Lika SME1 User manual

SME1 –SME2 –SME5

MAN SMEx I_E 1.0 5www.lika.it

www.lika.biz

User manual

SME1, SME2, SME5

Chapters

1 Safety summary

2 Identification

3 Installation

4 Output signals

5 Electrical connections

6 Dimensional drawing

7 Maintenance

8 Troubleshooting

Description

This manual describes products of the SME1, SME2,

SME5 series. The purpose of these sensors is to

measure linear or angular displacements on

industrial machines and automation systems. The

measurement system includes a magnetic tape and

a magnetic sensor. The tape has alternating

magnetic north/south poles are magnetized at a

certain distance called the pole pitch. As the sensor

is moved along the magnetic tape (or magnetic

ring), it detects the displacement and produces an

output signal equivalent to that of an incremental

encoder or a linear scale. The flexibility of the tape

allows it to be used for both linear and angular

applications.

The sensor has to be matched with the appropriated

magnetic tape (see chap. 2.1).

1 -Safety summary

We strongly recommend carefully reading this user

manual and following the installation guidelines:

•Sensor head should be installed as close as

possible to your control unit.

•Always use shielded cables and twisted if

possible.

•Avoid running the sensor cable near high

voltage power cables (e.g. drive cables).

•Install EMC filters on sensor power supply if

needed.

•Avoid mounting sensor head near capacitive or

inductive noise sources such as relays, motors,

and switching power supplies.

Connect according to the supplied pin-out.

2 -Identification

The sensor can be identified by the label's data

(ordering code, serial number). This information is

listed in the delivery document. All technical

features according to the ordering code are shown

on the catalogue.

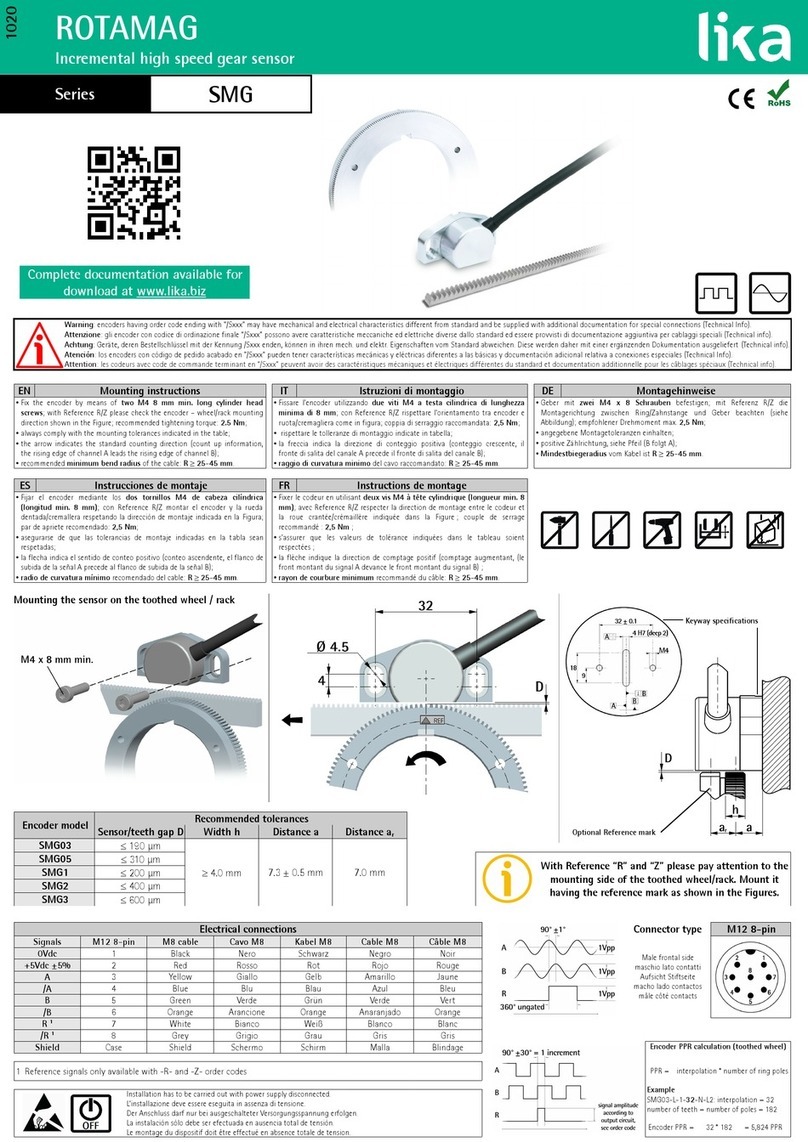

2.1 Sensor and tape combinations

Sensor Magnetic tape

SME1 MT10

SME2 MT20

SME5 MT50

3 -Installation

Install the product according to the protection level

provided.

Protect the system against knocks, friction, solvents,

temperatures under -10°C (14°F) and over +70°C

(+158°F).

Be sure that the system is mounted where hard or

sharp objects (e.g. metal chips) do not come into

contact with the magnetic scale and the bottom of

the sensor head. If these conditions cannot be

avoided provide a wiper or pressurized air.

Sensor can be fixed by means of two M3 screws

over the buttonholes. Make sure that the gap

between sensor and tape is in respect with (fig. 8)

along the total measuring length. Avoid contact

between the parts. You can check planarity and

parallelism between sensor and magnetic tape using

a feeler gauge. The max. allowed gap (D) is listed in

chap. 2.1.

