Blue Giant MDC6620M Operating instructions

MECHANICAL EDGE-OF-DOCK LEVELER MDC SERIES

INSTALLATION & OWNER’S MANUAL

DO NOT INSTALL, OPERATE OR SERVICE THIS PRODUCT UNLESS YOU HAVE READ AND FULLY

UNDERSTOOD THE ENTIRE CONTENTS OF THIS MANUAL. FAILURE TO DO SO MAY RESULT IN

PROPERTY DAMAGE, BODILY INJURY OR DEATH.

!WARNING

TABLE OF CONTENTS

Table of Contents............................................................................................3

Check Shipment Notice ..................................................................................3

Owner’s Record of Purchase..........................................................................3

Safety.......................................................................................................... 4-5

Installation Instructions ............................................................................... 7-8

Operating Instructions............................................................................... 9-10

Maintenance ............................................................................................11-12

Trouble Shooting...........................................................................................13

Replacement Parts ............................................................................... ..14-15

Warranty ................................................................................................. 18-19

OWNER’S PURCHASE RECORD

Dealer: Date in Service:

Owner: Number of Units:

Order Number: Year of Construction:

Serial Numbers:

CHECK SHIPMENT BEFORE INSTALLATION

The leveler has been carefully checked at the manufacturer’s plant before shipment. In order to ensure that no

damage has occurred during transport, the levelershould be checked upon receipt for transport damage and to ensure

correct operation. Damage due to transport is to be listed on the signed copy on the freight document. The freight

forwarder must be notied of any damage within 48 hours. Damaged levelers must not be put into use.

Blue Giant offers a full line of dock levelers, dock safety equipment, accessories, ergonomic and scissor lift

equipment, and industrial trucks. Concurrent with our continuing product improvement program, specications are

subject to change without notice. Some features illustrated may be optional in certain market areas. Visit

www.BlueGiant.com for latest product information.

3

MD-CM 01/02/2008 (Part # 411-253-0)

4MD-CM 01/02/2008 (Part # 411-253-0)

1. Do not install this leveler, operate and/or service unless

you have been trained and authorized to do so.

2. Do not install, operate and/or service this leveler until

you have read and understood all of the safety informa-

tion and instructions contained herein and on the leveler.

3. Do not operate this leveler until you have checked its

condition. Report the need for leveler repairs to your

supervisor immediately and do not operate leveler until

repairs are made. Neglect may cause a minor repair to

become a major service problem and cause the leveler to

become unsafe.

4. Do not work under or around leveler being installed

without rst placing adequate barriers to positively pre-

vent vehicle trafc from entering the work area.

5. All electrical wiring, hook-up, repair and troubleshoot-

ing must be performed by qualied service personnel.

All wiring, hook-up and repairs must be made to meet all

applicable codes. Before doing any electrical work, make

certain the power is disconnected and properly tagged

and / or locked out.

6. Before performing any maintenance, secure dock lev-

eler properly.

7. Do not load leveler beyond capacity shown on serial

name plate on leveler.

8. Stay clear of dock leveler and vehicle when vehicle is

backing in or leaving dock area.

9. Secure vehicle by chocking vehicle wheels or use of

vehicle restraint, as detailed by OSHA, before operating

dock leveler.

10. Do not use or move the dock leveler if anyone is

under, in front and/or on dock leveler.

11. Keep hands and feet clear of dock leveler pinch points

at all times. Never use hands to lift dock ramp and/or lip

onto vehicle or to store dock leveler.

12. Never try to lift or move any part of the Dock Leveler

without using the Comfort grip handle.

13. Do not drive on leveler unless lip is securely on

vehicle bed and has a minimum of 4” (100mm) projection

on vehicle bed.

14. Do not exceed 3 mph when driving over dock leveler.

15. Do not drive over edges of the leveler and / or dock

bumper blocks (bumpers blocks are not structural).

16. Do not leave equipment or material unattended on lev-

eler.

17. Do not leave the leveler unattended in the deployed

position.

18. Do not use fork truck or any other material handling

equipment to lower leveler ramp.

19. Never attempt to perform repairs. Always defer repairs

to a qualied service technician.

20. Do wear safety equipment as required.

21. Workplace practical guide for safe use of this

product may restrict the use of any substance that may

compromise or impair safe operational use.

