Linear Technology DC1937B Quick setup guide

1

dc1937bf

DEMO MANUAL DC1937B

DESCRIPTION

LTC3350EUHF

High Current Supercapacitor Backup

Controller and System Monitor

Demonstration circuit 1937B is a supercapacitor charger

and backup controller with supercapacitor health and

system monitoring; featuring the LT C

®

3350. The LTC3350

hasabucksupercapacitor charger, backup boost controller

and an input ideal diode to disconnect the input supply

in backup mode. An output ideal diode allows the super-

capacitors to supply the output when VCAP is above the

set backup voltage. As the capacitor stack voltage drops

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and

QuikEval is a trademark of Linear Technology Corporation. All other trademarks are the property

of their respective owners.

PERFORMANCE SUMMARY

down to the set output voltage, the LTC3350 will operate

as a boost regulator to supply the output until the energy

in the supercapacitors are depleted.

Design files for this circuit board are available at

http://www.linear.com/demo/DC1937B

Specifications are at TA= 25°C

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Supply Range 10.8 12 20 V

Input Current Limit 2 A

VOUT Backup Operating Voltage Boost Mode 6 V

VCAP Float Voltage Buck Mode 10 V

Max Charge Current 5.33 A

tBACKUP PBACKUP = 25W, IBOOST = 9.67A, 3 ≤ VCAP ≤ 10 3.2 s

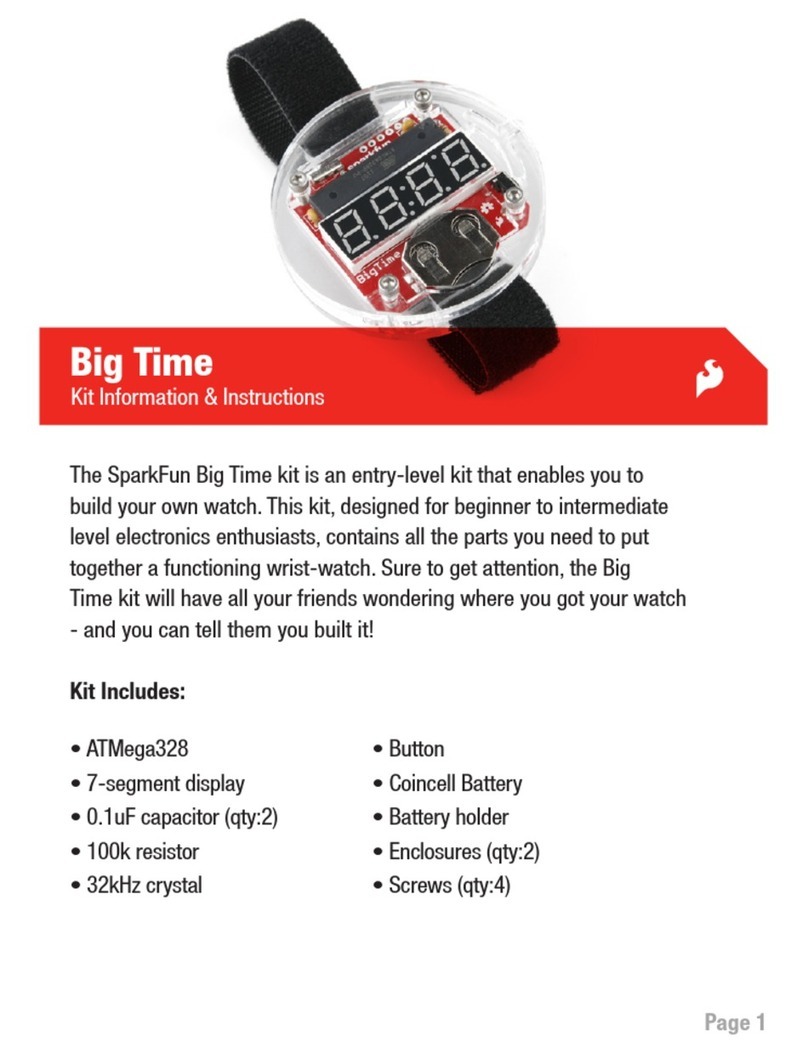

BOARD PHOTO

2

dc1937bf

DEMO MANUAL DC1937B

QUICK START PROCEDURE

ObtainandconnectaDC590BboardtotheDC1937Bboard.

