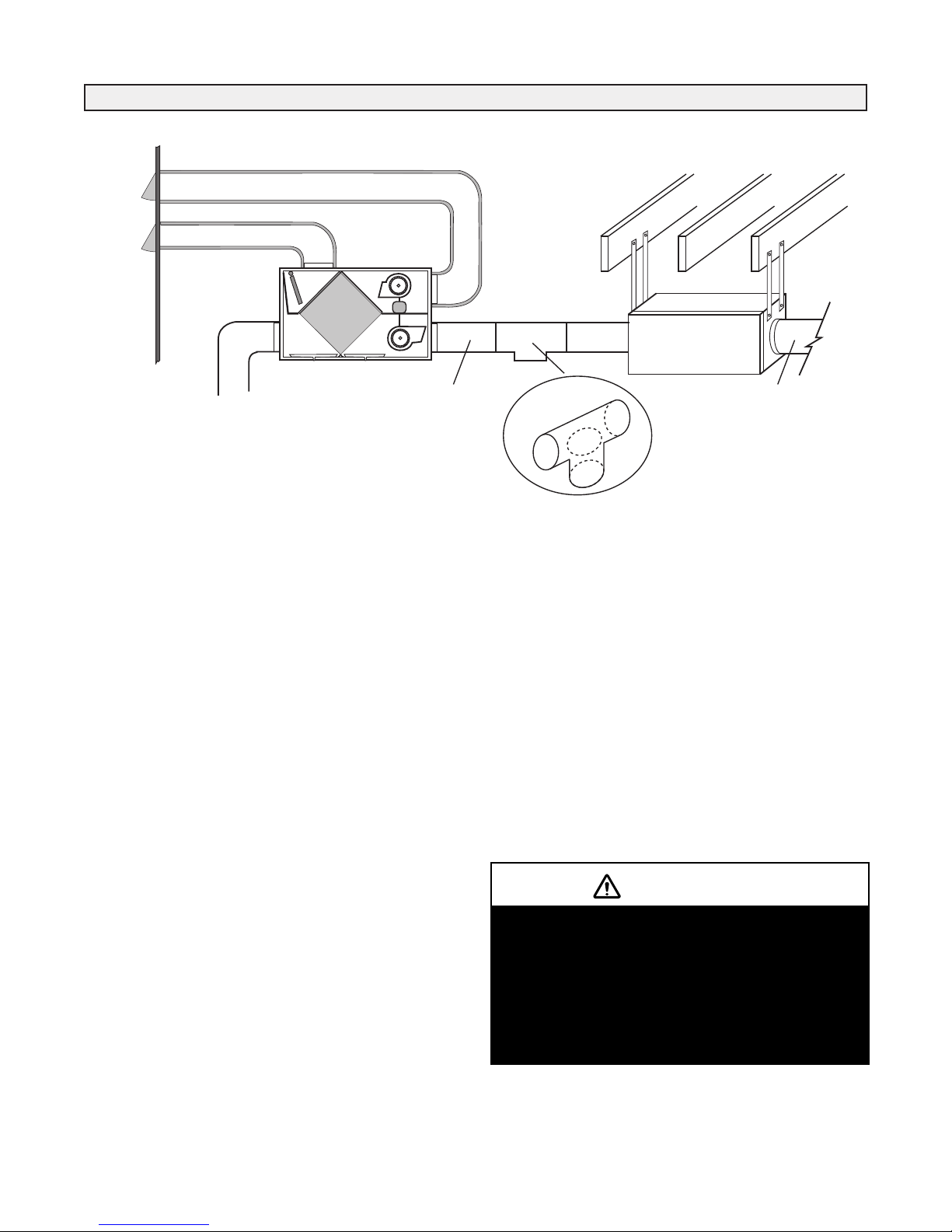

Optional Installation Kit: Part# 99-7TFP

Includes:

– two 7” Duct Connection Collars

– 12.5’ of 7” Duct

– four Nylon Duct Zip Ties

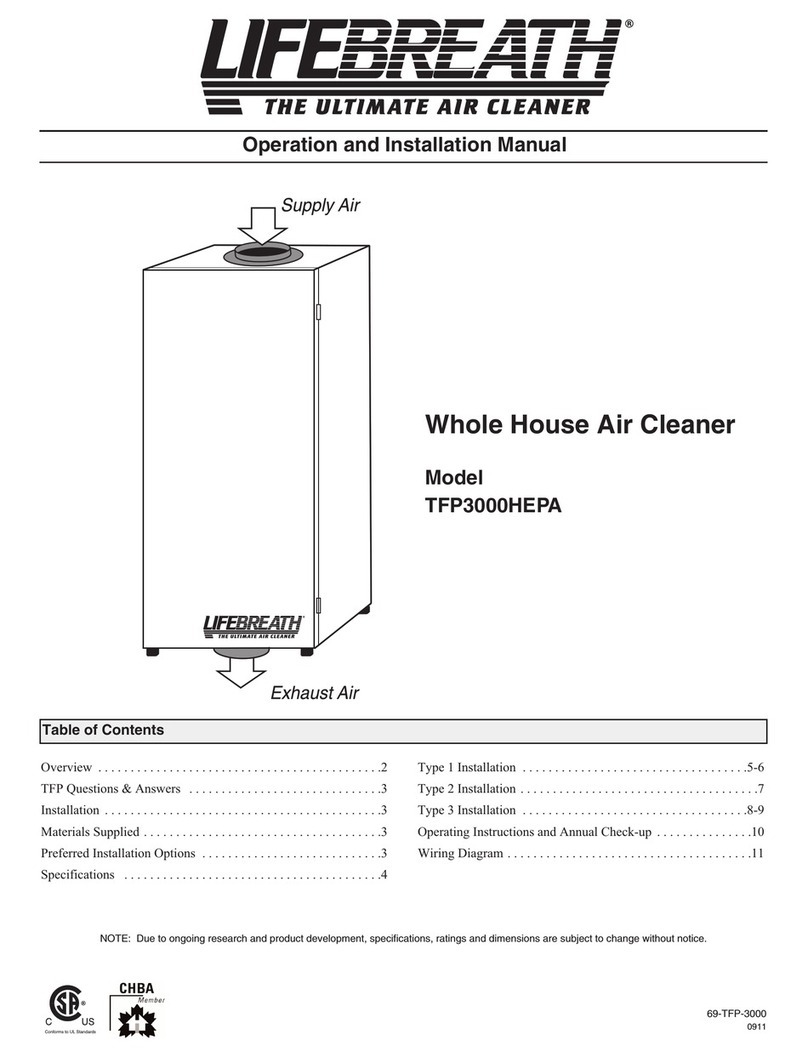

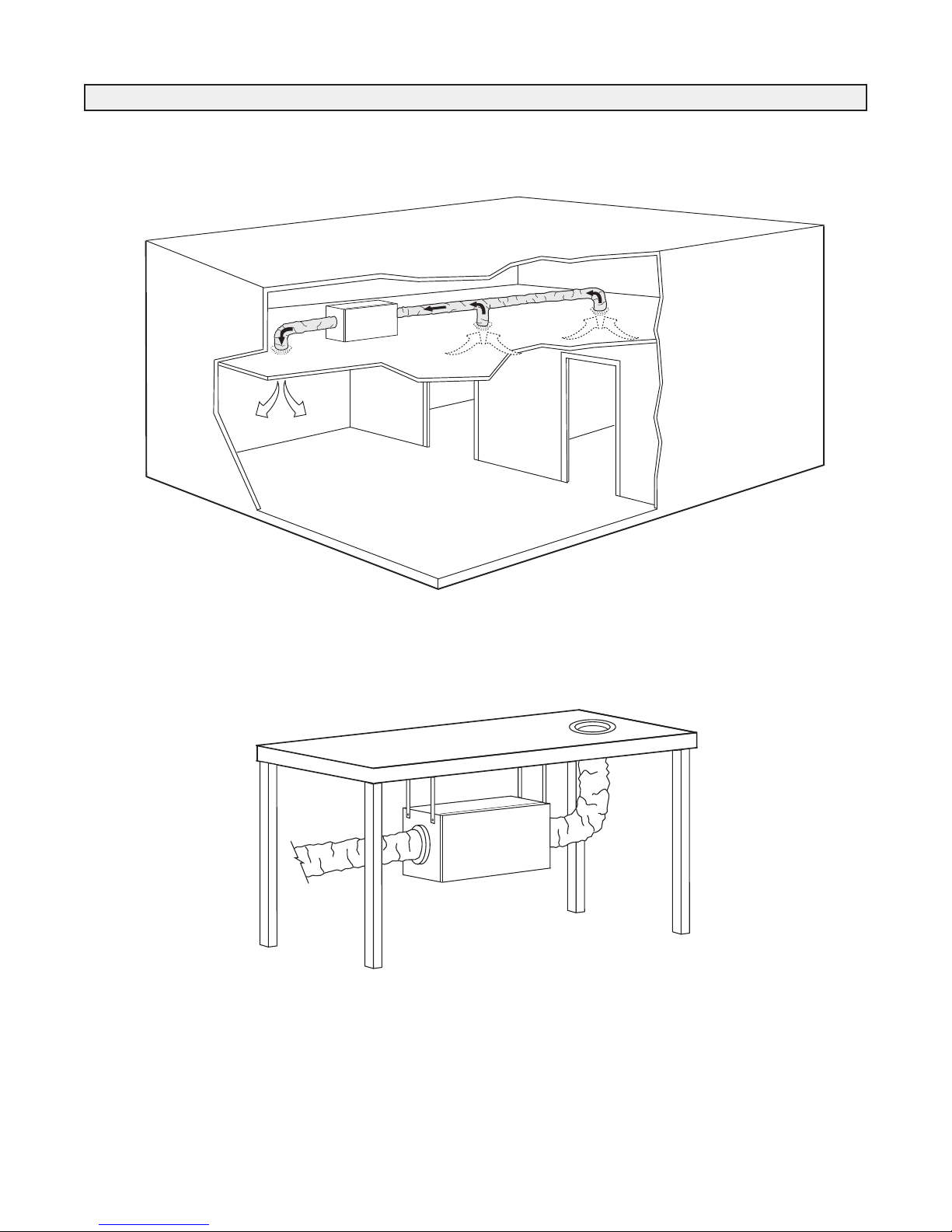

Location

The TFP should be installed in a conditioned space with easy

access for maintenance and an annual check up. A TFP is usually

installed in a basement area where air flow noise will be negligible

to the occupants.