This manual is intended to be readily available. Keep it

near the leveler as a ready reference for anyone who may

operate or service it. If the leveler being operated is not

equipped with a manual, request to obtain one and have

it located near the leveler.

An authorized dealer or distributor is readily available to

answer questions about leveler operation and mainte-

nance and will provide additional information should it

be required.

SAFETY PROCEDURES

INTRODUCTION

The following is intended to be a quick reference to some of the important procedures to follow while using the MD-CM Series Edge-

Of-Dock Leveler. It is not intended to cover, or suggest that it does cover, all procedures required to be followed to ensure safe op-

eration. Operators should be aware of and abide by all workplace safety regulations that may apply to the operation of the MD-CM

Series Edge-Of-Dock Leveler. These laws and regulations include but are not limited to:

- Occupational Safety and Health Act (USA).

- Occupational Safety and Health Acts for Individual States (USA).

- Canadian Material Handling Regulations.

For further information on these regulations and / or industry standards that may apply to this equipment, please contact:

American National Standards Institute (ANSI)

1430 Broadway

New York, NY 10018

(212) 642-4900

!WARNING

The operating instructions are not subject to notication of amendment. The descriptions and illustrations included in our operating instructions and

replacement parts list are not binding. In the interests of continuing product development, we reserve the right to make any changes at any time to

the product construction, structure, components and accessories, concurrent with our continuing product improvement program, specications are

subject to change without notice. Please contact Blue Giant for latest product information, or visit our web site www.BlueGiant.com for the most

current product information.

EXCLUSION OF LIABILITY

The manufacturer assumes no liability for damage or injury to persons or property which have occurred as a result of defects or faults in the dock

levelers delivered or due to incorrect use. The manufacturer also assumes no liability for lost prots, operating down times, or similar indirect losses

which the buyer has incurred. Damage to third parties, irrespective of its nature, is not subject to compensation.

SAFETY WARNINGS

! CAUTION

This message indicates a potentially hazardous situa-

tion which, if not avoided, may result in minor or mod-

erate injury.

This message indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

!DANGER !WARNING

This message indicates a potentially hazardous situ-

ation which, if not avoided, could result in death or

serious injury.

IMPORTANT

This message is used when special precautions

should be taken to ensure a correct action or to avoid

damage to or malfunction of the equipment and/or a

component.

Safety Signs and Safety Messages

Improper operation can cause accidents. Don’t take chances with incorrect or damaged equipment. Read and understand the pro-

cedures for safe operation and maintenance outlined in this manual. Don’t hesitate to ask for help.

Stay alert! Follow safety rules, regulations, and procedures. Avoid accidents by recognizing dangerous procedures or situations

before they occur.

Safety signs and messages are placed in this manual to provide instructions and identify specic areas where potential hazards exist

and special precautions should be taken. Know and understand the meaning of these instructions, signs, and messages. Damage

to the equipment, death, or serious injury to you or other persons may result if these messages are not followed. If warning decals

are damaged, they must be replaced. Contact your Distributor for replacements.

5

MD-CM 01/02/2008 (Part # 411-253-0)

INSTALLATION INSTRUCTIONS

6MD-CM 01/02/2008 (Part # 411-253-0)

INSTALLATION INSTRUCTIONS

Do not install, operate and/or service this leveler until

you have read and understood all of the safety infor-

mation and instructions contained herein and on the

leveler.

Do not work under or around leveler being installed

without rst placing adequate barriers to positively

prevent vehicle trafc from entering the work area.

Keep hands and feet clear of dock leveler pinch

points

2. Remove strapping from the EOD and discard all shipping

material.

Mechanical Edge-Of-Dock Installation

across the full length of the back frame.

8. Vertical weld both ends of back frame to curb angle, full

length of vertical contact. Tighten the wedge anchor nuts se-

curely.

9. Position the left-hand bumper bracket (as viewed when

standing on the driveway in front of the Dock Leveler) so

that there is 1/2” (13mm) clearance between the bracket side

and the comfort grip handle pocket, and the bracket is level

with the top of the curb angle. Weld all horizontal and verti-

cal contact areas between bracket and curb angle and plug

weld mounting holes that overlap curb angle. Install concrete

wedge anchors 5/8” x 6” (15mm x 150mm) in mounting holes

that are not welded.