Using short twisted pair leads for the power connections

and with the LOAD and the power supply OFF. Refer to

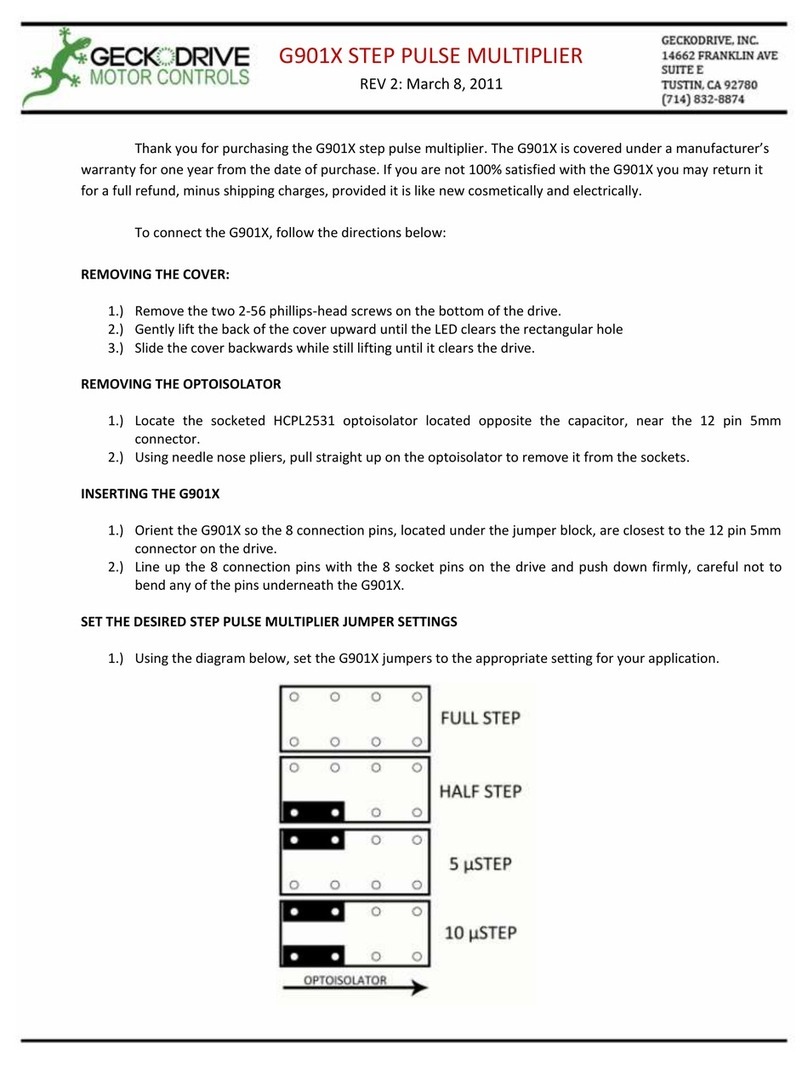

Figure 1 and Figure 2 for the proper measurement and

equipment setup. Follow the procedure below.

1. Refer to the DC590B Quick Start Guide for QuikEval™

setup and software installation details.

2. Make sure the USB cable is connected between the

computer and the DC590B controller board.

3. Connect a 14-pin ribbon cable from the DC590B board

to the DC1937B board.

4. Set the VCCIO jumper, JP6, on the DC590B board to

the 5V position.

5. Set the JP1 jumper on the DC1937B board to the

DC590 position.

6. Start the Linear Technology QuikEval program. This

program should automatically detect the presence of

the LTC3350 demo board (DC1937B) and activate the

appropriate GUI, as seen in Figure 5.

TYPICAL APPLICATION

High Current Supercapacitor Charger and Backup Supply

Backup Operation

V

IN

PFI OUTFB

OUTFET

TGATE

SW

BGATE

ICAP

VCAP

CAP4

CAP3

CAP2

CAP1

CAPRTN

CAPFB

INFET VOUTSP VOUTSN

I

CHG

(STEP-DOWN) I

BACKUP

VCAP < VOUT

(STEP-UP)

VCAP > V

OUT

(DIRECT

CONNECT)

V

OUT

LTC3350

10F

VCAP

10F

10F

10F

dc1937b TA01a

I2C

VIN

2V/DIV

VCAP

2V/DIV

VOUT

2V/DIV

400ms/DIV

BACK PAGE APPLICATION CIRCUIT

0V

dc1937b TA01b

PBACKUP = 25W

VOUT

VCAP

VIN

7. With power off, connect a 0V to 20V, 25W supply

between the VIN and GND terminals with a series

ammeter and a voltmeter as shown in Figure 1.

8. Turn on and set the VIN input power supply to 12V and

observe the CAP voltages, input and charge current

on the GUI.

NOTE. Make sure that the input voltage does not

exceed 20V.

NOTE. The LTC3350 is intended to operate with a low

impedance source. If operating near the PFI rising

threshold, make sure the input voltage does not drop

more than 30mV • (R5 + R6)/R6, 266mV, during a

charge event.

9. On the LTC3350 Control Window, click on the CAP

and ESR Measurement START button. An In Process

indicator displays whilethe measurement is in process.

NOTE. Supercapacitors initially have large leakage

currents which causes the capacitance measurement

to be low. The capacitor measurements will be more

accurate after the 10F capacitors have been continu-

ously charged for more than 30 minutes.

3

dc1937bf

DEMO MANUAL DC1937B

10. Connecta0Wto25Wconstantpowerloadboxbetween

VOUT and GND and set to 25W.

11. Connect an oscilloscope probe each to VIN, VOUT,

VCAP and PFO. Set the oscilloscope to trigger on the

falling edge of PFO.

12. Remove the input power and observe how the output

drops to the regulation point and is maintained until

the energy in the supercapacitors are exhausted.

QUICK START PROCEDURE

13. The LTC3350 has the ability to monitor and report on

the supercapacitor and system voltages, currents, die

temperature and capacitor health. See the software

section and data sheet for more information.

14. The DC1937B can be modified to operate at differ-

ent frequencies, operating voltages, input and boost

currents. The Hardware Config tab allows the user to

enter the appropriate changes so the GUI can report

the correct measurements. See the Software section

for more details.

Figure 1. Proper Measurement Equipment Setup

Figure 2. Measuring Input or Output Ripple

4

dc1937bf

DEMO MANUAL DC1937B

APPLICATION INFORMATION

Figure 3. Charger Efficiency Figure 4. Boost Efficiency

VCAP (V)

0

EFFICIENCY (%)

100

10

90

70

50

30

80

60

40

20

05 93 7

dc1937b F03

10

4 82 61

IOUT (A)

0

EFFICIENCY (%)

100

10

90

70

50

30

80

60

40

20

01.5 3.50.5 2.5

dc1937b F04

4.0

1.0 3.02.0

VCAP = 5V

VCAP = 4V

VCAP = 3V

The DC1937B was designed to provide 25W of power for

a total of 1.8 seconds with a backup voltage of 6V. It was

also determined that the maximum life expectancy of this

product is six years with a maximum ambient tempera-

ture of 45°C. When choosing the capacitance needed the

condition of the supercapacitor at end of life (EOL) needs

to be considered. EOL is typically when the capacitance

decreases by 30% and when the ESR doubles. With this

knowledge and a few calculations the capacitors needed

for this application can be chosen. Refer to the LTC3350

data sheet for more details on the formulas used in the

following examples.

Since the backup time and backup power are known, the

next item that needs to be determined is the maximum

voltage to be applied to the capacitor VCELL(MAX) to provide

the maximum life expectancy for the application. Refer to

the capacitor manufacture’s data sheet for this informa-

tion. A VCELL(MAX) of 2.5V was chosen for the 6 year life

expectancy of this product.

