Lincoln Electric Idealarc DC-1500 User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric 12881 User manual

Lincoln Electric

Lincoln Electric Vantage 500 CE User manual

Lincoln Electric

Lincoln Electric IMVERTEC IM738-A User manual

Lincoln Electric

Lincoln Electric B18252-1 User manual

Lincoln Electric

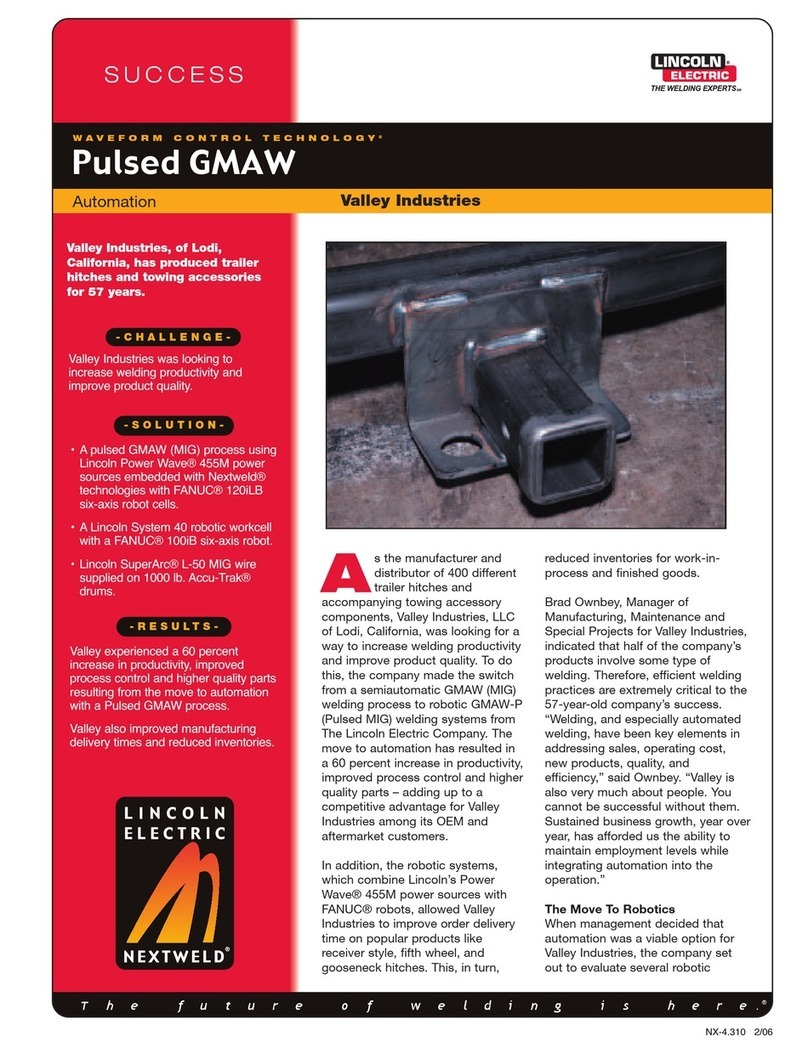

Lincoln Electric Pulsed GMAW User manual

Lincoln Electric

Lincoln Electric MULTI-SOURCE SVM155-A User manual

Lincoln Electric

Lincoln Electric IDEALARC DC-655 User manual

Lincoln Electric

Lincoln Electric POWERPLUS 1000HD User manual

Lincoln Electric

Lincoln Electric Magnum K115-1 User manual

Lincoln Electric

Lincoln Electric TOMAHAWK TM 625 IM10020 User manual