10. Position the right-hand bumper bracket so that there is a

1/2” (13mm) clearance between the bracket and the dock lev-

eler deck plate. Weld all horizontal and vertical contact areas

between bracket and curb angle and plug weld mounting holes

that overlap curb angle. Install concrete wedge anchors 5/8” x

6” (15mm x 150mm) in mounting holes that are not welded.

11. Install the comfort grip handle in the pocket on the left side

of the deck. To do so, remove the bolt from the bottom of

the handle, insert handle through pocket, then re-install bolt

through hole in handle.

12. Lubricate all pivot points using SAE30 motor oil or equiva-

lent.

1. Clean up the entire work area and apply touch-up paint to

all welds, scratches and burns.

2. Ensure all concrete wedge anchors have been securely

tightened.

3. Test operate the unit through several full cycles of opera-

tion. Refer to: Operating Procedures. If problems are noted,

See Section on Troubleshooting.

4. Leave these Instructions for use by owner.

Installation Inspection

!WARNING

!WARNING

!WARNING

The EOD leveler must be welded to a rmly embedded

steel channel or other dock steel as described in the

installation instructions. Do not attempt to use only

bolts or anchors to attach the dock leveler to the con-

crete.

Use caution when removing strapping from the EOD

leveler. Keep hands clear of pinch points and wear

appropriate safety attire - glasses, gloves and work

boots.

4. Position the back frame so that the top of the frame is 5/32”

(4mm) below the level of the top of the curb angle (plus 1/8”

(4mm), minus 0” (4mm)). Ensure top of frame is parallel with

the top of the curb angle.

5. Tack weld top of back frame securely to curb angle.

6. Ensure that the back frame is rmly against curb angle or

dock face concrete and plug-weld the back frame to the curb

angle at the four circular holes in the frame. If curb angle does

not overlap these holes, use the back plate as a template and

drill four holes 5/8” dia. x 6” (15mm x 150mm) deep, in the

dock face concrete. Clean out holes and insert and perma-

nently install appropriate concrete wedge anchors. (See page

4). Tighten enough to secure the Back Frame.

7. Finish weld the top of the back frame to the curb angle.

Weld 1/4” x 5” (6mm x 125mm) long welds on both ends of

the back frame. Repeat the 1/4” welds on 9” (225mm) centers

Use caution when lifting or moving the EOD leveler. Do

not attempt to lift without suitable hoisting equipment

capable of lifting as much as 600 lbs.

!WARNING

Read and understand this entire manual prior to oper-

ating.

1. Inspect the loading dock curb angle and verify that it is rmly

embedded and anchored in the concrete and is minimum 3”

x 8” x 1/4” (75 x 75 x 6mm) steel. If there is no curb angle, if

anchoring or embedding is questionable, or is not of minimum

size specied, proceed with advise installation mounting types

per page 6.

7

MD-CM 01/02/2008 (Part # 411-253-0)

INSTALLATION MOUNTING TYPES

Note : All hardware must be purchased separately as part of an optional mounting kit.

Consult your local distributor/dealer for more information.

Figure 2 : 8” Pour-In Channel Arrangement.

• Must be poured-in with dock concrete.

• 8” Structural channel minimum, 11.5 lb/ft.

• Weld-on curb angle concrete anchors to be minimum 5/8” x 6” long

located on 12” centers with one anchor 3” from each end.

8” Pour-In Channel

Figure 3 : Approach Ramp Arrangement

• Position ramp as illustrated. Outside edge of ramp ush with out-

side edge of curb angle.

• Tack-weld ramp to curb angle.

• Drill 3/4” dia. holes using ramp as a template. Insert 5/8” expansion

sleeves (010-116). Install and tighten 5/8” x 1-1/2” button-head

bolts (010-117) using 3/8” Allen key wrench.

• Weld the ramp to the curb angle as illustrated. 1/4” x 5” welds on

9” centers.

Optional Approach Ramp Installation

RAMP

BUTTON

HEAD

BOLT

WELD

CURB

A

NGLE

A

NCHOR

EXPANSION

SLEEVE

One Piece Angle Plate

BEVELED

EDGE

Figure 4 : One Piece Angle Plate

• 1/4” minimum plate thickness. Top plate 13” wide, face

plate 10-” wide. Length to suit EOD Leveler model.

