5

5

STEP 1. MOUNT THE LIGHTS

1. Remove the nyloc nut and M10 washer from M10

x 35mm bolt attached to the bottom of mounting

bracket

2. Locate the bracket in a suitable position

using the M10 x 35mm bolt. It is

recommended that the base area of the mounting

bracket is totally supported

3. Align the light to preferred driving position

4. Fit the washer and M10 nyloc nut, then tighten

using a 17mm socket and ratchet to specied

torque (26lb-ft). Do not use rattle guns

5. Tighten 2 x M10 x 35mm side bolts to

recommended torque (35Nm).

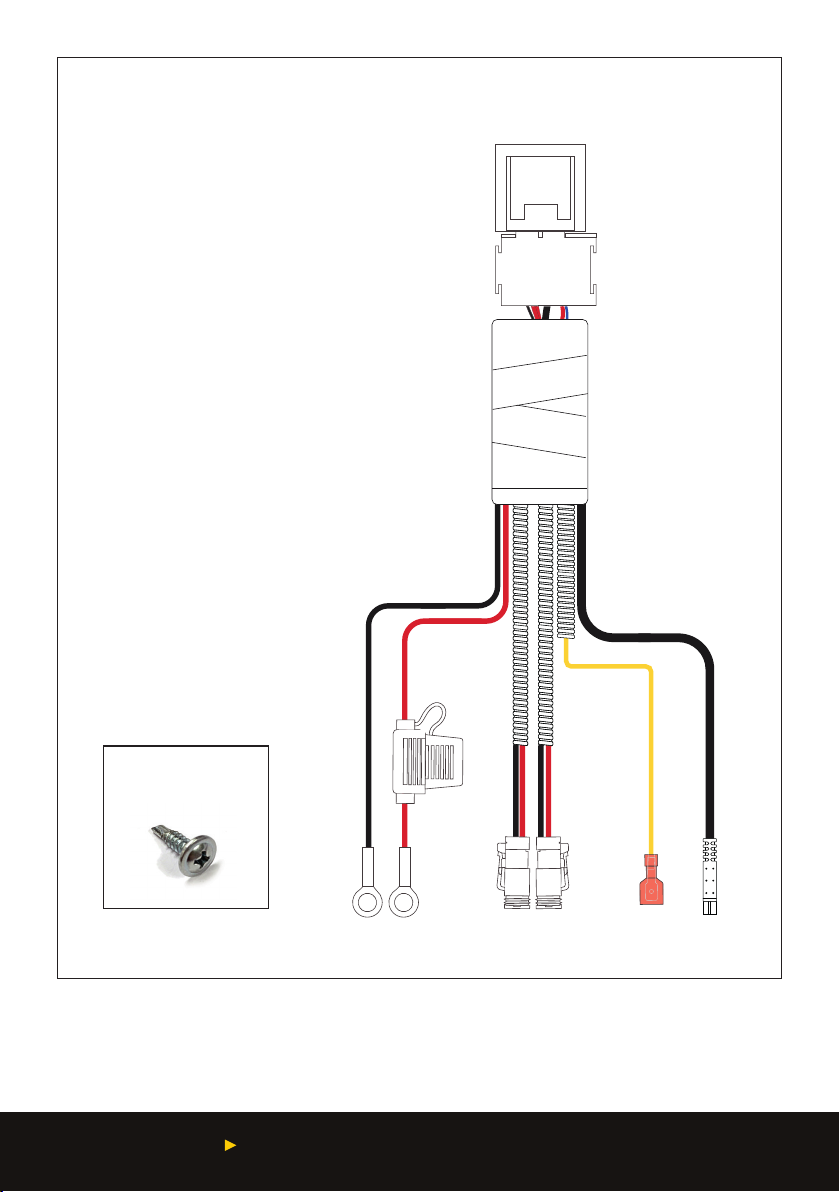

WIRING HARNESS INSTALLATION

STEP 2. INSTALL THE RELAY AND

CONNECT THE LIGHTS

1. Lay out the harness to check length and

positioning

2. Remove the main ground wire from the negative

battery terminal. WARNING: This may result in

loss of radio security code and clock settings.

Please consult your owner’s manual before

disconnecting

3. Mount the 40 amp relay (see gure 1) in a suitable

place within the engine bay, using the screw

supplied (gure 2) and your drill with a Phillips

head driver bit. Ensure that the red (positive)

and black (negative) ring terminals reach the

appropriate battery terminals. DO NOT CONNECT

RING TERMINALS TO THE BATTERY AT THIS

STAGE

4. Route the insulated sleeved wires that run from

the relay to the driving light connectors to each

of your installed Striker LED Driving Lights and

connect the driving light connectors to the back

of each light. Ensure that cables do not touch the

radiator or come in contact with any sharp edges

5. Secure all excess wire to the vehicle with cable

ties supplied.

NOTE: If you are using a different switch

with dash illumination (not included), a

Lightforce Switch Adaptor (not included,

see Figure 9) will be required. Follow the

instructions included with the Lightforce

Switch Adaptor. The yellow dash illumination

cable (item 8 in gure 1) will need to be wired

to the dash light / park light circuit.