2

SAFETY INSTRUCTIONS

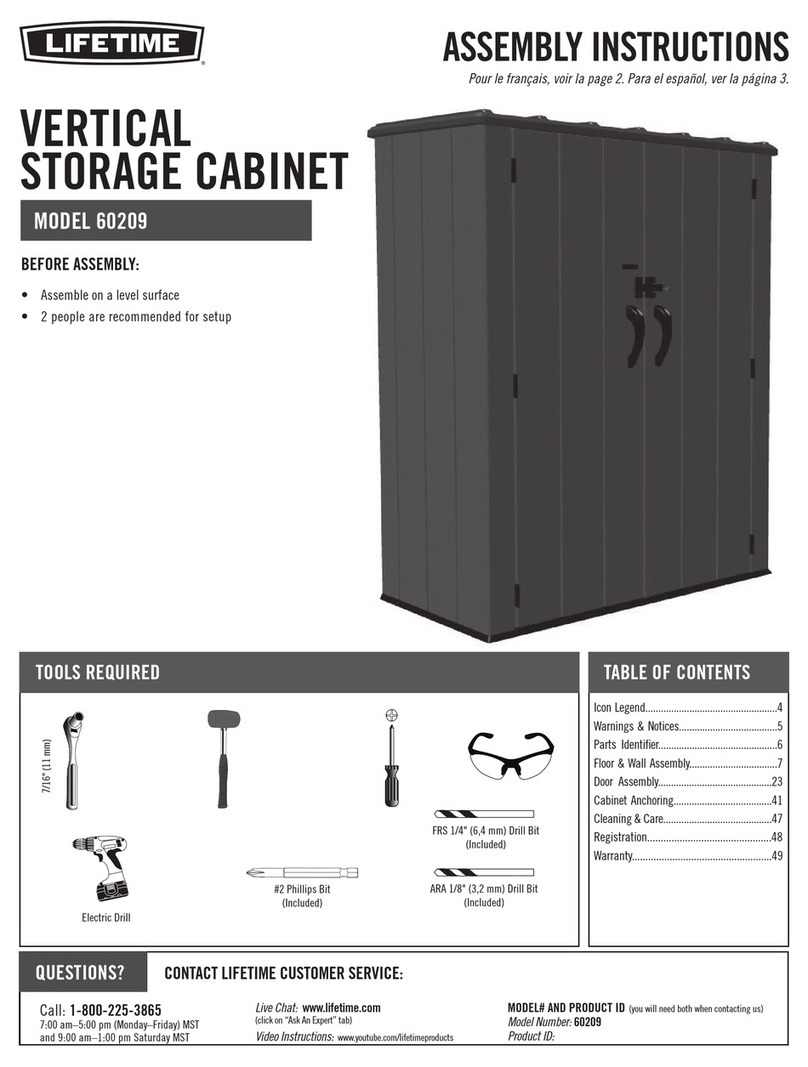

Most injuries are caused by misuse and/or not following instructions. Use caution when using this shed.

To ensure safety, do not attempt to assemble this shed without following the instructions carefully. Check entire box

and inside all packing material for parts and/or additional instruction material. Before beginning assembly, read the

instructions and identify parts using the hardware identier and parts list in this document. Proper and complete

assembly, use and supervision are essential for proper orientation and to reduce the risk of accident or injury.

FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN SERIOUS

INJURY OR PROPERTY DAMAGE AND WILL VOID WARRANTY.

• Do not use or store hot objects such as grills, blowtorches, welding equipment, etc. in the shed.

• If using a ladder during assembly, use extreme caution.

• Two capable adults are required for shed assembly. (It is also recommended that a third adult function as an instruction reader.)

