Linear Technology DC1187A User manual

Looking for a discount?

Check out our current promotions!

This coversheet was created by Verical, a division of Arrow Electronics, Inc. (“Verical”). The attached document was created by the part supplier,

not Verical, and is provided strictly 'as is.' Verical, its subsidiaries, affiliates, employees, and agents make no representations or warranties

regarding the attached document and disclaim any liability for the consequences of relying on the information therein. All referenced brands,

product names, service names, and trademarks are the property of their respective owners.

00000005981LF-000

EOS Power

Buy Now

We have 45,000 LP502030-PCM-NTC-LD-A02554 - EEMB - Lithium Battery Rectangular 3.7V 250mAh Rechargeable in

stock now. Starting at $0.034. This EEMB part is fully warrantied and traceable.

1-855-837-4225

Give us a call

International: 1-555-555-5555 1-415-281-3866

1-415-281-3866

Arrow Electronics,

Verical Division

P.O. Box 740970

Los Angeles, CA 90074-0970

Arrow Electronics, Inc

9201 East Dry Creek Road

Centennial, CO 80112

DC1187A

ANALOG DEVICES

Buy Now

LTC3212

1

DESCRIPTION

WARNING!

Do not look directly at operating LED.

This circuit produces light that can damage eyes.

Demonstration circuit 1187 is an RGB LED Driver

and Charge Pump featuring the LTC3212.

The LTC3212 is a low noise charge pump capable

of driving three LEDs up to 25mA each. This de-

vice requires only one flying capacitor, two by-pass

capacitors, and one to three programming resis-

tors. Each LED may be turned on individually, in

combination with each other, or in white mode us-

ing a single wire interface. White mode optimizes

the red, green, and blue current settings to provide

the best white color.

LED currents are regulated using internal low

dropout current sources. Automatic mode switch-

ing optimizes efficiency by switching modes only

when a dropout is detected. Refer to the LTC3212

datasheet for more information on this device.

Design files for this circuit board are available.

Call the LTC factory.

L

, LTC, LTM, and LT are registered trademarks of Linear Technology Corporation.

Other product names may be trademarks of the companies that manufacture the

products.

PERFORMANCE SUMMARY

Specifications are at T

A

= 25°C

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Supply Range

2.7 5.5

V

I

VIN

Shutdown Current LEDEN = LOW 3 8 µA

I

VIN

Operating Current

ICPO

= 0mA, 1X Mode

ICPO

= 0mA, 2X Mode

0.4

2.0

mA

mA

I

LED

R

ISET

= 33.87K

Ω

(Not in White Mode)

R

ISET

= 58.87K

Ω

(Not in White Mode)

R

ISET

= 8.87K

Ω

(Not in White Mode)

5.24

3.0

20.0

mA

mA

mA

I

LEDG

(WHITE MODE)

R

ISETG

= 33.87K

Ω

R

ISETG

= 58.87K

Ω

R

ISETG

= 8.87K

Ω

5.24

3.0

20.0

mA

mA

mA

I

LEDB

(WHITE MODE)

R

ISETG

= 33.87K

Ω

R

ISETG

= 58.87K

Ω

R

ISETG

= 8.87K

Ω

3.93

2.62

15.0

mA

mA

mA

I

LEDR

(WHITE MODE) R

ISETG

= 33.87K

Ω

R

ISETG

= 58.87K

Ω

R

ISETG

= 8.87K

Ω

4.72

2.71

18.0

mA

mA

mA

I

LED

Dropout Voltage (V

ILED

) Mode Switching Threshold, I

LED

= 15mA 150

mV

Charge Pump Output Clamp Voltage

5.1

V

I

CPO

0 75 mA

DEMO CIRCUIT

1187

QUICK START GUIDE

LTC3212

RGB LED Driver and

Charge Pump

LTC3212

2

OPERATING PRINCIPLES

The DC1187 has a programmable IC on board that

communicates to the DC590 USB to I

2

C board

and drives the LTC3212 via a single wire interface.