• Place angle plate on existing dock as shown. Use as drill template.

• Lag to sound concrete as follows:

Top Plate - Drill 3/4” dia. x 3-1/2” deep holes. Insert 5/8” expansion

sleeves (010-116). Install and tighten 5/8” x 1-1/2” button-head

bolts (010-117) using 3/8” Allen key.

Face Plate - Drill 5/8” dia x 6” deep holes. Insert 5/8” x 6” long

concrete anchor wedges (010-108) and tighten.

Two Piece Angle Plate

Figure 5 : Two Piece Angle Plate

• 1/4” minimum plate thickness. Top plate 13” wide, face

plate 10” wide. Length to suite EOD Leveler model.

• Place top plate on top of existing dock, front edge ush with

dock face, full length.

• Drill 3/4” dia. x 3-1/2” deep holes using plate as template.

Insert 5/8” expansion sleeves (010-116). Install and tighten

5/8” x 1-1/2” button-head bolts (010-117) using 3/8” Allen

key wrench.

• Place face plate in position as shown. Position top edge for

welding and tack-weld to top plate.

• Drill 5/8” dia. x 6” deep holes using plate as a template. Insert

5/8” x 6” long concrete wedge anchors (010-108) and tighten.

• Weld the two plates together as illustrated. 1/4” x 5” long welds on

9” centers.

Face Plate Types - For

use on existing docks with

no curb steel

BEVELED

EDGE

WELD

(BY OTHERS)

8” POUR-IN CHANNEL ANCHOR

(BY OTHERS)

8MD-CM 01/02/2008 (Part # 411-253-0)

OPERATING INSTRUCTIONS

• The Mechanical Edge-of-Dock (EOD) Leveler is intended

to be used as a bridge located between a loading dock

oor surface and the rear deck upper surface of a vehicle.

• The EOD Leveler upper deck plate complete with a

hinged, vertically hanging lip plate is located ush with

the oor surface and is permanently mounted on the outer

edge of the loading dock.

• The rear deck surface of a vehicle is parked and blocked

in place against the dock bumpers that are integral com-

ponents of the EOD Leveler, in working alignment with the

EOD Leveler. An EOD Leveler used in conjunction with

a Vehicle Restraint are ideal for this application. Consult

your local Dealer/Distributor.

• The EOD Leveler is operated by pulling back on the com-

fort grip handle. The hinged lip plate raises to a horizontal

position as the deck is rotated up into a vertical position.

As the operator pushes the comfort grip handle forward,

rotating the deck forward into a horizontal position, the lip

moves forward horizontally until the underside comes to

rest on the deck of the vehicle.

• A bridge is now formed that is supported at the building

end by the dock oor and at the vehicle end by the vehicle

deck.

• The EOD must now be walked to insure the kicker bar is

disengaged.

• No other means of support is provided when in this posi-

tion.

•The EOD Leveler is restored to its original stored position

by the operator before the vehicle is allowed to depart.

Do not install this leveler, operate and/or service un-

less you have been trained and authorized to do so.

Do not install, operate and/or service this leveler until

you have read and understood all of the safety infor-

mation and instructions contained herein and on the

leveler.

Do not operate this leveler until you have checked its

condition. Report the need for leveler repairs to your

supervisor immediately and do not operate leveler un-

til repairs are made. Neglect may cause a minor repair

to become a major service problem and cause the lev-

eler to become unsafe.

Never try to lift or move any part of the Dock Leveler

without using the comfort grip handle.

Keep hands and feet clear of dock leveler pinch points

at all times. Never use hands to lift dock ramp and/or

lip onto vehicle or to store dock leveler.

Do not drive on leveler unless lip is securely on vehi-

cle bed and has a minimum of 4” (100mm) projection

on vehicle bed.

Do not exceed 3 mph when driving over dock leveler.

Do not drive over edges of the leveler and / or dock

bumper blocks (bumpers blocks are not structural).

FUNCTIONAL DESCRIPTION

OPERATION (CONTACT SUPERVISOR FOR ASSISTANCE)

2. The dock operator ensures the vehicle is blocked

securely (using either a vehicle restraint and/or wheel

chocks) to prevent forward creep or unexpected

departure.

