LincolnElectric.com E3.115 © Lincoln Global, Inc., All Rights Reserved 2008

THE LINCOLN ELECTRIC COMPANY TIG WELDER

LincolnElectric.com

TIG WELDER Invertec®V310-T AC/DC OPTIONS Invertec®V310-T AC/DC

THE LINCOLN ELECTRIC COMPANY

Selectable Half Wave Shapes

Not only can you choose Sine, Square or Triangular, the Positive

vs. Negative half of the wave shape can be independently

changed.

Example: Select a square positive wave to minimize high peak

current that erodes the tungsten and select a triangular wave

for the negative half to minimize heat input to the weld.

Selectable AC Wave Shapes

Shown:

K2228-1 Invertec®V305-T AC/DC

with K2630-1 Cool Arc®35 Water Cooler

•Adjustable AC Frequency

•Expanded AC Balance Control

•Selectable AC Waveshapes

•High Speed DC TIG Pulsing

Excellent Welding Performance

Expanded AC Balance

Inverters can be set to a higher ratio of Electrode

Negative (%EN) for:

• Better penetration with narrow bead profile

• Minimized tungsten erosion (keep a sharp point)

• Minimize etching adjacent to the weld

High Speed DC TIG Pulsing

Conventional TIG Pulsing (<10 Pulses per second pps)

• Timed filler metal & consistent bead appearance

• Reduces heat input by alternating between peak current

and background to minimizes distortion

High Speed TIG Pulsing (Up to 2500 pps)

• Increased puddle agitation for improved weld microstructure

• Focused stable arc

• Increased travel speeds

• Reduced heat input

Adjustable AC Output Frequency

Higher Frequency narrows or focuses the arc cone,

allowing precise control of arc and access into tight joints.

Lower Frequency widens the arc cone, minimizing agitation

of base metal.

Smaller Heat

Affected Zone

Smaller Bead Profile

New Cart – Makes a Complete System (K2694-1)

•Low cylinder platform - Holds a full size 160lb bottle

•Storage compartment with latch

•Open tool tray with rubber mat

•Torch hanger

Cool Arc®35 – The Smart Cooler (K2630-1)

•Shuts machine output off if loss of coolant is sensed.

•Speed adjusts based on coolant temperature for quiet operation and long life.

•Fits in a neat modular fashion below the Invertec®V310-T AC/DC

•Gets its power from the Invertec®V310-T AC/DC No extra outlets to plug into.

New Cart

Makes a Complete Solution

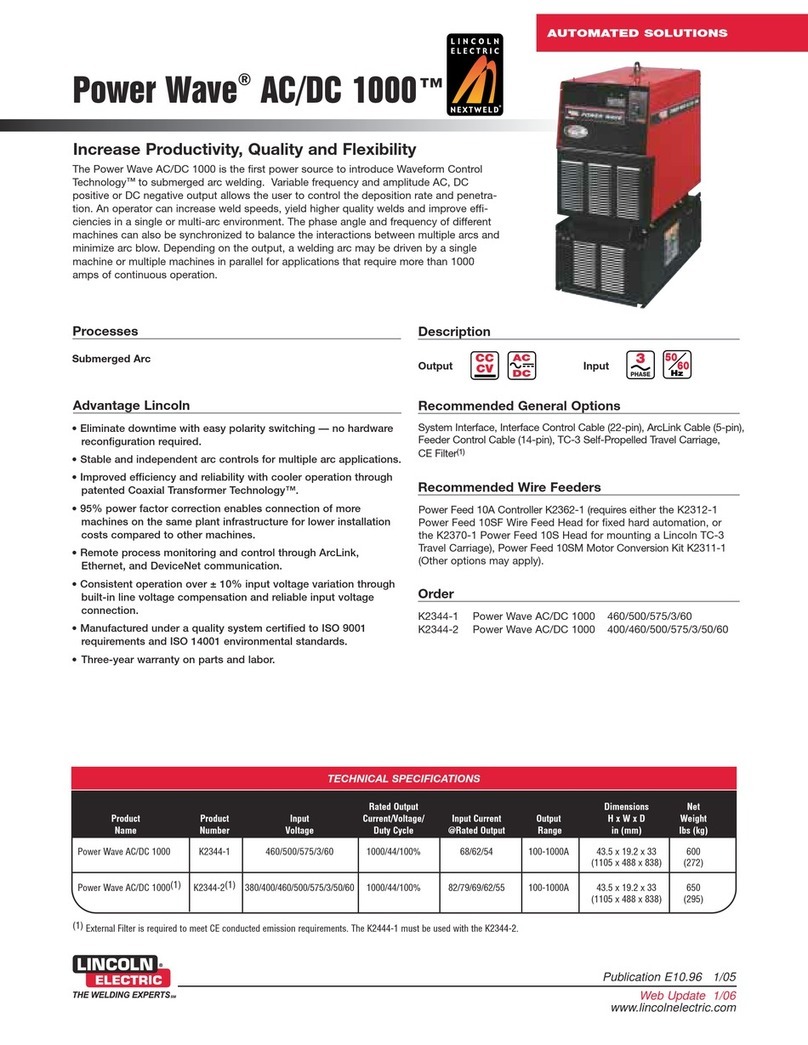

Product Product Input Power Input Current @ H x W x D Net Weight

Name Number Phase Voltage/Hertz Rated Output Rated Output (1) Output Range inches (mm) lbs.(kg)

