2

lindab | we simplify construction

Description

Lindab InCapsa is a system that makes it easier to assemble, suspend and cover a

ventilation syste

Lindab InCapsa consists of few products that can easily be assembled in different combi-

nations to fit most rooms. In a few steps, you can install and cover a duct system behind

panels of sheet metal.

Lindab InCapsa is suitable for rooms with straight walls and 90° degree corners. In rooms

with different set-ups, e.g. furnished attics, sloping ceilings and curved walls, other solu-

tions should be used.

The system comes in three sizes, Ø100, Ø125 and Ø160, and is compatible with Lindab’s

duct systems.

Advantages of InCapsa

• Everything is fully assembled in one go.

• All work can be carried out by one category of professional.

• Saves both time and money.

• The system is easy to mount and demount.

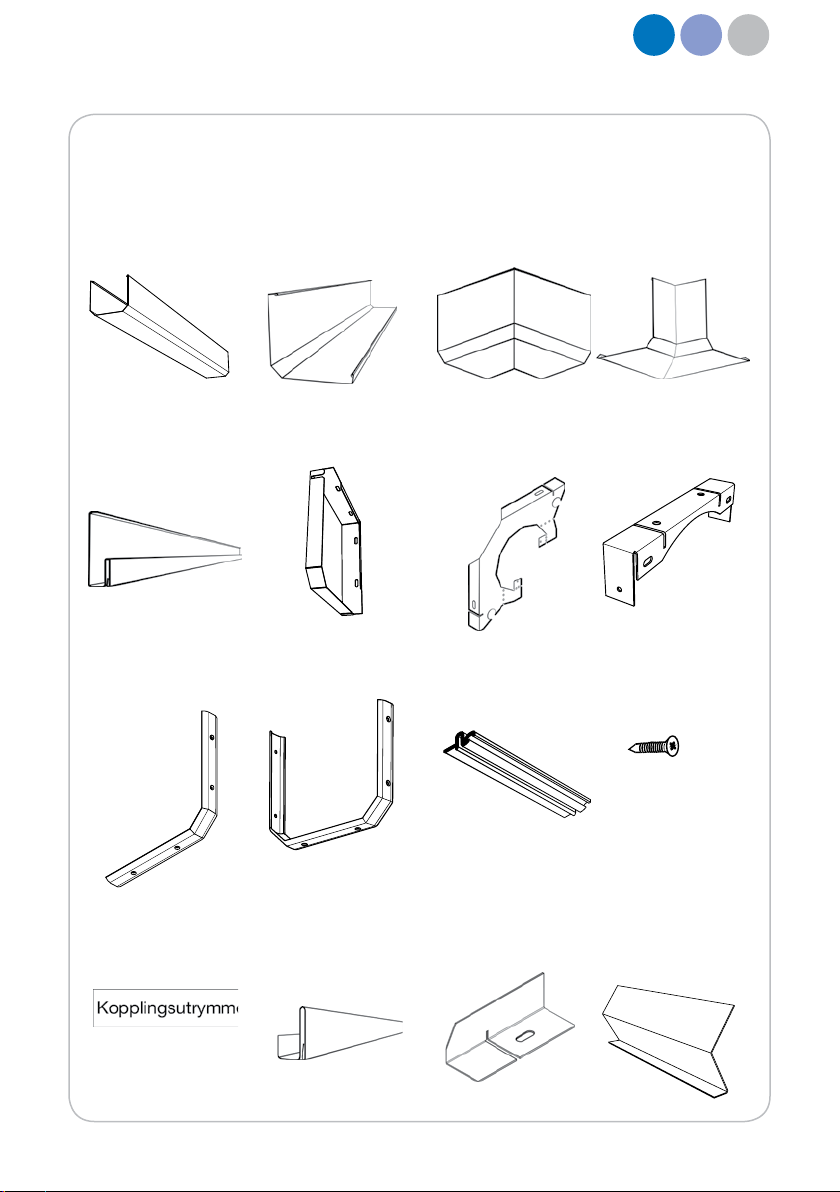

Contents

Components...................................................................................................................... 3