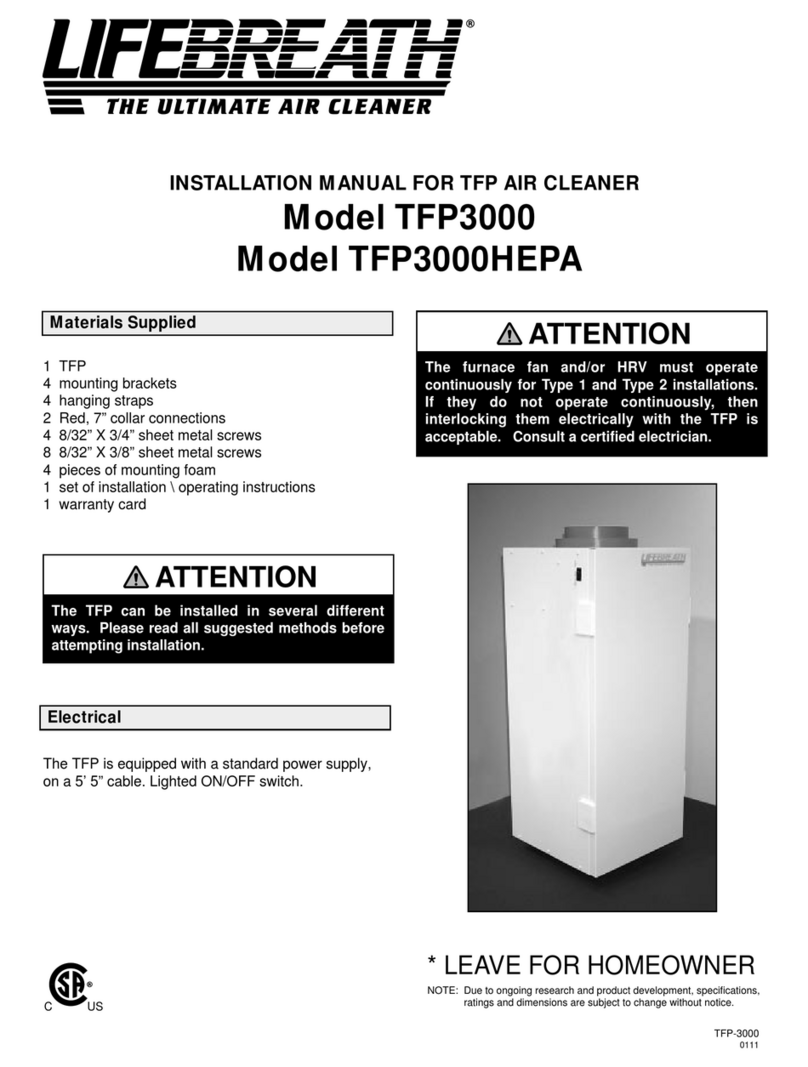

1 TFP

4 Mounting Brackets

4 Hanging Straps

2 Collar Connections

4 Port Collar Screws

8 Mounting Bracket Screws

4 Pieces of Mounting Foam

1 Set of Installation/Operating Instructions

1 Wiring Diagram

1 Warranty Card

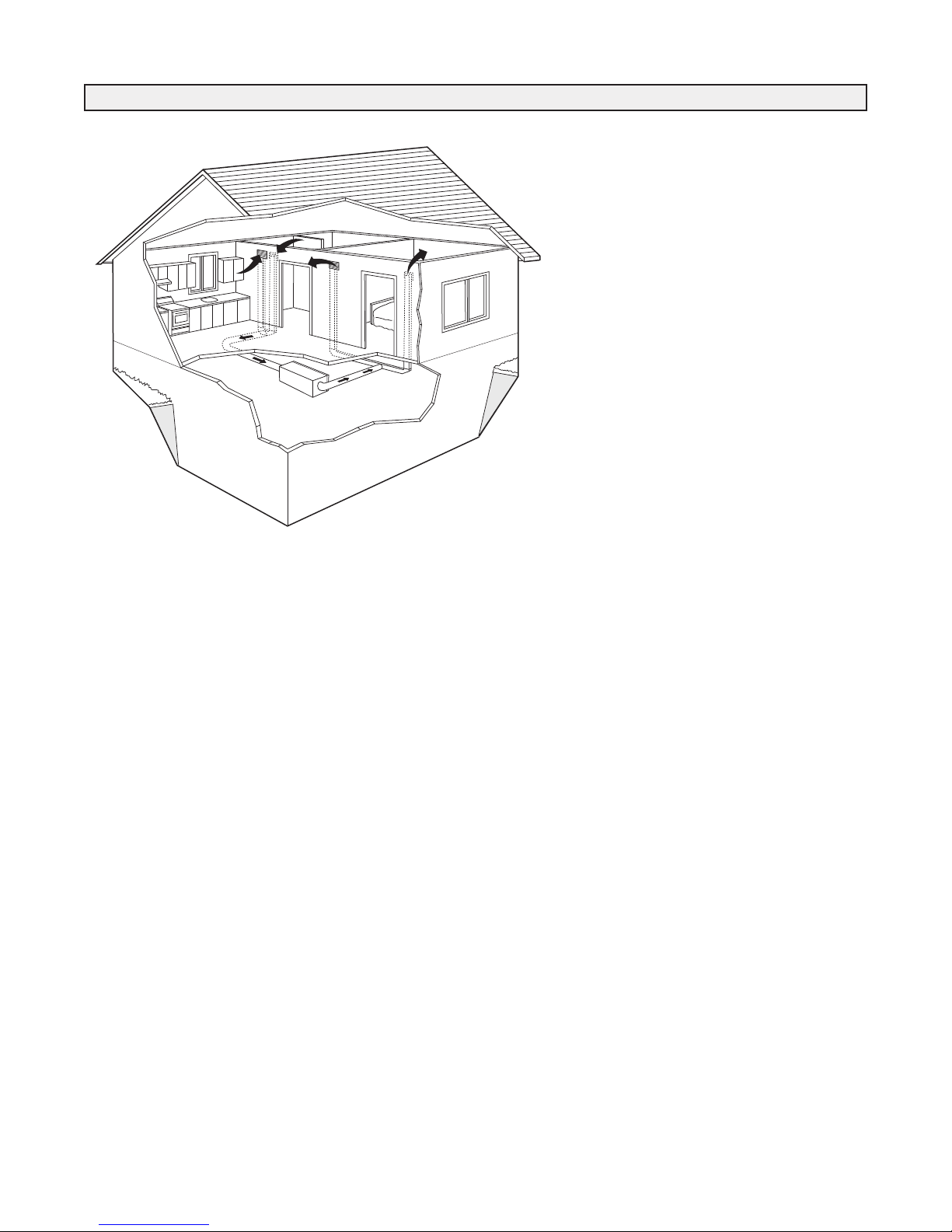

There are three basic installation options. Select the best method

for your needs.

1. TFP to a Forced Air System; use Return/Return Method

(horizontal or vertical TFP installation)

2. TFP to a Fully Dedicated HRV System

- recommended when you wish to clean the incoming air from

the HRV

3. Stand Alone System – recommended for homes without forced

air systems (ie. radiantly heated homes).

3

Options

InstallationOverview

TFP Questions & Answers

Materials Supplied

Preferred Installation Options