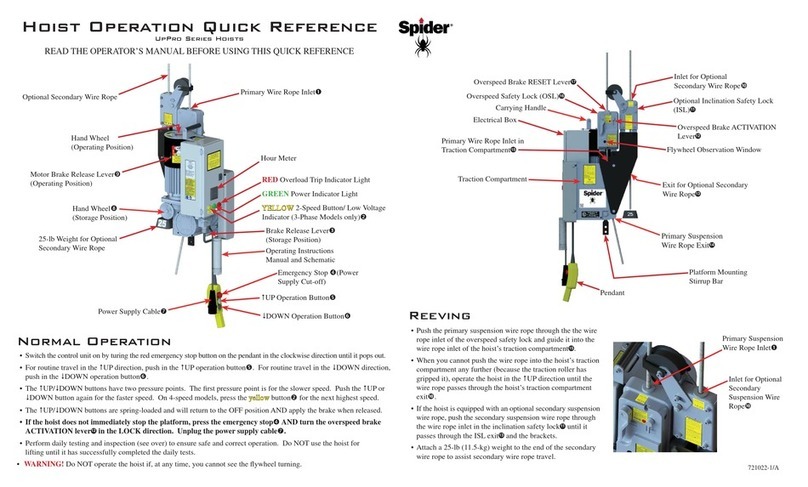

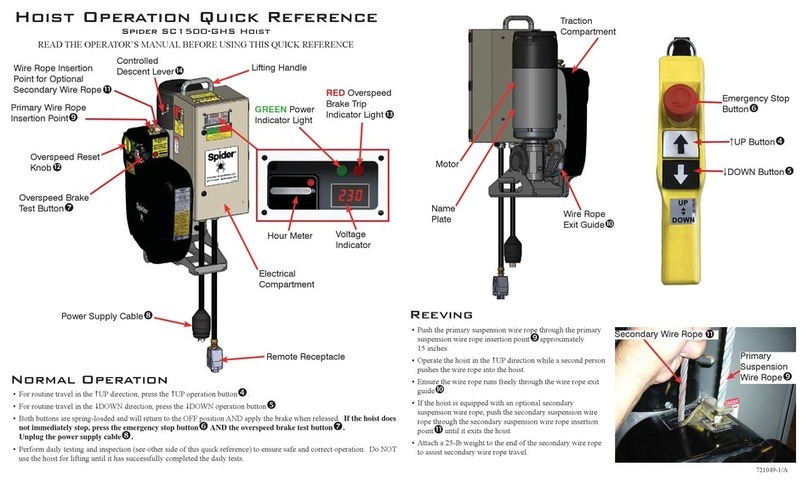

De-reeving Secondary Suspension Wire Rope

• The secondary suspension wire rope MUST be de-reeved before the primary suspension wire rope.

• Inordertoremovetheoptionalsecondarysuspensionwirerope,theremustbenoslackontheprimarysuspensionwire

ropeandtheplatformmustbesupportedonastablesurface.

• Removethecounterweightfromtheendofthesecondarysuspensionwirerope.

• Pullthesecondarysuspensionwireropeoutofthehoistbyhand.

• Ifnecessary,theprimarysuspensionwireropecannowberemovedfromthehoist.

De-reeving Primary Suspension Wire Rope

• The secondary suspension wire rope MUST be de-reeved before the primary suspension wire rope.

• WARNING! Topreventhoistsandplatformfromtippingandavoidinjuries,ensurethattheplatformisproperly

supportedonastable,atsurfacebeforeputtingslackontheprimarysuspensionwirerope.

• PressthepowerbuttonANDtheDOWNoperationbuttontode-reevetheprimarysuspensionwireropeout

ofthehoist.Toremovethelast15inchesofwirerope,ifnecessary,grabthewireropeabovetheprimarysuspension

wireropeinsertionpoint,holdtheoverspeedbrakeresetknob12 intheresetposition(vertical)andslowlypullthe

primarysuspensionwireropeoutofthehoist.

Daily Testing and Inspection

• Beforeoperatingthehoist,inspectthefollowing:

▫ Wirerope

▫ Powersupply

▫ Rigging

▫ Platform

▫ Hoist

▫ Allpartsarepresent,inproperworkingorder,andarenotdamaged.

▫ Bolts,nuts,andclampsarewellsecured.

▫ EnsurethehoistissecuredtothestirrupwithSAEGrade5fastenersandlocknutsthatareproperlyinstalled.

• Inadirtyenvironmentthatcontainsepoxy,paint,cement,sandblastresidue,orcorrosivematerial,inspectthe

operationoftheoverspeedbrakeseveraltimesaday.Protectivehoistcoversarerecommended.Contactyoursupplier.

Test the Controlled Descent

• Raisetheplatformapproximately3feet.

• Disconnect the power supply.

NOTE:Failuretodisconnectthepowersupplybeforetestingthecontrolleddescentwillactivatetheoverspeed,

resultinginaninaccuratecontrolleddescenttest.

• Liftthecontrolleddescentlever14 .

NOTE:Thecontrolleddescentleverreleasedthemotorbrake,whichwillallowtheplatformtobeloweredslowly

duringcontrolleddescent.

