Dampers

–+

123

0

1

–+

12

0

3

0

1

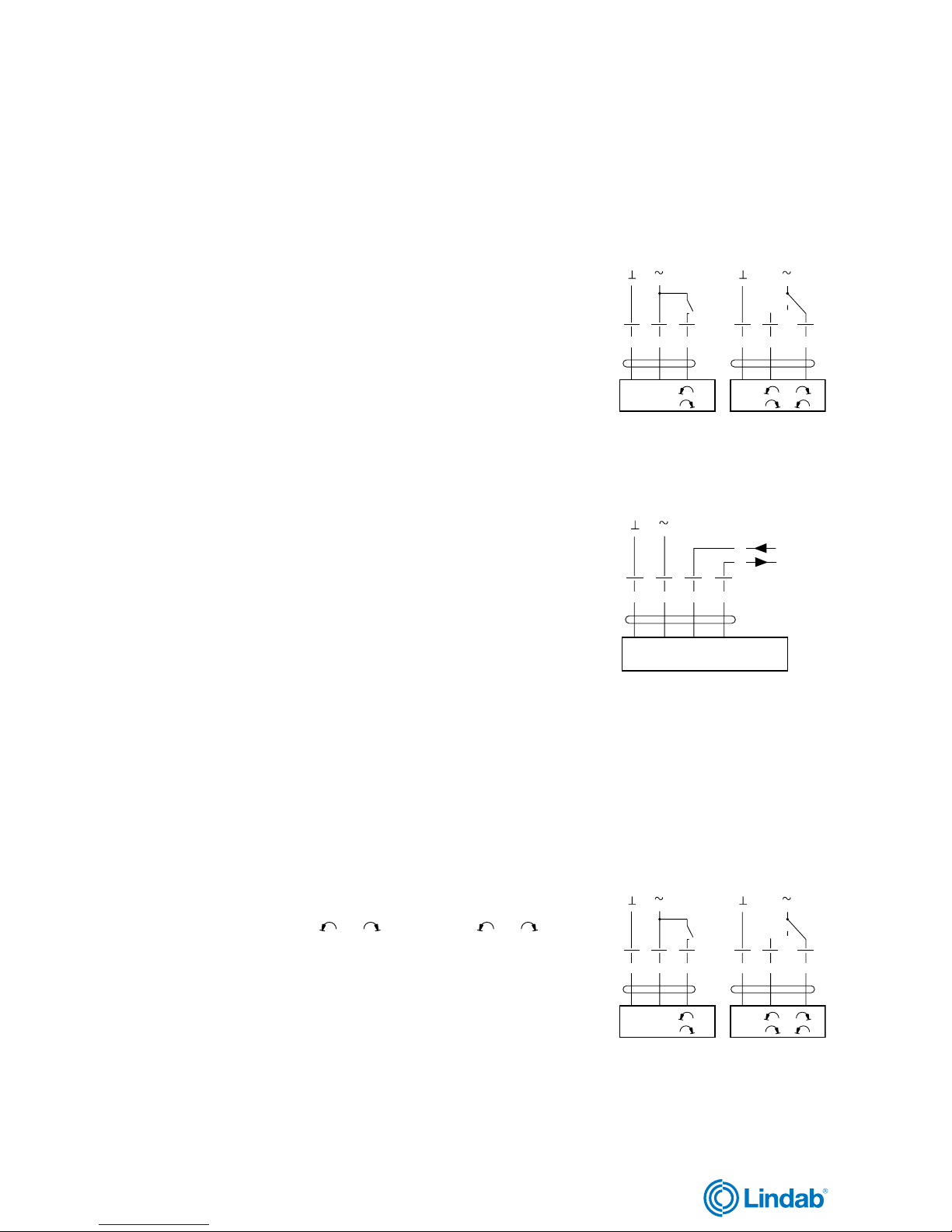

NM 24 A-F NM 230 A-F

Power supply............................. AC 19,2–28,8 V, 50/60 Hz AC 85–265 V, 50/60 Hz

DC 19,2–28,8 V

Power consumption .................. 1,5 W 2,5 W

For wire sizing ........................... 3,5 VA 6 VA

Connection ................................ Cable 1 m, 3×0,75 mm2 Cable 1 m, 3×0,75 mm2

Operating angle......................... Max. 95°, adjustable 0–100% Max. 95°, adjustable 0–100 %

Torque at rated voltage.............. Min. 10 Nm Min. 10 Nm

Direction of rotation................... Switch selectable Switch selectable

0 or 1 0 or 1

Position indication..................... Mechanical Mechanical

Running time for 95° ................. 150 s 150 s

Sound power level..................... Max. 35 dB (A) Max. 35 dB (A)

Protection class......................... III Safety extra-low voltage II Safety insulated