The current in each LED output is set by adjusting

the resistance at the associated ISET pin. Each

ISET pin is connected to an 8.87K

Ω

resistor in se-

ries with a 50K

Ω

potentiometer. This allows the

user to adjust each ISET resistance between

8.87K

Ω

and 58.87K

Ω

to experiment with different

color variations and intensities. The current for

LEDG is set by the RSETG potentiometer, R4. The

currents for LEDR and/or LEDB are also set by the

RSETG potentiometer when in white mode and

when ISETR and/or ISETB are tied to VIN via JP2

and JP3 respectively. Otherwise, the LEDR and

LEDB output currents are set by the RSETR po-

tentiometer, R6, and RSETB potentiometer, R5,

respectively.

QUICK START PROCEDURE

Demonstration circuit 1187 is easy to set up to

evaluate the performance of the LTC3212. Refer to

Figure 1 for proper measurement equipment setup

and follow the procedure below:

NOTE.

When measuring the input or output voltage ripple, care

must be taken to avoid a long ground lead on the oscilloscope

probe. Measure the input or output voltage ripple by touching the

probe tip directly across the VIN or CPO and GND terminals. See

Figure 2 for proper scope probe technique.

1.

Place jumpers in the following positions:

JP1 LEDEN:

Up, DC590 position.

JP2 ISETR:

Down, RSETR position.

JP3 ISETB:

Down, RSETB position.

2.

Make sure that the RSETG, RSETR, and

RSETB potentiometers are set approximately to

the center position (adjustment slot is

perpendicular to top of board).

3.

Refer to the DC590 Quick Start Guide for

QuikEval

TM

setup and software installation

details.

4.

If using the DC590B board, make sure the

VCCIO jumper, JP6, on the DC590B board is

set to the 5V position. The microcontroller on

the DC1187 board needs 5V to operate

properly.

5.

Make sure the USB cable is connected between

the computer and the DC590 controller board.

6.

Connect DC1187 to the DC590 USB Serial Con-

troller using the supplied 14-conductor ribbon

cable as shown in Figure 1.

7.

With power off, connect the input power supply

to VIN

and GND with a series ammeter and a

voltmeter as shown in Figure 1.

8.

Turn on the input power supply and set the VIN

voltage to 3.6V.

NOTE.

Make sure that the input voltage does not exceed 6V.

9.

Run the QuikEval program. The program de-

tects the DC1187 and displays the LTC3212

control window (shown in Figure 3).

10.

Select the Green/Red option button on the

LTC3212 control window and observe that the

RGB LED illuminates light greenish.

11.

Adjust RSETG fully counterclockwise and ob-

serve that the RGB LED changes to a yellowish

green color.

12.

Adjust RSETR fully clockwise and observe that

the RGB LED color changes to light orange.

13.

Move the ISETR jumper from the RSETR posi-

tion to the RSETG position and observe that the

RGB LED color changes to light green.

14.

Select the Blue/Green option button on the

LTC3212 control window and observe that the

RGB LED illuminates light blue.

LTC3212

3

15.

Slowly adjust RSETB fully counterclockwise

then adjust RSETG fully clockwise. Observe

that the RGB LED changes from light blue to

greenish blue.

16.

Move the ISETB jumper from RSETB to

RSETG and observe the RGB LED color

change.

17.

Select the Blue/Red option button on the

LTC3212 control window and observe that the

RGB LED illuminates bluish red.

18.

Move the ISETR jumper to the RSETR position

and the ISETB jumper to the RSETB position.

Observe that the LED illuminates pink.

19.

Select the White Mode option button on the

LTC3212 control window. Observe that the RGB

illuminates a whitish color.

20.

Slowly adjust the RSETG potentiometer fully

counter-clockwise and observe that the LED

changes intensity but not color.

21.

Select the LEDs OFF option button and turn off

power when done.

LTC3212

4

Figure 1. Proper Measurement Equipment Setup

VIN

GND

Figure 2. Measuring Input or Output Ripple

LTC3212 SOFTWARE CONTROL WINDOW

The LTC3212 software control window consists of

7 LED Enable Mode option buttons, which allow

the user to select which LEDs to turn on or off, or

select white mode. White mode turns on the three

LEDs at an optimal intensity to display white light.

