P223 FLUX AWS A5.17-97: F7A4-EM12K and A5.23-97: F8A2-EA1-A2

Publication C5.10.1 12/03

www.lincolnelectric.com

Lincolnweld®P223 lux is an industry

standard or spiral pipe welding on

up to X80 grade pipe, especially

where good impact properties are

required. It is also well-suited or

longitudinal seam welding on pipe,

producing a low bead pro ile with

very straight edges, while minimizing

undercuts. Its ast reezing slag

makes it ideal or even small diame-

ter pipe. In most cases, the slag is

sel -peeling. For these same rea-

sons, P223 is an excellent choice or

many two-pass welding applications.

While designed or two-pass welding

applications, P223 is a neutral lux

which is also suitable or use in mul-

tiple pass welding with mild steel

and low alloy electrodes.

ADVANTAGE LINCOLN

• The weld deposits o neutral

P223 lux are extremely resistant

to procedural variations.

• Fast solidi ication o weld metal

and slag or excellent bead

appearance.

• Low dust levels make handling at

the work station clean and easy.

• Excellent weld pro iles with straight

and consistent weld bead edges.

• Fast reezing slag makes P223

suitable or smaller diameter pipe.

• Slag is sel -peeling on most appli-

cations.

• Designed to deliver Charpy

V-Notch impact properties that

exceed most line pipe require-

ments.

• Low di usible hydrogen levels.

• Manu actured under a quality

system certi ied to ISO 9001.

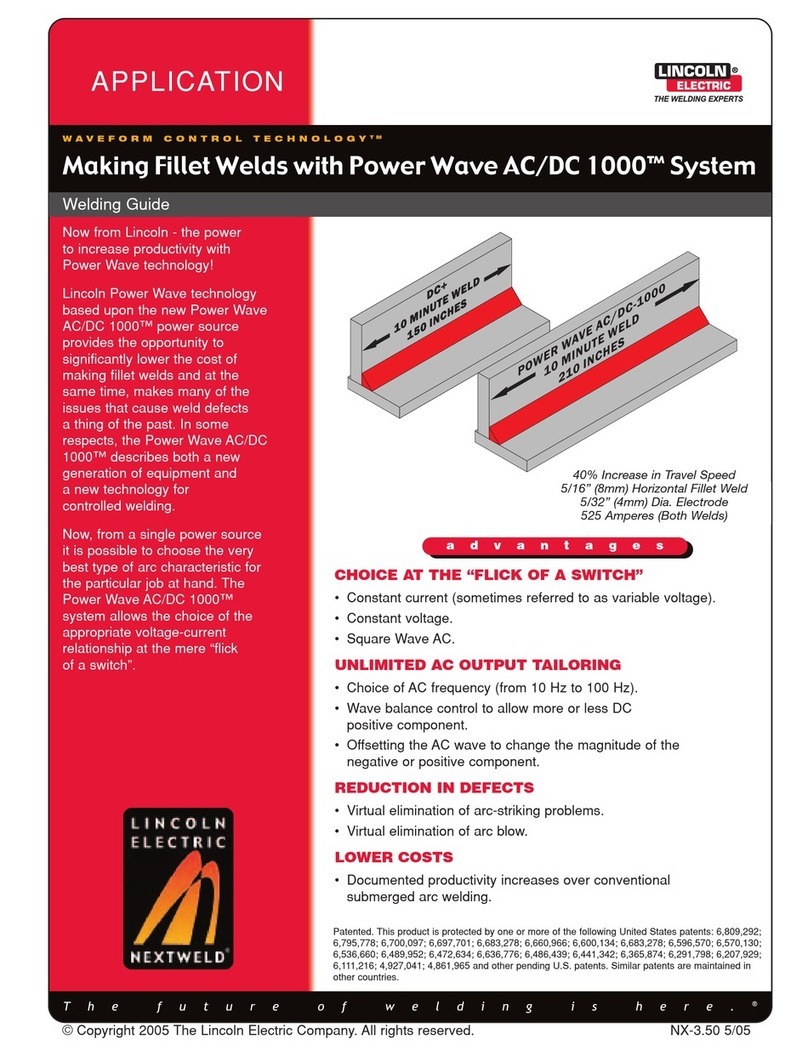

TYPICAL APPLICATIONS

• Oil and gas line pipe abrication

through X-80 grades.

• Single pass or multiple pass

welding.

• Single arc or multiple arc (up to

3 arc tandem welding).

• Straight seam or spiral seam

welding.

