Linear LTM2987 User manual

1

dc2023afa

DEMO MANUAL DC2023A

DESCRIPTION

16-Channel Power Supply

System Featuring the LTM2987

Power System Manager

TheDC2023Aisademonstration system fortheLT M

®

2987

16-channel I2C/SMBus/PMBus power system manager

with EEPROM. The LTM2987 monitors and controls 16

power supply rails. The DC2023A demonstrates the abil-

ity of the LTM2987 to sequence, trim, margin, supervise,

monitor, and log faults for 16 power supply rails. Each

power supply channel’s output voltage is monitored and

the LTM2987 monitors its own internal die temperature.

The DC2023A is a single circuit board that contains sixteen

independentpowersupplyrails.Theboard employs sixteen

LT C

®

3405A 300mA switch-mode regulators, which are

configured tobecontrolled bytheLTM2987. The LTM2987

is available in a µModule

®

(micromodule) package and

contains two LTC2977 devices. This board provides a

sophisticated 16-channel digitally programmable power

supply system. The rail voltages are programmable within

the trim range shown in the Performance Summary.

This demonstration system is supported by the

LTpowerPlay™graphical user interface(GUI) that enables

complete control of all the features of the LTM2987. To-

gether,the LTpowerPlay software and DC2023Ahardware

system create a powerful development environment for

designing and testing LTM2987 configuration settings.

These settings can be stored in the device’s internal

EEPROM or in a file. This file can later be used to order

pre-programmed devices or to program devices in a

production environment. The software displays all of

the configuration settings and real time measurements

from the LTM2987. Telemetry allows easy access and

decoding of the fault log created by the LTM2987. The

board comes pre-programmed with the EEPROM values

appropriate for the sixteen power supplies used on the

DC2023A. Just plug and play!

Multiple DC2023A board sets can be cascaded together

to form a high channel count power supply (see Multi-

Board Arrays). This cascaded configuration demonstrates

features of the LTM2987 which enable timing and fault

information to be shared across multiple ICs. The user can

L, LT, LTC, LTM, Linear Technology, the Linear logo and µModule are registered trademarks

and PowerPlay is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners.

configure up to eight DC2023A boards, thereby control-

ling up to 128 separate power supply rails. Larger arrays

of LTM2987s are supported through programmable I2C

base address or bus segmentation.

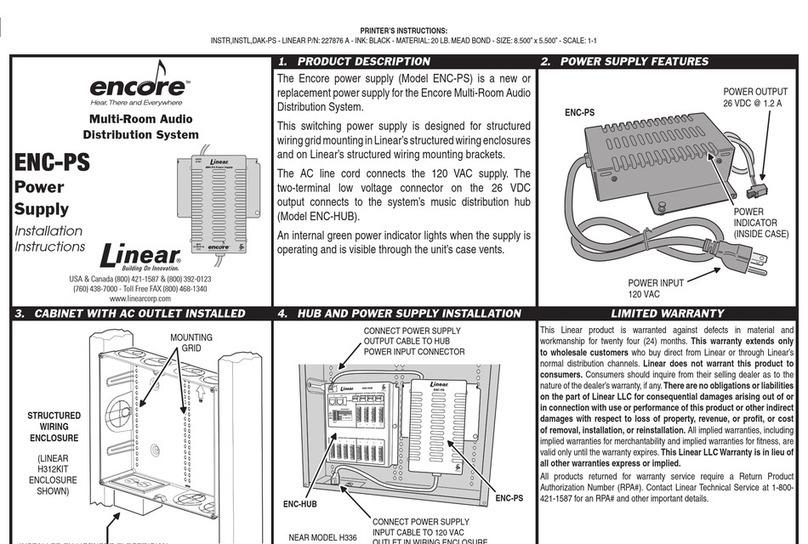

The DC2023A demo board can be powered by an external

power supply, such as a +12VDC supply. Communication

with the software is provided through the DC1613 USB-to-

I2C/SMBus/PMBus Controller. The following is a checklist

of items which can be obtained from the LT C website or

LT C Field Sales.

• USB-to-I2C/SMBus/PMBus Controller (DC1613)

• LTpowerPlay Software

DC2023A Features

• Sequence, Trim, Margin, and Supervise Sixteen Power

Supplies

• Manage Faults, Monitor Telemetry, and Create Fault

Logs

• PMBus Compliant Command Set

• Supported by LTpowerPlay GUI

• Margin or Trim Supplies to 0.25% Accuracy

• Fast OV/UV Supervisors Per Channel

• Supports Multi-Channel Fault Management

• Automatic Fault Logging to Internal EEPROM

• Operates Autonomously without Additional Software

• Sixteen OV/UV VOUT and Tw o VIN Supervisors

• Telemetry Reads Back VIN, VOUT, and Temperature

• 16-Channel Time-Based Output Sequencer

• I2C/SMBus Serial Interface

• IntegratedDecoupling Capacitors andPull-Up Resistors

• Powered from 6V to 14VDC

• Available in 144-Lead 15mm ×15mm BGA

Design files for this circuit board are available at

http://www.linear.com/demo

2

dc2023afa

DEMO MANUAL DC2023A

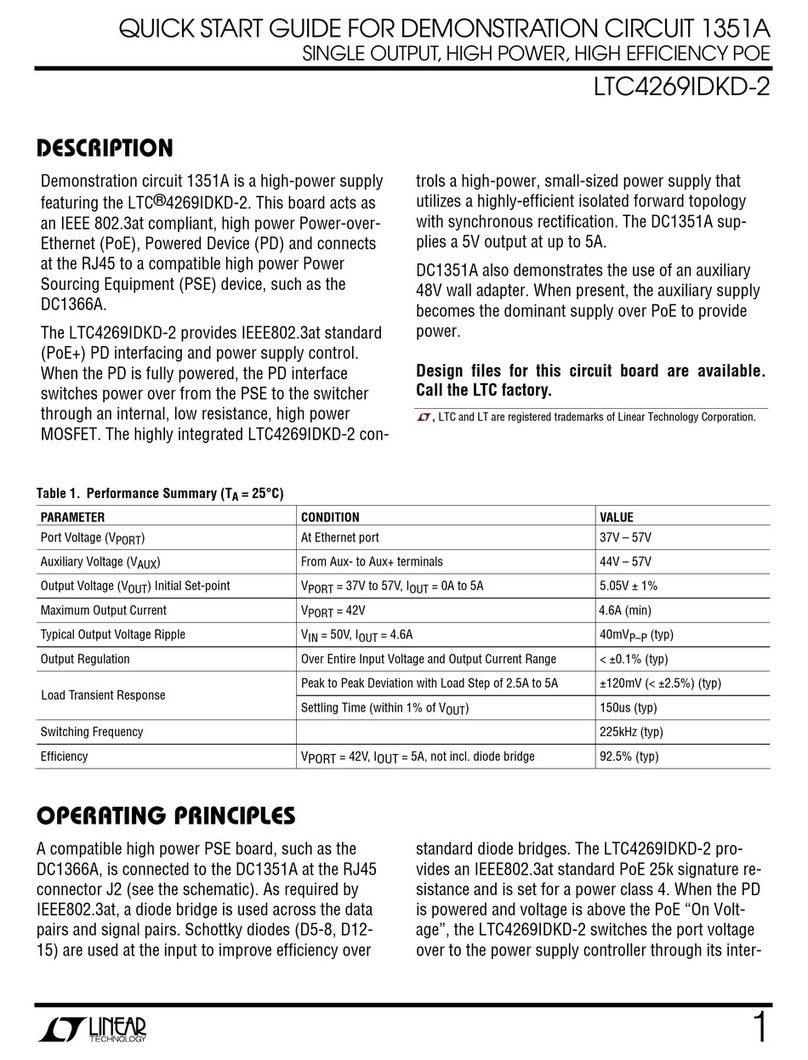

PERFORMANCE SUMMARY

GLOSSARY OF TERMS

Specifications are at TA= 25°C

POWER SUPPLY CHANNEL CH(0:7) CH(8:15)

Manager 1/2 LTM2987 1/2 LTM2987

Nominal Untrimmed Output Voltages 1.0V, 1.1V, 1.2V, 1.3V, 1.4V, 1.5V, 1.7V, 1.8V 2.0V, 2.2V, 2.5V, 2.7V, 3.0V, 3.1V, 3.2V, 3.3V

Rated Output Current 0.3A

Default Margin Range ±5%

Output Trim Range (VFS_VDAC = 1.38V) +13/–19 % +11/–15%

Temperature 2 Internal

Common Characteristics—Specifications Valid Over Full Operating Temperature Range

PARAMETER CONDITIONS

VALUE

MIN TYP MAX UNITS

Supply Input Voltage Range 6 14 V

ADC Total Unadjusted Error VIN_ADC ≥ 1V ±0.25 %

ADC Voltage Sensing Input Range Differential Voltage: VIN_ADC = (VSENSEP[n] – VSENSEM[n]) 0 6 V

The following list contain terms used throughout the

document.

