Lilliput Owon XDS2000 Series User manual

XDS2000 Dual-Channel Series

Digital Storage Oscilloscopes

User Manual

www.owon.com.cn

Apr. 2018 edition V1.0.0

Copyright © LILLIPUT Company. All rights reserved.

The LILLIPUT's products are under the protection of the patent rights, including ones which have

already obtained the patent rights and those which are applied for. The information in this manual will

replace all materials published.

The information in this manual was correct at the time of printing. However, LILLIPUT will continue

to improve products and reserves the rights to change specification at any time without notice.

is the registered trademark of the LILLIPUT Company.

Fujian LILLIPUT Optoelectronics Technology Co., Ltd.

No. 19, Heming Road

Lantian Industrial Zone, Zhangzhou 363005 P.R. China

Tel: +86-596-2130430 Fax: +86-596-2109272

Web: www.owon.com.cn E-mail: [email protected]

General Warranty

OWON warrants that the product will be free from defects in materials and workmanship

for a period of 3 years from the date of purchase of the product by the original purchaser

from the OWON Company. The warranty period for accessories such as probes is 12

months. This warranty only applies to the original purchaser and is not transferable to a

third party.

If the product proves defective during the warranty period, OWON will either repair the

defective product without charge for parts and labour, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by

OWON for warranty work may be new or reconditioned like new. All replaced parts,

modules and products become the property of OWON.

In order to obtain service under this warranty, the customer must notify OWON of the

defect before the expiration of the warranty period. Customer shall be responsible for

packaging and shipping the defective product to OWON's designated service centre, a

copy of the customers proof of purchase is also required.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. OWON shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than OWON representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-OWON supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

Please contact the nearest OWON's Sales and Service Offices for services or a complete

copy of the warranty statement.

For better after-sales service, please visit www.owon.com.cn and register the purchased

product online.

Excepting the after-sales services provided in this summary or the applicable warranty

statements, OWON will not offer any guarantee for maintenance definitely declared or hinted,

including but not limited to the implied guarantee for marketability and special-purpose

acceptability. OWON should not take any responsibilities for any indirect, special or consequent

damages.

i

Table of Contents

1. General Safety Requirements.......................................................................................... 1

2. Safety Terms and Symbols............................................................................................... 2

3. Junior User Guidebook................................................................................................... 4

Introduction to the Structure of the Oscilloscope.....................................................................5

Front Panel ...............................................................................................................................................5

Front Panel Menu Buttons........................................................................................................................6

Rear Panel ................................................................................................................................................6

Control Area.............................................................................................................................................7

User Interface Introduction........................................................................................................8

How to Implement the General Inspection............................................................................. 10

How to Implement the Function Inspection............................................................................ 10

How to Implement the Probe Compensation..........................................................................11

How to Set the Probe Attenuation Coefficient........................................................................ 12

How to Use the Probe Safely.....................................................................................................13

How to Implement Self-calibration..........................................................................................13

Introduction to the Vertical System......................................................................................... 14

Introduction to the Horizontal System....................................................................................15

Introduction to the Trigger System ......................................................................................... 16

4. Advanced User Guidebook............................................................................................ 17

How to Set the Vertical System................................................................................................ 18

Use Mathematical Manipulation Function .............................................................................20

Waveform math......................................................................................................................................21

User defined function.............................................................................................................................22

Digital Filter...........................................................................................................................................22

Using FFT function................................................................................................................................22

Use Vertical Position and Scale Knobs.................................................................................... 25

How to Set the Horizontal System ........................................................................................... 25

Zoom the Waveform ..............................................................................................................................26

How to Set the Trigger/Decoding System................................................................................ 26

Single Trigger.........................................................................................................................................27

Alternate Trigger (Trigger mode: Edge) ................................................................................................35

Logic Trigger..........................................................................................................................................35

Bus Trigger.............................................................................................................................................36

Bus Decoding.........................................................................................................................................42

How to Operate the Function Menu........................................................................................ 46

How to Implement Sampling Setup .......................................................................................................46

How to Set the Display System..............................................................................................................48

ii

How to Save and Recall a Waveform.....................................................................................................50

How to Record/Playback Waveforms ....................................................................................................57

How to Clone a waveform......................................................................................................................61

How to Implement the Auxiliary System Function Setting....................................................................63

How to Update your Instrument Firmware.............................................................................................67

How to Measure Automatically..............................................................................................................68

How to Measure with Cursors................................................................................................................72

How to Use Autoscale............................................................................................................................75

How to Use Built-in Help.......................................................................................................................77

How to Use Executive Buttons...............................................................................................................77

How to Print the Screen Image...............................................................................................................79

5. Communication with PC............................................................................................... 80

Using USB Port..........................................................................................................................80

Using LAN Port.........................................................................................................................81

Connect directly .....................................................................................................................................81

Connect through a router........................................................................................................................82

6. Demonstration ............................................................................................................... 85

Example 1: Measurement a Simple Signal..............................................................................85

Example 2: Gain of a Amplifier in a Metering Circuit.......................................................... 86

Example 3: Capturing a Single Signal..................................................................................... 87

Example 4: Analyze the Details of a Signal............................................................................. 88

Example 5: Application of X-Y Function................................................................................ 90

Example 6: Video Signal Trigger.............................................................................................91

7. Troubleshooting............................................................................................................. 93

8. Technical Specifications................................................................................................ 94

Trigger....................................................................................................................................................96

General Technical Specifications.............................................................................................98

9. Appendix ........................................................................................................................ 99

Appendix A: Enclosure............................................................................................................. 99

Appendix B: General Care and Cleaning ............................................................................... 99

1.General Safety Requirements

1

1. General Safety Requirements

Before use, please read the following safety precautions to avoid any possible bodily

injury and to prevent this product or any other connected products from damage. In

order to avoid any contingent danger, ensure this product is only used within the

range specified.

Only the qualified technicians can implement the maintenance.

To avoid Fire or Personal Injury:

Connect the probe correctly. The grounding end of the probe corresponds to the

grounding phase. Please don't connect the grounding end to the positive phase.

Use Proper Power Cord. Use only the power cord supplied with the product and

certified to use in your country.

Connect or Disconnect Correctly. When the probe or test lead is connected to a

voltage source, please do not connect and disconnect the probe or test lead at random.

Product Grounded. This instrument is grounded through the power cord grounding

conductor. To avoid electric shock, the grounding conductor must be grounded. The

product must be grounded properly before any connection with its input or output

terminal.

When powered by AC power, it is not allowed to measure AC power source

directly, because the testing ground and power cord ground conductor are

connected together, otherwise, it will cause short circuit.

Check all Terminal Ratings. To avoid fire or shock hazard, check all ratings and

markers of this product. Refer to the user's manual for more information about ratings

before connecting to the instrument.

Do not operate without covers. Do not operate the instrument with covers or panels

removed.

Use Proper Fuse. Use only the specified type and rating fuse for this instrument.