WARNING!Iftheoverspeedbraketripswhiletestingthecontrolleddescentwith the power supply disconnected,the

controlleddescentsystemisnotworkingproperlyandTHEHOISTSHOULDNOTBEUSED.

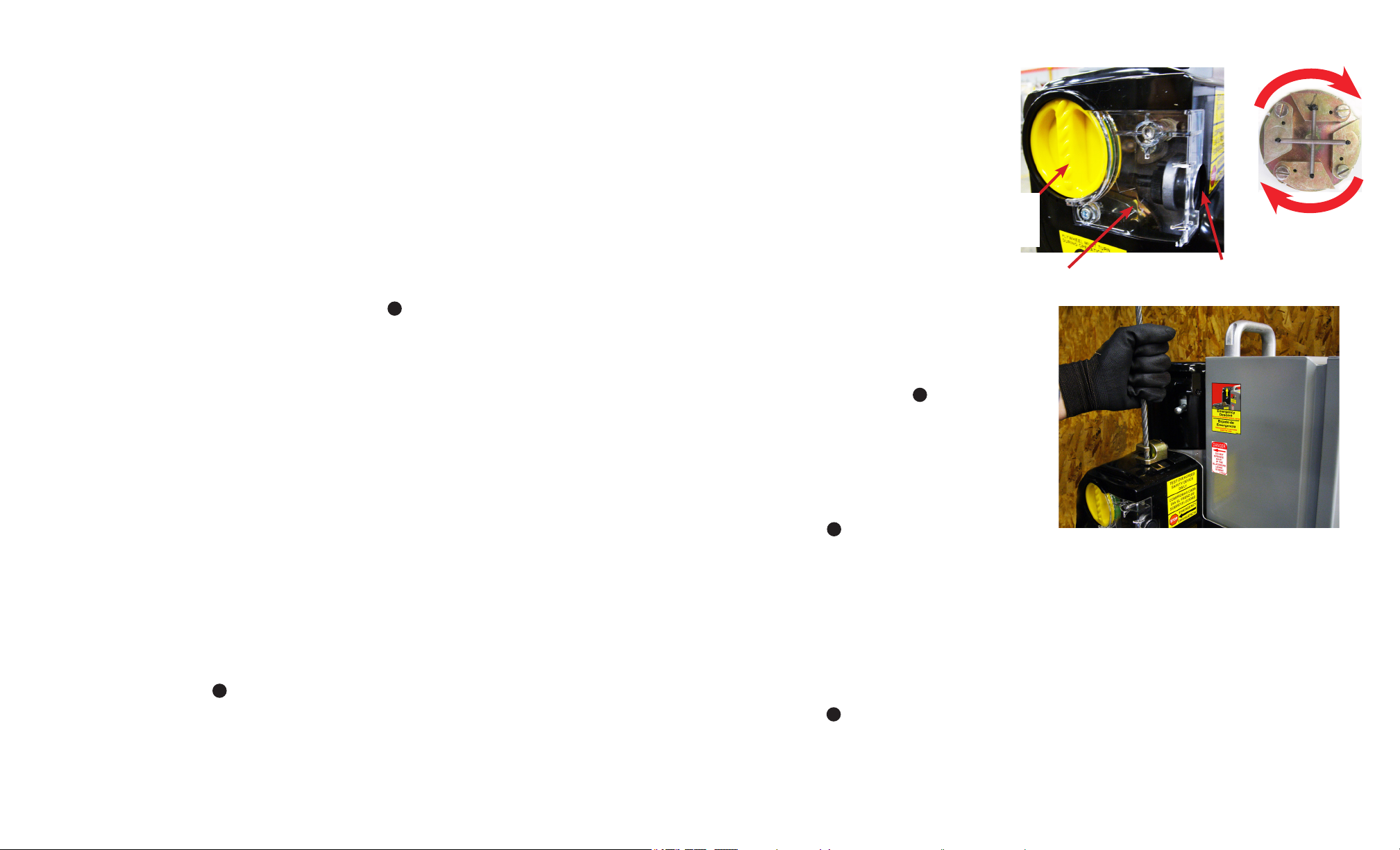

Test the Overspeed Brake

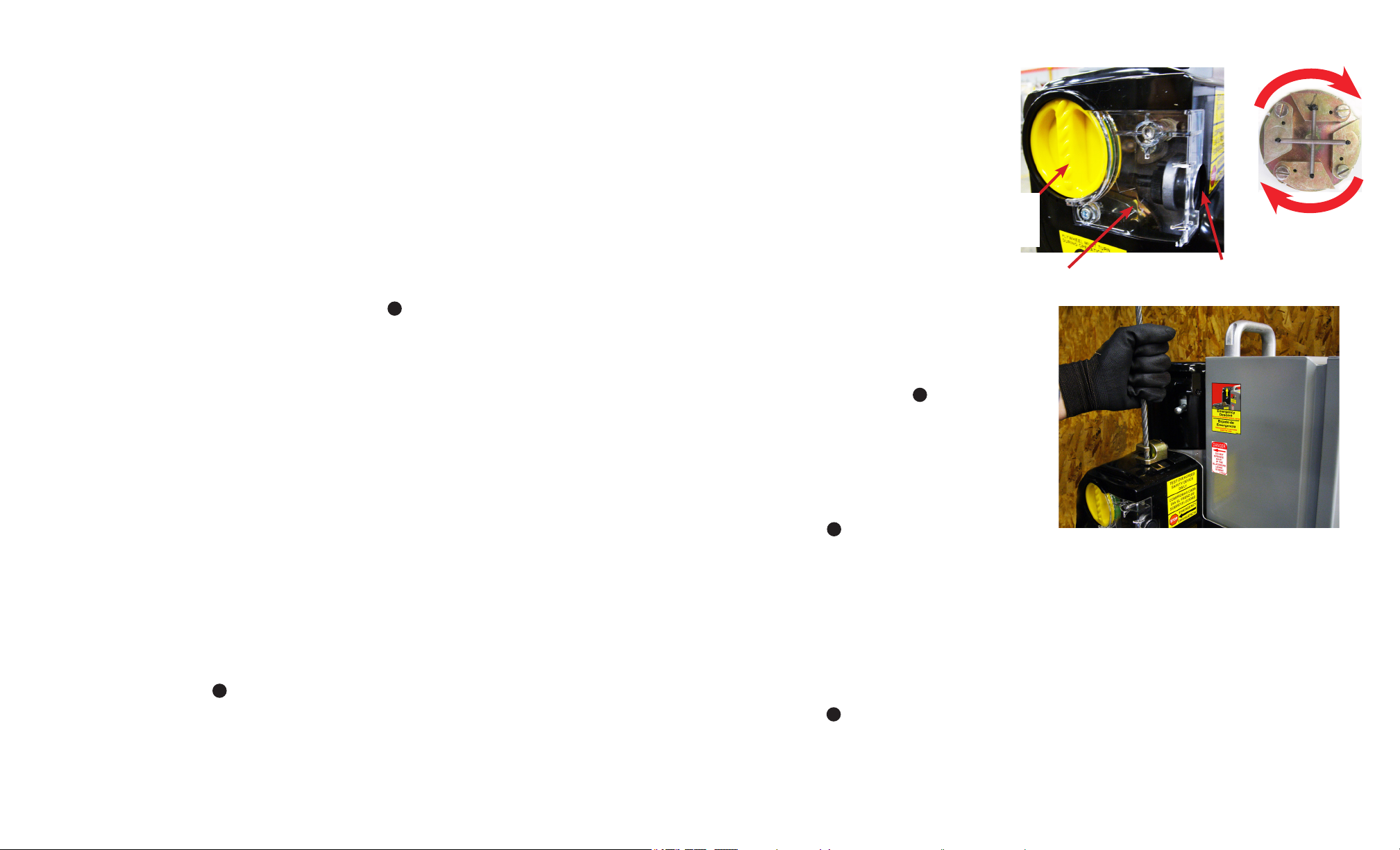

• WhilepoweringthehoistUPandDOWN

approximately3feet,lookthroughthewindow

intotheoverspeedcompartmenttoseewhether

theywheelisturning.

NOTE: Do NOT use the hoist if you cannot

seetheywheelturning.

Flywheel Overspeed Brake

Test Button

Flywheel

Movement

Overspeed Brake

Reset Knob (in

reset position)

• De-reevethewirerope.

• Re-insertthewireropeabout12"intothehoist.

• Holdingthewireropermly,pullitoutquickly.If

thebrakeisworkingcorrectly,itwillgrabandhold

thewireropeinlessthan4".WhentheDOWN

buttonispressed,theREDlight13 intheelectrical

boxwillilluminatetoindicatetheoverspeedbrake

hasbeenactivatedandtheDOWNcircuithasbeen

interrupted.

• Repeatthistestatleast3times.Ifthebrakedoes