Protection type .......................... IP 54 IP 54

Ambient temperature range ...... -30 to +50°C -30 to +50°C

Ambient moisture ...................... 95 % RH 95 % RH

–+

123

0

1

–+

12

0

3

0

1

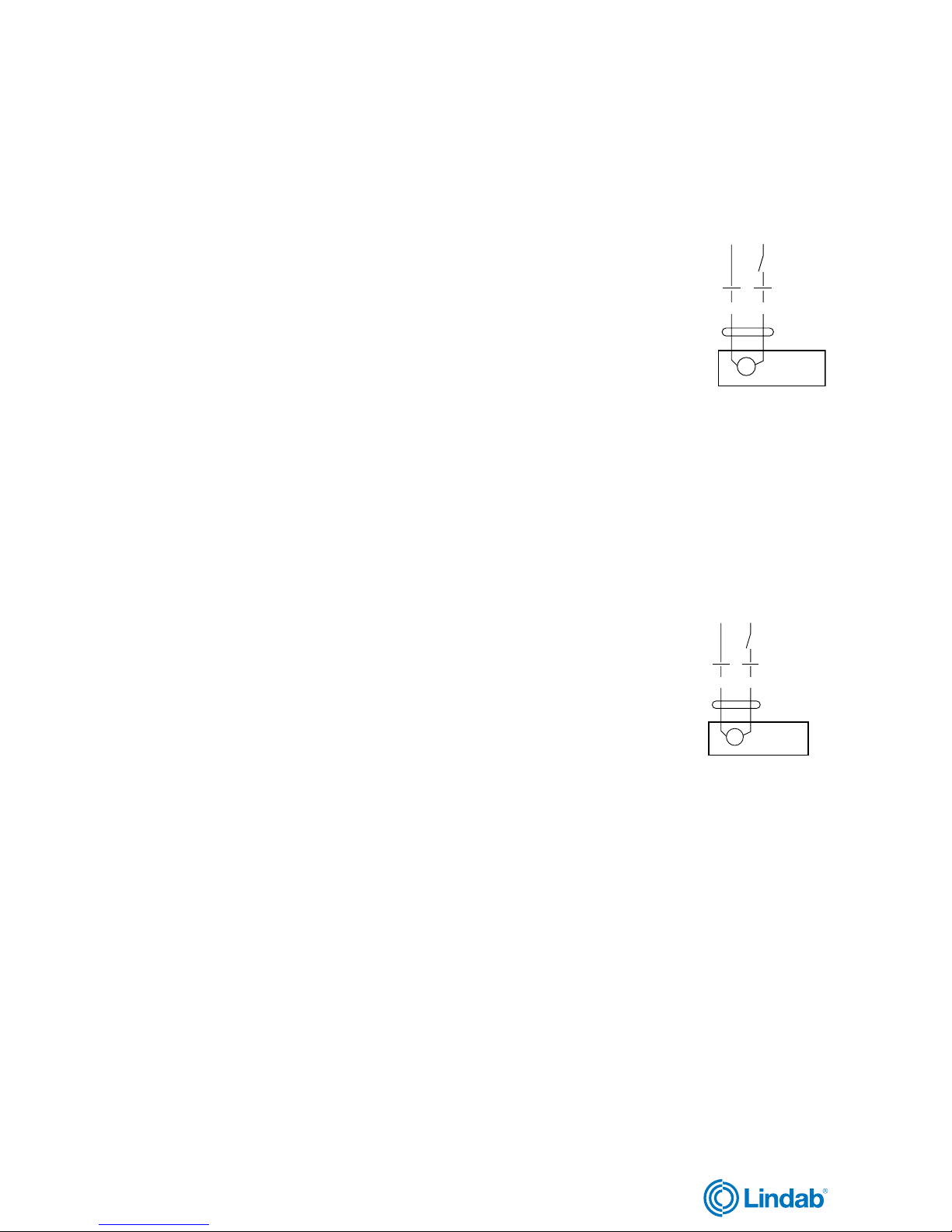

SM 24 A SM 230 A

Power supply............................. AC 19,2–28,8 V, 50/60 Hz AC 85–265 V, 50/60 Hz

DC 19,2–28,8 V

Power consumption .................. 2 W 2,5 W

For wire sizing ........................... 4 VA 6 VA

Connection ................................ Cable 1 m, 3×0,75 mm2 Cable 1 m, 3×0,75 mm2

Operating angle......................... Max. 95°, adjustable 0–100% Max. 95°, adjustable 0–100%

Torque at rated voltage.............. Min. 20 Nm Min. 20 Nm

Direction of rotation................... Switch selectable Switch selectable

0 or 1 0 or 1

Position indication..................... Mechanical Mechanical

Running time for 95° ................. 150 s 150 s

Sound power level..................... Max. 35 dB (A) Max. 35 dB (A)

Protection class......................... III Safety extra-low voltage II Safety insulated