SME1 –SME2 –SME5

MAN SMEx I_E 1.0 6www.lika.it

www.lika.biz

3.1 Mounting tolerances

Sensor

Gap

Sensor/Magnetic tape

(D)

SME1 0,4 mm

SME2 1,0 mm

SME5 2,0 mm

3.2 Mounting gap with Reference

The sensor lights on when the reference output is

active.

Sensor

Gap

Sensor/LKM1309

(D)

SME1 0,1 –0,2 mm

SME2 0,1 –0,8 mm

SME5 0,1 –2,4 mm

3.3 Mounting position with magnetic rings

Sensor

Gap

Sensor/Magnetic ring

(D)

SME1 0,4 mm

SME2 1,0 mm

SME5 2,0 mm

For mounting tolerances refer to paragraph 3.1

4 -Output signals

4.1 Index “I”

With ordering code “N” the output signal "I" is not

available.

SME1 –SME2 –SME5

MAN SMEx I_E 1.0 7www.lika.it

www.lika.biz

4.2 Index “R”

With ordering code "R" and in combination with

LKM-1309

As the sensor is moved along the magnetic tape, it

detects the displacement and produces an output

signal equivalent to that of an incremental encoder

or a linear scale. The signal output is proportional

to the measuring speed and to the displacement of

the sensor. Resolution after quadrature (4 edge

reading) can be determined by the ordering code on

the sensor.

5 -Electrical connections

Output Colour

Ayellow

/A blue

Bgreen

/B orange

0white

/0 grey

GND black

+Vdcred

* see ordering code

"1" = +5Vdc ± 5%

"2" = +10Vdc +30Vdc

Note: All sensors can have inverted signals.

A = A signal

/A = inverted A signal (or complementary signal)

All our magnetic sensors can have A, /A, B, /B, 0, /0

output signals. We recommend always connecting

the inverted signals if the receiving device will

accept them. Otherwise each output should be

insulated separately.

ATTENTION: connecting /A, /B, or /0 together, to

+Vdc or 0Vdc may cause permanent damage to the

sensor.

5.1 Specifications of the cable

Wires : 6 x 0.14mm2+ 2 x 0.24mm2

Screening : Copper

External Ø : Ø 5.2 mm ± 0.2 mm (Ø 0.2 in ± 0.01in)

Impedance : 6 x 145 Ω, 2 x 87 Ω

Notes:

•While connecting, power must be switched OFF;

•Check correct connections before switching ON;

•We recommend that the sensor head be

mounted as far as possible from any capacitive

or inductive noise source such as motors, relays

and switching devices;

•Avoid routing the sensor cable near high voltage

power cables in order to reduce influences of

electric noise;

•Only use shielded cables and wire with a cross

section between 0,14mm2and 0,5 mm2

•The shield of the cable and 0Vdc wire should be

connected to ground (GND);

•Electric noise sources should be linked with

noise suppression filters;

•Total length of connection cable from sensor to

receiving device should not exceed 50 m (55').

SME1 –SME2 –SME5

MAN SMEx I_E 1.0 8www.lika.it

www.lika.biz

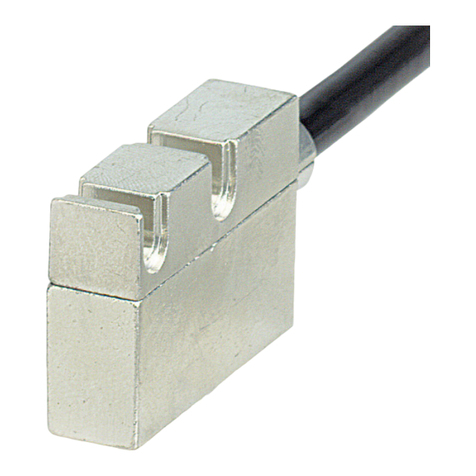

6 -Dimensional drawing

7 -Maintenance

The magnetic measurement system doesn't need

any particular maintenance but as with all precision

devices it must be handled with care. From time to

time we recommend the following operations:

•Check the gap between sensor and magnetic

tape along the measuring length. Wear of the

machine may increase the tolerances.

•The surface of the magnetic tape should

occasionally be cleaned using a soft cloth to

remove dust, chips, moisture etc.

8 -Troubleshooting

The following list shows some typical errors that

occur during installation and operation of the

magnetic measurement system.

Problem:

The system doesn't work (no pulse output):

•The tape or sensor has been mounted incorrectly

(the active part of the tape doesn't face the

sensor's active side).

•A magnetic piece or tape is in between the

sensor and the tape. Only non-magnetic

materials are allowed between sensor and tape.

•The sensor touches the tape because tolerance

gap between sensor and tape are not observed.

Check sensor's active side if damaged.

•The sensor has been damaged by short circuit or

wrong connection.

Problem:

The measured values are inaccurate:

•The gap between sensor and tape is not

observed along the total measurement length.

•The connection cable runs near to high voltage

cable or shield is not connected correctly. See

chap. 6.

•The max. counting frequency of your receiving

device is too low.

•A section of the magnetic tape has been

damage mechanically or magnetically along the

measuring length

•The measuring error is caused by torsion of the

machine structure. Check parallelism and

symmetry of machine movement.

Lika Electronic

Via S. Lorenzo, 25 –36010 Carrè (VI) -Italy

Tel. +39 0445 382814

Fax +39 0445 382797

This manual suits for next models

2

Other Lika Accessories manuals