notworkcorrectlyeverytime,DONOTUSETHE

HOIST.Returnthehoisttoyoursupplier.

• Resettheoverspeedbrakebyturningtheoverspeed

brakeresetknob12 clockwise.

Test the Overspeed Brake Test Button

• PressthepowerbuttonANDtheUPoperationbuttonandraisetheplatformapproximately3feet.

• PressthepowerbuttonANDtheDOWNoperationbutton,and,atthesametime,haveasecondpersonpress

theoverspeedbraketestbutton.

• Theplatformshouldstopimmediately.WARNING! Ifthehoistdoesnotimmediatelystoptheplatformwhenthe

overspeedbraketestbuttonispushed,thisindicatesthemotorisoutofphase.Stoppushingallthreebuttonsand

CORRECTTHEPROBLEMBEFORETHEHOISTISPUTINSERVICE.

• ResettheoverspeedbrakebypoweringthehoistUPafewinchestodisengagethebrakeandthenturntheoverspeed

brakeresetknob12 clockwise.

Test the Emergency Stop Button

• Whilerunningthehoistineitherdirection,haveasecondpersonpresstheredemergencystopbutton.

• Oncetheemergencystopbuttonhasbeenpressed,thehoistshouldnotmoveatall.

• Toresettheemergencystopbutton,pullthebuttonout.