The number of capacitors in the stack also needs to be

chosen plus the Utilization Factor (αB). αBis the amount

of energy in the capacitor to be used for backup. A typi-

cal αBis 80%, but a conservative αBof 70% was used

on the DC1937B. The minimum capacitance required for

each capacitor in the stack at EOL can be calculated by

the following equation:

CEOL ≥

4P

BACKUP

• t

BACKUP

nηVCELL(MAX)2•

αB+ αB– 1– αB

( )

ln 1+ αB

1– αB

–

1

Where ηrepresents the boost efficiency, n represents the

number of capacitors in the stack. Based on an efficiency

of 90% and the backup requirements, the minimum CEOL

is calculated as:

CEOL ≥

4•25W •1.8s

4• 0.9 •(2.5V)2•

0.7+0.7 – 1– 0.7

( )

ln 1+0.7

1– 0.7

–1

=6.816F

The maximum capacitor ESR at end of life can then be

determined below:

ESREOL ≤η(1– αB)nV2(CELL(MAX)

4PBACKUP

5

dc1937bf

DEMO MANUAL DC1937B

The capacitor ESREOL is determined below:

ESREOL ≤0.9(1– 0.7)• 4 •(2.5V)2

4•25W

=67.5mΩ

Now the EOL parameters are known, the capacitor can be

chosenbasedon the manufacture’scapacitorspecification

for EOL. For the DC1937B, the NESSCAP ESHSR-0010C0-

002R7 was chosen with a CEOL of 7F, an ESREOL of 64mΩ

and a maximum current of 10.1A.

To verifythe capacitors are adequate at EOL we first need to

determine the minimum stack voltage (VSTK(MIN)) at EOL.

VSTK(MIN) will be limited by either the maximum power

transfer rule or by current limit, whichever is greater. The

minimum capacitor voltage due to the maximum power

transfer rule can be calculated with the following formula:

VSTK(MIN) =4•ESREOL •n•PBACKUP

η

VSTK(MIN) is the maximum stack voltage (n• VCELL). The

desired VSTK(MIN) due to the maximum power transfer

rule is calculated as:

4• 4 •64mΩ•25W

0.9 =5.333V

VSTK(MIN) can also be determined by the current limit and

the ESREOL as shown in the following equation:

VSTK(MIN) =

P

BACKUP

ηI

LMAX

+nESREOLILMAX

Where ILMAX is the boost peak current limit. The EOL

VSTK(MIN) based on boost peak current limit is calculated

below:

25W

0.9 •9.67A

+4•64mΩ•9.67A =5.348V

Now VSTK(MIN) at EOL is known, the VSTK(MIN) can be

rearranged to calculate actual αBat EOL. The calculated

VSTK(MIN) can also be used to determine if the chosen

capacitor will be sufficient for worst case EOL conditions,

when both ESREOL and CEOL have been reached.

tBACKUP =

ηC

STK

4P

BACKUP

•

γ(MAX)V2(STK(MAX) –γ(MIN)V2(STK(MIN) – V2LOSS

Where CSTK is the total stack capacitance, VSTK(MIN) is

based on the higher calculated VSTK(MIN),

γ(MAX) =1+1– 4nESREOL •PBACKUP

ηV2STK(MAX)

,

γ(MIN) =1+1– 4nESREOL •PBACKUP

V2STK(MIN)

and

V2LOSS =4nESREOLP

BACKUP

ηln γ(MAX)VSTK(MAX)

γ(MIN)VSTK(MIN)

The worst case EOL backup time is calculated below:

γ(MAX) =1+1– 4 • 4• 64mΩ•25W

0.9 •(10V)2=1.8459

γ(MIN) =1+1– 4• 4 •64mΩ•25W

0.9 •(5.348V)2=1.0740

VLOSS2=

4• 4 •64mΩ•25W

0.9 •

ln 1.8459 •10V

1.0740 •5.348V

=33.207V2

tBACKUP =

0.9 •

7

4

F

4•25W •

1.846 •(10V)2–1.074•(5.348V)2– 33.207V2

=1.9s

The above results show that if both ESREOL and CEOL are

reached then the backup requirement will be met. If the

backup requirement was not met, then a capacitor with

lower ESR and/or more capacitance should be chosen.

APPLICATION INFORMATION

6

dc1937bf

DEMO MANUAL DC1937B

USING THE LTC3350 SOFTWARE

The LTC3350 program provides the ability to measure

and monitor the system voltages and currents plus the

health of the supercapacitors. It also allows the user to

set up alarms to report on specific events such as power

fail or cap measurement done. Refer to Figure 5 for an

illustration of the LTC3350 control window.

VIEW LTC3350 PRODUCT PAGE button opens an Internet

browser and searches the Linear Technology Corporation

website for information on the LTC3350 when an Internet

connection is available.

CAP and ESR Measurement START button starts a ca-

pacitor and ESR measurement. An indicator below the

START button indicates the status of the capacitor/ESR

measurement. The different states are; In Process, Done,

Pending or Failed.

Number of Caps Selected text box indicates the number

of capacitors selected using the CAP_SLCTx pins.

SMBALERT Detected indicator indicates if an SMBALERT

has been detected or not.

Clear SMBUS ALERT button sends an SMBus alert re-

sponse address to clear the SMBALERT. Note, the condi-

tion that caused the SMBALERT must be cleared before

the SMBALERT signal can be cleared.

CAP text box indicates the latest measured capacitance in

Farads for large capacitors and mF for smaller capacitors.

This measurement is based on the CAP scale setting in the

control register plus the Current and Oscillator Resistor

Settings on the Hardware Config tab.

ESR text box indicates the latest measured ESR in mΩ.

VCAP text box indicates the latest VCAP voltage in Volts.

ICHRG text box indicates the latest measured charge/

boost current in amps. This measurement is based on the

RSNSC setting on the Hardware Config tab.

VCAPx text box indicates the latest measured capacitor

voltage in Volts for the corresponding VCAP.

VIN text box indicates the latest measured input voltage

in Volts.

IIN text box indicates the latest measured input current in

amps. This measurement is based on the RSNSI setting

on the Hardware Config tab.

VOUT textbox indicates the latest measured VOUT in Volts.

GPImon

text box indicates the latest measured GPI voltage

in Volts. An internal buffer can be enabled for measuring

high impedance inputs.

Die Temp text box displays the latest internally measured

die temperature in °C.

Register text boxes displays the associated register values

in hexadecimal format.

Read Values button causes the LTC3350 to read all of the

ADC measured values. This is useful when the LTC3350

GUI “Auto Update” is disabled.

