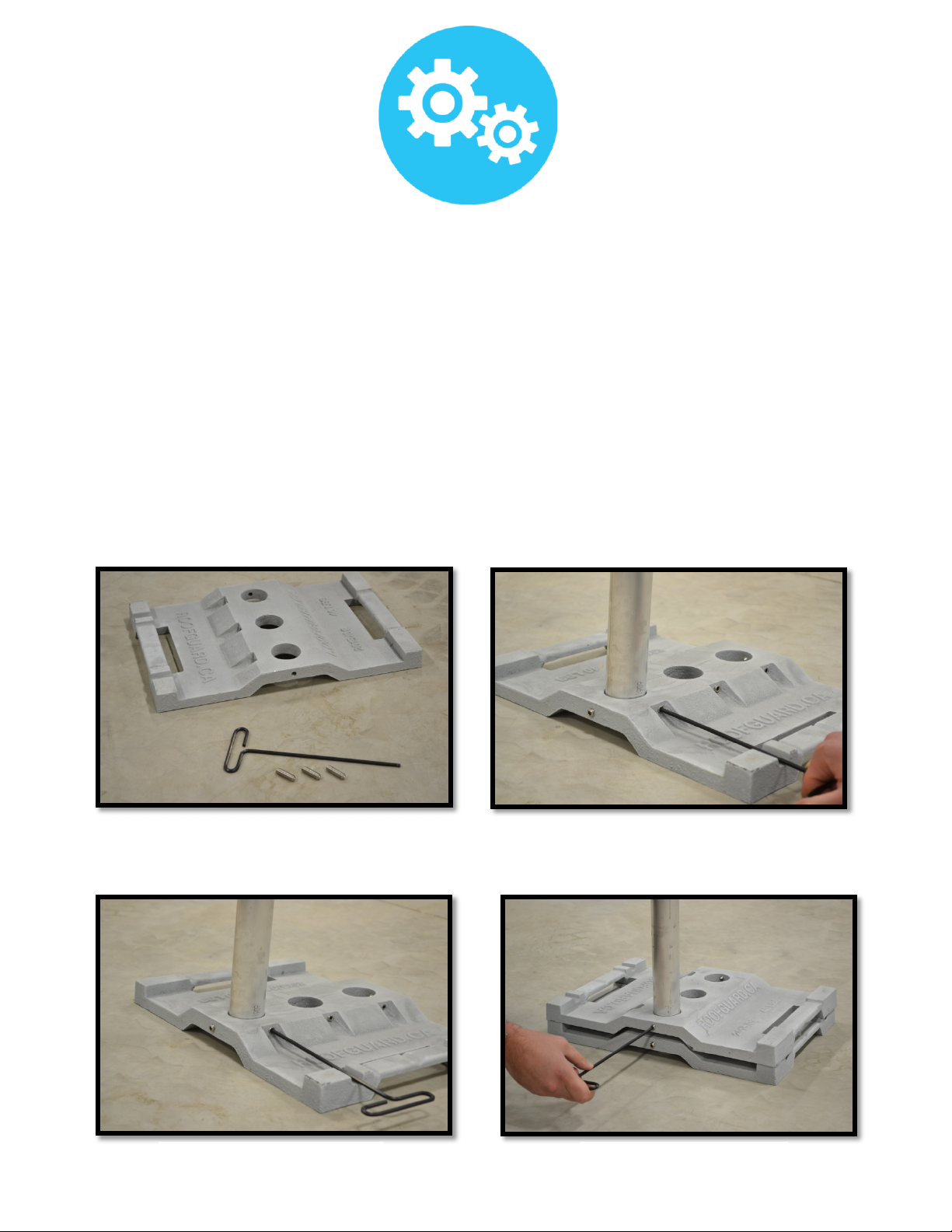

5.5 Use a 3/16” hex drive bit (provided) or wrench, and torque baseplate screws to 25ft-

lbs. All set screws for stacked plates must be secured against the wall of the vertical posts.