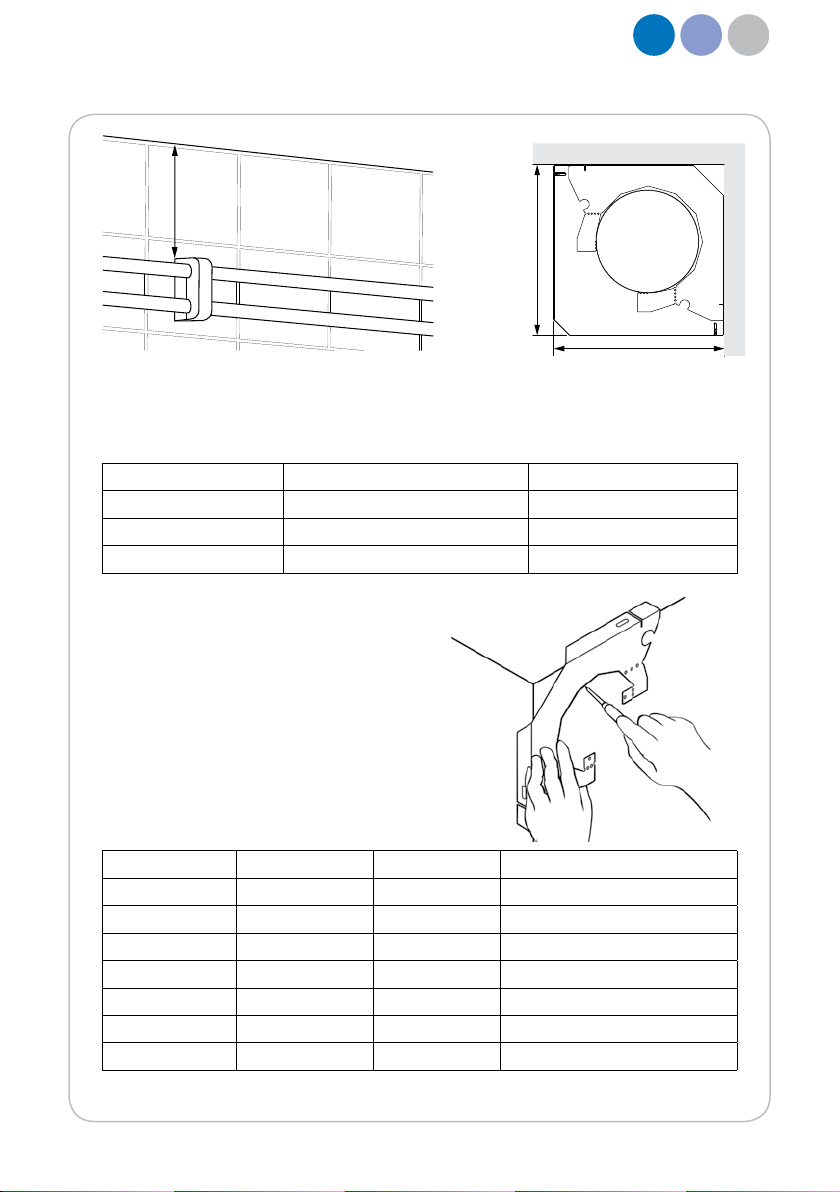

Planning and measurement .............................................................................................. 4

Making holes ..................................................................................................................... 5