Channel – The collection of functions that monitor, su-

pervise, and trim a given power supply rail.

EEPROM – Non-volatile memory (NVM) storage used to

retain data after power is removed.

Margin – Term used typically in board level testing that

increases/decreases the output voltage to look for sensi-

tivity/marginality problems

Monitor – The act of measuring voltage, current and

temperature readings.

NVM – Non-volatile memory, see EEPROM.

PMBus – An industry standard power-management proto-

col with a fully defined command language that facilitates

communication with power converters and other devices

in a power system.

Rail – The final output voltage that the power supply

controller manages.

Supervise – The act of quickly responding to a voltage,

current, temperature condition that is compared to pre-

programmed values (fault settings).

Trim – The act of adjusting the final output voltage. A

servo loop is typically used to trim the voltage.

3

dc2023afa

DEMO MANUAL DC2023A

LTpowerPlay GUI SOFTWARE

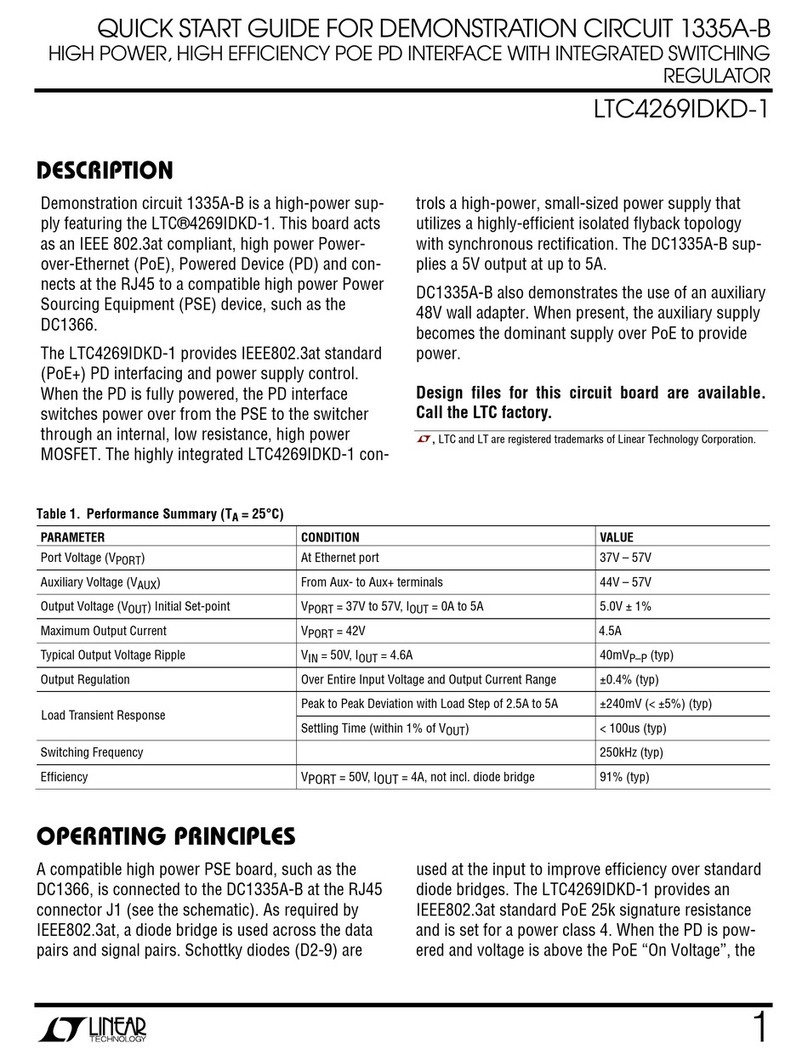

LTpowerPlay is a powerful Windows-based development

environment that supports Linear Technology Power

System Management ICs with EEPROM, including the

LTM2987 16-channel PMBus Power System Manager.

The software supports a variety of different tasks. You

can use LTpowerPlay to evaluate Linear Technology ICs

by connecting to a demo board system. LTpowerPlay can

also be used in an offline mode (with no hardware pres-

ent) in order to build a multi-chip configuration file that

can be saved and reloaded at a later time. LTpowerPlay

provides unprecedented diagnostic and debug features. It

becomes a valuable diagnostic tool during board bring-up

to program or tweak the power management scheme in

a system or to diagnose power issues when bringing up

rails. LTpowerPlay utilizes the DC1613 I2C/SMBus/PMBus

Controller to communicate with one of many potential tar-

gets, including the DC2023A demo system or a customer

board. The software also provides an automatic update

feature to keep the software current with the latest set

of device drivers and documentation. The LTpowerPlay

software can be downloaded from:

http://www.linear.com/ltpowerplay

To access technical support documents for LT C power

system management products visit Help, View Online

Help on the LTpowerPlay menu.

Figure 1. Screen Shot of the LTpowerPlay GUI

4

dc2023afa

DEMO MANUAL DC2023A

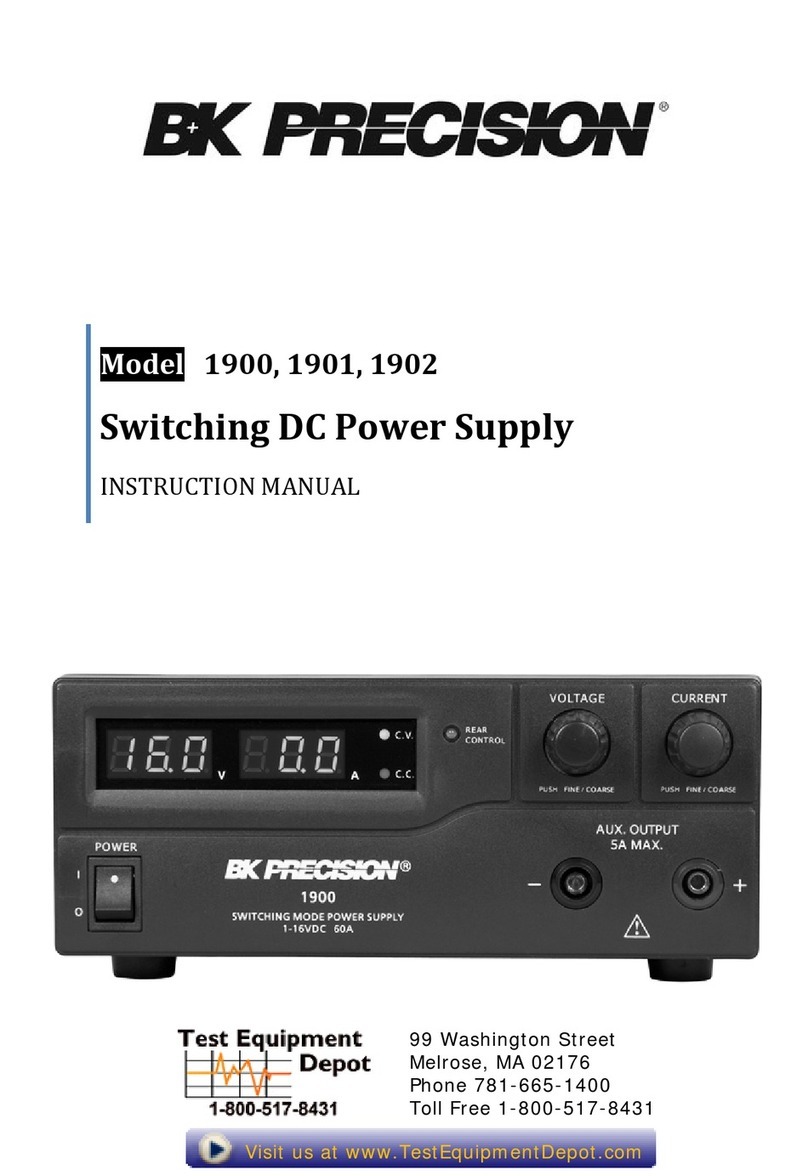

QUICK START PROCEDURE

Thefollowing proceduredescribes howto setup aDC2023A

demo system.