Auto Update Enable/Disable button causes the LTC3350

to read all of the LTC3350 registers periodically and writes

to any register changed when enabled. The Read Values,

Read All, or Update All buttons can be used instead to

update the registers when in the disabled state.

Read All button causes the LTC3350 to read all of the

LTC3350 registers. This is useful when the LTC3350 GUI

Auto Update is disabled.

CHARGER CONTROL TAB

The Charger Control tab contains the indicators and con-

trols for the capacitor charger and monitor plus the GPI

buffer enable as shown in Figure 5.

ChargerStatusSTATUSBitsindicateswhentheassociated

chrg_status register bits are set. See the data sheet from

more information on these bits.

Charger Status Read text box displays the last read

chrg_status register value in hexadecimal format.

CAP ESR Period text box allows the user to set a period

in which the LTC3350 will perform a capacitance and

ESR measurement. The text box is formatted in hours,

minutes, and seconds. The LSB for the CAP ESR Period

register is 10 seconds.

CAP ESR Period Write text box displays the value that

will be or has been written to the cap_esr_period register

value in hexadecimal format.

CAP ESR Period Read text box displays the last value read

from the cap_esr_period register in hexadecimal format.

7

dc1937bf

DEMO MANUAL DC1937B

USING THE LTC3350 SOFTWARE

Figure 5. LTC3350 Control Window

VCAP FB text box allows the user to set the CAPFB refer-

ence voltage from 0.6375V to 1.2V in 37.5mV increments.

The value in the text box is rounded to the nearest mV. The

VCAP text box is also updated with the calculated value

of the CAPFB reverence voltage and the resistor network

entered on the Hardware Config tab.

VCAP FB Write text box displays the value that will be or has

beenwrittentothevcapfb_dacregisterinhexadecimalformat.

VCAP FB Read text box displays the last value read from

the vcapfb_dac register in hexadecimal format.

VCAP text box allows the user to set the VCAP float volt-

age within the limits of the CAPFB reference voltage and

the CAPFB resistor network on the Hardware Config tab.

The value in the text box is rounded to the nearest mV.

The VCAP FB text box is also updated with the calculated

value using the CAPFB resistor network entered on the

Hardware Config tab.

VSHUNT text box allows the user to set the shunt regulator

voltage up to 3.6V or disable the shunt regulator. The shunt

voltage will be reset to the default value of 2.7057 every

time INTVCC is restored. Set VSHUNT to 0V to disable the

shunt regulator.

VSHUNTWritetextboxdisplaysthe value that will be or has

been written to the vshunt register in hexadecimal format.

VSHUNT Read text box displays the last value read from

the vshunt register in hexadecimal format.

Stop CAP Measurement sets the ctl_stop_capesr bit in

the ctl_reg register. This will cause any CAP/ESR mea-

surement in process to stop. This bit will reset when the

measurement has ceased.

CAP SCALE button sets the cap scale from large scale,

default scale for larger capacitors, to small scale for

smaller capacitors. The resolution is increased by 100x

in small scale.

GPI BUFFER ENABLE button sets the ctl_gpi_buffer_en

bit when enabling the GPI input buffer. When the GPI

BUFFER ENABLE is off then the GPI input is measured

without the input buffer.

Control Reg Write text box displays the value that will be

or has been written to the ctl_reg register in hexadecimal

format.

Control Reg Read text box displays the last value read

from the ctl_reg register in hexadecimal format.

8

dc1937bf

DEMO MANUAL DC1937B

Figure 6. Monitor Status/Alarms Tab

MONITOR STATUS/ALARMS TAB

The Monitor Status/Alarms tab contains the indicators for

the mon_status and alarm_reg bits plus control buttons

for the Monitor Status Mask, Alarm Mask and Alarm Clear

bits as shown in Figure 6.

Monitor Status STATUS Bits indicate when the associated

mon_status register bits are set. See the data sheet from

more information on these bits.

Monitor Status Read text box displays the last read

mon_status register value in hexadecimal format.

Mask Monitor Status buttons will allow the rising edge of

the associated monitor status bit to trigger the SMBALERT

when the mask bit is set to 1.

Mask Mointor Write text box displays the value that will

be or has been written to the msk_mon_status register

in hexadecimal format.

Mask Monitor Read text box displays the last read

msk_mon_status register value in hexadecimal format.

Alarm Bits indicatewhen the associated alarm_regregister

bits are set. See the data sheet from more information on

these bits.

Alarm Read text box displays the last read alarm_reg

register value in hexadecimal format.

Mask Alarm buttons will allow the associated alarm bit

to trigger the SMBALERT when the mask bit is set to 1.

Mask Alarm Write text box displays the value that will

be or has been written to the msk_alarms register in

hexadecimal format.

Mask Alarm Read text box displays the last read msk_

alarms register value in hexadecimal format.

Clear Alarm buttons will cause the associated alarm to

clear when the alarm condition no longer exists. The Clear

alarm bit will reset low when the alarm is cleared.

Clear Alarm Write text box displays the value that will

be or has been written to the msk_alarms register in

hexadecimal format.

Clear Alarm Read text box displays the last read msk_

alarms register value in hexadecimal format.

USING THE LTC3350 SOFTWARE

9

dc1937bf

DEMO MANUAL DC1937B

SET ALARMS TAB

The Set Alarms tab contains text boxes to allow the user

to set specific levels for each alarm register as shown in

Figure 7. Each alarm has an associated Write text box to

display the value that will be or has been written to the

associatedregister in hexadecimal format. Each alarm also

hasanassociatedReadtext box which displays the last read

contents of the associated register in hexadecimal format.

VIN/VOUT/VCAP/CAP/GPI UV alarm text boxes allow the

user to enter a voltage that will trigger an alarm when the

associated voltage drops below the entered voltage value

and the associated alarm mask bit is set.

VIN/VOUT/VCAP/CAP/GPI OV alarm text boxes allow the

user to enter a voltage that will trigger an alarm when the

associated voltage rises above the entered voltage value

and the associated alarm mask bit is set.

IIN OC alarm text boxes allow the user to enter a current

or the voltage across the sense resistor that will trigger an

alarm when the input current increase above the entered

value and the msk_iin_oc alarm mask bit is set.