Avoid exposed circuit. Do not touch exposed junctions and components when the

instrument is powered.

Do not operate if in any doubt. If you suspect damage occurs to the instrument, have

it inspected by qualified service personnel before further operations.

Use your Oscilloscope in a well-ventilated area. Make sure the instrument installed

with proper ventilation, refer to the user manual for more details.

Do not operate in wet conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

2.Safety Terms and Symbols

2

2. Safety Terms and Symbols

Safety Terms

Terms in this manual. The following terms may appear in this manual:

Warning: Warning indicates the conditions or practices that could result in

injury or loss of life.

Caution: Caution indicates the conditions or practices that could result in

damage to this product or other property.

Terms on the product. The following terms may appear on this product:

Danger: It indicates an injury or hazard may immediately happen.

Warning: It indicates an injury or hazard may be accessible potentially.

Caution: It indicates a potential damage to the instrument or other property might occur.

Safety Symbols

Symbols on the product. The following symbol may appear on the product:

Hazardous Voltage

Refer to Manual

Protective Earth Terminal

Chassis Ground

Test Ground

To avoid body damage and prevent product and connected equipment damage, carefully

read the following safety information before using the test tool. This product can only be

used in the specified applications.

Warning:

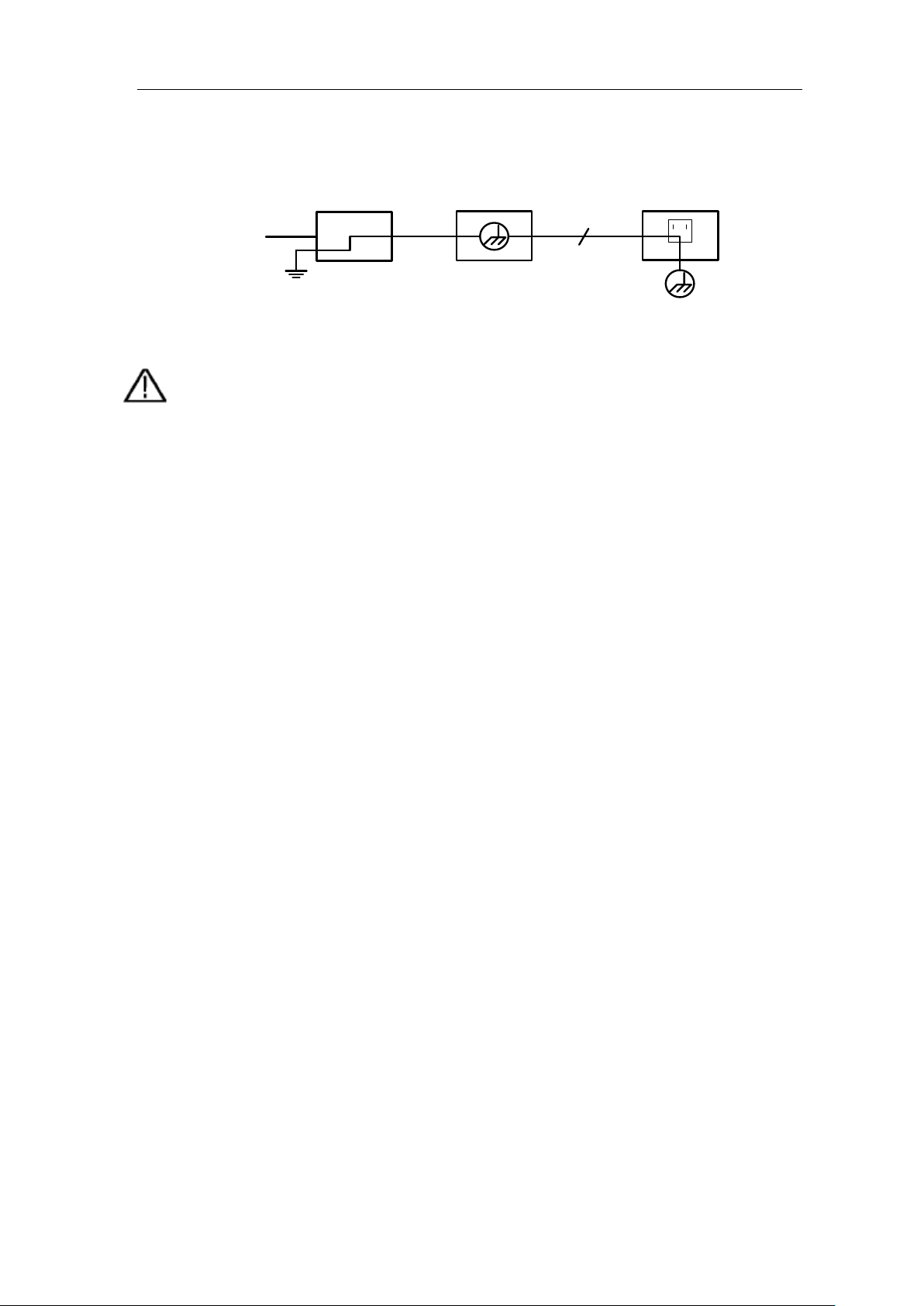

The two channels of the oscilloscope are not electrically isolated. The channels should

adopt a common ground during measuring. To prevent short circuits, the 2 probe

2.Safety Terms and Symbols

3

grounds must not be connected to 2 different non-isolated DC levels.

The diagram of the oscilloscope ground wire connection:

Ground Clip

Signal Input

Oscilloscope Electrical Outlet

Probe

Power Cord

It is not allowed to measureAC power when the oscilloscope is AC powered.

Warning:

To avoid fire or electrical shock

, when the oscilloscope input signal

connected

is more than

42V peak (30Vrms) or on circuits of more than

4800VA

, please take note of below items:

Only use accessory insulated voltage probes and test lead.

Check the accessories such as probe before use and replace it if

there are any damages.

Remove probes, test leads and other accessories immediately after

use.

Remove USB cable which connects oscilloscope and computer.

Do

not apply input voltages above the rating of the instrument

because the probe tip voltage will directly transmit to the

oscilloscope. Use with caution when the probe is set as 1:1.

Do not use exposed metal BNC or banana plug connectors.

Do not insert metal objects into connectors.