Lincoln Electric

Lincoln Electric Idealarc DC-1500 User manual

Lincoln Electric

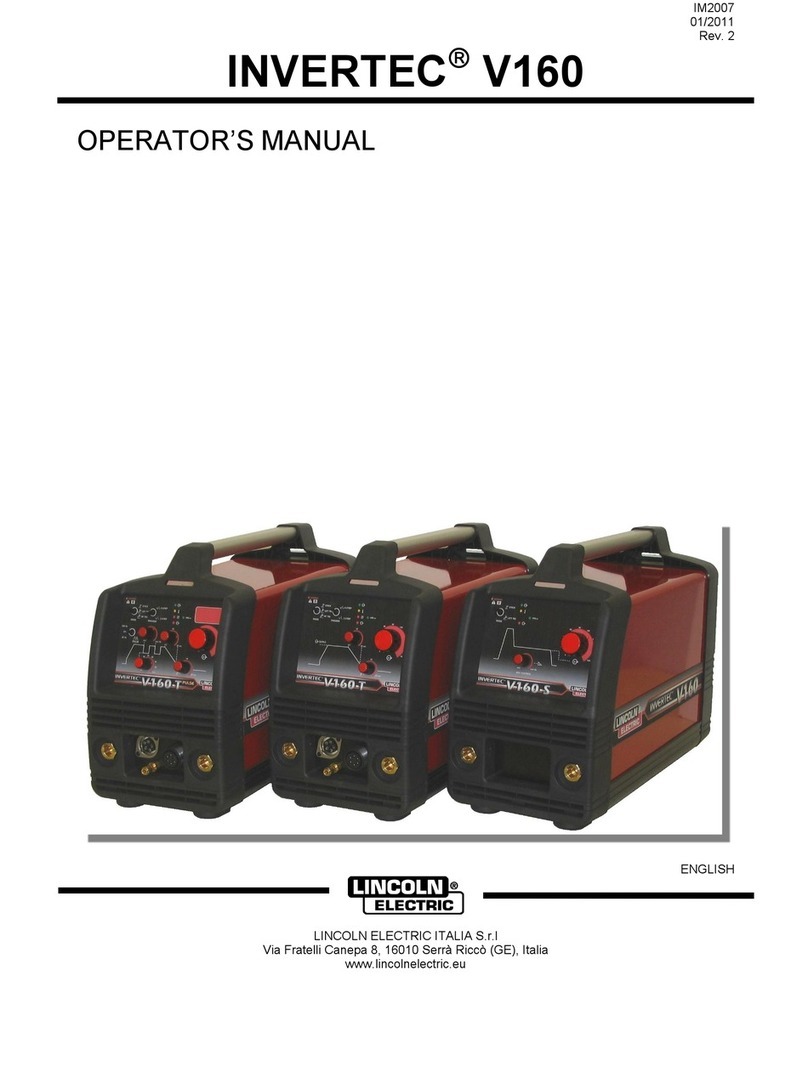

Lincoln Electric INVERTEC V160 User manual

Lincoln Electric

Lincoln Electric LINC FEED 33S User manual

Lincoln Electric

Lincoln Electric Airgas RED-D-ARC DX500e User manual

Lincoln Electric

Lincoln Electric Pro-cut 20 User manual

Lincoln Electric

Lincoln Electric IM723-A User manual

Lincoln Electric

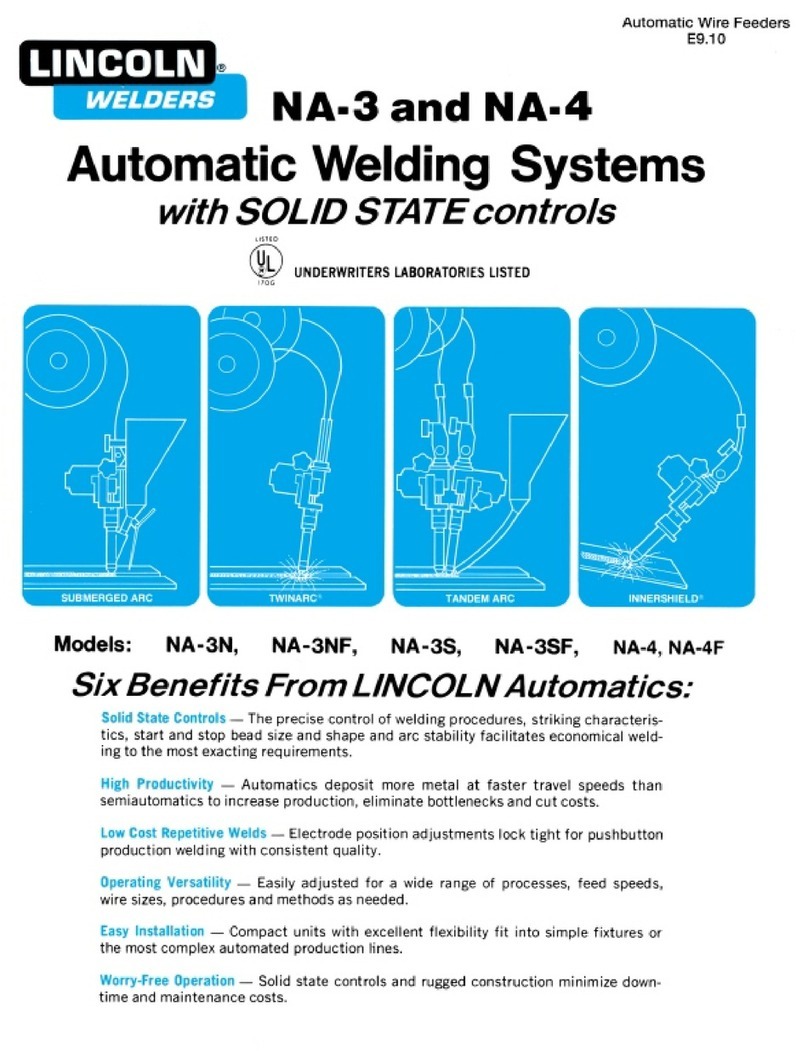

Lincoln Electric NA-3 User manual

Lincoln Electric

Lincoln Electric CobraMAX K2252-1 User manual

Lincoln Electric

Lincoln Electric FLEXTEC 500 P User manual

Lincoln Electric

Lincoln Electric 9919 User manual