Invertec®K2228-1 3-Phase 460/50/60 210A / 18.4V / 100% 7.3 5-310A 17.3 x 10.6 x 24 75

V310-T AC/DC 230A / 19.2V / 60% 8.3 Max. OCV: (439 x 269 x 609) (34)

310A / 22.4V / 40% 12.3 80V

230/50/60 210A / 18.4V / 100% 13.9

230A / 19.2V / 60% 15.8

310A / 22.4V / 30% 24.6

208/50/60 210A / 18.4V / 100% 15.3

230A / 19.2V / 60% 17.5

310A / 22.4V / 30% 27.3

1-Phase 460/50/60 200A / 18.0V / 100% 13.6

220A / 18.8V / 60% 14.9

310A / 22.4V / 35% 23.1

230/50/60 200A / 18.0V / 100% 21.9

220A / 18.8V / 60% 24.6

310A / 22.4V / 25% 41.5

208/50/60 200A / 18.0V / 100% 24.2

220A / 18.8V / 60% 27.7

310A / 22.4V / 25% 47.3

(1)Input current on 60 hertz input.

PROCESSES

•Stick

•TIG

OUTPUT INPUT

ONE-PAK®PKG. (K2695-1) INCLUDES

•K2228-1 Invertec®V310-T AC/DC

•K2630-1 Cool Arc®35 Water Cooler

•K2694-1 Inverter Cart

•K2267-1 TIG Mate™20 Torch Kit

•K870 Foot Amptrol®

•K918-1 Zippered Cable Cover

KEY OPTIONS

•K2630-1 Cool Arc®35 Water Cooler

•K2694-1 Inverter Cart

•K2666-1 TIG Mate™17 Air Cooled TIG Torch Starter Pack

•K870 Foot Amptrol®

•K963-3 Hand Amptrol®

•More options at end of section

LITERATURE

E3.115

Options

Tool tray with rubber mat and storage compartment Torch hanger

The Invertec®V310-T AC/DC is the most technologically

advanced AC/DC TIG welder in its class. It fits the bill

for serious fabrication, maintenance, and production

work. Its compact, lightweight size makes it ideal

for field applications like advanced motorsports,

aerospace, shipbuilding, and construction.

•Dynamic LCD Display (patent pending)

•Adjustable AC Frequency and Selectable Waveshapes

•Soft, Crisp and AC Stick Modes

•Optional Cool Arc®35 “Smart” water cooler

•208-460 1/3 phase auto-reconnect

•High efficiency inverter

CONVENTIONAL TIG BALANCE

Electrode Positive = Cleaning + Tungsten Heating

Less Penetration (-)

TIME

%EP

%EN

+

-

WELDING

AMPERAGE

Electrode Negative (%EN) = Penetration

More Penetration (-)

TIME

%EP

%EN

+

-

WELDING

AMPERAGE

EXPANDED INVERTER TIG BALANCE

Wave Type Description Result

Square Responsive arc with Stable arc with good puddle

fast zero crosses and control and fast travel speed

reduced peak

amperages Minimizes tungsten superheating

Sine Traditional smooth Soft sounding arc

shaped waveform

Triangular Minimized area Lower amperages can

(heat) under the minimize heat input to the weld

curve shape

with high peaks High peaks more forceful for

anodized applications

Maintain Sharp

Tungsten Less Area Means

Less Heat Into Weld

Min. Frequency (20Hz)

20Hz

Max Frequency (200Hz)

200Hz

WELDING CURRENT

TIME

Background

Peak

PULSE FREQUENCY:

Number of Pulses Per Second

High Heat

(Peak)

Low Heat

(Background)

Field Installed

Options

TIG Torch

Starter Kits

Torch

Adapters

Magnum®

TIG Torches

Part # Description Part # Description Part # Description Part # Description

K857 Remote Output

Control 25 ft.

K2266-1 TIG-Mate™ 17

K1622-1 PTA-9/17 Twist-

Mate®Adapter

K1781-1

K1781-3

PTA-9 w/ 12.5 ft. cable

PTA-9 w/ 25 ft. cable

K870 Foot Amptrol®K1782-1

K1782-3

PTA-17 w/ 12.5 ft. cable

PTA-17 w/ 25 ft. cable

K963-3 Hand Amptrol®K2267-1 TIG-Mate™ 20 K1622-3 PTA-26 Twist-

Mate®Adapter

K1783-1

K1783-3

PTA-26 w/ 12.5 ft. cable

PTA-26 w/ 25 ft. cable

K814 Arc Start Switch

K1622-4 Water Cooled Twist-

Mate®Adapter

K1784-3

K1784-4

PTW-20 w/ 12.5 ft. cable

PTW-20 w/ 25 ft. cable

K2694-1 Inverter Cart K2413-1 TIG-Mate™ 9 K1784-1

K1784-2

PTW-18 w/ 12.5 ft. cable

PTW-18 w/ 25 ft. cable