3

Contents

1Safety instructions .......................................................................................................................................5

1.1 Regulations..................................................................................................................................................5

1.2 Advice for the use of electric chain hoists....................................................................................................6

1.2.1 Design according to DGUV V54 (BGV D8)..................................................................................................6

1.2.2 Additional requirements when designed according to DGUV V17 (BGV C1) ..............................................7

1.3 Prohibitions of use.......................................................................................................................................7

1.4 Directions for use.........................................................................................................................................7

1.5 Visible damages ..........................................................................................................................................8

1.6 Special features of electric chain hoists according to DGUV V17 (BGV C1)...............................................8

1.6.1 Prohibitions of use.......................................................................................................................................8

1.6.2 Moving of loads............................................................................................................................................8

1.6.3 Persons underneath suspended loads ........................................................................................................8

1.6.4 Types of loads .............................................................................................................................................8

1.6.5 Attaching lights or other equipment to the electric chain hoists ...................................................................9

1.7 Spare parts..................................................................................................................................................9

2Technical overview......................................................................................................................................9

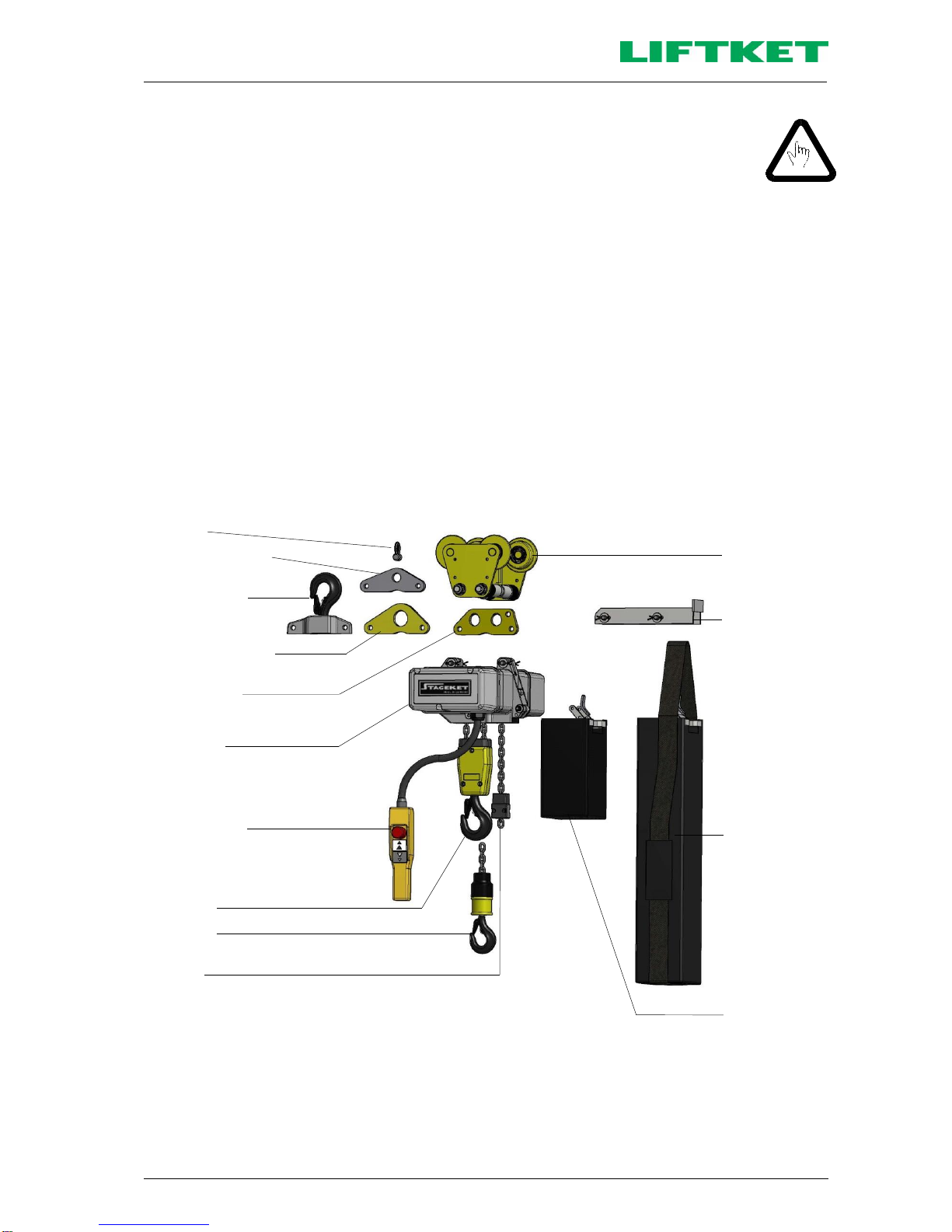

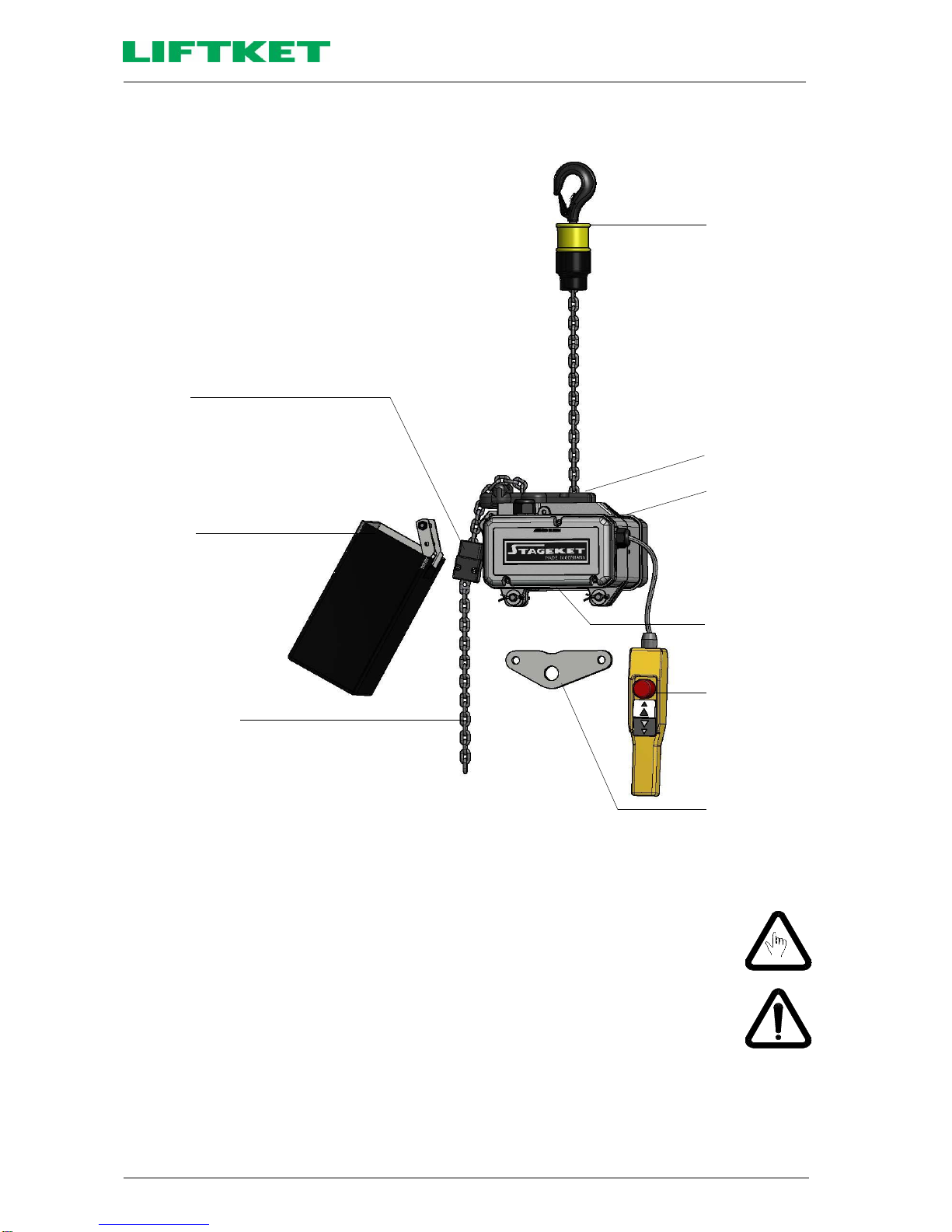

2.1 Assembly.....................................................................................................................................................9

2.1.1 Standard version and version MB in upright use according to DGUV V54 (BGV D8)..................................9

2.1.2 Version MB in inverted use according to DGUV V54 (BGV D8)................................................................10

2.1.3 Version SB in upright use according to DGUV V17 (BGV C1)...................................................................11

2.1.4 Further completion possibilities .................................................................................................................11

2.2 Explanation of type designation.................................................................................................................11

2.3 Sectional view............................................................................................................................................12

2.4 Illustration of the load chain configuration..................................................................................................13

3Assembly...................................................................................................................................................13

3.1 Mechanical assembly ................................................................................................................................13

3.1.1 Hook tackle................................................................................................................................................13

3.1.2 Hook block.................................................................................................................................................14

3.1.3 Stationary electric chain hoist....................................................................................................................15

3.1.3.1 Hoist suspension with suspension eye ......................................................................................................15