DOCK IS AVAILABLE FOR USE

1. The vehicle driver reverses the vehicle into position

rmly against the dock bumper extensions.

Note : The comfort grip operating handle is shown in position.

3. The operator pulls the comfort grip operating

handle backwards fully to rotate the handle to its lower

position. The deck plate is past the vertical position and

the lip plate is near horizontal.

!WARNING

9

MD-CM 01/02/2008 (Part # 411-253-0)

OPERATING INSTRUCTIONS

Do not attempt to operate the EOD leveler without

using the comfort grip handle.

4. The operator pushes the comfort grip operating

handle forward to rotate the deck plate back towards its

original position.

5. During this step, the lip plate will remain horizontal and

extend until it comes to rest on the transport vehicle oor.

Remove the comfort grip handle, before loading

and/or unloading cargo.

6. With the lip plate in full contact with the vehicle

load bed, the loading/unloading operation can be

completed.

8. The operator raises the deck, by pulling back on the

comfort grip handle, only enough to release the lip from

the surface of the transporter vehicle load bed. When

the lip pivots downward to a pendant position, the unit is

allowed to return to stored position.

9. The operator releases the vehicle restraint or

removes the wheel chocks to allow the vehicle to

depart. The operator then indicates to the vehicle driver

that it is safe to depart.

7. When trafc across the dock leveler has ceased

the operator must return the EOD Leveler to its stored

position.

!WARNING

IMPORTANT

The lip plate must overlap the transporter vehicle

load bed by a minimum of 4” (100mm) full width.

!WARNING

The vehicle should never be allowed to depart

with the lip plate resting on the load bed.

!WARNING

10. The comfort grip handle is then returned to the

stored position. The dock is once again available for

use.

10 MD-CM 01/02/2008 (Part # 411-253-0)

MAINTENANCE

Routine Servicing And Maintenance

Regular maintenance and care of the equipment is

very important for cost and operation efciency and

more importantly operator safety. Faulty equipment is a

potential source of danger to the operator, and to other

personnel working near it. As with all quality equipment,

keep the equipment in good operating condition by

following the recommended schedule of maintenance.

Failure to do so will void the manufacturer’s warranty.

Authorize Usage

The importance of this procedure is emphasized in this

manual with a brief review and later with more detailed

instructions. For more information regarding authorize

usage contact manufacture.

Available support by dealer/distributor:

• Equipment usage training and authorization

• Workplace practical guide for safe use of this product

• Ease of service; inspection and planned maintenance

• Equipment daily inspection check list

GREASE FITTINGS

DECK HINGE PIVOT POINTS

KICKER BAR

ADJUSTMENT

NUT

Figure 6 : Mechanical Edge-Of-Dock Leveler - Lubrication Points

Do not work under or around the dock leveler

without rst placing adequate barriers to posi-

tively prevent vehicle trafc from entering the

work area.

Never attempt to perform repairs. Always defer

repairs to a qualied service technician.

!WARNING

Maintenance Sequence

1. Cleaning, including surrounding area.

2. Visual inspection of all components.

3. Lubrication as required.

4. Test operate all functions.

5. Adjustments if required.

11

MD-CM 01/02/2008 (Part # 411-253-0)

MAINTENANCE

A

A

1

2

DIM A

SECTION A-A

SCALE 1 : 4

Note: Dim. A is for general reference only.

12 MD-CM 01/02/2008 (Part # 411-253-0)

TROUBLE SHOOTING

Problem Cause and Solution

EOD Leveler requires more effort than usual when raised

to position.

• Adjustment of Extension Springs required

- Increase tension of both springs equally

Note: Increase spring tension only enough to provide

usual lifting effort

When pulling the comfort grip handle up to raise the

EOD into position, the lip does not remain horizontal as

deck is pushed forward.

Lip does not deploy onto vehicle bed.

• Lip Kicker Bar did not swing into position over xed

block

• Adjust adjusting screw outward to raise lip and allow

lock bar to swing into position over block

• Lip Kicker bar binding at mounting bracket. Bar must

swing freely

• Lubricate or straighten

Lip Kicker Bar does not swing down to release position

when unit is lowered onto vehicle bed.

• Kicker bar is binding in its mounting bracket

- Lubricate or straighten. Bar must swing freely

Lip remains partially extended after vehicle drives away. • Lip hinge has seized up

- Free up and lubricate

Lip hits back of vehicle rst.

