Linergy SPY CENTER BASIC SCB050 Series User manual

VER .

1.0

SPY CENTER

BASIC

MANUAL

SERIES SCB050

SERIES SCB060

CENTRAL POWER SUPPLY SYSTEM

FOR INSTALLATIONS WITH CENTRALIZED

SUPPLY LUMINAIRES

Please strictly comply with all warnings and instructions indicated in this

operating manual.

Keep this manual properly for future reference and do not use this unit until you

have carefully read all the information and warnings described.

MANUAL

index

.

CHAPTER 1

Introduction

System description

Unpacking

Rules for connection

Local ventilation

CHAPTER 2

Rules for installation

Removal of the CPS and battery box

Local temperatures

Battery maintenance

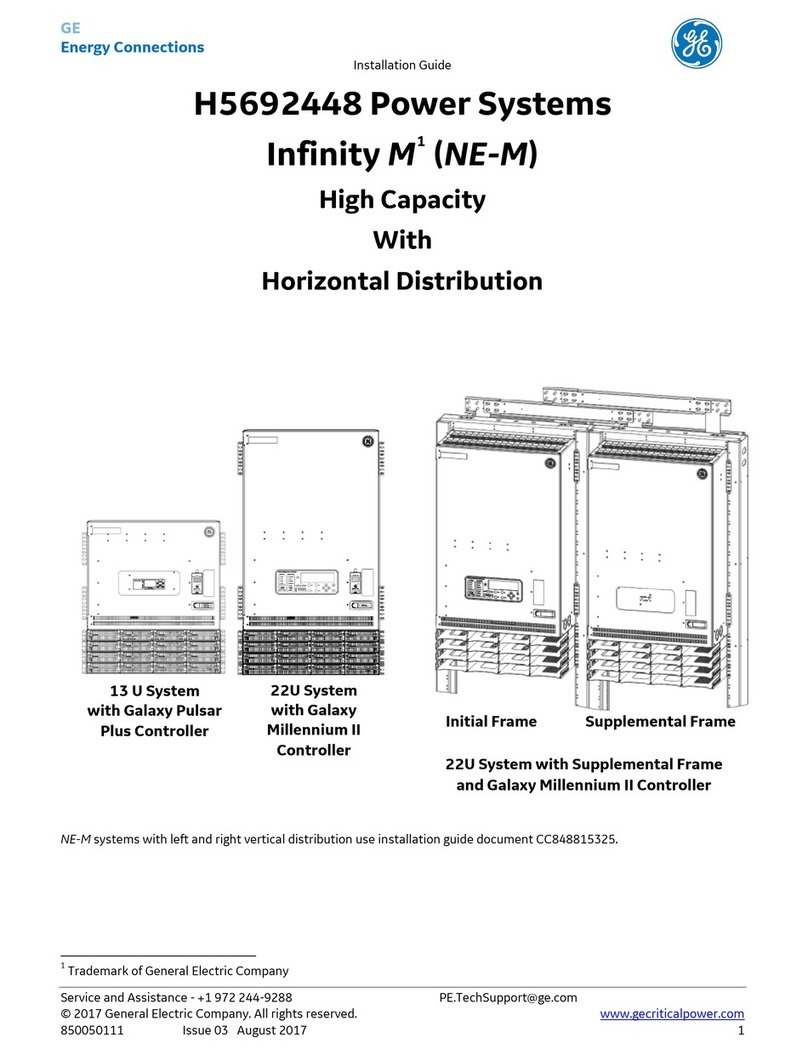

CPS rear view

Electrical connections diagram

Connection example

NC / NO relay

CPS connection to the battery box

EPO

System on / off

CHAPTER 3

Display

LED signaling

Key function

Operation mode

CHAPTER 4

Comunication port

Intelligent slot

Power Manager

SCBLAN

SCBMOD

CHAPTER 5

Error reports

Failure reports

pg.1

pg.2

pg.3

pg.4

pg.5

pg.6

pg.7

pg.8

pg.9

pg.10

pg.11

pg.12

pg.13

pg.14

pg.15

pg.16

pg.18

pg.19

pg.19

pg.20

pg.24

pg.24

pg.25

pg.25

pg.26

pg.28

pg.28

1

INTRODUCTION

Thank you for choosing this product.

Before installing the CPS, read this manual carefully. This manual provides instructions for the safety,

installation and operation of the equipment. It also allows the most complete knowledge of the product

in order to obtain the best service from it.

Keep this manual.

WARNING!

The equipment described in this manual must be intended only for the use for which it was specifically

designed. Any other use is to be considered improper and dangerous.

The Central Power Supply of the SPY CENTER BASIC series, provide electrical continuity to all types

of users, in case of lack of the main power supply.

Specifically designed for power supply applications of emergency systems, they provide a pure sine

wave at the output, and allow different and various possibilities of load management thanks to

differentiated outputs.

ENVIROMENTAL

All our products comply with the objectives defined in the policy of the environmental management

system developed by the company in accordance with current legislation.

DISPOSAL OF THE PRODUCT

The CPS contains materials which in case of disposal are considered toxic and dangerous waste, for

example electronic cards and batteries. Treat these materials according to the laws in force by

contacting qualified personnel.

CHAPTER 1

In evaluating the packaging, the choice of material was made by choosing recyclable materials. For

correct disposal, please separate and identify the type of material making up the packaging. Dispose of

all materials according to the regulations in force in the country in which the product is used.