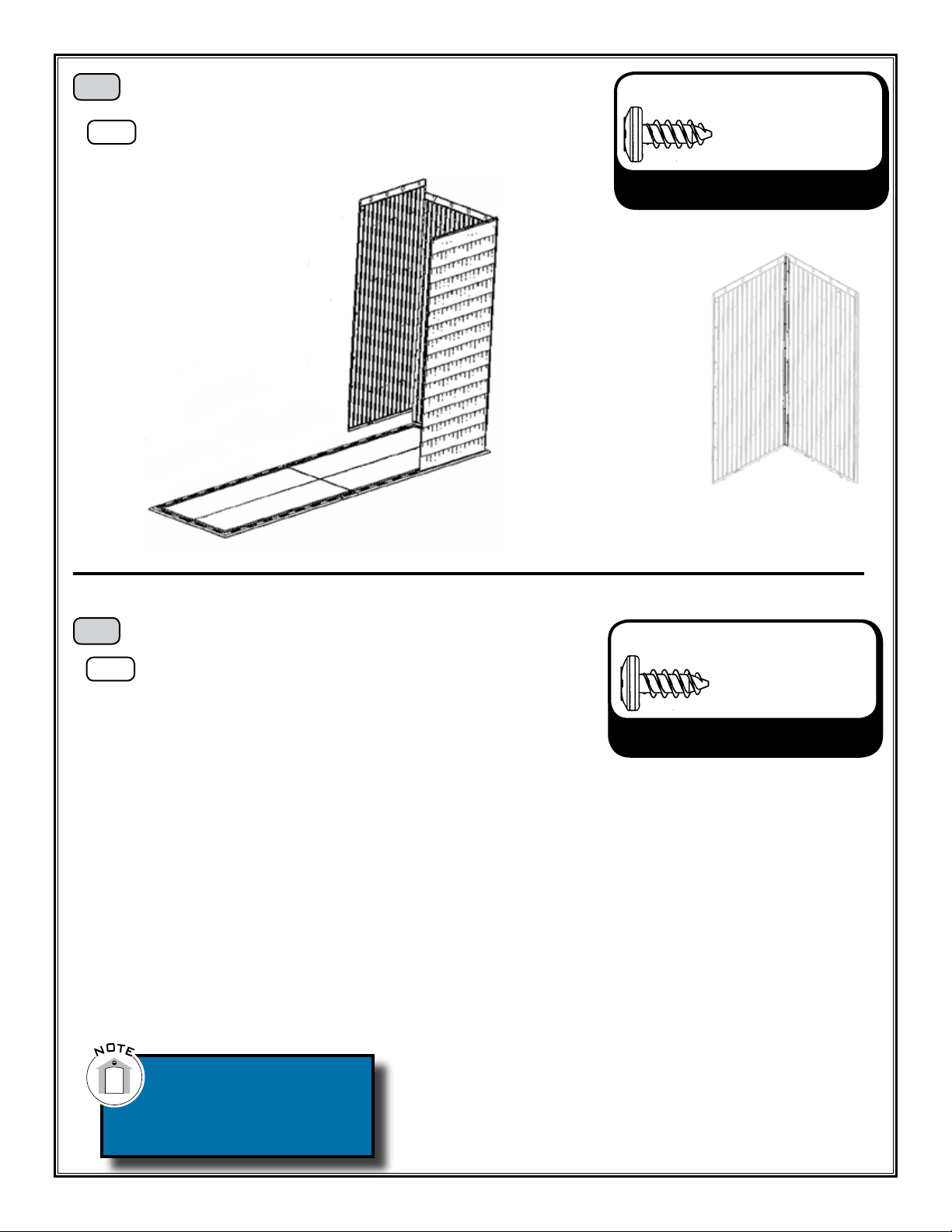

MODEL #6414

Sentinel

11’ x 3.5’ Outdoor Shed

Consult all local building codes, as well as city and county ordinances, to ensure

that the construction of the Outdoor Shed does not require a building permit. Proper

building permit documentation may be required in your neighborhood, and it would be

unfortunate to learn this after constructing the Shed.