• Adjust adjusting screw to provide clearance

See page 12 & 13 for Component Identication

• Bumper worn out; replace Bumper.

13

MD-CM 01/02/2008 (Part # 411-253-0)

REPLACEMENT PARTS

MECHANICAL MDC SERIES: ALL MODELS

16 1719 321

12

10 17

14

4

15

7

6

8

5

9

18

11

21

13 20

14 MD-CM 01/02/2008 (Part # 411-253-0)

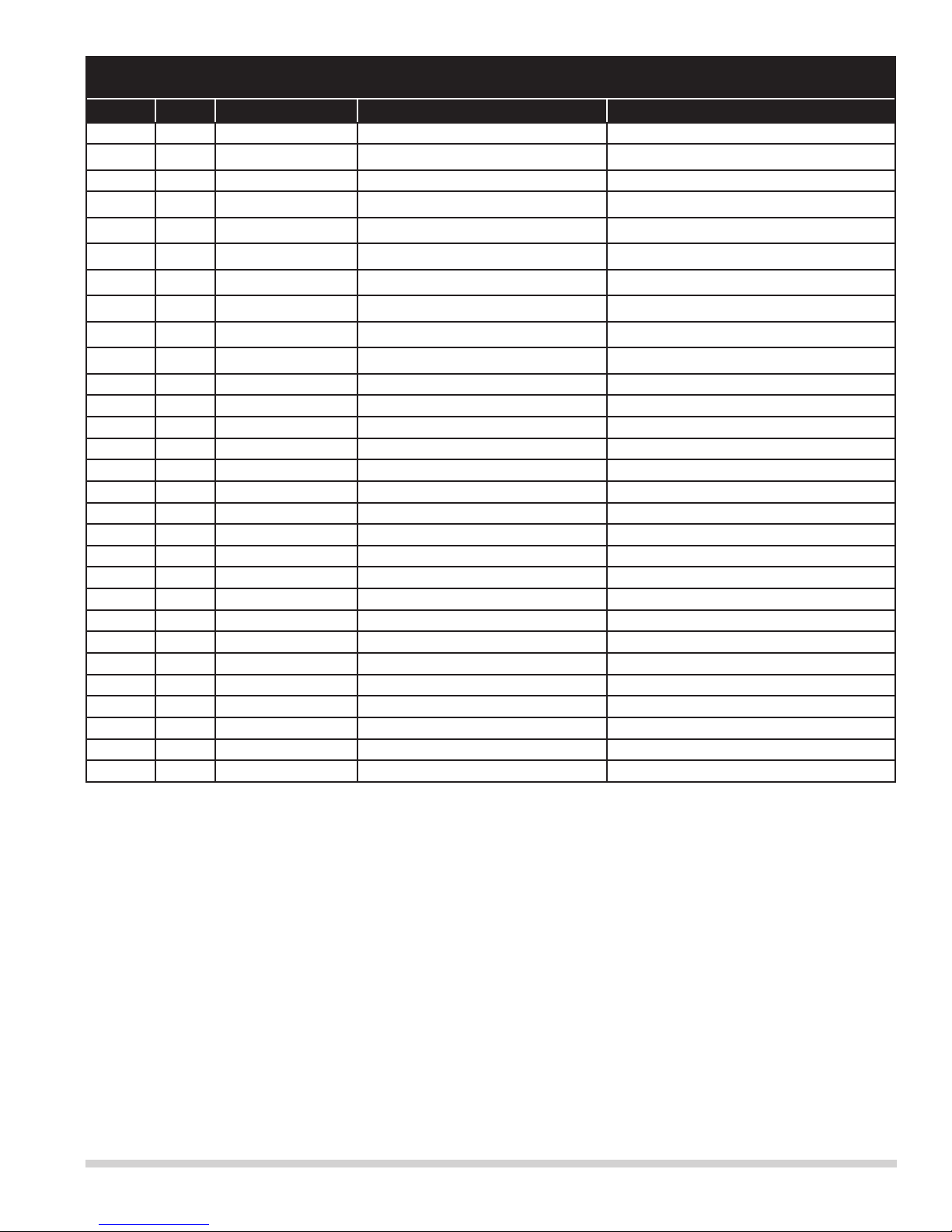

AVAILABLE REPLACEMENT PARTS

ITEM QTY PART NUMBER GENERAL DESCRIPTION SPECIFIC DESCRIPTION

1 1 017-083 TENSION SPRING ALL MODELS EXCEPT MDC6620

017-061 TENSION SPRING MDC6620M (15" & 17" LIP)