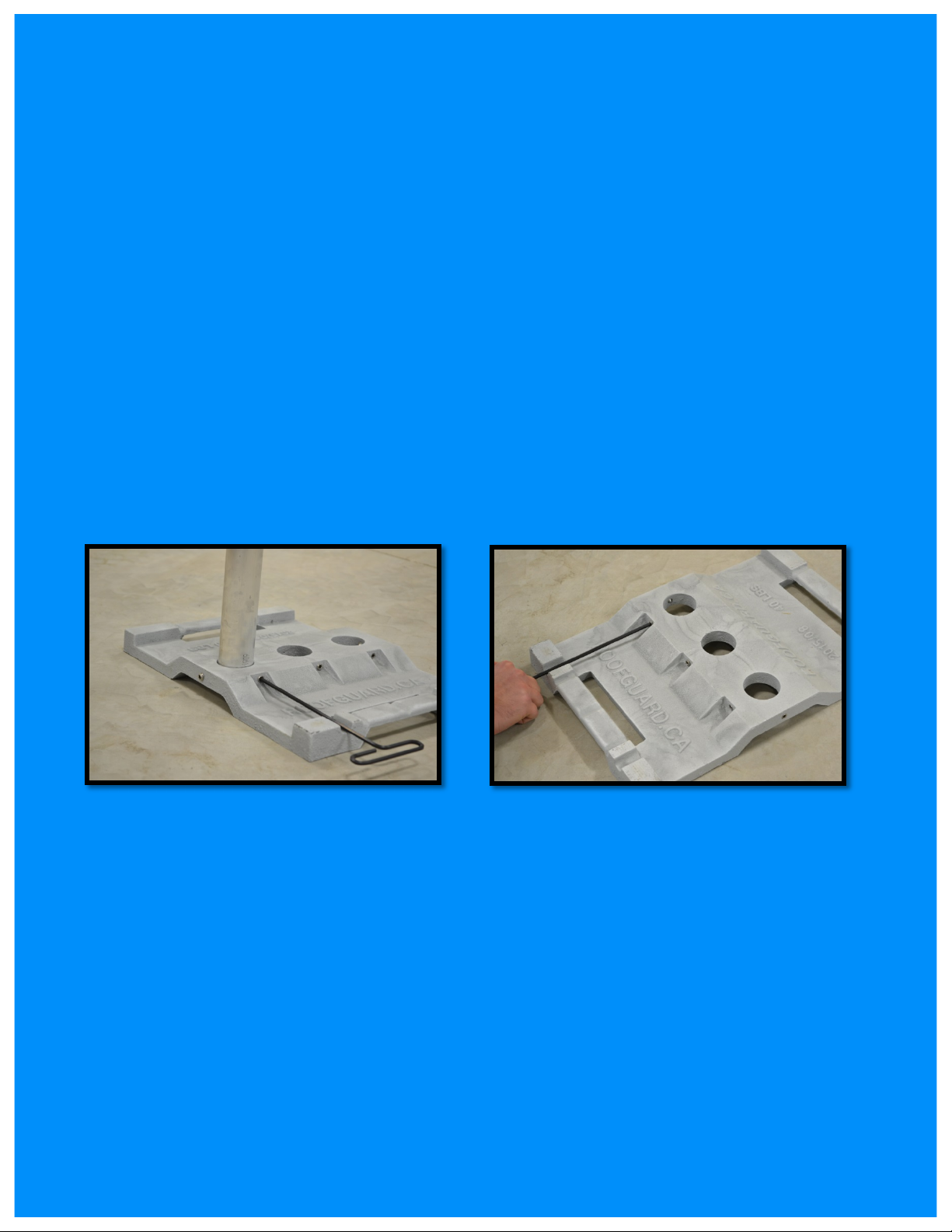

5.6 Once torqued the set screw can be ‘marked’ with the blue crayon (provided) to provide

a visual indicator that the screw has been secured and warn of tampering. (If the blue wax

is removed, it may indicate a tool was re-inserted in the set-screw.)

5.7 If toe-boards are to be used, the lumber can be cut and placed under the toe-board

adapter (from 5.2). The toe-board adapter can be lifted (sliding up the rails) to place the

lumber, and then lowered back onto the top of the lumber. Using the three holes provided,

secure the toe-board to the toe-board adapter with three #10 or #12 screws 1.5” or

longer. Longer screws should not protrude from the lumber where they may introduce a

hazard to workers.