USING THE LTC3350 SOFTWARE

Figure 7. Set Alarms Tab

CAPLOalarm text box allows the user to enteracapacitance

based on the current ctl_cap_scale setting in the ctl_reg. A

CAP LO alarm will be triggeredif the measured capacitance

islower than the enteredvalueandthe msk_cap_lobit is set.

ESR HI alarm text box allows the user to enter an ESR

value based on the RSNSC resistor value entered in the

Hardware Config tab. An ESR HI alarm will be triggered

if the measured ESR is higher than the entered value and

the msk_esr_hi bit is set.

ICHRG UC alarm text boxes allow the user to enter acurrent

or the voltage across the sense resistor that will trigger

an alarm when the charge current decreases below the

entered value and the msk_ichrg_lo bit is set.

Die Temp Cold alarm text box allows the user to enter a

die temperature in °C that will trigger an alarm when the

temperature decreases below the entered value and the

msk_dtemp_cold bit is set.

Die Temp Hot alarm text box allows the user to enter a

die temperature in °C that will trigger an alarm when the

temperature increases above the entered value and the

msk_dtemp_hot bit is set.

10

dc1937bf

DEMO MANUAL DC1937B

Figure 8. Hardware Config Tab

Apply button writes to all of the alarm registers and reads

the values back from the LTC3350.

Cancel button changes all the entered values that have

not yet been written to the LTC3350 back to their previ-

ous values.

Restore Defaults button changes all of the LTC3350 alarm

registers back to the default values determined from the

GUI. This does not set the alarm to the LTC3350’s default

settings of 0x0000.

HARDWARE CONFIG TAB

The Hardware Config tab, shown in Figure 8, contains text

boxes to allow the user to enter the values to configure

the necessary resistors to match the configuration of the

demo board. These values are used by the GUI to calculate

measured CAP and ESR values, display input/charge cur-

rents and max VCAP voltage for a given reference setting,

and also used in the Set Alarm tab text boxes.

VPFI Resistor Settings text boxes allow the user to enter

thePFIresistordivider network in kΩ.Thecalculated falling

PFI threshold set point is displayed in Volts.

VOUT Resistor Settings text boxes allow the user to enter

the VOUT resistor divider network in kΩ. The calculated

VOUT backup set point is displayed in Volts.

RITST text box allows the user to enter the RITST resistor

in Ω. The calculated test current setting is displayed in mA.

REXT text box allows the user to enter the external load

resistance, R28 and R29, added in Ω if any. Enter –1 if

thereis not any external loading and OPEN will be displayed

in the text box. See the Using Large Capacitor section for

more details.

RT text box allows the user to enter the RT resistor in kΩ.

The calculated oscillator setting is displayed in kHz.

Total RBalance text box allows the user to enter the

equivalent total balance resistance in Ω if any for ca-

pacitancestacks or packs that have external balancing.

Enter–1 if there is not any external balancing and OPEN

will be displayed in the text box.

RSNSI text box allows the user to enter the RSNSI resis-

tor in mΩ. The calculated input current limit setting is

displayed in Amps.

RSNSCtextboxallowstheusertoentertheRSNSCresistor

in mΩ. The calculated maximum charge current setting

is displayed in Amps.

VCAP Resistor Settings text boxes allow the user to enter

the CAPFB resistor divider network in kΩ. The calculated

maximum VCAP set point is displayed in Volts.

CAP1 Voltage Divider text boxes allow the user to enter

the CAP1 resistor divider network in kΩ if used. This is

primarily used for the Zeta/SEPIC application (Data sheet

Application Circuit 6). The displayed CAP1 voltage is

calculated from the maximum VCAP voltage. Enter –1 in

the CAP1 Voltage Divider RTop and RBot text boxes then

OPEN will be displayed in both text boxes.

USING THE LTC3350 SOFTWARE

11

dc1937bf

DEMO MANUAL DC1937B

The DC1937B standard configuration is designed for

supercapacitors of 50F or less. The standard configura-

tion measures the time it takes to discharge the capacitor

stack by 200mV at 10mA to calculate the capacitance.

Larger supercapacitors have larger leakage currents,some

over a milliamp, causing an inaccuracy in the capacitive

measurement. To increase the measurement accuracy,

the capacitor test current can be increased by loading

the capacitor stack with external resistors, R28 and R29,

during the measurement. The low threshold N-MOSFET,

M6, is controlled by the ITST pin which turns on the load

when needed.

OPTIONAL EXTERNAL TEST CURRENT

USING LARGE CAPACITORS

Figure 9. External Test Current

Larger capacitors also take longer to balance. If one ca-

pacitor is far enough off balance that it reaches the shunt

voltage before the capacitor stack is fully charged. The

charge current effectively is reduced to the shunt current

until the capacitor stack is fully charged. The standard

DC1937B board is set up for a 500mA maximum shunt

current. This current can be increased by turning on exter-

nal shunt resistors across each capacitor, R30 thru R36.

The controlling FETs, M7 thru M10, are turned on from

the voltage drop across the corresponding shunt resistor

whentheshunt regulator turns on. The 2.7Ω shunt resistors

between the supercapacitor and the CAPx pin as shown in

Figure 10 can be used to provide a larger shunt current.

Figure 10. High Current Shunting

I

SHUNT =

V

SHUNT

2•RSHUNT

+

V

SHUNT

RSHUNT(OPT)

The circuit in Figure 10 allows a larger shunt current to

protect the capacitors and charge up to the maximum

capacitor stack voltage faster but it does not increase the

balancing current.

Having a larger balancing current will help keep the large

capacitors in balance and may prevent the shunt voltage

from being reached. It will also reduce the capacitor volt-

age from the shunt voltage faster after shunting stops and

balancing begins. This is accomplished by increasing the

shunt resistors from 2.7Ω to at least 250Ω and up to 1kΩ.

Using resistors close to 250Ω will cause the balancing

currents to be smaller, less than 10mA with capacitor volt-

ages below 1.8V. Increasing the resistance much above

1kΩ can cause ADC measurement inaccuracies. The ITST

resistor must be increased to 1MΩ or greater; 10MΩ if

possible, to reduce the voltage drop across the CAP4 shunt

resistor, R20, from the internal current source during the

capacitancemeasurement. The circuitin Figure11provides

up to a 2A shunt/balance current and a 200mA capacitor

measurement test current.