2 1 017-083 TENSION SPRING MDC7225M (15" & 17" LIP)

MDC7230M (15" & 17" LIP)

MDC7825M (15" & 17" LIP)

MDC7830M (15" & 17" LIP)

017-061 TENSION SPRING MDC6620M (15" & 17" LIP)

MDC6625M (15" & 17" LIP)

MDC6630M (15" & 17" LIP)

MDC7220M (15" & 17" LIP)

3 3 200-01573 EXTENSION BAR ALL MODELS

4 1 252-0024-2 KICKER BAR ASSY. ALL MODELS

5 1 010-067 CAP SCREW ALL MODELS

6 1 200-01585-1 HANDLE TUBING ALL MODELS

7 1 200-01570 TUBE CAP ALL MODELS

8 1 250-0001 PIN ALL MODELS

9 2 013-020 SPRING PIN ALL MODELS

10 2 110-886 BUMPER ALL MODELS

11 2 300-170 CLEVIS PIN ALL MODELS

12 2 013-006 SPRING PIN ALL MODELS

13 4 010-086 CAP SCREW ALL MODELS

14 4 012-214 WASHER ALL MODELS

15 4 011-510 NUT ALL MODELS

16 2 010-083 CAP SCREW ALL MODELS

17 4 105-882 FLAT WASHER ALL MODELS

18 3 011-552 LOCK NUT ALL MODELS

19 1 200-01572 SPRING SHAFT ALL MODELS

20 4 012-222 LOCK WASHER ALL MODELS

21 2 013-012 SPRING PIN ALL MODELS

15

MD-CM 01/02/2008 (Part # 411-253-0)

NOTES

16 MD-CM 01/02/2008 (Part # 411-253-0)

NOTES

17

MD-CM 01/02/2008 (Part # 411-253-0)

WARRANTY

The Manufacturer’s Base Warranty policy, as posted on manufactures web site, applies at time of warranty claim to the following Product Classes

as listed below. Additional warranties for the following Product Classes, as listed below, may apply if pre-authorized and approved by manufac-

turer (please contact manufacturer for further information). Visit manufacturer’s web site for our current warranty policies.

BASE WARRANTY

The manufacturer warrants to the original purchaser of the loading dock equipment purchased from the manufacture to be free from defective

material and workmanship under normal use for a period of 1 year (365 days). Manufacturer warrants all electrical components (electrical con-

trols, switches, etc.) purchased from the manufacture to be free from defective in material and workmanship under normal use for a period of

ninety (90) days, subject to accepted Non-Conformance Report (NCR). All warranty coverage is to commence from the date of receipt by the rst

end user or sixty (60) days after date of shipment, whichever comes rst. Purchaser agrees upon the manufacturer’s standards of use as listed

below:

1) Product selection and usage based in regards to rated capacities, duty cycle limitations, grade limitations and/or design

specic application(s) requirements.

2) Product to be properly installed per manufacturer’s instructions, by manufacturer trained personnel.

a. The proper initial eld set-up, adjustment and lubrication are the sole responsibility of the end user, at time of installation.

3) Product to be properly maintained per manufacturer’s instructions, by manufacturer trained personnel.

a. Maintenance is not covered under this warranty and is the sole responsibility of the end user.

4) Product usage and operation must be per manufacturers instructions.

a. Product usage and operation training is the sole responsibility of the authorized manufacturer Service Company

5) No warranty is available for wear items as determined by the manufacturer (example: pins, bushings, cylinder(s), etc.).

6) Product usage and operation must be per manufacturers instructions.

a. Product usage and operation training is the sole responsibility of the authorized manufacturer Service Company.

The Warranty Registration Form must be completed in full and returned to the manufacturer within sixty (60) days of receipt in order for the

warranty to be deemed valid.