3.Junior User Guidebook

4

3. Junior User Guidebook

This chapter deals with the following topics mainly:

Introduction to the structure of the oscilloscope

Introduction to the user interface

How to implement the general inspection

How to implement the function inspection

How to make a probe compensation

How to set the probe attenuation coefficient

How to use the probe safely

How to implement an auto-calibration

Introduction to the vertical system

Introduction to the horizontal system

Introduction to the trigger system

3.Junior User Guidebook

5

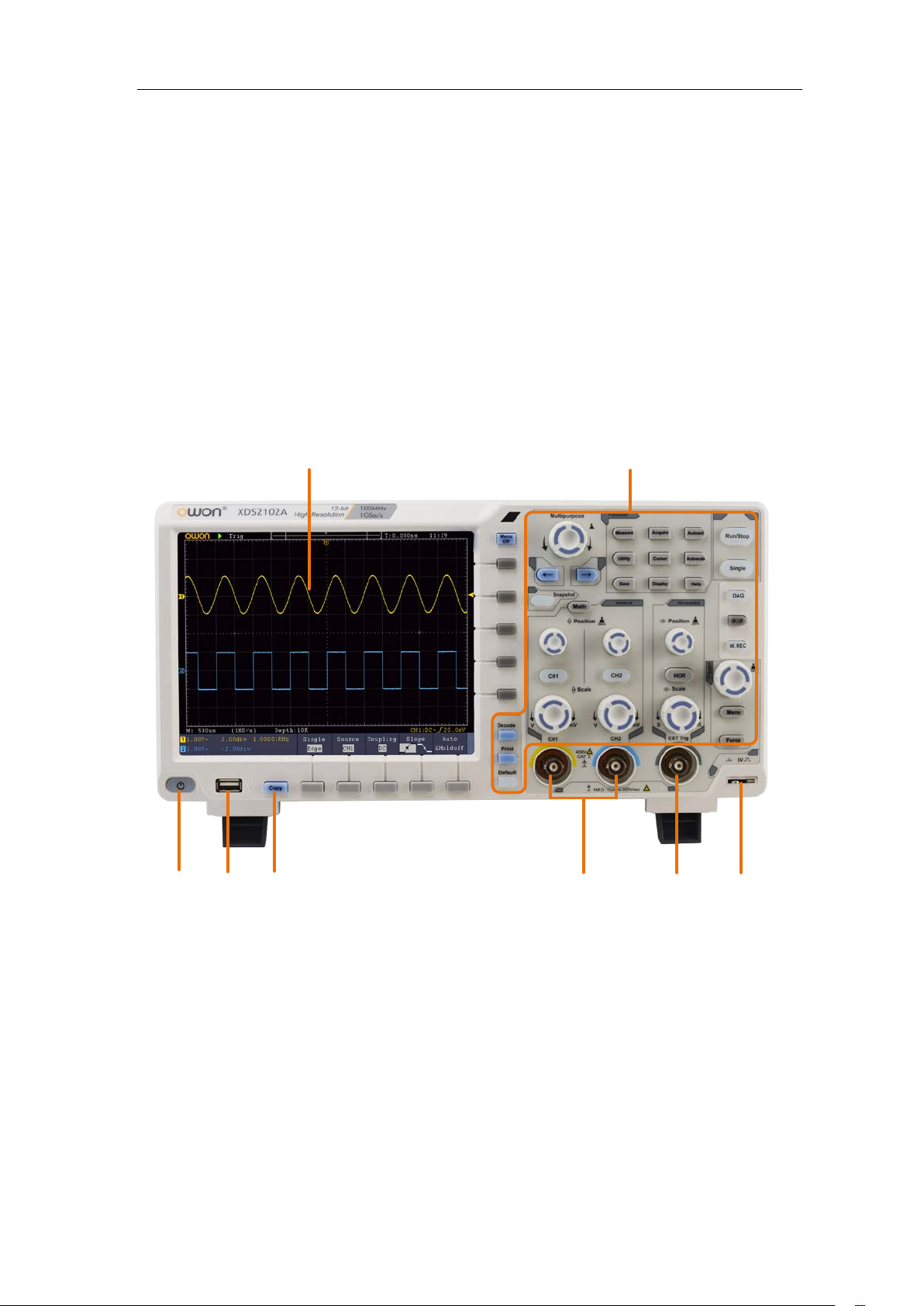

Introduction to the Structure of the Oscilloscope

This chapter makes a simple description of the operation and function of the front panel of

the oscilloscope, enabling you to be familiar with the use of the oscilloscope in the

shortest time.

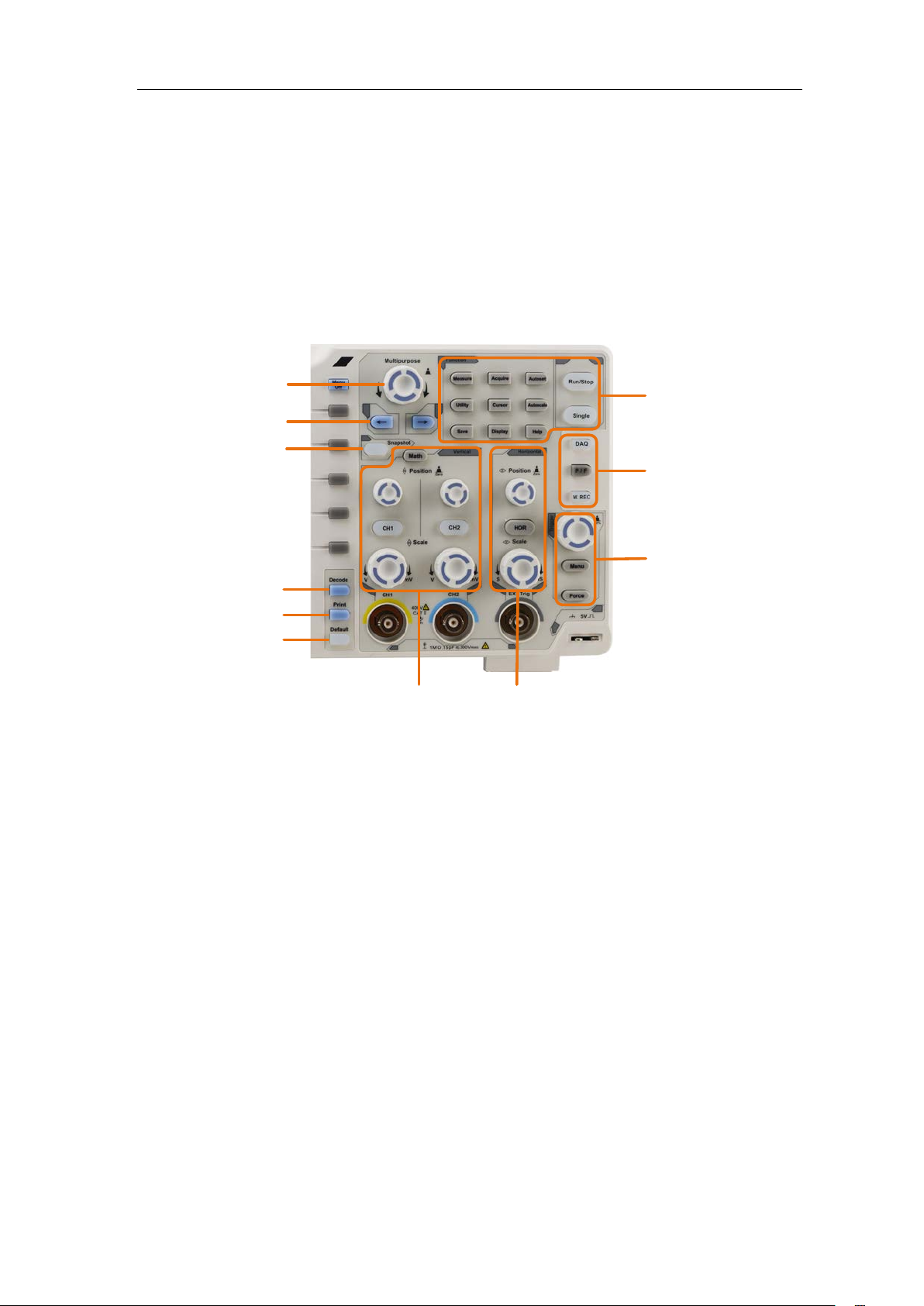

Front Panel

The front panel has knobs and function buttons. The 5 buttons in the column on the right

side of the display screen or in the row under the display screen are menu selection

buttons, through which, you can set the different options for the current menu. The other

buttons are function buttons, through which, you can enter different function menus or

obtain a specific function application directly.