12

dc1937bf

DEMO MANUAL DC1937B

USING LARGE CAPACITORS

Figure 11. High Current Balancing/Shunting

CALCULATING THE CAPACITANCE

The calculation for the standard DC1937B is:

CSTACK =

R

T

R

TST

•336µF •MEAS_CAP

for large scale and

CSTACK =

R

T

RTST

•3.36µF •MEAS_CAP

for small scale.

When using a capacitor stack with external balancing

resistors or any other external load on the capacitor

stack, those currents need to be added in the capacitor

measurement calculation. The following equations can be

used to calculate the capacitor test current when external

test load resistors and balance resistors are used.

Time = RT(in Ω) • 5.6e-5 for large scale.

Time = RT(in Ω) • 5.6e-7 for small scale.

ITST _EXT ≅

V

CAP

– 0.1V

RITST _ EXT

IBAL ≅VCAP – 0.1V

RBAL _ TOTAL

ITST ≅1.197V

RITST _ EXT

C=(ITST +ITST _EXT +IBAL )• TIME

0.2V

13

dc1937bf

DEMO MANUAL DC1937B

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 4 C2-C5 CAP, ELECTRIC DOUBLE LAYER, 10F, 2.7V NESSCAP, ESHSR 0010C0 002R7

2 1 C8 CAP, CHIP, COG, 120pF, ±5%, 25V, 0402 MURATA, GRM1555C1E121JA01D

3 2 C10, C25 CAP, CHIP, X5R, 0.1µF, ±10%, 25V, 0402 TDK, C1005X5R1E104K050BC

4 1 C11 CAP, CHIP, X5R, 1µF, ±10%, 25V, 0603 MURATA, GRM188R61E105KA12D

5 3 C12, C16, C24 CAP, CHIP, X7R, 0.1µF, ±10%, 16V, 0402 MURATA, GRM155R71C104KA88D

6 1 C13 CAP, CHIP, X5R, 4.7µF, ±10%, 6.3V, 0603 TDK, C1608X5R0J475K080AB

7 1 C14 CAP, CHIP, X5R, 1µF, ±10%, 16V, 0402 TDK, C1005X5R1C105K050BC

8 1 C15 CAP, 27µF, 25V, ALUM. ELECTRO, 20%, 6.3 × 4.5 SUN ELECT, 25HVH27M

9 1 C18 CAP., 0.01μF, X7R, 16V, 10%, 0402 AVX, 0402YC103KAT2A

10 :2 C19, C20 CAP, CHIP, X5R, 47µF, ±20%, 25V, 1206 TDK, C3216X5R1E476M160AC

11 2 C22, C23 CAP, CHIP, X5R, 2.2µF, ±10%, 25V, 0402 TDK, C1005X5R1E225K050BC

12 4 C26, C27, C28, C29 CAP, CHIP, X5R, 22μF, ±10%, 16V, 0805 TDK, C2012X5R1C226K125AC

13 1 D1 DIODE, SWITCHING, 80V, 0.125A, SOD-523 DIODES INC, 1N4448HWT-7

14 1 L1 IND., PWR., SHIELDED, 3.3μH, 20% COILCRAFT, XAL7030-332MEB

15 2 M1, M4 FET, N-MOS, 20V, 16A, POWER-PAK 1212-8 VISHAY, SIS438DN-T1-GE3

16 2 M2, M3 MOSFET N-CH 25V, 40A TSDSON-8 INFINEON, BSZ060NE2LS

17 1 R3 RES, CHIP, 649kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402649KFKED

18 1 R4 RES, CHIP, 162kΩ, ±1%,1/16W, 0402 VISHAY, CRCW0402162KFKED

19 1 R5 RES, CHIP, 787kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402787KFKED

20 1 R6 RES, CHIP, 100kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402100KFKED

21 5 R7, R20, R23, R24, R25 RES, CHIP, 2.7Ω, ±1%, 1/2W, 0805 WIDE ROHM SEMI, LT R 10EVHFL2R70

22 2 R8, R9 RES, CHIP, 100kΩ, ±5%, 1/16W, 0402 VISHAY, CRCW0402100KJNED

23 3 R12, R13, R14 RES, CHIP, 1kΩ, ±5%, 1/16W, 0402 VISHAY, CRCW04021K00JNED

24 1 R19 RES, CHIP, 0Ω JUMPER, 1/16W, 0402 VISHAY, CRCW04020000Z0ED

25 1 R21 RES, CHIP, 121Ω, ±1%, 1/16W, 0402 VISHAY, CRCW0402121RFKED

26 1 R22 RES, CHIP, 71.5kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW040271K5FKED

27 1 R26 RES, CHIP, 866kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402866KFKED

28 1 R27 RES, CHIP, 118kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402118KFKED