1. Download and install the LTpowerPlay GUI:

http://www.linear.com/ltpowerplay

2. Remove the board from the ESD protective bag

and place it on a level surface. Connect the DC1613

I2C/SMBus/PMBus Controller to the DC2023A board

using the 12-pin ribbon cable.

3. Confirm that the CONTROL switch is set to the RUN

position.

4. Plug the USB to I2C/SMBus/PMBus Controller into a

USB port on your PC. The board should power up with

all power good LEDs and +5V LED illuminated green.

The USB-to-I2C/SMBus/PMBus Controller supplies

~100mA of current which should be sufficient for a

single demo board.

5. Ifmultiple boards arebeing powered, connect a+12VDC

power supply with > 0.5A capacity to the VIN input jack

of the DC2023A.

6. Launch the LTpowerPlay GUI.

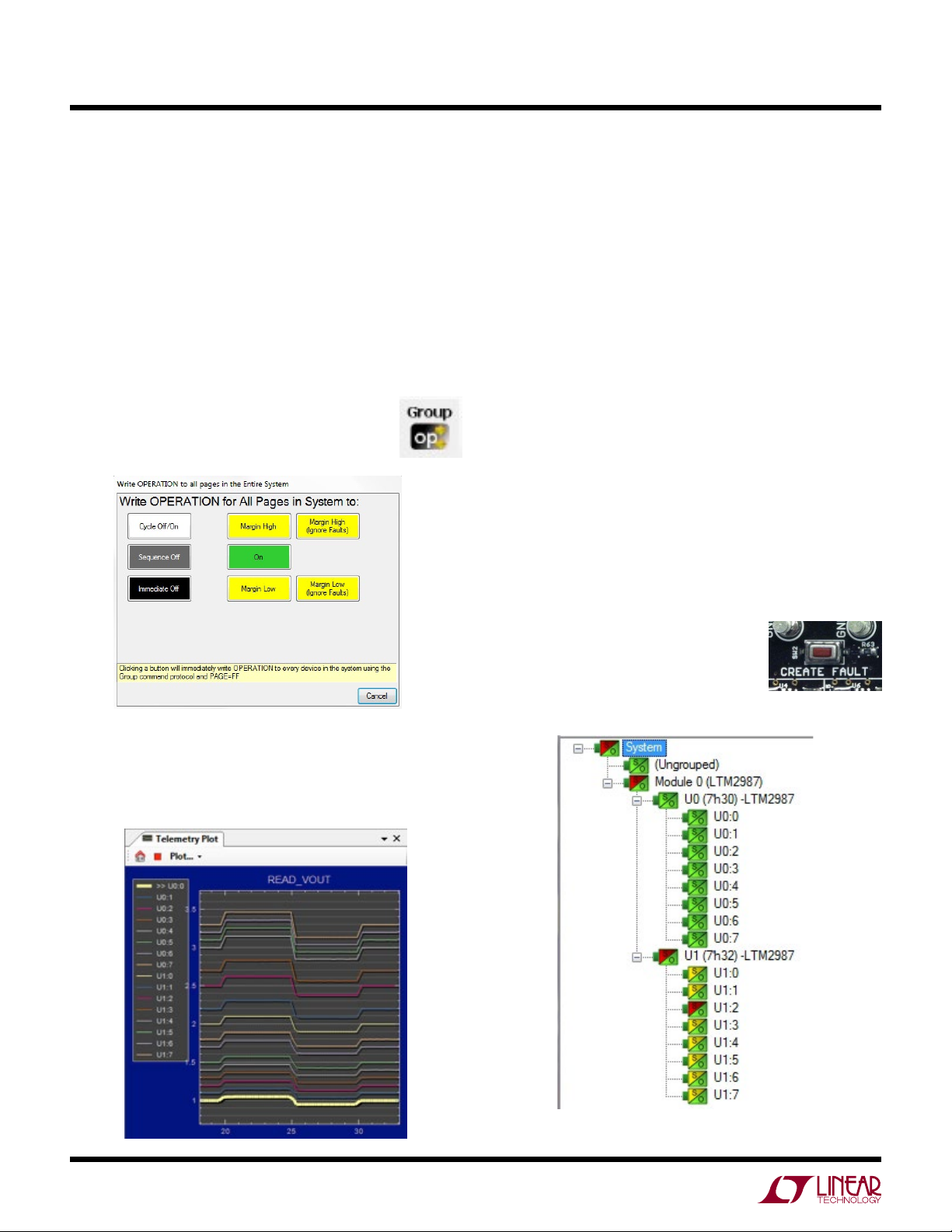

a. The GUI automatically identifies the DC2023A and

builds a system tree. The system tree on the left hand

side should look like this:

Figure 2. Connecting DC2023A board and the DC1613 I2C/SMBus/PMBus Controller

Note:For multiple board arrays, the GUI automatically

ensures each device has a unique address. In this

scenario, it isrecommended at this point to

store these addresses to NVM (EEPROM)

by clicking the “RAM to NVM” icon in the

toolbar.

5

dc2023afa

DEMO MANUAL DC2023A

QUICK START PROCEDURE

b. A green message box will be displayed for a few

seconds in the lower left hand corner confirming

that the DC2023A is communicating:

c. Save the demo board configuration to a (*.proj) file

by clicking the "Save" icon. This creates a backup

file. Name it whatever you want.

7. The CONTROL switch is configured to control all 16

channels. Slide the switch to RUN to enable, OFF to

disable all channels. For multiple board arrays, the

CONTROL switch is wired to a signal that is common

across all boards. All CONTROL switches must be set

to the RUN position to enable all boards.

Loading a DC2023A Configuration (*.Proj) File with

the GUI

1. In the upper left hand corner of the GUI, File > Open

> browse to your *.proj file. This will load the file into

the GUI.

2. Click on the “Go Online” icon, then click on the

“PC->RAM” arrow. This loads the configuration into

the working RAM of the LTM2987.

3. To store the configuration to NVM (EEPROM), click on

the “RAM->NVM” icon.