3.1.3.2 Hoist suspension with single hole suspension eye....................................................................................16

3.1.3.3 Hoist suspension with hook suspension....................................................................................................17

3.1.4 Gear ventilation..........................................................................................................................................18

3.1.5 Chain box ..................................................................................................................................................18

3.1.5.1 Mounting the chain box..............................................................................................................................18

3.1.5.2 Oversize chain box....................................................................................................................................19

3.1.6 Assembling the load chain in single fall version.........................................................................................20

3.1.7 Assembling the load chain in double fall version .......................................................................................21

3.1.8 Replacing the load chain, the chain guide and the hold down...................................................................22

3.1.9 Lift limiter...................................................................................................................................................22

3.2 Electric connections...................................................................................................................................22

3.2.1 Mains power ..............................................................................................................................................22

3.2.2 Operating voltages.....................................................................................................................................23

3.2.3 Direct control .............................................................................................................................................24

3.2.4 Low voltage control....................................................................................................................................24

3.2.5 Electrical limit switches for lift limiting........................................................................................................25

3.3 Configuration of electric chain hoists according to DGUV V17 (BGV C1)..................................................25

3.4 Limit switches in upright use......................................................................................................................26

3.5 Limit switches in inverted use....................................................................................................................26

3.6 Operation and emergency limit switches ...................................................................................................26

3.6.1 Gear limit switches.....................................................................................................................................26

3.6.2 External emergency limit switches.............................................................................................................27

3.7 Incremental encoder..................................................................................................................................28

3.8 Mechanical underload protection...............................................................................................................29

3.9 Electronic overload and underload protection............................................................................................30

3.10 Control pendant.........................................................................................................................................32

4Electric chain hoist with trolley...................................................................................................................33

4.1 Types of trolleys.........................................................................................................................................33

4.2 Permissible curve radius............................................................................................................................33

4.3 Horizontal movement of electric chain hoists.............................................................................................34

4.4 Attachment of lightening devices to electric chain hoists...........................................................................34