8

2

53

74

6

1

Figure 3-1 Front panel

1. Display area

2. Control (button and knob) area

3. Probe Compensation: Measurement signal (5V/1kHz) output.

4. EXT Trigger Input

5. Signal Input Channel

6. Copy button: You can save the waveform by just pressing this button in any user

interface.

7. USB Host port: It is used to transfer data when external USB equipment connects to

the oscilloscope regarded as "host device". For example: Saving the waveform to USB

flash disk needs to use this port.

3.Junior User Guidebook

6

8. Power on/off

Backlight of this button:

Red light: The oscilloscope is turned off (connects with AC Power);

Green light: The oscilloscope is turned on (powered by AC Power).

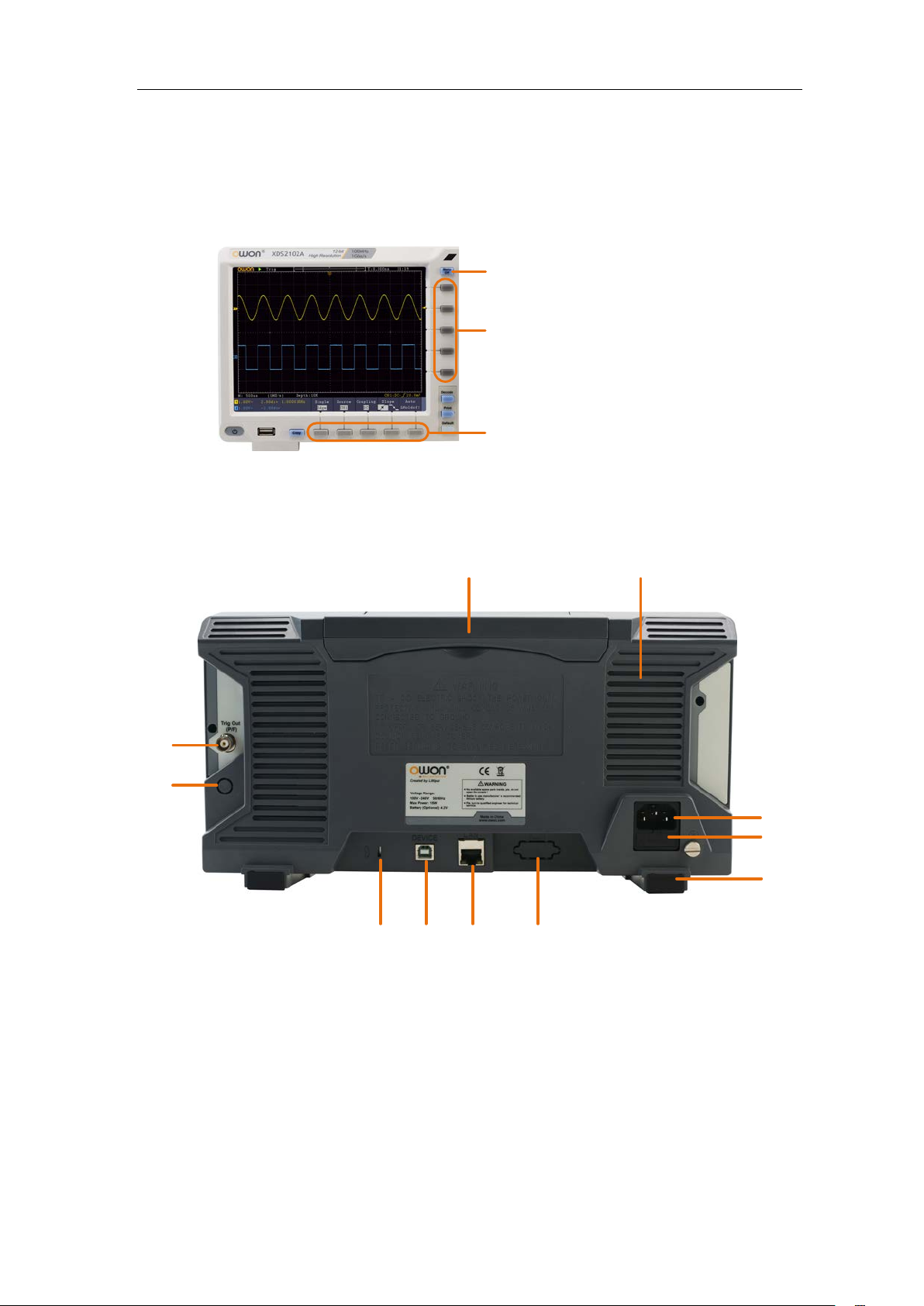

Front Panel Menu Buttons

Select the right menu item

Select the bottom menu item

Remove the left and right menu

Figure 3-2 Menu Buttons

Rear Panel

987 6

11

12

5

3

4

10

Figure 3-3 Rear Panel

1. Handle

2. Air vents

3. AC power input jack

4. Fuse

5. Foot stool: Adjust the tilt angle of the oscilloscope.

6. VGA port: To connect the oscilloscope with a monitor or a projector as VGA output

(optional).

7. LAN port: the network port which can be used to connect with PC.

3.Junior User Guidebook

7

8. USB Device port: It is used to transfer data when external USB equipment connects to

the oscilloscope regarded as "slave device". For example: to use this port when

connect PC to the oscilloscope by USB.

9. Lock Hole: You can lock the oscilloscope to a fixed location using the security lock

(please buy it yourself) to secure the oscilloscope.

10.AV Port: AV signal output port (optional).

11.Trig Out(P/F) port: Trigger signal output or Pass/Fail output.

Control Area

8

7

6

1

2

3

11

10

54

9

Figure 3-4 Control Area Overview

1. Function button area: Total 11 buttons

2. DAQ: Multimeter Recorder (This function is not available in XDS2000 series.)

P/F: Pass/Fail

W.REC: Waveform Record

3. Trigger control area with 2 buttons and 1 knob.

The Trigger Level knob is to adjust trigger voltage. Other 2 buttons refer to trigger

system setting.