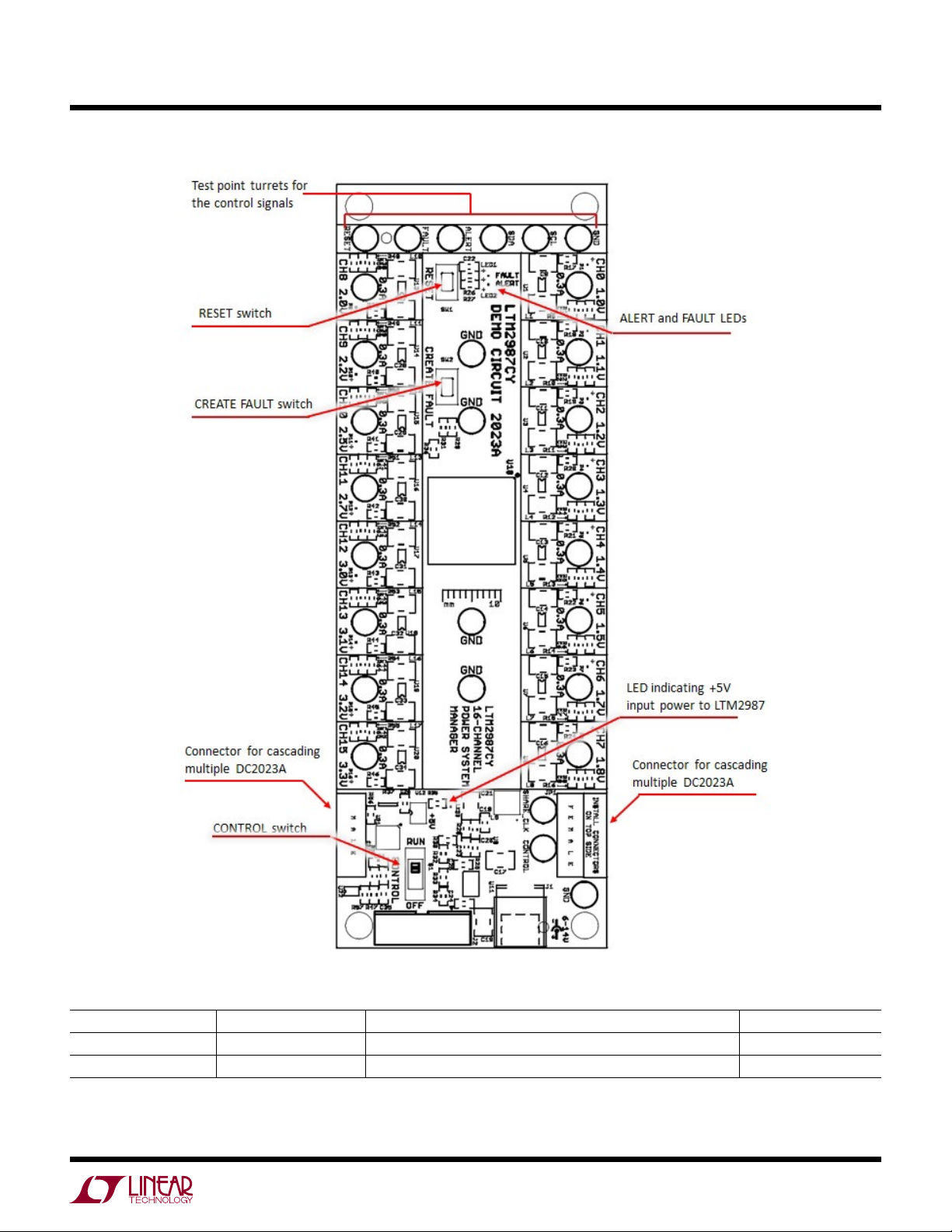

Figure 3. DC2023A Top Side Details

6

dc2023afa

DEMO MANUAL DC2023A

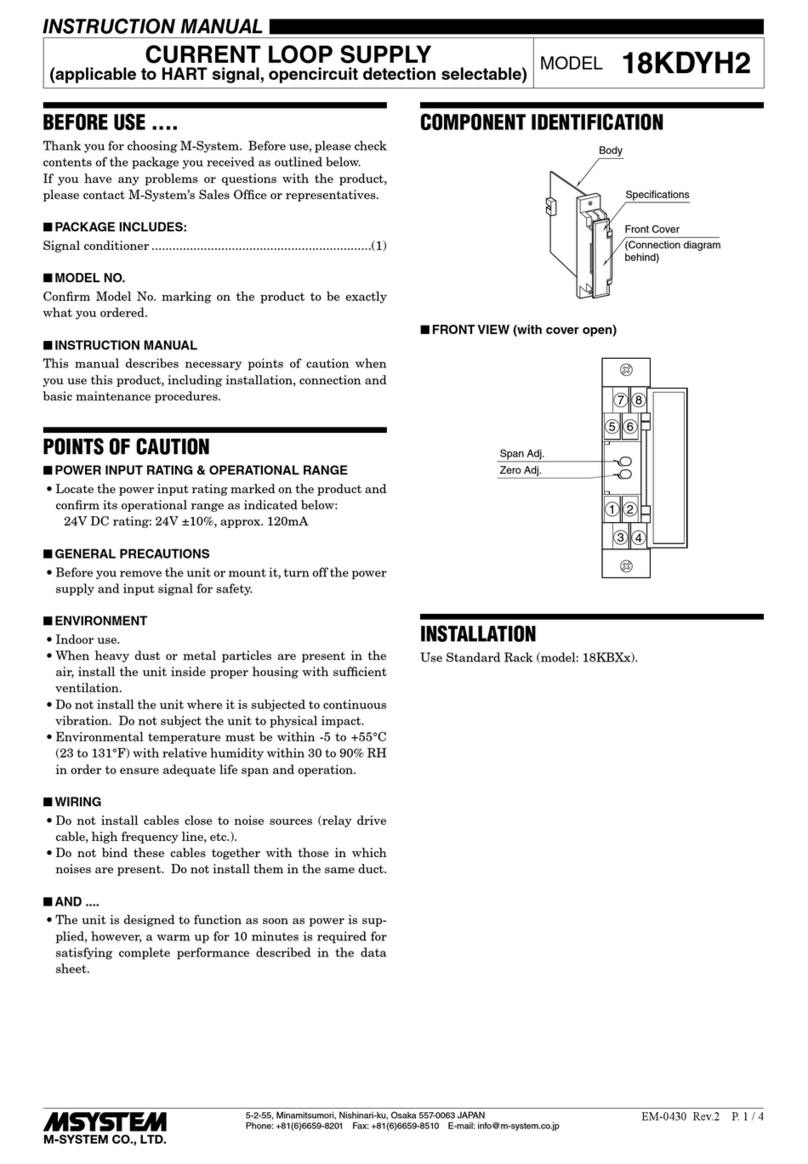

Margin All Rails

The LTM2987 power manager on the DC2023A not only

monitors each of the sixteen outputs but can margin the

outputs either high or low. Margining is the operation

that moves a rail either up or down for testing purposes.

It allows a system to be fully characterized over supply

limits without the use of external hardware or resources.

The GUI provides an easy way to margin all rails high

or all low by clicking one of four buttons. To invoke the

margining dialog, click the GroupOp icon in the toolbar.

The buttons labeled “ignore faults” will margin

without creating a fault even if the fault limits

are exceeded.

COMMON DEMO BOARD OPERATIONS

A look at the telemetry window shows the effect of the

margin high or margin low operation. The following screen

shot shows all rails going from nominal set points to

margin high, margin low, and back to nominal voltages.

Each LTC2977 inside the module has a multiplexed ADC

that is used to provide voltage, current, and temperature

readback values. The telemetry plot in the GUI is similar to

amulti-channel oscilloscope whichis capable of displaying

any parameter that is displayed in the telemetry window.

Due to the nature of a multiplexed ADC converter, it has

an associated ADC loop time. The total ADC loop time

(~100ms to 160ms) for a given channel is dependent on

the device’s configuration. Refer to the LTM2987 data

sheet for complete ADC timing specifications.

Creating a Fault

There is a pushbutton on the DC2023A board that is used

to force a fault and demonstrate the demo board’s ability to

detect it and respond according to the configuration. When

depressed, the pushbutton creates a fault on channel 10,

the 2.5V output (GUI channel U1:2). The user should see

all outputs power off, the fault LED momentarily illuminate,

thealert LED illuminate continuously, and all rails sequence

back on after a retry period. The user may also short any

power supply output indefinitely. This

is a good way to induce UV faults and

shows that a shorted channel will not be

damaged. Use a jumper wire or a coin

to short any output.

7

dc2023afa

DEMO MANUAL DC2023A

COMMON DEMO BOARD OPERATIONS

The LTM2987 has a feature which allows it to sequence its

channels off in a controlled manner, as opposed to turning

all rails off immediately. The SequenceOffOnFault bit in the

MFR_CONFIG_LTC2977registersets this behavior on each

channel. The DC2023A demo board has been configured

to sequence off all channels when a fault occurs. Pressing

the “CREATE FAULT” pushbutton causes the FAULT pin

to be asserted low which triggers all rails to power down

based on the TOFF_DELAY times.

Figure 5. Sequencing Off (SeqOffOnFault=0)

Figure 4 shows FAULTB asserting low, and each of the

channels sequencing off per the TOFF_DELAY settings.

Figure 5 shows the same except that the 3.0V rail (CH12)

does not have its SequenceOffOnFault bit set. The 3.0V

rail powers down immediately as defined by the fault

response setting.

Clearing a Fault

To clear a fault, the user may click the CF icon in the GUI

or simply push the RESET pushbutton on the demo board.

In both cases, the red (+) on the CF icon and alert LED

on the board will be cleared. You will notice that all rails

are automatically re-enabled after a programmable retry

period. The alert LED may be cleared by pushing the Clear

Faults (CF) icon in the GUI. After clearing faults, the system

tree may remain “yellow” if any non-volatile fault

logs are present. For further information, see the

Working with the Fault Log section.

Resetting The DC2023A

A reset pushbutton is provided on the board. To reset all

devices on the DC2023A board and reload the EEPROM

contents into operating memory (RAM), press RESET

(SW1) on the DC2023A.

DC2023A LEDs

Each individual channel on DC2023A also has its own

green “power good” LED (CH0 through CH15). When USB

power (DC1613 Controller) or external power (6-14V jack)

is applied, the +5V green LED will illuminate, indicating

that the LTM2987 is powered. The red LEDs will illuminate

when an alert or a fault has occurred.

Figure 4. Sequencing Off (SeqOffOnFault=1)

8

dc2023afa

DEMO MANUAL DC2023A

Sequencing Output Channels

The LTM2987 has been pre-programmed to different

TON_DELAY values for each channel. The TON_DELAY

parameter isapplied toeach device relative toits respective

CONTROL pin. When multiple demo boards are connected

together, all CONTROL pins are wire OR’d. Therefore the

TON delays are enforced relative to one edge. The same

applies to TOFF_DELAY values. When the CONTROL

switch is set to the OFF position, all rails will power down

sequentially based on each of the device’s TOFF_DELAY

values. Figure 6 shows an oscilloscope screen capture of

COMMON DEMO BOARD OPERATIONS

Figure 6. Sequencing Output Channels with DC2023A Using TON_DELAY and TOFF_DELAY

Figure 8. TOFF_DELAY Configuration

Figure 7. TON_DELAY Configuration

three output rails sequencing up and down in response

to the CONTROL pin.