29 1 RSNSC RES, CHIP, 6mΩ, ±1%, 1W, 1632 SUSUMU, PRL1632-R006-FT1

30 1 RSNSI RES, CHIP, 16mΩ, ±1%, 1W, 1632 SUSUMU, PRL1632-R016-FT1

31 1 U1 SUPERCAP BACKUP CONTROLLER LINEAR TECH., LTC3350EUHF#PBF

Additional Demo Board Circuit Components

32 1 C1 CAP, CHIP, X7R, 0.1µF, ±10%, 16V, 0402 MURATA, GRM155R71C104KA88D

33 2 C6, C7 CAP, CHIP, X5R, 1µF, ±10%, 25V, 0603 MURATA, GRM188R61E105KA12D

34 0 C9, C17 CAP, CHIP, 0402

35 0 C21 CAP, 6.3 × 4.5

36 3 D2, D3, D4 LED, SUPER RED, 660nm, 0603, 1.6 × 0.8mm LUMEX, SML-LX0603SRW-TR

37 0 D5 DIODE ZENER, 5.6V, 250mW, DFN1006-2 DIODES INC, BZT52C5V6LP-7

PARTS LIST

14

dc1937bf

DEMO MANUAL DC1937B

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

38 2 R1, R2 RES, CHIP, 20Ω, ±1%, 1/16W, 0402 VISHAY, CRCW040220R0FKED

39 0 R10, R11 RES, CHIP, 0402

40 3 R15, R16, R18 RES, CHIP, 5.1kΩ, ±5%, 1/16W, 0402 VISHAY, CRCW04025K10JNED

41 1 R17 RES, CHIP, 1MΩ, ±5%, 1/16W, 0402 VISHAY, CRCW04021M00JNED

42 0 R28-R29 RES, CHIP, 2W, 2512

43 0 R30-R37 RES, CHIP, 2W, 2512

44 2 R38, R39 RES, CHIP, 2.4MΩ, ±5%, 1/16W, 0402 VISHAY, CRCW04022M40JNED

45 1 M5 MOSFET, N-CH 20V, 5.9A, SOT-23 VISHAY, SI2374DS-T1-GE3

46 0 M6 MOSFET, N-CH 20V, 5.9A, SOT-23 VISHAY, SI2374DS-T1-GE3

47 0 M7-M10 MOSFET, N-CH 8V, 12A, POWERPAK SC-70 6L VISHAY, SIA436DJ

48 1 U2 I2C EEPROM MICROCHIP, 24LC025-I/ST

Hardware: For Demo Board Only

49 10 E1- E10 TURRET, 0.09 DIA MILL-MAX, 2501-2-00-80-00-00-07-0

50 6 E11- E16 TURRET, 0.061 DIA MILL-MAX, 2308-2-00-80-00-00-07-0

51 1 J1 CONN, 2x14 2mm HEADER MOLEX, 87831-1420

52 1 JP1 HEADER, 3PINS, 2mm WURTH, 62000311121

53 1 XJP1 SHUNT 2mm 1X3 WURTH, 60800213421

54 4 STAND-OFF, NYLON 0.50 tall KEYSTONE, 8833(SNAP ON)

55 1 FAB, PRINTED CIRCUIT BOARD DC1937B-3

15

dc1937bf

DEMO MANUAL DC1937B

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

6V BACKUP

10.8V - 20V

10.8V - 20V

UNLESS NOTED:

RESISTORS: OHMS, 0402, 1%, 1/16W

CAPACITORS: uF, 0402, 6.3V, 10%

12V NOMINAL

25W

X5R X5RX5R X5R

25W

DC590 INTVCC

PULL - UP

PWR

OPT

0508

0508

0508

0508

0508

OPTIONAL EXTERNAL

TEST CURRENT

OPTIONAL EXTERNAL SHUNT CURRENT

R38 AND R39 ARE FOR

STAND-ALONE OPERATION ONLY

AND THE I2C BUS IS NOT USED.

SMBUSALERT

ITST

ITST

GCAP4 GCAP3 GCAP2 GCAP1

CAP1

CAP4

CAP4 CAP3 CAP2

CAP3 CAP1

CAP1

CAP2

CAP3

CAP4

GCAP1

GCAP2

GCAP3

GCAP4

CAP2

VCC

VCC INTVCC

INTVCC

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

MMPRODUCTION FAB

-3 05-04-15

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

MMPRODUCTION FAB

-3 05-04-15

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

MMPRODUCTION FAB

-3 05-04-15

SIZE

DATE:

IC NO. REV.

SHEET OF

TITLE:

APPROVALS

PCB DES.

APP ENG.

TECHNOLOGY Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SCHEMATIC

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SCALE = NONE

www.linear.com

3

DEMO CIRCUIT 1937B

11

HIGH CURRENT SUPERCAPACITOR

N/A

LTC3350EUHF

NC

MM

BACKUP CONTROLLER AND SYSTEM MONITOR

05 - 04 - 15

SIZE

DATE:

IC NO. REV.

SHEET OF

TITLE:

APPROVALS

PCB DES.

APP ENG.

TECHNOLOGY Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SCHEMATIC

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SCALE = NONE

www.linear.com

3

DEMO CIRCUIT 1937B

11

HIGH CURRENT SUPERCAPACITOR

N/A

LTC3350EUHF

NC

MM

BACKUP CONTROLLER AND SYSTEM MONITOR

05 - 04 - 15

SIZE

DATE:

IC NO. REV.

SHEET OF

TITLE:

APPROVALS

PCB DES.

APP ENG.