4. Horizontal control area with 1 button and 2 knobs.

"HOR" button refer to horizontal system setting menu, "Horizontal Position" knob

control trigger position, "Horizontal Scale" control time base.

5. Vertical control area with 3 buttons and 4 knobs.

"CH1" and "CH2 " correspond to setting menu in CH1 and CH2, "Math" button refer

to math menu, the math menu consists of six kinds of operations, including CH1-CH2,

CH2-CH1, CH1+CH2, CH1*CH2, CH1/CH2 and FFT. Two "Vertical Position" knob

control the vertical position of CH1/CH2, and two "Scale" knob control voltage scale

of CH1, CH2.

3.Junior User Guidebook

8

6. Default: Call out the factory settings.

7. Print

8. Turn on/off Decode function.

9. Snapshot

10.Direction key:Move the cursor of the focused parameter.

11.Mknob (Multipurpose knob): when a symbol appears in the menu, it indicates

you can turn the M knob to select the menu or set the value. You can push it to close

the menu on the left and right.

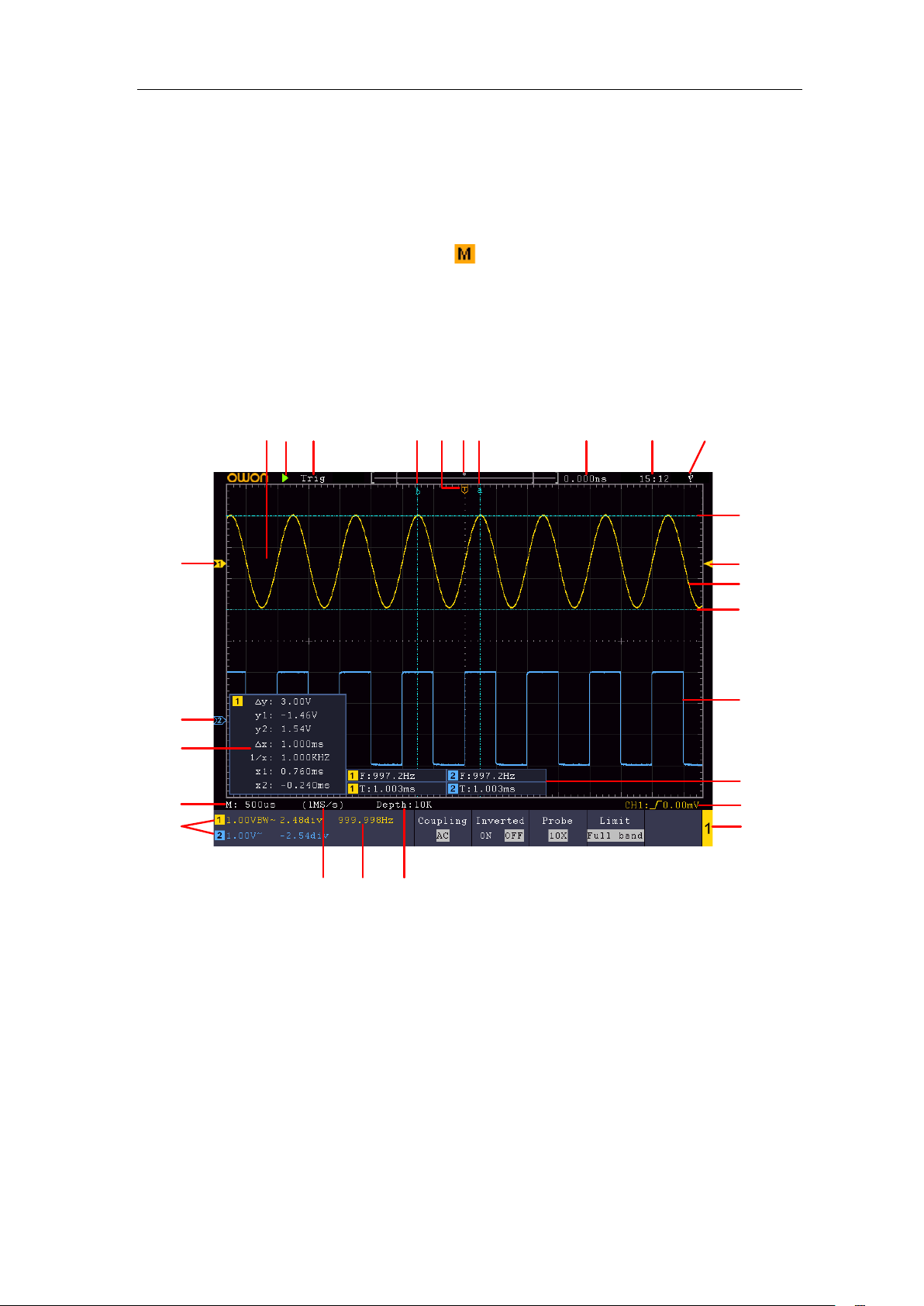

User Interface Introduction

13

15

10

23

20

6789

12

13

16

17

18

22

24

5

14

21

24

19

11

4

12

Figure 3-5 Illustrative Drawing of Display Interfaces

1. Waveform DisplayArea.

2. Run/Stop

3. The state of trigger, including:

Auto: Automatic mode and acquire waveform without triggering.

Trig: Trigger detected and acquire waveform.

Ready: Pre-triggered data captured and ready for a trigger.

Scan: Capture and display the waveform continuously.

Stop: Data acquisition stopped.

4. The two blue dotted lines indicates the vertical position of cursor measurement.

3.Junior User Guidebook

9

5. The T pointer indicates the horizontal position for the trigger.

6. The pointer indicates the trigger position in the record length.

7. It shows present triggering value and displays the site of present window in

internal memory.

8. It shows setting time.

9. It indicates that there is a USB disk connecting with the oscilloscope.

10. The pointer shows the trigger level position.

11. The waveform of CH1.

12. The two blue dotted lines indicate the horizontal position of cursor measurement.

13. The waveform of CH2.

14. It indicates the measured type and value of the corresponding channel. "T" means

period, "F" means frequency, "V" means the average value, "Vp" the peak-peak

value, "Vr" the root-mean-square value, "Ma" the maximum amplitude value,

"Mi" the minimum amplitude value, "Vt" the Voltage value of the waveform's

flat top value, "Vb" the Voltage value of the waveform's flat base, "Va" the

amplitude value, "Os" the overshoot value, "Ps" the Preshoot value, "RT" the rise

time value, "FT" the fall time value, "PW" the +width value, "NW" the -Width

value, "+D" the +Duty value, "-D" the -Duty value, "PD" the Delay A->B

value, "ND" the Delay A->B value, "TR" the Cycle RMS, "CR" the Cursor

RMS, "WP" the Screen Duty, "RP" the Phase, "+PC" the +Pulse count, "-PC"

the - Pulse count, "+E" the Rise edge count, "-E" the Fall edge count, "AR" the

Area, "CA" the Cycle area.