Each channel has an LED which visually indicates if the

channel has power. When the CONTROL pin is switched

on and off, you will observe the relative on/off timing of

the 16 channels.

For the LTM2987, the TON_DELAY and TOFF_DELAY

values extend to 13.1 seconds, providing very long on

and off sequencing of power supply rails.

9

dc2023afa

DEMO MANUAL DC2023A

COMMON DEMO BOARD OPERATIONS

Figure 9. Why Am I Off Tool in the LTpowerPlay GUI

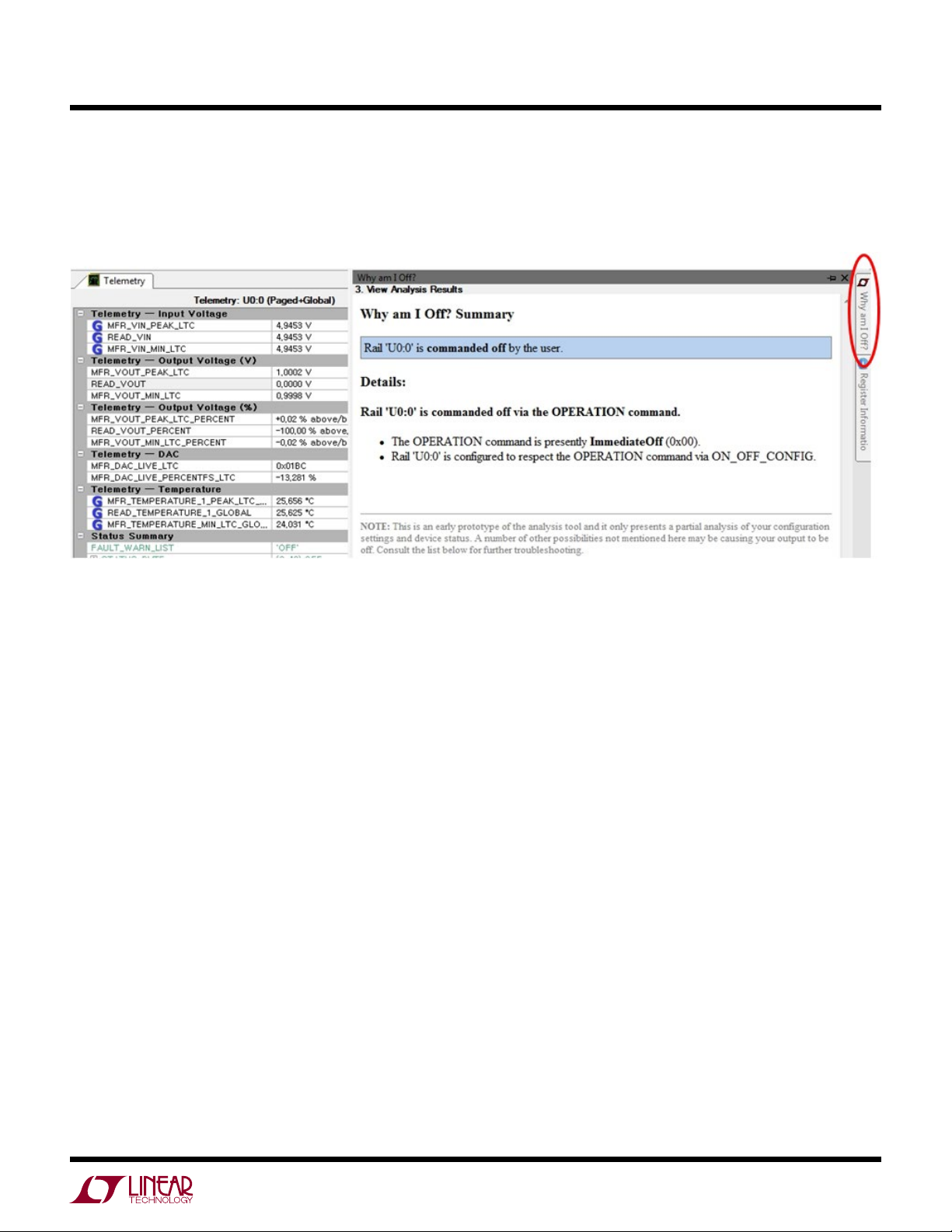

Why Am I Off? Tool

Use the Why am I Off tool in the LTpowerPlay GUI to di-

agnose the reason a power supply channel is turned off.

The tool can be located in the top right corner of the GUI,

next to the Register Information tab. Hover your cursor

over this tab to show the tool.

10

dc2023afa

DEMO MANUAL DC2023A

ADVANCED DEMO BOARD OPERATIONS

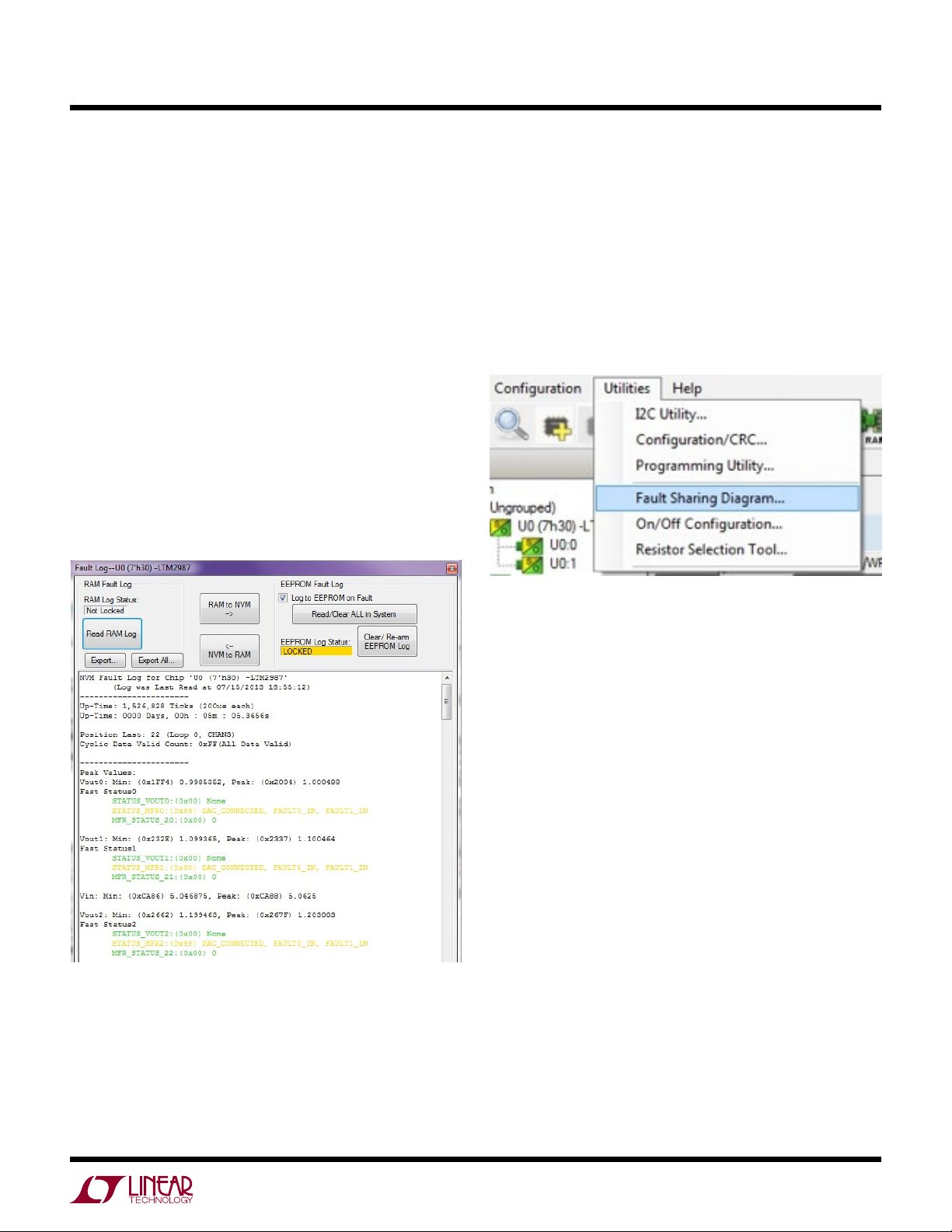

What Is a Fault Log?

