mod. 514 GB

3/28

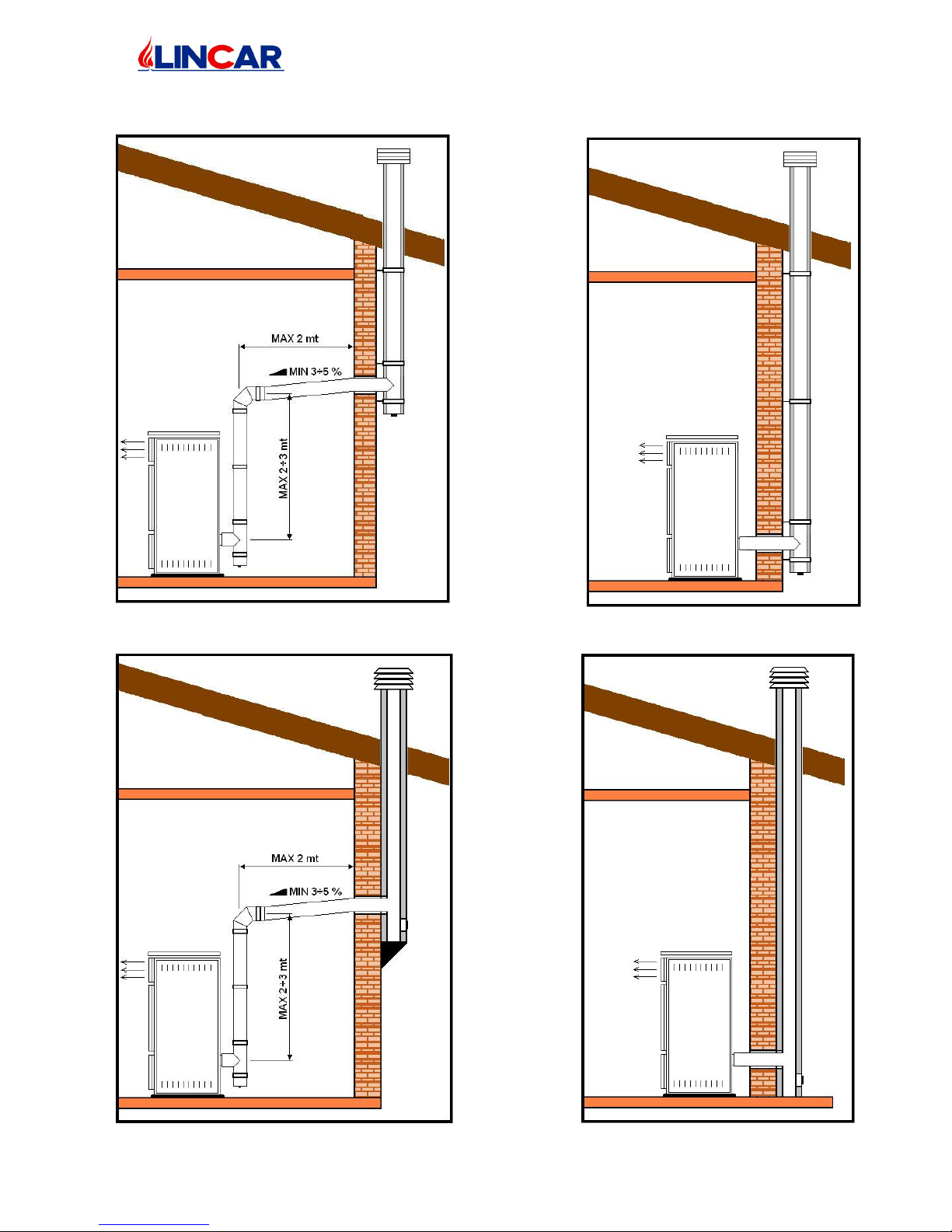

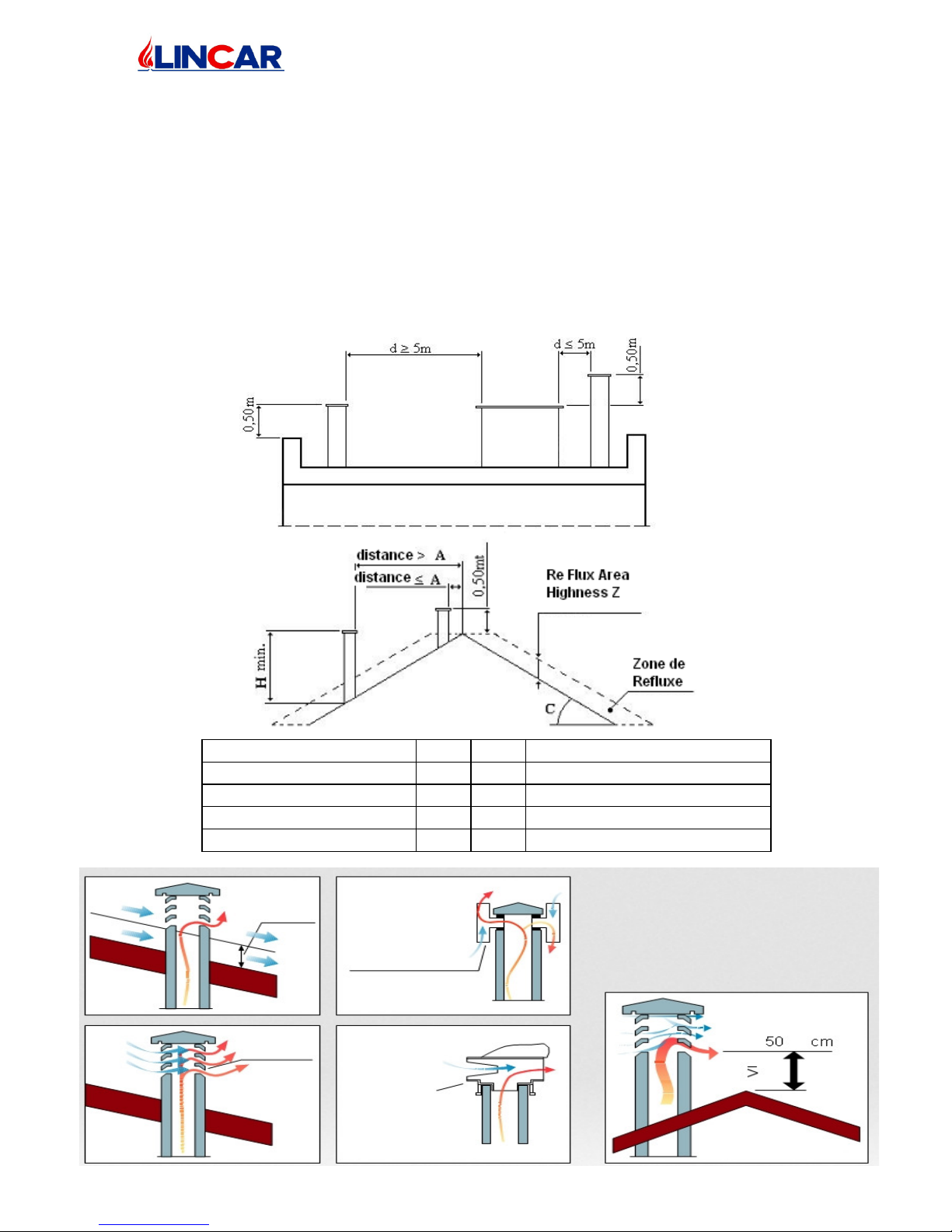

1INSTALLATION

RESERVED TO INSTALLER

1.1 Normative and prescriptions

•Read carefully the contents of this handbook, it contains important information and

instructions for installation, use, maintenance and product safety.

•The appliance must be installed inside an environment considered suitable for

installation and use by competent authorities. All laws, standards and regulations in force

on the installation site must be observed, especially regarding fire prevention.

•Technological connection and appliance installation must be carried out by qualify staff

authorized to release a conformity certificate according with the normative in force and

current standards.

•All the normative concerning civil town planning and/or industrial in force must be

respected inside the environment of installation of the appliance.

•All laws, standards and regulations in force on the installation site must be observed,

regarding: gas and flues, electricity, water and steam, drains and waste disposal, forced

ventilation/extraction, air intake and air conditioning. All the local and energy supplier

authorities prescriptions must be respected.

•The installation must be carried out and certified according to the normative in force

regarding installations, exhaust fumes connections, electricity, water, ventilation /

suction.