15. The icon shows the selected trigger type, e.g. represents triggering on the

rising edge for an Edge trigger. The reading shows the trigger level value of the

corresponding channel.

16. Channel identifier of current bottom menu.

17. The readings show the record length.

18. The frequency of the trigger signal.

19. The readings show current sample rate.

20. The readings indicate the corresponding Voltage Division and the Zero Point

positions of the channels. "BW" indicates bandwidth limit.

The icon shows the coupling mode of the channel.

"—" indicates direct current coupling

"~" indicates AC coupling

" " indicates GND coupling

21. The reading shows the setting of main time base.

22. It is cursor measure window, showing the absolute values and the readings of the

cursors.

23. The blue pointer shows the grounding datum point (zero point position) of the

waveform of the CH2 channel. If the pointer is not displayed, it means that this

channel is not opened.

24. The yellow pointer indicates the grounding datum point (zero point position) of

3.Junior User Guidebook

10

the waveform of the CH1 channel. If the pointer is not displayed, it means that

the channel is not opened.

How to Implement the General Inspection

After you get a new oscilloscope, it is recommended that you should make a check on the

instrument according to the following steps:

1. Check whether there is any damage caused by transportation.

If it is found that the packaging carton or the foamed plastic protection cushion has

suffered serious damage, do not throw it away first till the complete device and its

accessories succeed in the electrical and mechanical property tests.

2. Check the Accessories

The supplied accessories have been already described in the "Appendix A: Enclosure"

of this Manual. You can check whether there is any loss of accessories with reference

to this description. If it is found that there is any accessory lost or damaged, please get

in touch with the distributor of OWON responsible for this service or the OWON's

local offices.

3. Check the Complete Instrument

If it is found that there is damage to the appearance of the instrument, or the

instrument can not work normally, or fails in the performance test, please get in touch

with the OWON's distributor responsible for this business or the OWON's local

offices. If there is damage to the instrument caused by the transportation, please keep

the package. With the transportation department or the OWON's distributor

responsible for this business informed about it, a repairing or replacement of the

instrument will be arranged by the OWON.

How to Implement the Function Inspection

Make a fast function check to verify the normal operation of the instrument, according to

the following steps:

1. Connect the power cord to a power source. Long press the button on the

bottom left of the instrument.

The instrument carries out all self-check items and shows the Boot Logo. Push the

Utility button, select Function in the bottom menu. Select Adjust in the left menu,

select Default in the bottom menu. The default attenuation coefficient set value of the

probe in the menu is 10X.

2. Set the Switch in the Oscilloscope Probe as 10X and Connect the Oscilloscope

with CH1 Channel.

Align the slot in the probe with the plug in the CH1 connector BNC, and then tighten

3.Junior User Guidebook

11

the probe with rotating it to the right side.

Connect the probe tip and the ground clamp to the connector of the probe

compensator.

3. Push the Autoset Button on the front panel.

The square wave of 1 KHz frequency and 5V peak-peak value will be displayed in

several seconds (see Figure 3-6).

Figure 3-6 Auto set

Check CH2 by repeating Step 2 and Step 3.

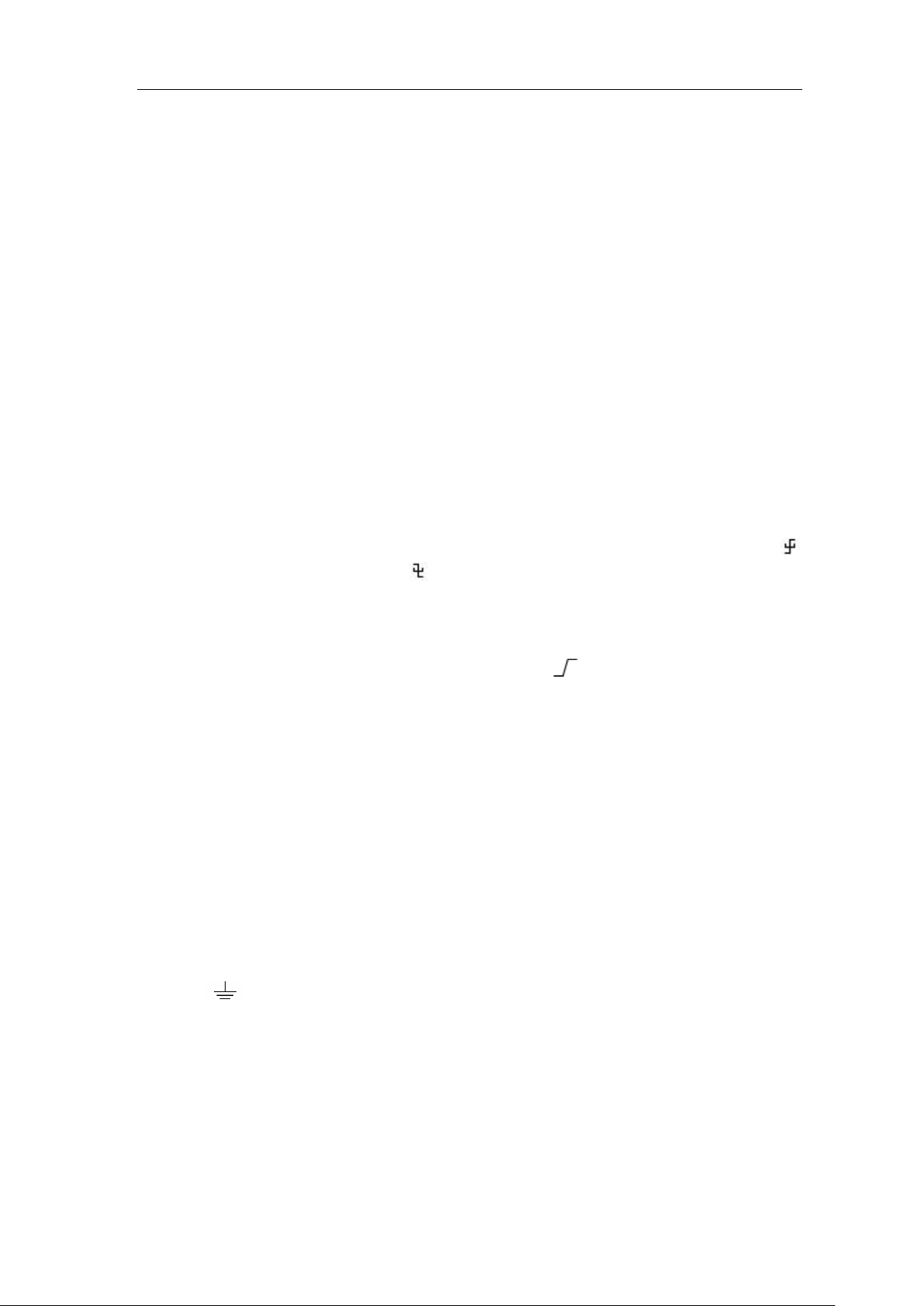

How to Implement the Probe Compensation

When connect the probe with any input channel for the first time, make this adjustment to

match the probe with the input channel. The probe which is not compensated or presents a

compensation deviation will result in the measuring error or mistake. For adjusting the

probe compensation, please carry out the following steps:

1. Set the attenuation coefficient of the probe in the menu as 10X and that of the switch

in the probe as 10X (see "How to Set the Probe Attenuation Coefficient" on P12), and

connect the probe with the CH1 channel. If a probe hook tip is used, ensure that it

keeps in close touch with the probe. Connect the probe tip with the signal connector

of the probe compensator and connect the reference wire clamp with the ground wire

connector of the probe connector, and then push the Autoset button on the front

panel.