A Pulse text box displays how many pulses were

LTC3212

5

sent to the LTC3212. The Update button updates

the microcontroller with the proper timing informa-

tion and updates the LTC3212 to match the se-

lected LED Enable mode option button. The Up-

date button will need to be selected if whenever

VIN applied, the 14 conductor ribbon cable is con-

nected, if the DC590 board is connected, or if the

PIC RESET button on the DC1187 board was de-

pressed. The PIC RESET button resets the PIC

microcontroller on the demo board. The “View

LTC3212 Product Page” button searches the LTC

web site for the LTC3212, providing an internet

connection is available.

LED ENABLE SETTINGS

PULSES R G B

0 0 0 0

1 0 0 1

2 0 1 0

3 0 1 1

4 1 1 0

5 1 0 1

6 1 0 0

7+ WHITE MODE

Figure 3. LTC3212 Control Window

LTC3212

6

LTC3212

7

Table of contents

Other Linear Technology DC Drive manuals

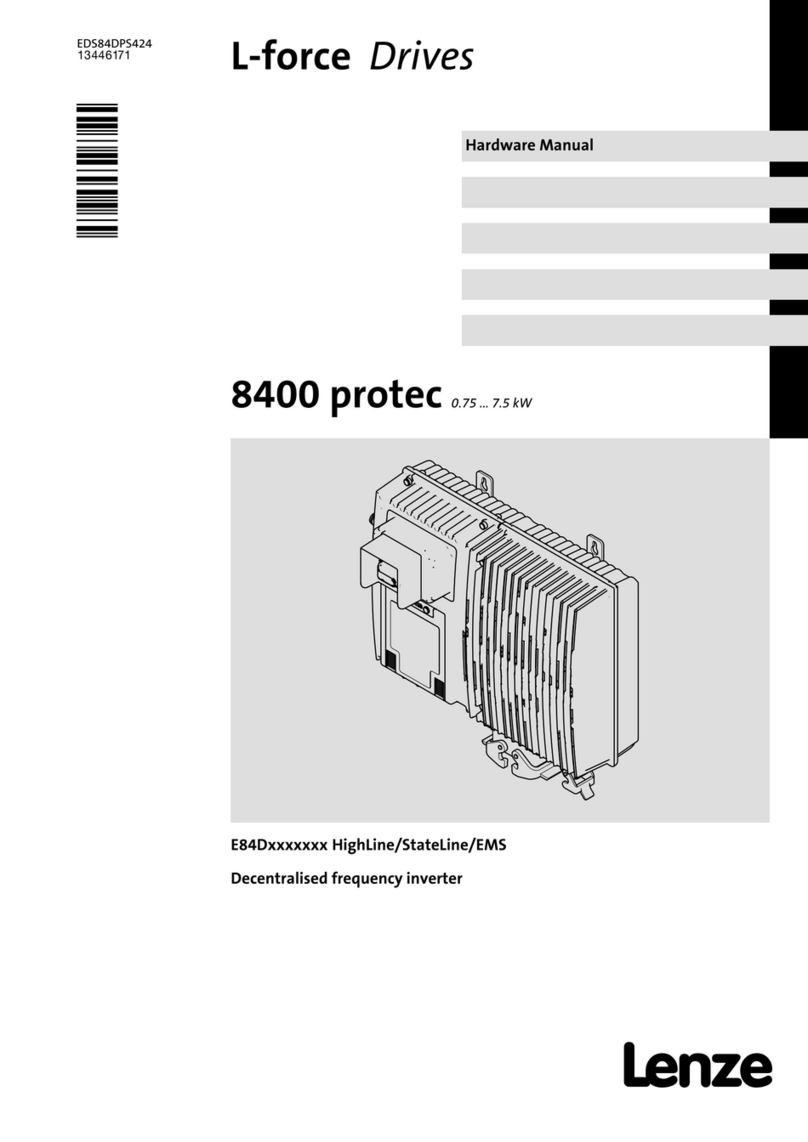

Popular DC Drive manuals by other brands

AutomationDirect

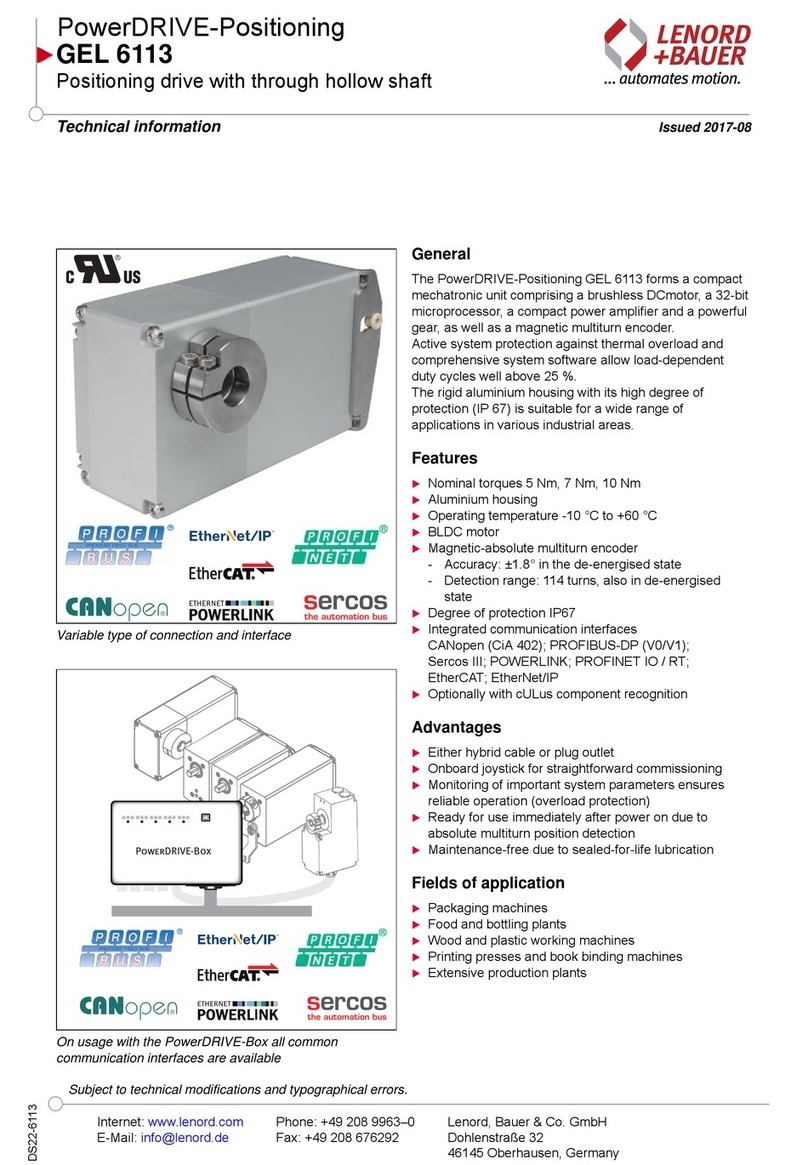

AutomationDirect IRON HORSE GSD5 Series user manual

Lenze

Lenze 8400 protec Hardware manual

K&R

K&R GT600-4T132G user guide

Acclaim Lighting

Acclaim Lighting Pixel Driver 400 user guide

SIEB & MEYER

SIEB & MEYER SD2S 0362X49xy Hardware description

ABB

ABB ACS880-01 Series Quick installation and start-up guide

Seco

Seco BVFD163WD quick start guide

DeVilbiss

DeVilbiss QS-5001 Service bulletin

Danfoss

Danfoss VLT AutomationDrive FC 301 Programming guide

Beijer Electronics

Beijer Electronics Korenix JetNet 7612G Quick installation guide

Grundfos

Grundfos MGE 71 Series Installation and operating instructions

Powtran

Powtran PI500 series manual