Protection type .......................... IP 54 IP 54

Ambient temperature range ...... -30 to +50°C -30 to +50°C

Ambient moisture ...................... 95 % RH 95 % RH

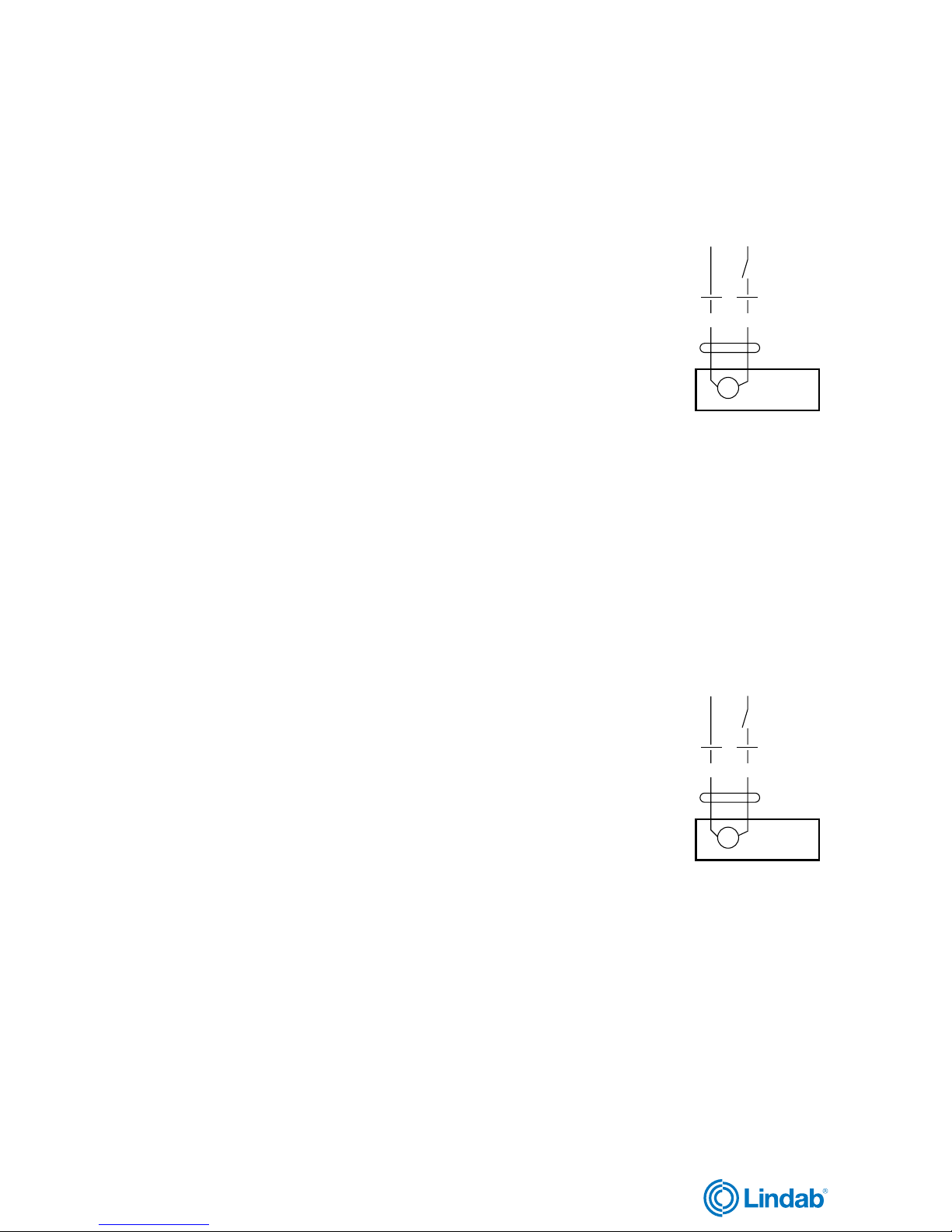

GM 24 A GM 230 A

Power supply............................. AC 19,2–28,8 V, 50/60 Hz AC 85–265 V, 50/60 Hz

DC 19,2–28,8 V

Power consumption .................. 4,5 W 4,5 W

For wire sizing ........................... 7 VA 7 VA

Connection ................................ Cable 1 m, 3×0,75 mm2 Cable 1 m, 3×0,75 mm2

Operating angle......................... Max. 95°, adjustable 0–100% Max. 95°, adjustable 0–100%

Torque at rated voltage.............. Min. 40 Nm Min. 40 Nm

Direction of rotation................... Switch selectable Switch selectable

0 or 1 0 or 1

Position indication..................... Mechanical Mechanical

Running time for 95° ................. 150 s 150 s

Sound power level..................... Max. 45 dB (A) Max. 45 dB (A)

Protection class......................... III Safety extra-low voltage II Safety insulated

Protection type .......................... IP 54 IP 54

Ambient temperature range ...... -30 to +50°C -30 to +50°C

Ambient moisture ...................... 95 % RH 95 % RH

–+

123

0

1

–+

12

0

3

0

1