2. Check the displayed waveforms and regulate the probe till a correct compensation is

achieved (see Figure 3-7 and Figure 3-8).

3.Junior User Guidebook

12

Overcompensated Compensated correctly Under compensated

Figure 3-7 Displayed Waveforms of the Probe Compensation

3. Repeat the steps mentioned if needed.

Figure 3-8 Adjust Probe

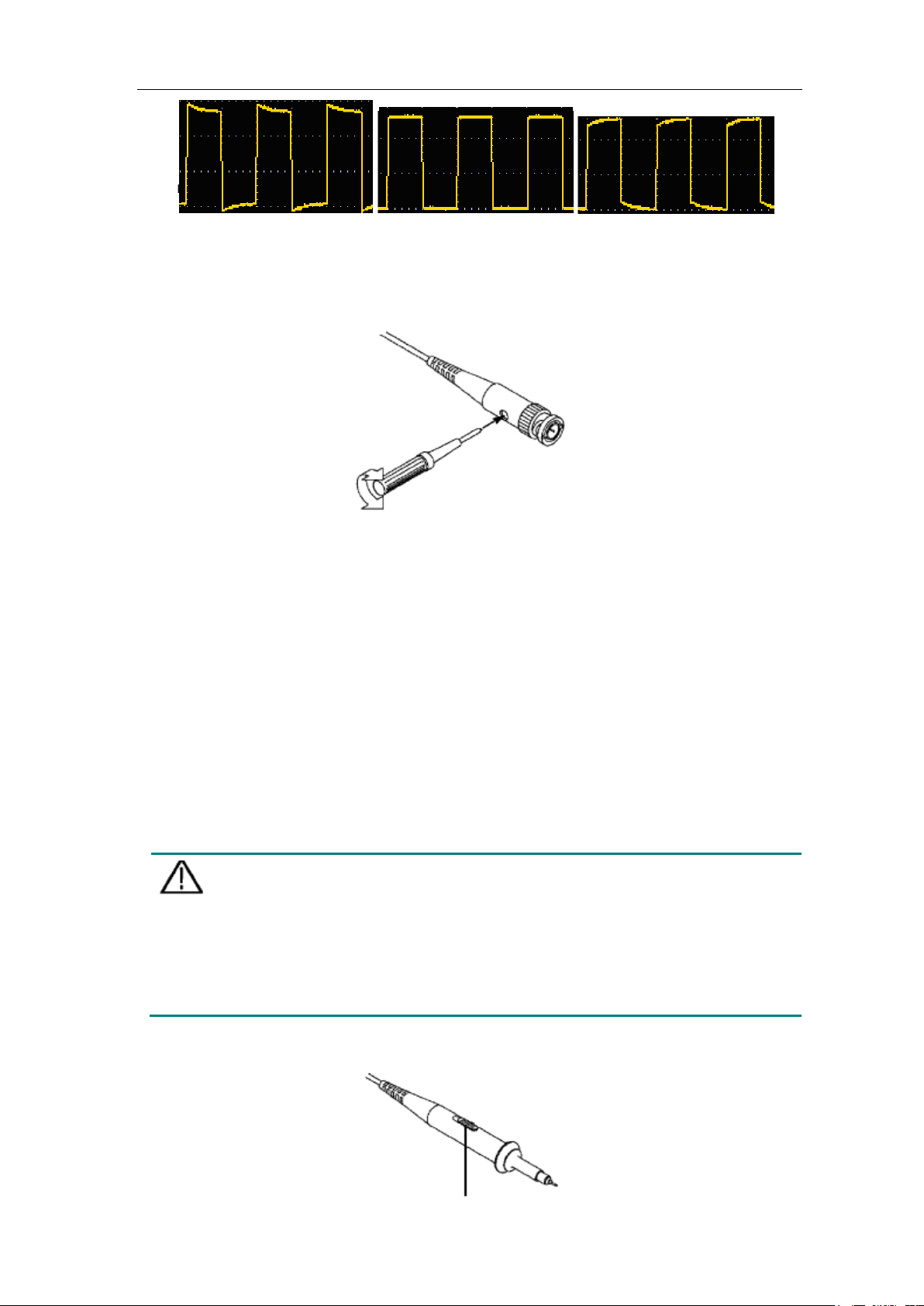

How to Set the Probe Attenuation Coefficient

The probe has several attenuation coefficients, which will influence the vertical scale

factor of the oscilloscope.

To change or check the probe attenuation coefficient in the menu of oscilloscope:

(1) Push the function menu button of the used channels (CH1 or CH2 button).

(2) Select Probe in the bottom menu; select Attenu in the right menu, turn the Mknob to

select the proper value corresponding to the probe.

This setting will be valid all the time before it is changed again.

Caution:

The default attenuation coefficient of the probe on the instrument is preset to

10X.

Make sure that the set value of the attenuation switch in the probe is the

same as the menu selection of the probe attenuation coefficient

in the

oscilloscope.

The set values of the probe switch are 1X and 10X (see Figure 3-9).

3.Junior User Guidebook

13

Figure 3-9 Attenuation Switch

Caution:

When the attenuation switch is set to 1X, the probe will limit the bandwidth

of the oscilloscope in 5MHz. To use the full bandwidth of the oscilloscope,

the switch must be set to 10X.

Identify the Probe Attenuation Coefficient Automatically

The oscilloscope can identify the probe attenuation coefficient of the 100:1 (impedance

5K±20%) or 10:1 (impedance 10K±20%) probe with the identifying pin. When you

attach the probe, the oscilloscope set the attenuation automatically on the oscilloscope

vertical menu for the channel to match the probe.

For example, if you attach a 10:1 probe with the identifying pin, the screen will prompt

"The probe attenuation factor is X10", and set the attenuation to 10X automatically on the

oscilloscope vertical menu for the channel.