•The manufacturer disclaims all responsibility caused by no correct installation,

using, tampering, maintenance or no respect of normative in force.

1.2 Preliminary operations

•Take away the packing

•Before installation, check the appliance integrity. In case of doubt, do not use the

appliance and call the dealer.

•Packing materials is for recycle, getting it in the specify container

1.3 Appliance positioning

•The installation environment should have :

−A suitable floor for stove weight and calorific radiation, otherwise preventive

measures should be adopted. (i.e. Plate for charge distribution ).

−A suitable floor for stove calorific radiation to guarantee the building against any

fire risk.

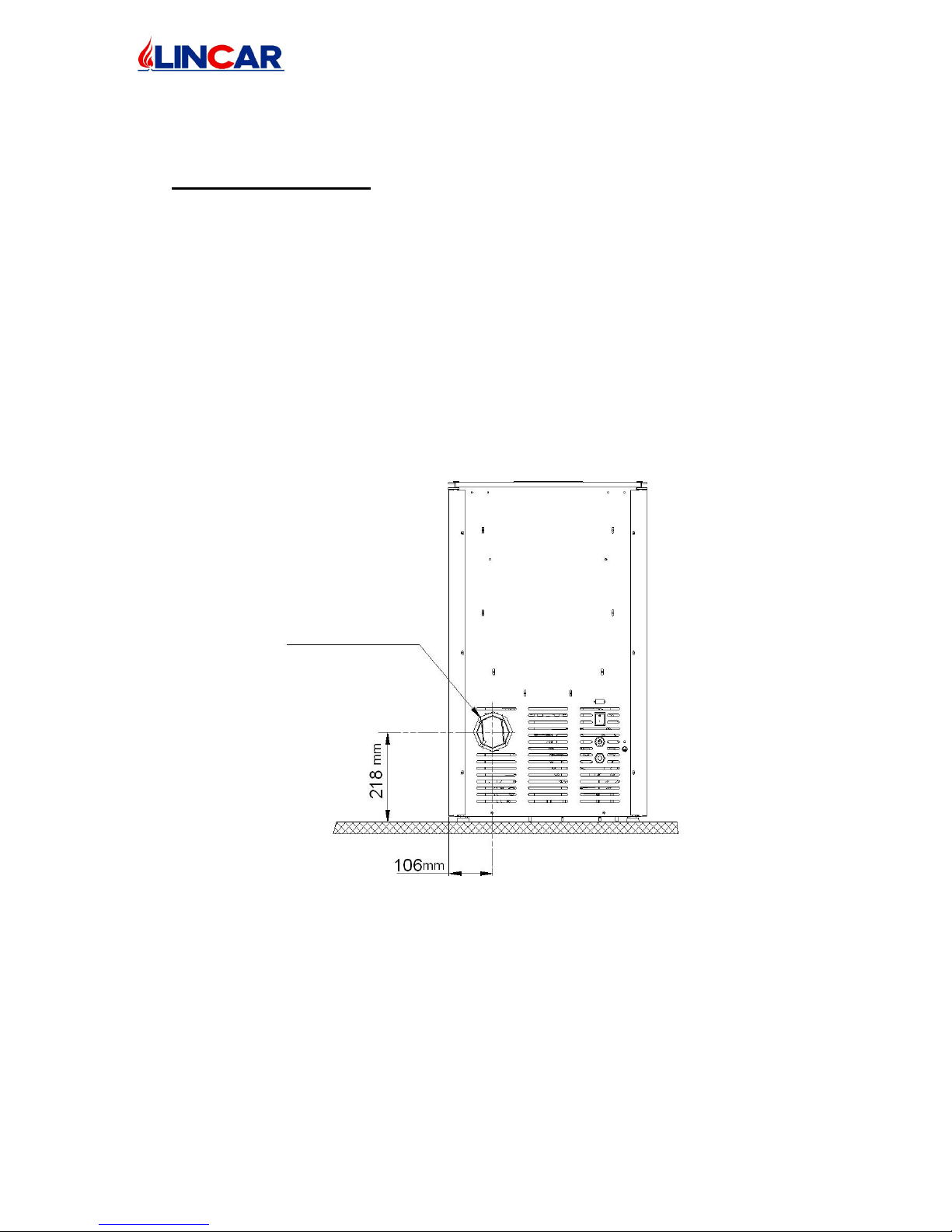

−The stove should be installed so that gas flue, chimney and cleaning could be easily

done.