PRODUCT INFORMATION

• Basicity Index: 1.60

• Particle Size:

+12 Mesh 2% max.

-12/+100 Mesh 96% min.

-100 Mesh 2% max.

• Density: 1.3 g/cm3

CONFORMANCES

For Mild Steel:

Lincolnweld®L-61

AWS A5.17-97: F7A4-EM12K

ASME SFA-5.17

For Low Alloy Steel:

Lincolnweld®L-70

AWS A5.23-97: F8A2-EA1-A2

ASME SFA-5.23

RECOMMENDED ELECTRODES

Single Pass or Two-Pass Welds:

Lincolnweld®L-61, AWS EM12K

Lincolnweld®L-70, AWS EA1

(intended or applications requiring

robust Charpy impact properties).

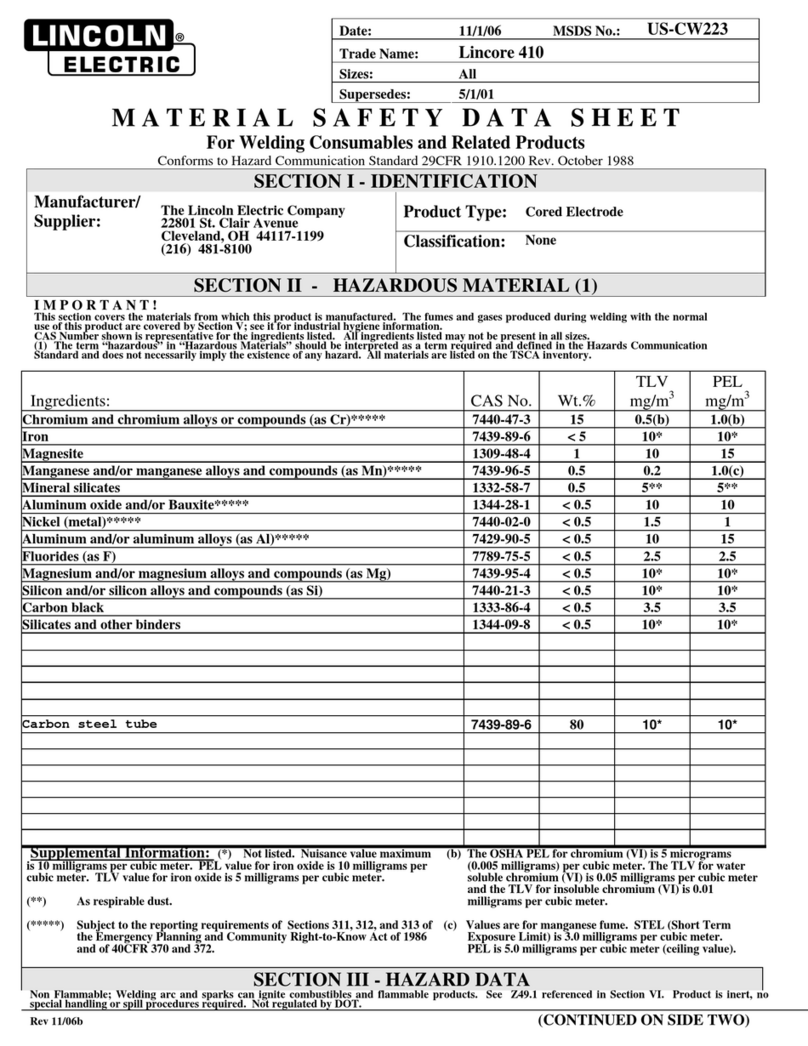

Charpy V-Notch Charpy V-Notch Charpy V-Notch Charpy V-Notch

Flu /Wire ft•lbf (Joules) ft•lbf (Joules) ft•lbf (Joules) ft•lbf (Joules)

Combination @ 0ºF (-18ºC) @ -20ºF (-29ºC) @ -40ºF (-40ºC) @ -60ºF (-51ºC)

Actual Test Results 75 76 87 45

As-welded (101) (103) (117) (61)

P223/L-61

Actual Test Results 113 101 99 82

As-welded (153) (136) (134) (111)

P223/L-70

MECHANICAL PROPERTIES(1) –Two-pass seam weld on 0.688" wall X-65 pipe

AC/AC two-wire tandem arc procedure

(1)Mechanical property results obtained on single pass or two-pass welds will vary with base plate composition,

welding procedure, heat input, etc. These results are shown only to demonstrate the potential or the products

being used.

Tested on Pipe