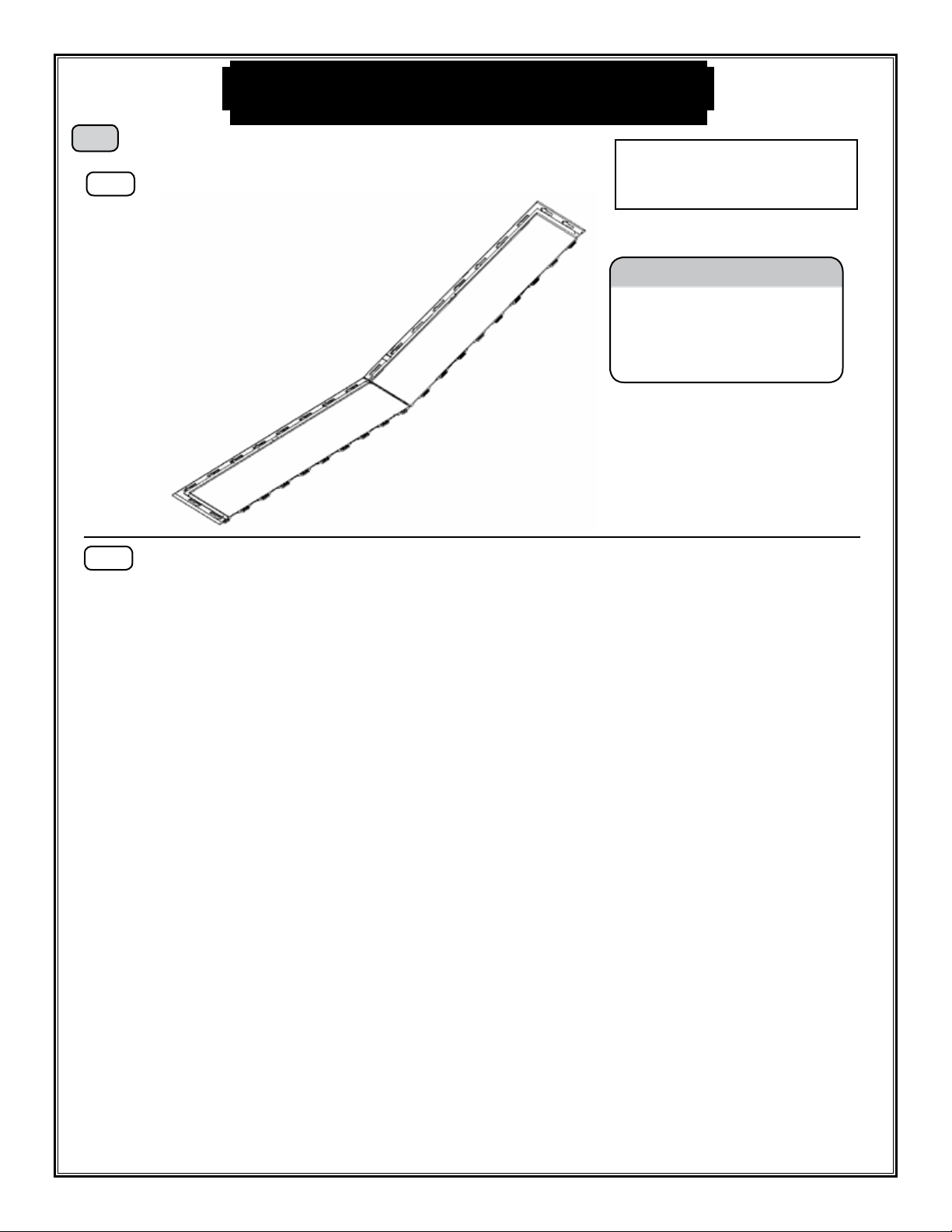

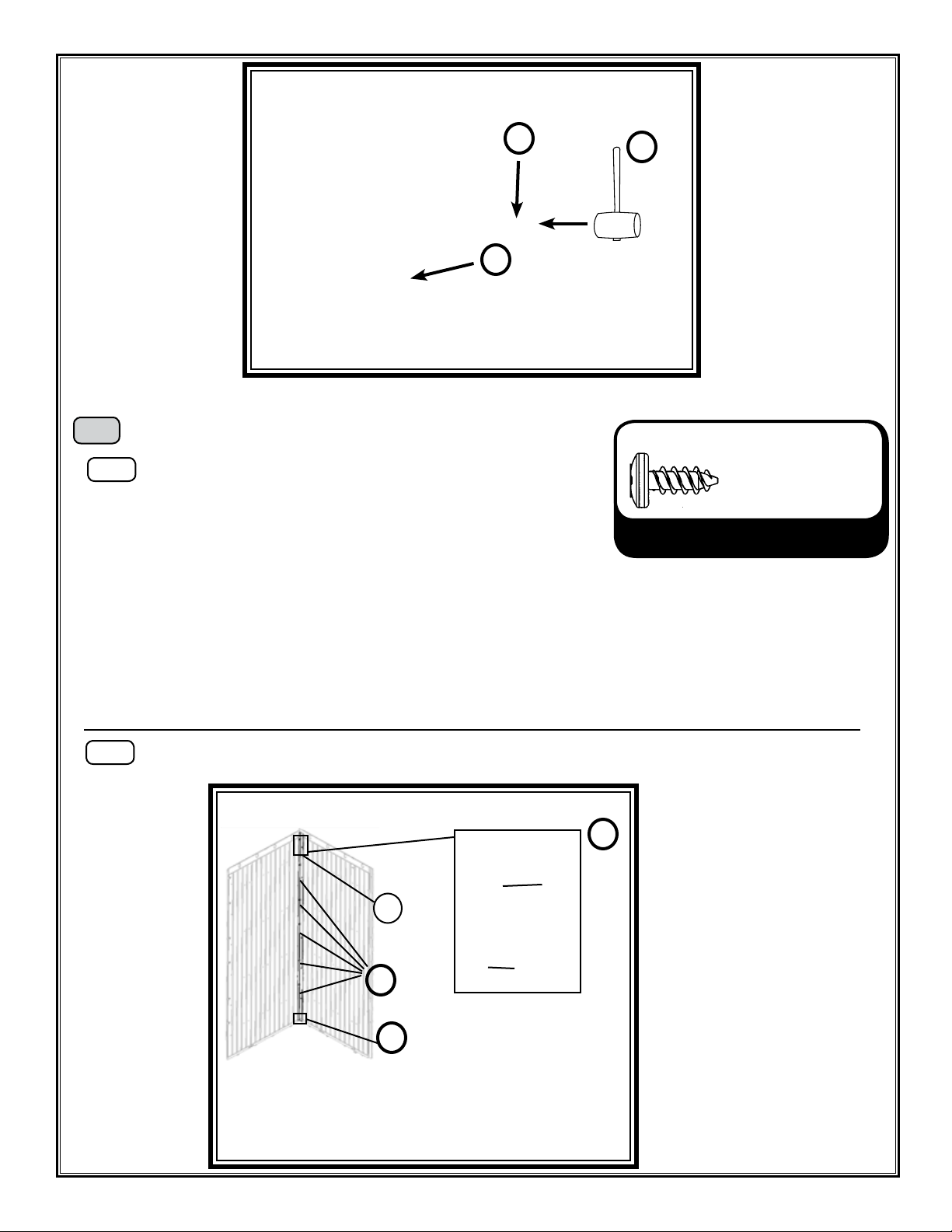

Surface must be leveled before installation. We recommend building a level work

space with a cement or patio style surface. If the surface is not properly leveled, the

Outdoor shed will not assemble correctly. Proper surface leveling will save you time

in the long run, so please do not ignore this step.

Instruction #1016304 7/18/2006

Level Surface Notice:

Building Code Notice:

You may use a 1/2” phillips head screwdriver bit and a power screwdriver or drill,

instead of a hand screwdriver. However, be aware that the plastic pieces of your

shed can be damaged by overtightening of screws. To avoid damage we strongly

recommend the use of a low-powered power screwdriver or a drill that has an

adjustable clutch that is set on a low torque setting. If neither is available, use a hand

screwdriver. In any case use caution to avoid overtightening the screws.

Screwdriver Notice:

Sharp objects may damage your oor. If resting sharp, heavy objects on your shed

oor, place a block of wood between the sharp object and oor.

Floor Puncture Notice:

You could win $200!

Register your product at www.lifetime.com and receive three important benets:

1. You automatically will be entered to win $200 in our monthly drawing!

2. In the unlikely event of a product recall or safety modication, we can

notify you immediately and directly.

3. You may choose to receive Preferred Customer Announcements and

promotions regarding new Lifetime products.

www.lifetime.com