−A minimal distance from flammable materials ( Security Distances)

−A suitable ventilation as normative in force.

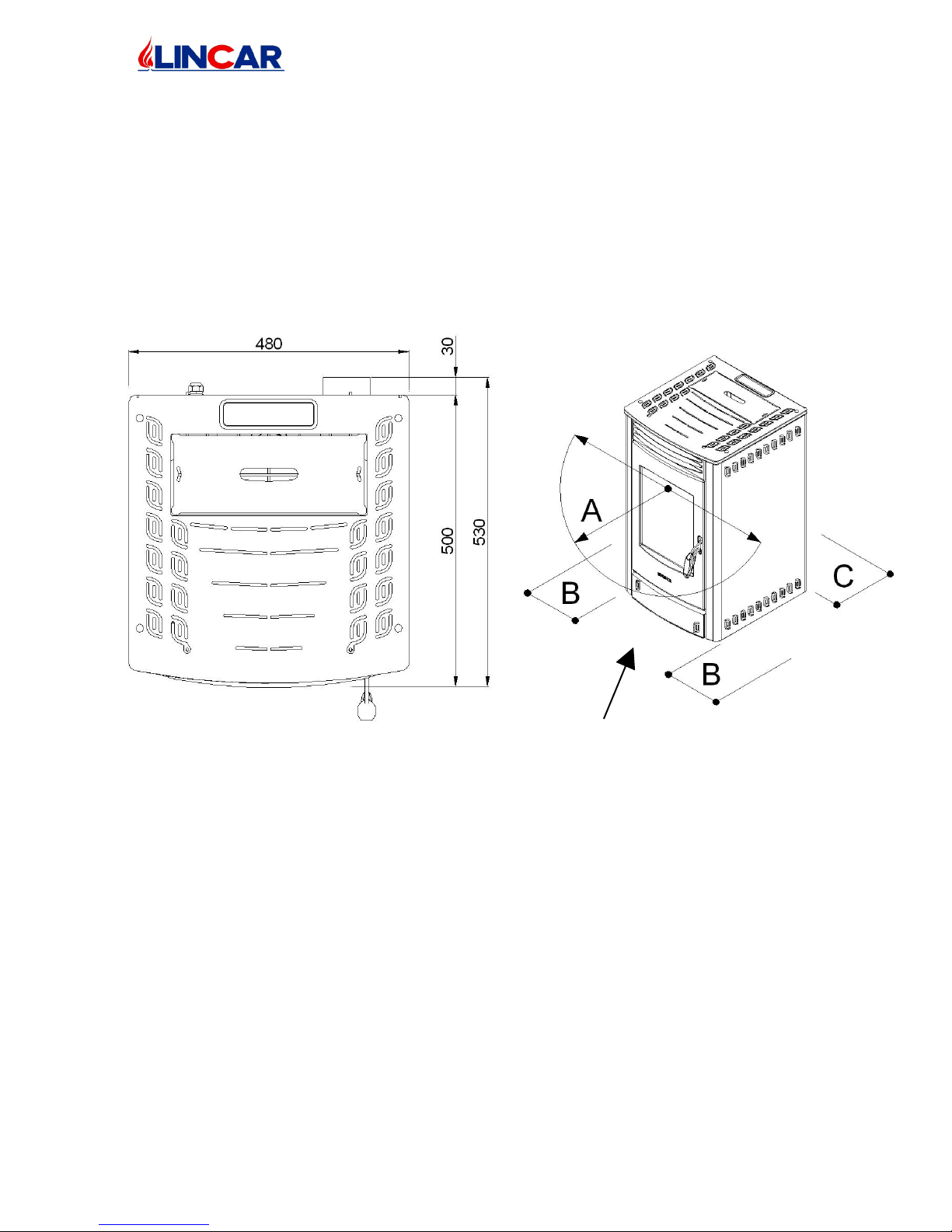

FLOOR PROTECTION

•The equipment has to be put on a refractory surface. In case of flammable floor (

moquette, parquet ..) it’s necessary to put a refractory base ( stainless steel, ceramic etc )

with the following dimensions :

−Hold up in front ≥500 mm;

−Hold up lateral ≥300 mm;

−Hold up back ≥100 mm