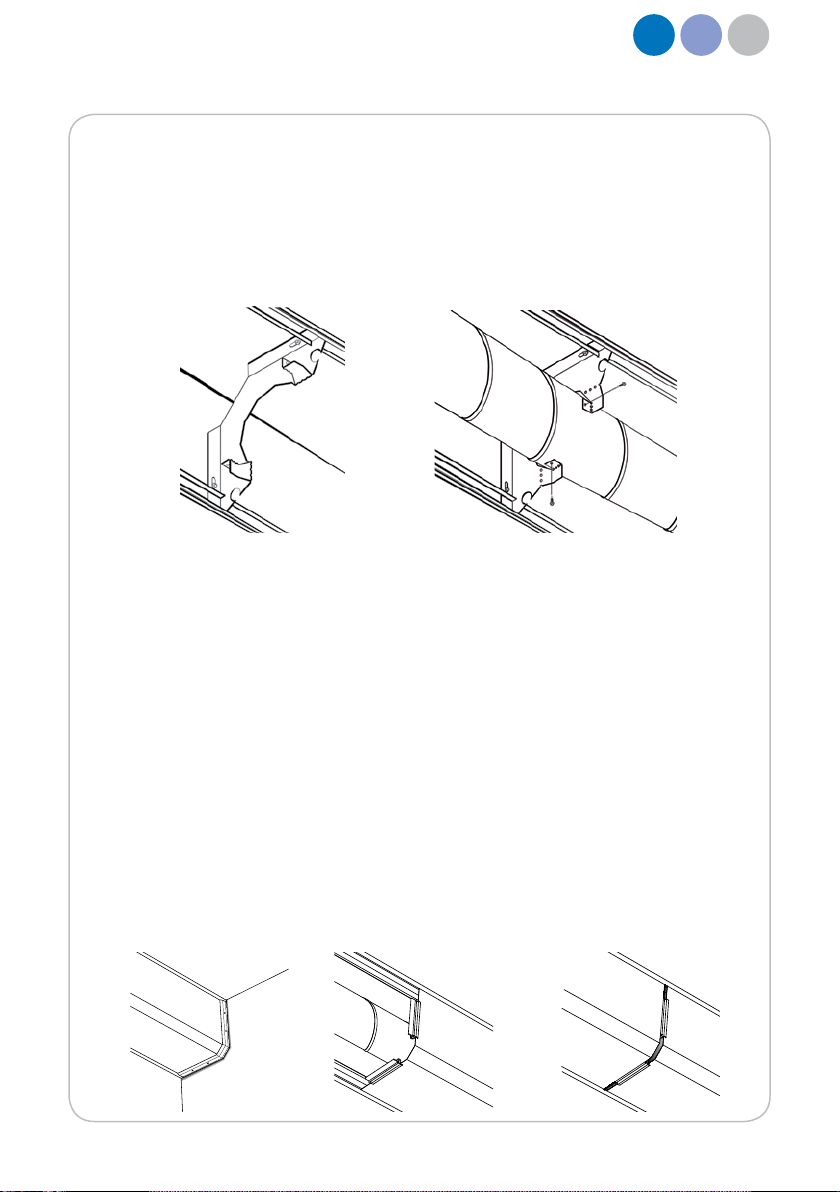

Rails and consoles ............................................................................................................ 6

Support plates....................................................................................................................8

Duct system ...................................................................................................................... 9

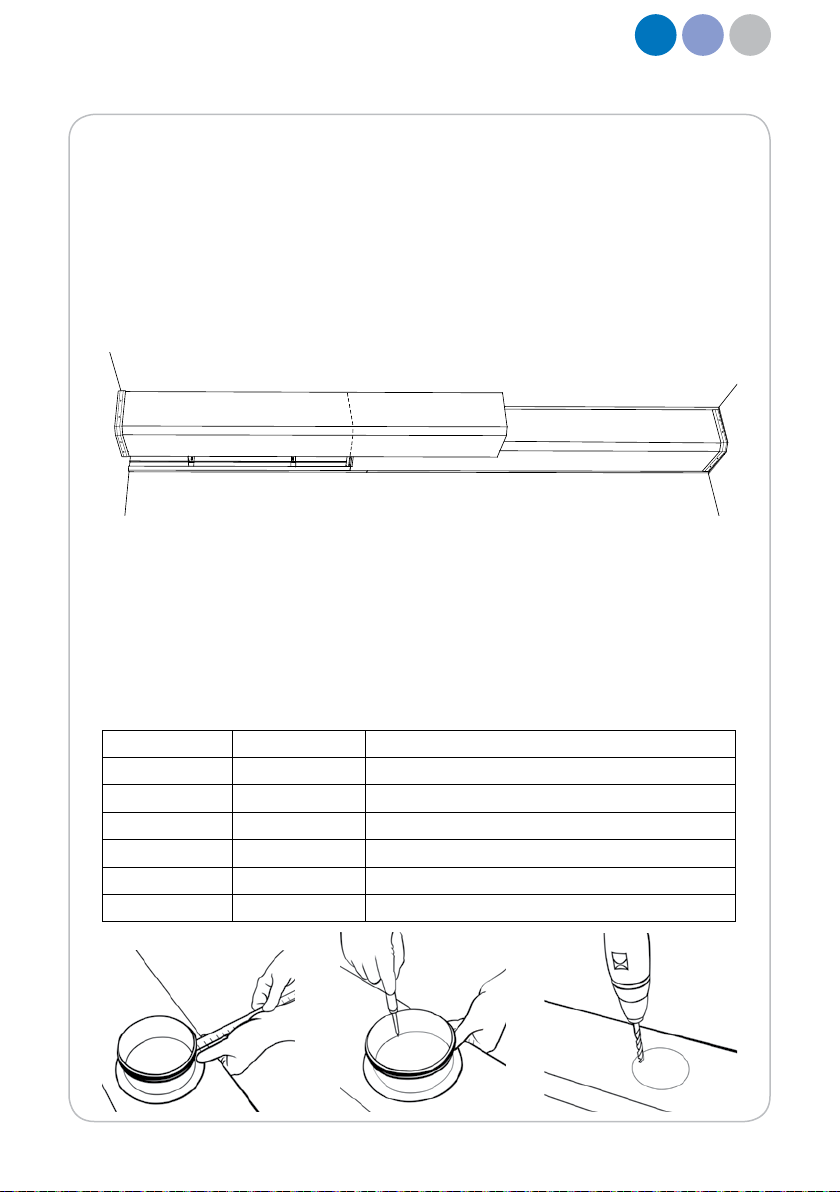

Panels and joints................................................................................................................9

Crossing the ceiling..........................................................................................................11

Dimensional transitions....................................................................................................12

Gable................................................................................................................................15

Electrical installations...................................................................................................... 17

Vertical obstacles ............................................................................................................ 18

Touch-up paint ................................................................................................................ 18

Rail alignment plate..........................................................................................................18

Fire................................................................................................................................... 19