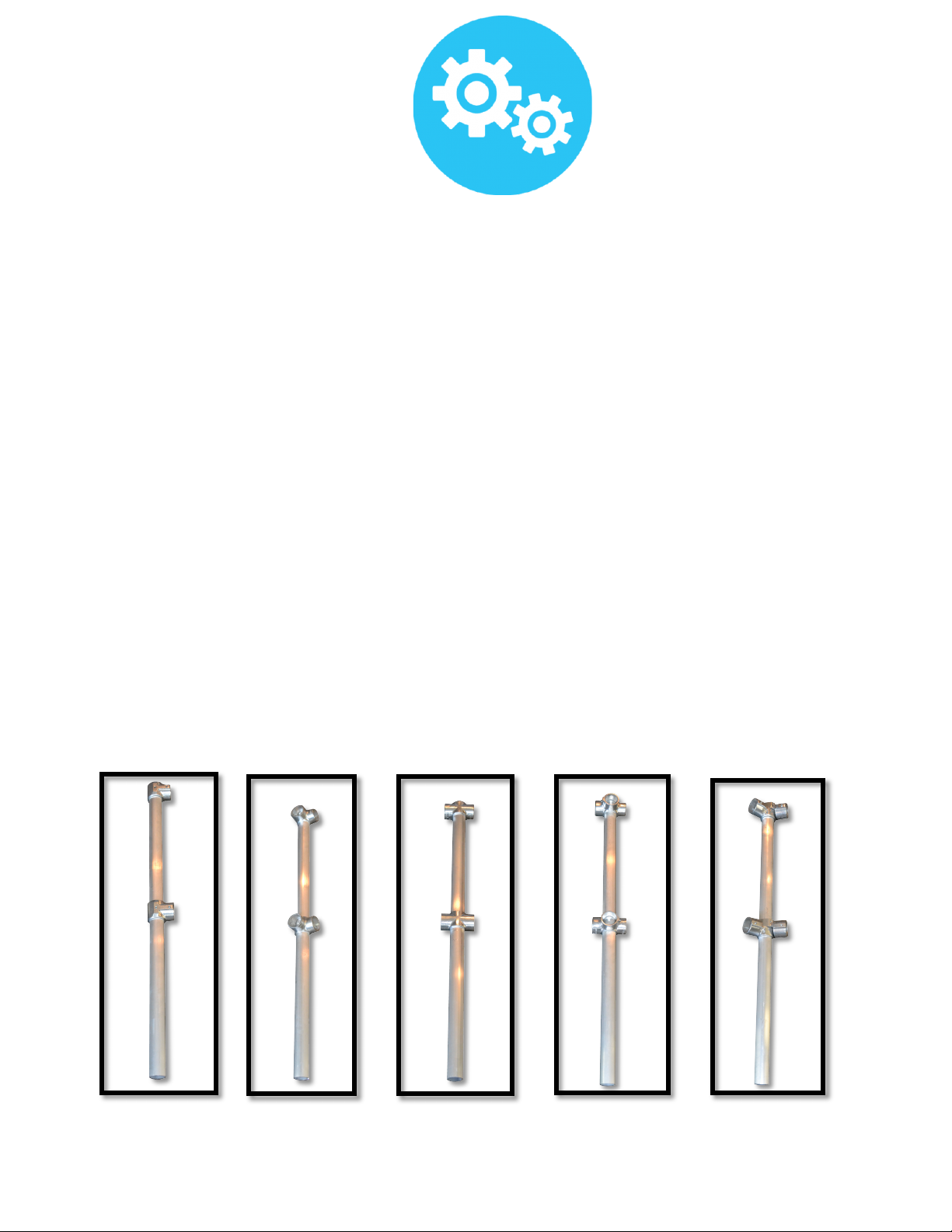

5.8 Once all vertical posts are set, the horizontal rails can be placed into the fittings and

secured with the hex drive bit (provided). To provide a visual indicator that the screw has

been secured and warn of tampering mark set screw with crayon. (If the blue wax is

removed, it may indicate a tool was re-inserted in the set-screw.)

5.9 Working form one end to the other, complete the assembly of the rails as per the layout

drawing. Once complete, the system should be reviewed to ensure the design is as per the

layout drawing and each set screw has been torqued and marked. At this point the system

is safe and ready for use.