Lindos Electronics Application Notes

Copyright Lindos Electronics

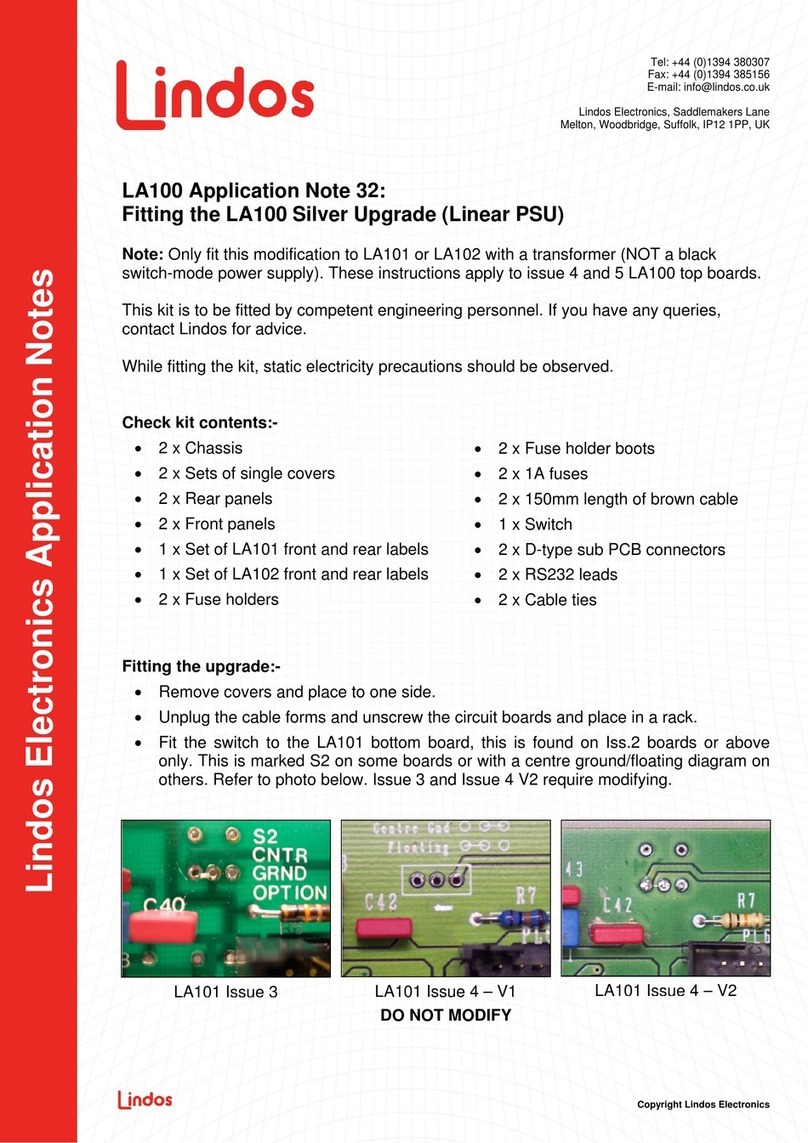

Using an ohmmeter, confirm that holes 25 & 26 are not connected, and hole 26

(the one nearest the back) is connected to pin 3 of IC18 (IC18 is on a heat sink,

and pin 3 is nearest the back of the PCB).

Solder a new 26 way connector into position PL1. Ensure the notch faces forward

(like PL2).

Solder the new transformer into place.

Solder the preformed 11DQ03 into position D10 ensuring it is inserted with correct

polarity. (Band on diode to ‘-’ on PCB)

Solder a preformed wire link into position R3

Solder a new bridge rectifier CH228 into position D4, ensuring it is inserted with

correct polarity. (‘+’ on component to ‘+’ on PCB)

Solder the 6R8 resistor and remaining 11DQ03 diode to the bottom of the PCB as

follows:

Solder the anode of the new diode to the anode of D10.

(The band on the diode body identifies the cathode.)

Solder one end of 6R8 to the cathode of D10.

Solder together the free ends of the new components.

Connect the junction of the new components to PL1 pin

25 using the insulated silver wire supplied.

Tack the wire in place with super glue and clean the flux

residue from the PCB.

Solder the IEC mains inlet onto the PCB with the brown

and blue wires arranged as they were at the start.

Replace the plastic cover over the mains connections to the transformer.

Reassembly

Feed the ribbon cables from the front panel through the slots in the chassis. The

new display cable needs a twist. The twist should be made so that it is between the

front panel and the chassis.

Fit the front panel to the chassis with the 4 original screws. Do not overtighten or

the front panel will crack.

Attach the earthing conductor to the chassis with the original screw, nut and two

shakeproof washers, one either side of the solder tag.

Replace the IEC mains inlet unit with the original screws and nuts. The centre pin

of the connector should be closest to the top of the chassis.

Place the top board in position. Ensure the new resistor and diode do not foul the

chassis and adjust their position if necessary. Finally check the wiring of the new

bottom board modifications, then screw the board into place.

Replace all the ribbon cable connectors.

Replace the battery, but do not connect yet.

Testing

With an ohmmeter check the following:

- IEC mains connector to chassis should be short circuit.*

- IEC connector live to neutral should be about 695W.*

- Live to chassis and neutral to chassis should be open circuit.*

- Chassis to each end of D10 should be open circuit.

- Cathode of D10 to PL1 pin 25 should be 6R8.

- PL1 pin 25 to PL1 pin 26 should be about 55kW.

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Transformer

Connections

(underside of pcb)

brown blue