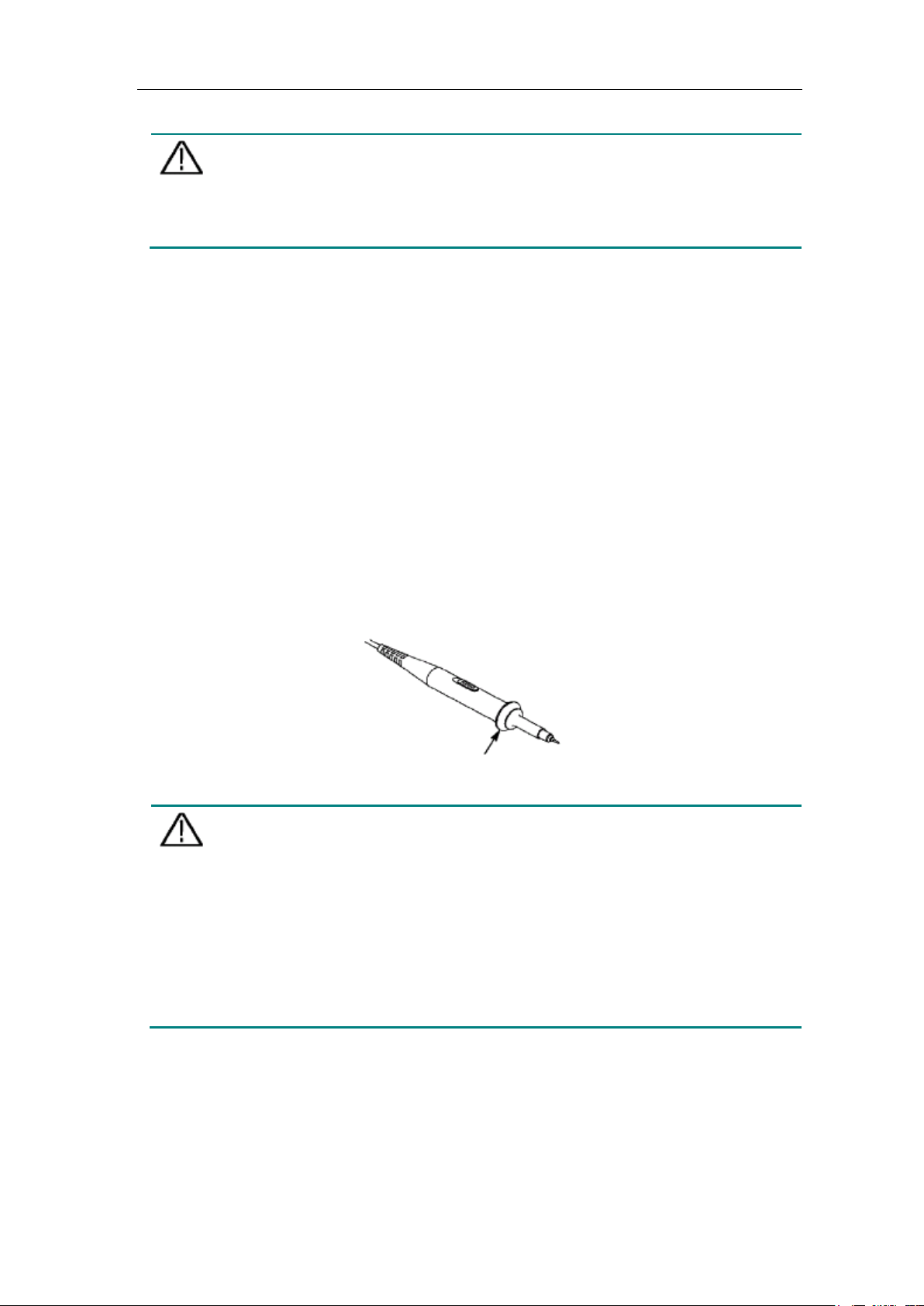

How to Use the Probe Safely

The safety guard ring around the probe body protects your finger against any electric

shock, shown as Figure 3-10.

Figure 3-10 Finger Guard

Warning:

To avoid electric shock, always keep your finger behind the safety guard

ring of the probe during the operation.

To protect you from suffering from the electric shock, do not touch any

metal part of the probe tip when it is connected to the power supply.

Before making any measurements, always

connect the probe to the

instrument and connect the ground terminal to the earth.

How to Implement Self-calibration

The self-calibration application can make the oscilloscope reach the optimum condition

rapidly to obtain the most accurate measurement value. You can carry out this application

program at any time. This program must be executed whenever the change of ambient

3.Junior User Guidebook

14

temperature is 5℃or over.

Before performing a self-calibration, disconnect all probes or wires from the input

connector. Push the Utility button, select Function in the bottom menu, select Adjust. in

the left menu, select Self Cal in the bottom menu; run the program after everything is

ready.

Introduction to the Vertical System

As shown in Figure 3-11, there are a few of buttons and knobs in Vertical Controls. The

following practices will gradually direct you to be familiar with the using of the vertical

setting.

Figure 3-11 Vertical Control Zone

1. Use the Vertical Position knob to show the signal in the center of the waveform

window. The Vertical Position knob functions the regulating of the vertical display

position of the signal. Thus, when the Vertical Position knob is rotated, the pointer

of the earth datum point of the channel is directed to move up and down following

the waveform.

Measuring Skill

If the channel is under the DC coupling mode, you can rapidly measure the DC

component of the signal through the observation of the difference between the wave

form and the signal ground.

If the channel is under the AC mode, the DC component would be filtered out. This

mode helps you display the AC component of the signal with a higher sensitivity.

Vertical offset back to 0 shortcut key

Turn the Vertical Position knob to change the vertical display position of channel

and push the position knob to set the vertical display position back to 0 as a shortcut

key, this is especially helpful when the trace position is far out of the screen and want

it to get back to the screen center immediately.

2. Change the Vertical Setting and Observe the Consequent State Information Change.

3.Junior User Guidebook

15

With the information displayed in the status bar at the bottom of the waveform

window, you can determine any changes in the channel vertical scale factor.

Turn the Vertical Scale knob and change the "Vertical Scale Factor (Voltage

Division)", it can be found that the scale factor of the channel corresponding to

the status bar has been changed accordingly.

Push buttons of CH1, CH2 and Math, the operation menu, symbols, waveforms

and scale factor status information of the corresponding channel will be displayed

in the screen.

Introduction to the Horizontal System

Shown as Figure 3-12, there are a button and two knobs in the Horizontal Controls. The

following practices will gradually direct you to be familiar with the setting of horizontal

time base.

Figure 3-12 Horizontal Control Zone

1. Turn the Horizontal Scale knob to change the horizontal time base setting and

observe the consequent status information change. Turn the Horizontal Scale knob to

change the horizontal time base, and it can be found that the Horizontal Time Base

display in the status bar changes accordingly.

2. Use the Horizontal Position knob to adjust the horizontal position of the signal in the

waveform window. The Horizontal Position knob is used to control the triggering

displacement of the signal or for other special applications. If it is applied to

triggering the displacement, it can be observed that the waveform moves horizontally

with the knob when you rotate the Horizontal Position knob.

Triggering displacement back to 0 shortcut key

Turn the Horizontal Position knob to change the horizontal position of channel and

push the Horizontal Position knob to set the triggering displacement back to 0 as a

shortcut key.

3. Push the Horizontal HOR button to switch between the normal mode and the wave

Table of contents

Other Lilliput Test Equipment manuals