The manufacturer shall remedy any defects deemed covered under this warranty by replacing or repairing any defective equipment or parts

while incurring reasonable expenses, as determined by manufacturer, for all parts, labor and freight unless otherwise stated herein. Freight

expenses for shipping repair/replacement parts will be incurred under conditions of standard shipping terms. Any overnight or special freight

requirements will be billed to the end user or authorized dealer as recognized by the manufacturer.

Any Original Equipment Manufactured (OEM) part that is replaced during the Base Warranty time period will be either: further covered for the

remainder of the Base Warranty time period, or for a further 90 days: whichever is longer.

ADDITIONAL WARRANTY TIME PERIODS:

Parts or components which fail under normal usage and are proven to be defective will be deemed eligible for repair or replacement, (providing

no special conditions apply, as stated below) providing the failure occurs within the Additional Warranty Time Period of a given Product Class as

stated below. Replacement parts will be supplied F.O.B. factory.

Edge-Of-Dock Leveler, no further coverage beyond the expiration of the Base Warranty time period of one (1) year parts, labor and freight.

WARRANTY CLAIMS AND VALIDATION:

1) Authorization must be given by manufacturer, prior to any “corrective” work is undertaken.

a. Upon manufacturer’s approval of “corrective” work, authorized manufacturer Service Company is required to make

complete repairs.

i. Authorized manufacturer Service Company location is to be within 125 miles/200 kilometers from customer location,

unless pre-authorized in writing by manufacturer.

b. Manufacturer’s warranty claim form is then required to be completed.

i. Warranty form is required to be sent to the manufacturer within thirty (30) days of claim.

1. Manufacturer at its discretion may require and request further information:

a. Documentation i.e., service orders, invoices, etc...

b. Photographs of defective and/or repaired product and/or components.

c. Manufacturer at its discretion may require and request return of all defective parts.

i. Requires manufacturers authorized Service Company to request RGA (return goods authorization) approval, prior to

return of defective parts to manufacturer.

1. Return of completed RGA and/or defective parts is within thirty (30) days of request.

2) Manufacture at its discretion may require and request site inspection at any given time it deems it is required, to better provide

greater details that have not been met as stated above.

WARRANTY IS VOID IF:

1) Warranty Registration Form is not completed and returned to the manufacturer within sixty (60) days of receipt.

2) The original purchaser does not notify the manufacturer of the defect within ninety (90) days after the defect has been detected.

3) Equipment is modied in any manner not approved by the manufacturer.

4) Equipment unauthorized conditions of use:

• operated beyond its rated capacity,

• in excess of its determined duty cycle,

• operated in excess of its determined maximum grade,

• Or combination of the above therein, which can directly be attributed to be the cause of failure.

5) Equipment is used in abrasive, corrosive, and/or conditions of excessive cold /moisture without having been factory specied to be engineered to

withstand such conditions.

18 MD-CM 01/02/2008 (Part # 411-253-0)

19

MD-CM 01/02/2008 (Part # 411-253-0)

WARRANTY

NO WARRANTY IS AVAILABLE FOR THE FOLLOWING:

1) No warranty claim is available for normal maintenance, including initial eld set-up and adjustments (i.e., lubrication, adding oil, etc.).

2) Wear items as determined by manufacturer (example: pins, bushings), etc.). Contact manufacturer for complete listing.

3) Repairs required as a result of:

• Failure to follow maintenance and/or lubrication procedures specied in the owner’s manual.

• Abuse, willful damage, accident, neglect, and/or beyond contemporary weather

• Shipping damage. (Claim must be made with the freight carrier)

4) Rental equipment and/or standard installation and service tools, unless approved by the manufacturer.

THE MANUFACTURER DOES NOT ASSUME RESPONSIBILITY OR LIABILITY FOR INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES, OR FOR LOSS OF PROFIT OR DAMAGE TO TRADE OR BUSINESS WHICH RESULTS FROM THE

EQUIPMENT.

THE ABOVE WARRANTIES ARE IN LIEU OF ANY OTHER WARRANTIES, EITHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION CONTAINED HEREIN.

© 2008 Blue Giant Equipment Corporation

85 HeartLakeRoadSouth

Brampton, Ontario, Canada L6W3K2

Phone: 905-457-3900 Fax: 905-457-2313

•

www.BlueGiant.com

BLUE GIANT EQUIPMENT CORPORATION

MD-CM 01/02/2008 (Part # 411-253-0)

This manual suits for next models

7

Table of contents