A fault log is a non-volatile record of the power system

leading up to the time of fault. It holds the most recent

monitored values (up-time, voltage, current, temperature)

that can be analyzed to help determine the cause of the

fault. It is a powerful diagnostic feature of the LTM2987

on the DC2023A demo board.

Create a Fault and Fault Log

To create a fault log, you must create a fault, as described

in the Creating a Fault section. If multiple boards are

configured, select the appropriate device in the system

tree by clicking on the appropriate LTM2987 chip. We will

proceed to work with the fault log.

Working with the Fault Log

Once a fault has occurred, the Fault Log (FL) icon will show

a red (+) sign on it, indicating that the GUI has detected a

fault log in the device. Clicking the icon will bring

up a dialog box. Note that it is context sensitive.

Be sure that the desired device is selected in the

system tree.

Notice that the checkbox “Log to EEPROM on Fault” is

checked. Once a fault occurs, the device will automatically

write the fault log data to EEPROM (NVM). At this point,

the log is locked and will not change until it is cleared by

the user. To read the EEPROM log data, first click the “NVM

to RAM” button. At this point the RAM Log is locked and

not updated even though the telemetry readings continue.

Click the “Read RAM Log” button. The log data will appear

in the text box below.

11

dc2023afa

DEMO MANUAL DC2023A

ADVANCED DEMO BOARD OPERATIONS

The log contains timestamp, up-time, channel voltage

readings, an input voltage reading, an on-chip temperature

reading, etc. There will be a number of loops; each loop

contains data obtained in one ADC loop time with the

most recent ADC loop data on top and the oldest data at

the bottom of the log. The up-time indicates, at the time

of fault, the amount of time the device has been powered

up or time since the previous reset.

In this case, the fault log will show that channel U1:2

faulted due to a VOUT_UV_FAULT condition. On the pre-

vious telemetry loop, the channel voltage reading was a

nominal value (2.5V).

To clear the fault log, click the “Clear/Rearm EEPROM

Log” button. This allows the selected device to be ready

for a new fault event. To clear all faults, click the Clear

Faults (CF) icon.

Fault Sharing Setup in the GUI

Fault sharing provides a means of propagating a fault de-

tected by a power system manager to other power system

managers via FAULT pins. Use the Fault Sharing Setup

Tool to configure the fault sharing in the GUI. Select the

LTM2987 labeled U0 in the system tree. Go to Utilities >

FaultSharing Diagram.For moredetails on thistopic, please

refer to the Fault Management section in the data sheet.

The fault sharing dialog will appear as shown in Figure10.

All Response and all Propagate switches are closed by de-

fault. In this configuration, a fault on one of the LTM2987

channels will shut down all 16 channels, and a fault on any

LTM2987 channel will propagate to all channels on the

DC2023A demo board since the fault pins are tied together.

Note: All FAULT pins on the LTM2987 are tied together on

the DC2023A demo board. These pins are open drain and

have a common pull-up resistor to provide a logic high

level (inactive). All FAULT pins are active low.

There are two types of actions to fault conditions: How a

channel responds to another channel’s fault and whether

a particular channel propagates a fault to other channels.

FAULT pins are bidirectional, meaning the device may drive

its FAULT pin low (output) or may respond to the FAULT

12

dc2023afa

DEMO MANUAL DC2023A

ADVANCED DEMO BOARD OPERATIONS

pin when another device drives it low (input). Because all

FAULT pins are wire OR’d on the DC2023A, this hardware

configuration allows one to program each device’s fault

settings on a channel-by-channel basis. By default, the

LTM2987 is configured to shut down all channels if other

devices fault and to broadcast its own fault via the FAULT

pins. A fault on these channels will cause only that channel

to fault off. You can think of the “Response” switches as

“shut this channel down when another channel faults”, and

the “Propagate” switches as “drive a fault pin to broadcast

to other channels that this channel faulted”.

Fault Configuration Example

Let’s explore two different examples. Suppose we do not

want channel U0:0 (CH0 1.0V rail) to propagate its fault

to the other channels when it faults. And suppose we do

not want channel U0:1 (CH1 1.1V rail) to shut down in

response to another channel’s fault. We can configure the

switches as shown in Figure 11. Simply click the switches

to open/close. Click OK to close the dialog box. Click the

“PC->RAM” icon to write the changes to the DC2023A.

We can now create a fault on U0:0 (CH0) by shorting

the output to ground. You may use a coin or a jumper

to temporarily connect CH0 to the GND turret. You will

notice that the channel shuts off but the other channels

remain powered up because its fault is not propagated to

the other channels. After the retry period, channel U0:0

(CH0) will power back up. We can now observe the effect

of changing the response setting on U0:1 (CH1). If you

short U0:2 (CH2 1.2V rail) to ground, notice that all rails

shut down except U0:1 (CH1). This is an example of a

keep-alive channel that remains powered up independent

of faults on other channels.

Multiple DC2023A boards can be combined to control up

to 128 independent power supplies. Eight boards may

be cascaded. The number of boards is limited by an I/O

expander chip that has three address pins, allowing eight

different combinations. This setup demonstrates the co-

ordinated fault responses and accurate time base shared

across multiple LTM2987 modules.

Figure 10. Fault Sharing Utility in LTpowerPlay GUI

Figure 11. Updated Fault Sharing Configuration

13

dc2023afa

DEMO MANUAL DC2023A

SETUP PROCEDURE FOR MULTI-BOARD ARRAYS

Procedure:

1. Stack the boards side-by-side by plugging JP1 of one

board into JP2 of another DC2023A board.

2. Ensure different slave address settings for each of the

boards. The address of each board is set by the DIP

switch JP3 on the backside of the board. The setting

must be unique for each board in the array.

3. Plug in the +12V VIN power into one of the boards as

shown in Figure 12. Only one +12V power source is

allowed.

4. The USB to I2C/SMBus/PMBus Controller may be

plugged into any board. If no LTM2987s show up in

the GUI, click the hourglass icon to enumerate the I2C

bus and find the addresses of the parts. Go to step 2 to

ensure that each board has a unique DIP switch setting.

5. Since the individual CONTROL lines are connected

across the boards (CTRL is a common signal across

all boards in the array), make sure that all CONTROL

switches are set to the RUN position.

6. Relaunch LTpowerPlay. It will enumerate the entire

board array and build a representative system tree and

read all hardware settings into the GUI.

Attention: Once the GUI has launched, click the

“RAM->NVM” button in the toolbar to ensure that the slave

addressesare retainedafter a power off or reset.

Otherwise you may lose communication with

the slaves after a power cycle or reset event.

Figure 12. Array of Multiple DC2023A Demo Boards

14

dc2023afa

DEMO MANUAL DC2023A

SETUP PROCEDURE FOR MULTI-BOARD ARRAYS

Ensuring Slave Addresses Do Not Conflict

Thereis a small DIPswitchon the backside of the DC2023A.

It is used to set the slave address of an I/O expander which

provides for the addition of multiple boards to a setup.

The I/O expander has a base address of 0x20. The DIP

switch settings set the offset. The three switches that may

be changed are labeled A0, A1, A2. Examples below set

the boards to addresses 0x20 and 0x27.