TECHNOLOGY Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SCHEMATIC

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SCALE = NONE

www.linear.com

3

DEMO CIRCUIT 1937B

11

HIGH CURRENT SUPERCAPACITOR

N/A

LTC3350EUHF

NC

MM

BACKUP CONTROLLER AND SYSTEM MONITOR

05 - 04 - 15

RSNSC

0.006

PRL1632

U2

24LC025-I/ST

A0

1

SCLK

6

A2

3

VSS

4

SDA

5

A1

2

WP

7

VCC

8

C26

22uF

0805

16V

10%

E3

VOUT

R10

OPT

D

S

G

M3

BSZ060NE2LS

7

4

1

2

3

6

8

5

R18

5.1K

5%

E7

CAP1

C28

22uF

0805

16V

10%

D

S

G

M2

BSZ060NE2LS

7

4

1

2

3

6

8

5

C20

47uF

1206

25V

20%

M6

Si2374DS

R25

2.7

5%

R35

OPT

2W

2512

R27

118K

+

C15

27uF

25HVH27M

25V

20%

R31

OPT

2W

2512

R22

71.5K

R6

100K

R29

OPT

2W

2512

M5

Si2374DS

E12

CAPGD

C29

22uF

0805

16V

10%

+

C3

10F

2.7V

R36

OPT

2W

2512

TPA2

C17

OPT

R38

2.4M

5%

M9

SiA436DJ

R21

121

M7

SiA436DJ

R13

1K

5%

C14

1uF

16V

5.6V

D5

BZT52C5V6LP

R33

OPT

2W

2512

C1

0.1uF

16V

C23

2.2uF

25V

R11

OPT

E14 GND

+

C2

10F

2.7V

TPB2

E1

VIN

C24

0.1uF

16V

R26

866K

R39

2.4M

5%

R19

0

C12

0.1uF

16V

R8

100K

5%

E13

PFO

C25

0.1uF

25V

M8

SiA436DJ

TPB1 C6

1uF

0603

25V

L1

3.3uH

XAL7030-332MEB

C18

10nF

16V

R16

5.1K

5%

R14

1K

5%

+

C5

10F

2.7V

D2

PFO

RED

C22

2.2uF

25V

JP1

+

C21

OPT

6.3 DIA

C19

47uF

1206

25V

20%

C13

4.7uF

0603

M10

SiA436DJ

C11

1uF

0603

25V

D

S

G

M1

SiS438DN

7

4

1

2

3

6

8

5

RSNSI

0.016

PRL1632

R1

20

R37

OPT

2W

2512

D4

SMBALERT

RED

E11 SMBALERT

D

S

G

M4

SiS438DN

7

4

1

2

3

6

8

5

E9

VCAP

10V

R12

1K

5%

E16

GPI

R20

2.7

5%

TP2

SCL R7

2.7

5%

D1

1N4448HWT

SOD-523

+

C4

10F

2.7V

U1

LTC3350EUHF

VCAP

21

PFI

37

CAP_SLCT1

36

PFO

38

PGND

39

CFP

17

CFN

18

BST

26

BGATE

27

SMBALERT

3

CAPFB

6

OUTFB

7

SGND

8

RT

9

INFET

33

VOUTSN

30

VOUTSP

31

VOUTM5

32

VIN

34

SCL

1

SDA

2

ICAP

22

VCC2P5

23

SW

24

TGATE

25

CAP2

14

CAP3

15

CAP4

16

CAP_SLCT0

35

VCAPP5

19

OUTFET

20

INTVCC

29

DRVCC

28

CAPGD

4

VC

5

GPI

10

ITST

11

CAPRTN

12

CAP1

13

R34

OPT

2W

2512

R2

20

D3

CAPGD

RED

J1

HD2X7

+

1

+

3

+

5

+

7

+

9

+

11

+

13

+

2

+

4

+

6

+

8

+

10

+

12

+

14

R30

OPT

2W

2512

E5

CAP3

TP1

SDA

R9

100K

5%

E10

GND

E4

GND

R15

5.1K

5%

R5

787K

R23

2.7

5%

C7

1uF

0603

25V

R4

162K

E15

GND

E8

GND

C27

22uF

0805

16V

10%

E2

GND

R28

OPT

2W

2512

E6

CAP2

C9

OPT

TPA1

R32

OPT

2W

2512

C16

0.1uF

16V

R24

2.7

5%

R17

1M

5%

C10

0.1uF

25V

R3

649K

C8

120pF

25V

5%

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

tion that the interconnection of its circuits as described herein will not infringe on existing patent rights.

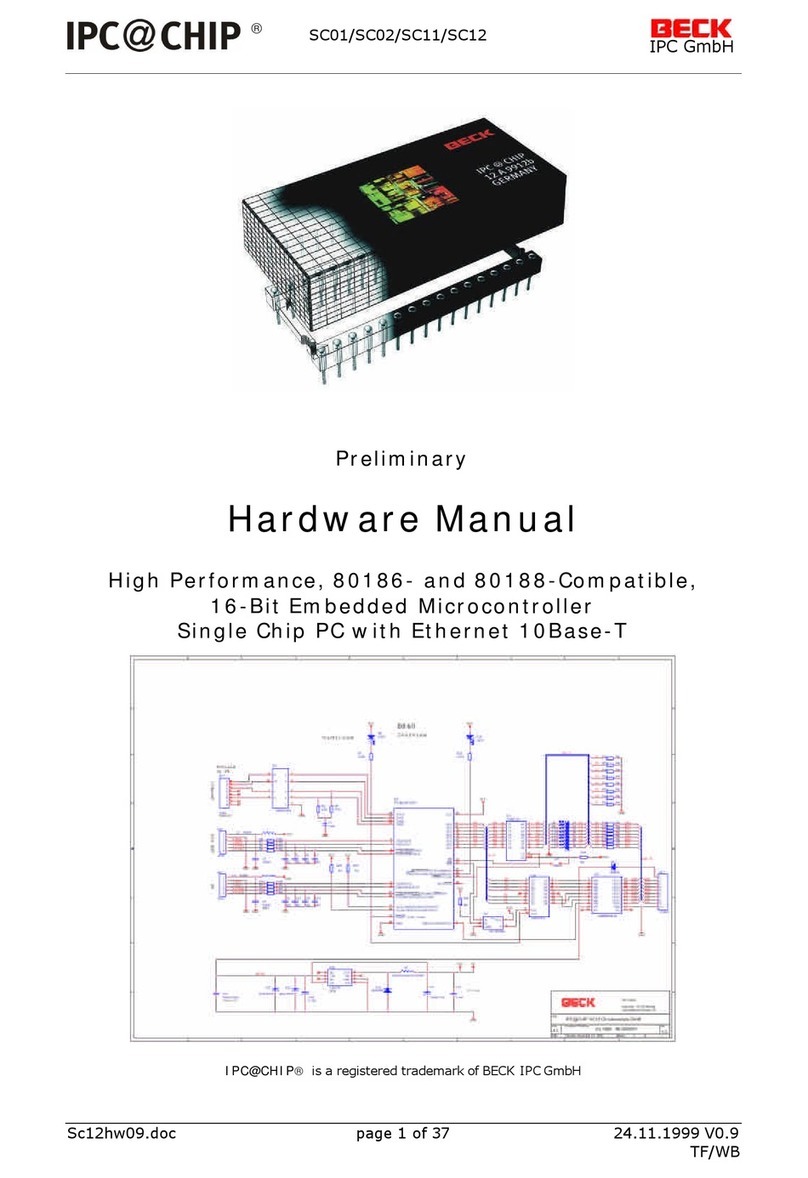

SCHEMATIC DIAGRAM

16

dc1937bf

DEMO MANUAL DC1937B

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ●FAX: (408) 434-0507 ●www.linear.com

LINEAR TECHNOLOGY CORPORATION 2015

LT 0715 • PRINTED IN USA

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application

engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

This manual suits for next models

1

Table of contents

Other Linear Technology Microcontroller manuals

Popular Microcontroller manuals by other brands

Nuvoton

Nuvoton NuMicro M0A21 Series Technical reference manual

Fujitsu

Fujitsu MB2140 Series Hardware manual

PLX Technology

PLX Technology PEX 8619BA Hardware reference manual

Microchip Technology

Microchip Technology SAMR34 Xplained PRO quick start guide

Texas Instruments

Texas Instruments MSP430F67781 manual

Atmel

Atmel megaAVR Getting started