Figure 13. DIP Switch Set to All Zeros (0x20) Figure 14. DIP Switch Set to All Ones (0x27)

15

dc2023afa

DEMO MANUAL DC2023A

DC2023 DETAILS—TOP

Table 1. DC2023A: Default Switch Configuration (Default Position Shown in Grey in the Figure Above)

REFERENCE DESIGNATOR SIGNAL NAME USAGE DEFAULT

JP3 SCLK, A0, A1, 2 DIP Switch Used to Set the Address Offset of LTM2987 OPEN

S1 CONTROL Switch Used to Enable/Disable the CONTROL Input Pins of LTM2987 RUN

16

dc2023afa

DEMO MANUAL DC2023A

DC2023 DETAILS—BOTTOM

17

dc2023afa

DEMO MANUAL DC2023A

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 1 U10 LTM2987 16-CH PWR SYSTEM MANAGER LINEAR TECHNOLOGY: LTM2987CY

Additional Demo Board Circuit Components

2 16 C1, C2, C3, C4, C5, C6, C7, C8, C38,

C39, C40, C41, C42, C43, C44, C45

CAP CER 220pF 50V 10% NPO 0603 MURATA: GRM188R71H221KA01D

3 18 C9, C10, C11, C12, C13, C14, C15,

C16, C19, C27, C28, C29, C30, C31,

C32, C33, C34, C46

CAP CER 10µF 10V 10% X5R 1210 MURATA: GRM32ER61A106KC01L

4 1 C17 CAP CER 10µF 25V 20% X5R 1210 MURATA: GRM32DR61E106MA12L

5 2 C18, C26 CAP CER 0.1µF 16V 10% X7R 0603 MURATA: GRM188R71C104KA01D

6 2 C20, C69 CAP CER 68pF 50V 5% NPO 0603 MURATA: GRM1885C1H680JA01D

7 17 C21, C47, C48, C49, C50, C51, C52,

C53, C54, C78, C79, C80, C81, C82,

C83, C84, C85

CAP CER 22µF 10V 10% X5R 1210 MURATA: GRM32ER61A226KE20L

8 1 C22 CAP CER 10nF 25V 10% X7R 0603 MURATA: GRM188R71E103KA01D

9 1 C23 CAP CER 47pF 50V 5% NPO 0603 MURATA: GRM1885C1H470JA01D

10 7 C24, C25, C35, C36, C37, C63, C66 CAP CER 1µF 16V 10% X7R 0603 MURATA: GRM188R71C105KA12D

11 16 C55, C56, C57, C58, C59, C60, C61,

C62, C70, C71, C72, C73, C74, C75,

C76, C77 (OPT.)

CAP CER 0.1µF 16V 10% X7R 0603 MURATA: GRM188R71C104KA01D

12 2 C64, C67 CAP CER 4.7µF 16V 10% X5R 0603 TDK: C1608X5R1C475K

13 1 C65 CAP TANT 47µF 16V 20% 7343 AVX: TPSD476M016R0150

14 1 C68 CAP CER 4.7pF 50V NP0 0603 MURATA: GRM1885C1H4R7CZ01D

15 1 D1 DIODE SCHOTTKY 30V CC SOT-323-3 STMICROELECTRONICS: BAT30CWFILM

16 16 L1, L2, L3, L4, L5, L6, L7, L8, L10,

L11, L12, L13, L14, L15, L16, L17

INDUCTOR SHLD POWER 4.7µH SMD ABRACON: ASPI-0315FS-4R7M-T2

WURTH: 744029004 (ALTERNATE)

17 1 L9 INDUCTOR POWER 2.2µH 2.85A SMD VISHAY: IHLP1616BZER2R2M01

18 17 LED3, P1, P2, P3, P4, P5, P6, P7,

P8, P9, P10, P11, P12, P13, P14,

P15, P16

LED GREEN SS TYPE BRIGHT SMD PANASONIC - SSG: LNJ326W83RA

19 2 LED1, LED2 LED RED HI BRT SS TYPE LO CUR SM PANASONIC - SSG: LNJ208R8ARA

20 17 Q1, Q2, Q3, Q4, Q5, Q6, Q7, Q8,

Q9, Q10, Q11, Q12, Q13, Q14, Q15,

Q16, Q17

MOSFET N-CH 30V 900MA SOT323-3 DIODE INC: DMG1012UW-7

VISHAY/SILICONIX: SI1304BDL-T1-E3

(ALTERNATE)

21 33 R1, R2, R3, R4, R5, R6, R7, R8,

R29, R58, R59, R60, R61, R62, R63,

R64, R65, R74, R75, R76, R77, R78,

R79, R80, R81, R119, R120, R121,

R122, R123, R124, R125, R126

RES 100k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07100KL

22 2 R9, R107 RES 402k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07402KL

23 1 R10 RES 267k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07267KL

24 1 R11 RES 200k1/10W 5% 0603 SMD YAGEO: RC0603FR-07200KL

25 1 R12 RES 158k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07158KL

26 1 R13 RES 133k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07133KL

27 1 R14 RES 115k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07115KL

28 1 R15 RES 88.7k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0788K7L

18

dc2023afa

DEMO MANUAL DC2023A

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

29 1 R16 RES 80.6k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0780K6L

30 17 R17, R18, R19, R20, R21, R22, R23,

R24, R35, R39, R40, R41, R42, R43,

R44, R45, R46

RES 3.01k 1/10W 1% 0603 SMD YAGEO: RC0603FR-073K01L

31 10 R25, R32, R36, R47, R56, R57, R98,

R99, R100, R135

RES 10.0k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0710KL

32 2 R26, R27 RES 698Ω 1/10W 1% 0603 SMD YAGEO: RC0603FR-07698RL

33 2 R28, R102 RES 73.2k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0773K2L

34 1 R30 RES 46.4k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0746K4L

35 1 R31 (OPT) RES 10.0k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0710KL

36 2 R33, R38 RES 249 OHM 1/10W 1% 0603 SMD YAGEO: RC0603FR-07249RL

37 1 R34 RES 1.00k 1/10W 1% 0603 SMD YAGEO: RC0603FR-071KL

38 1 R37 RES ARRAY 10k 4 RES 1206 VISHAY/DALE: CRA06S08310K0JTA

39 1 R48 RES 66.5k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0766K5L

40 1 R49 RES 57.6k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0757K6L

41 1 R50 RES 47.5K OHM 1/10W 1% 0603 SMD YAGEO: RC0603FR-0747K5L

42 1 R51 RES 42.2k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0742K2L

43 1 R52 RES 36.5k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0736K5L

44 1 R53 RES 34.8k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0734K8L

45 1 R54 RES 33.2K OHM 1/10W 1% 0603 SMD YAGEO: RC0603FR-0733K2L

46 1 R55 RES 32.4k 1/10W 1% 0603 SMD YAGEO: RC0603FR-0732K4L

47 16 R66, R67, R68, R69, R70, R71,

R72, R73, R127, R128, R129, R130,

R131, R132, R133, R134

RES 470Ω 1/4W 5% 1210 SMD VISHAY: CRCW1210470RJNEA

48 16 R82, R84, R86, R88, R90, R92,

R94, R96, R104, R106, R108, R110,

R112, R114, R116, R118

RES 0.0Ω 1/10W 0603 SMD YAGEO: RC0603JR-070RL

49 1 R83 RES 182k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07182KL

50 1 R85 RES 191k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07191KL

51 1 R87 RES 196k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07196KL

52 1 R89 RES 205k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07205KL

53 1 R91 RES 226k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07226KL

54 1 R93 RES 243k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07243KL

55 1 R95 RES 274k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07274KL

56 1 R97 RES 301k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07301KL

57 1 R101 RES 2.49k 1/10W 1% 0603 SMD YAGEO: RC0603FR-072K49L

58 1 R103 RES 340k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07340KL

59 1 R105 RES 357k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07357KL

60 1 R109 RES 374k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07374KL

61 1 R111 RES 464k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07464KL

62 1 R113 RES 511k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07511KL

63 1 R115 RES 549K OHM 1/10W 1% 0603 SMD YAGEO: RC0603FR-07549KL

64 1 R117 RES 604k 1/10W 1% 0603 SMD YAGEO: RC0603FR-07604KL

19

dc2023afa

DEMO MANUAL DC2023A

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

65 16 U1, U2, U3, U4, U5, U6, U7, U8,

U13, U14, U15, U16, U17, U18,

U19, U20

IC BUCK SYNC ADJ 0.3A SOT23-6 LINEAR TECHNOLOGY:

LTC3405AES6#TRMPBF

66 1 U9 IC BUCK SYNC 2.5A 16QFN LINEAR TECHNOLOGY: LTC3604IUD#PBF

67 1 U12 IC 2WIRE BUS BUFFER 8MSOP LINEAR TECHNOLOGY: LTC4313CMS8-2#PBF

68 1 U11 IC DUAL 4A DIODES 16-MSOP LINEAR TECHNOLOGY: LTC4415IMSE#PBF

69 1 U23 IC VREF SERIES PREC TSOT-23-6 LINEAR TECHNOLOGY:

LT6654BMPS6-1.25#TRMPBF

70 1 U21 IC I/O EXPANDER I2C 8B 20QFN MICROCHIP: MCP23008-E/ML

71 1 U22 IC EEPROM 2KBIT 400KHZ SOT23-5 MICROCHIP TECHNOLOGY: 24AA02T-I/OT

72 1 U24 IC BUFFER DUAL NON-INV SC706 TI: SN74LVC 2G34DCKR

Hardware – For Demo Board Only

73 1 J1 CONN PWR JACK 2.1X5.5MM HIGH CUR CUI INC: PJ-002AH

74 1 J2 CONN HEADER 12POS 2MM STR DL PCB FCI: 98414-G06-12ULF

75 1 JP1 CONN RECEPT 2MM DUAL R/A 14POS SULLINS CONNECTOR

SOLUTIONS:NPPN072FJFN-RC

76 1 JP2 CONN HEADER 14POS 2MM R/A GOLD MOLEX CONNECTOR CORPORATION:

87760-1416

77 1 JP3 SWITCH DIP 4POS HALF PITCH SMD C&K COMPONENTS: TDA04H0SB1

78 4 MH1, MH2, MH3, MH4 SPACER STACKING #4 SCREW NYLON KEYSTONE: 8831

79 1 S1 SW SLIDE DPDT 6VDC 0.3A PCMNT C&K COMPONENTS: JS202011CQN

80 1 SW1 SWITCH TACTILE SPST-NO 0.05A 12V BLK C&K COMPONENTS: PTS635SL25SMTR LFS

81 1 SW2 SWITCH TACTILE SPST-NO 0.05A 12V RED C&K COMPONENTS: PTS635SK25SMTR LFS

82 29 TP1, TP2, TP3, TP4, TP5, TP6, TP7,

TP8, TP9, TP10, TP11, TP12, TP13,

TP14, TP15, TP16, TP17, TP18,

TP19, TP21, TP22, TP23, TP24,

TP25, TP26, TP27, TP28, TP29,

TP30

TERM SOLDER TURRET 0.219" 0.078"L MILL-MAX: 2501-2-00-80-00-00-07-0

83 1 TP20 TERMINAL PIN TURRET 0.109" SOLDER MILL-MAX: 2308-2-00-80-00-00-07-0

20

dc2023afa

DEMO MANUAL DC2023A

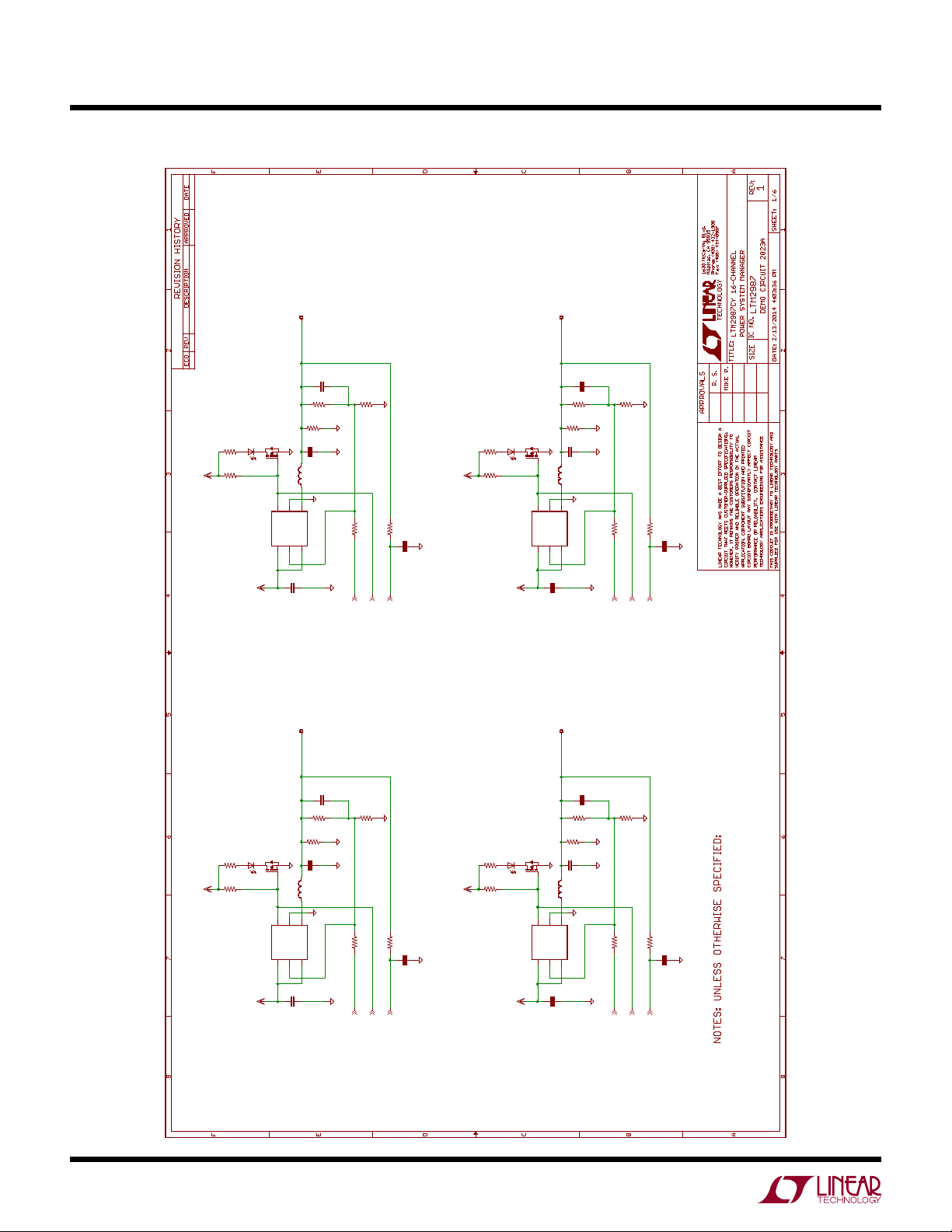

SCHEMATIC DIAGRAM

LTM2987 CH0 Power Stage LTM2987 CH1 Power Stage

LTM2987 CH2 Power Stage LTM2987 CH3 Power Stage

1210

1210 1210

1210

1210 1210

1210

1210 1210

1210

1210 1210

CH0

1.0V

CH1

1.1V

CH2

1.2V

CH3

1.3V

1 2

1 2

1 2

1 2

LTC3405AES6

4.7uH

100k

470

10u/10V

GND

VDD GREEN

DMG1012UW-7

22u/10V

220p

GND GND

GND

604k

OPT

0

GND

GND

VDD

3.01k

100k

402k

GND

LTC3405AES6

4.7uH

100k

470

10u/10V

GND

VDD GREEN

DMG1012UW-7

22u/10V

220p

GND GND

GND

549k

OPT

0

GND

GND

VDD

3.01k

100k

267k

GND

LTC3405AES6

4.7uH

100k

470

10u/10V

GND

VDD GREEN

DMG1012UW-7

22u/10V

220p

GND GND

GND

511k

OPT

0

GND

GND

VDD

3.01k

100k

200k

GND

LTC3405AES6

4.7uH

100k

470

10u/10V

GND

VDD GREEN

DMG1012UW-7

22u/10V

220p

GND GND

GND

464k

OPT

0

GND

GND

VDD

3.01k

100k

158k

GND

1

2

34

6

5

U1

L1

R126

R134

C9

P1

32

1

Q17

C85

C1

R117

C77

R118

R17

R1

R9

1

2

34

6

5

U2

L2

R125

R133

C10

P2

32

1

Q16

C84

C2

R115

C76

R116

R18

R2

R10

1

2

34

6

5

U3

L3

R124

R132

C11

P3

32

1

Q15

C83

C3

R113

C75

R114

R19

R3

R11

1

2

34

6

5

U4

L4

R123

R131

C12

P4

32

1

Q14

C82

C4

R111

C74

R112

R20

R4

R12

DACP_CH0

RUN_CH0

VSNSP_CH0

VOUT_CH0

DACP_CH1

RUN_CH1

VSNSP_CH1

VOUT_CH1

DACP_CH2

RUN_CH2

VSNSP_CH2

VOUT_CH2

DACP_CH3

RUN_CH3

VSNSP_CH3

VOUT_CH3

1 PRODUCTION MIKE P. 01-29-14

1. ALL RESISTORS ARE 1% 0603.

2. ALL CAPACITORS ARE 16V 0603.

3. THE INTERMEDIATE BUS IS VDD=5.0V

VIN

GND

SW

MODE RUN

VFB

VIN

GND

SW

MODE RUN

VFB

VIN

GND

SW

MODE RUN

VFB

VIN

GND

SW

MODE RUN

VFB

CUSTOMER NOTICE

B

SCALE = NONE

LTC CONFIDENTIAL

FOR CUSTOMER

USE ONLY

PCB DES.

APP ENG. www.linear.com

-

Table of contents

Other Linear Power Supply manuals