2

Symbols and Meaning

Symbols Meaning

Notice to the user

to pay special attention

High voltage hazard

Power ON

Shutdown OFF INVERTER

Shutdown CPS

Alternating current source (AC)

Direct current source (DC)

Ground protection

Audio alarm disabled

Overload indication

Battery

Recyclable

Do not disperse with ordinary waste

SYSTEM DESCRIPTION

This double conversion online unit ensures continuous power supply to emergency lighting systems or

security systems.

The double conversion system has the main feature of eliminating disturbances from the main network.

VFI (Voltage and Frequency Independent): in which the voltage at the rescuer's output is independent

of changes in the mains voltage and frequency variations are controlled within the limits prescribed by

the regulations.

A rectifier converts alternating current from the network into direct current. This current charges the

batteries and activates the INVERTER. Based on this current, the inverter generates a sinusoidal

alternating current that constantly supplies the loads.

Lighting or security systems are therefore powered entirely by the CPS. In the event of a power failure,

the batteries power the inverter.

This manual can be used for the model:

Ÿ Series SCB050

Ÿ Series SCB060

DESCRIPTION OF SYMBOLS

The following symbols shown may be displayed in the CPS during operation. Therefore, all users should

be familiar with it to understand its meaning.

3

UNPACKING AND INSPECTION

1) Unpack the packaging and check the contents inside.

The content of the packaging includes:

ŸThe CPS;

ŸThe manual;

ŸThe serial and USB communication cable

ŸCD with POWER MANAGER program

ŸBattery Box (with batteries connected)

ŸCable and fuse kit.

2) Check the appearance of the pallet at the time of delivery to make sure there were no damages

during transport.

If defects are found, notify them immediately to the carrier and the sender.

C P S

CD Power Manager

Kit cable + fuse

Box battery

4

RULES FOR MAKING ELECTRICAL CONNECTIONS

The installation of this equipment must be done by qualified personnel.

The connections must be made in the absence of voltage.

Respect the Phase - Neutral connections.

Always respect the indicated polarity.

The inversion of polarity causes immediate and irreversible damage to the rescuer. Damages due to

polarity inversion are in no case covered by the Linergy S.R.L.

Use tools with insulated handles.

1. Open the terminal block cover located on the UPS rear panel.

The inputs MUST BE PROTECTED BY MAGNETOTHERMAL SWITCH.

Before making the connections, open all the thermal magnetic disconnectors.

2. Make the earth connections to the terminals marked with the conventional symbol.

3. Connect the output line to the terminals marked OUTPUT, respecting the indications of PHASE (L)

and NEUTRAL (N).

4. Firmly secure the cables to the terminals and screw the protection plate back on

The CPS permanently connected to the mains supply are equipped with a single built-in emergency

power off command (EPO = Emergency Power Off) for connection to an external device that allows

the remote shutdown of the load and the supply of energy. of the CPS in any operational state.

Normally requested by the Fire Brigade.

5. Optional: Connect the remote shutdown switch to the contact marked EPO

(Emergency Power OFF).

The EPO contact is Normally Closed. The rescuer turns off when the contact is opened.

The rescuer is supplied with the EPO contact bridged.

6. Connect the battery box with the cable supplied as standard

7. After powering on the AC mains, turn the protection switch (INPUT BREAKER) to ON

At this point it will be possible to turn on the CPS

1

3

OUTPUT CONTROL

K1 K2 K3

NC COM NO +

-

EPO

OUTPUT 12Vdc

EXT BATTERY

5

VENTILATION PROJECT ACCORDING TO EN 50272-2 e CEI EN IEC 62458-2

The amount of air "Q" necessary for the ventilation of a battery compartment, must be calculated

according to the simplified formula:

3

Q = 0.05 x n x Igas x Crt x 10-3 (m / h)

0.05 = v x q x s (v = hydrogen density; q = hydrogen generated; s = safety factor)

n = number of battery elements

Igas = current that produces gas expressed in mA per Ah of delivered capacity, for the floating

recharge current (Ifloat) or for the fast charge current (Iboost).

Crt = nominal battery capacity (Ah for each battery)

The formula for calculating the quantity of air "Q" varies according to the battery technology

The amount of ventilation air flow should preferably be ensured by natural or forced (artificial)

ventilation.

For natural ventilation, the rooms or cabinets of the batteries must have sockets and vents with free

surface calculated with the following formula.

A = 28 x Q

3

Q = amount of ventilation air (m / h)

2

A = free surface of the intake and air vent (cm )

Calculation example: for VRLA batteries with AGM technology (maintenance-free batteries)

UPS: with 40 12V batteries (6 elements of 2V per battery), with a capacity of 100Ah

3

Q = 0.05 x n x Igas x Crt x 10-3 (m / h)

3

0.05 m / Ah

n = number of batteries x N of elements = 240 battery elements (total number of elements)

Igas: 1 (mA / Ah) (for floating voltage)

Crt = 100 (Ah)

3

Q = 0.05 x 240 x 1 x 100 x 10-3 = 1.2m / h

2

A = 28 x 1.2 = 33.6cm

The air "Q" necessary for the ventilation of a battery compartment, must be calculated according

to when reported by law.

A

h

A

h

h ≥ 2 m.

BATTERY

COMPART

MENT

BATTERY

COMPART

MENT

6

INSTALLATION

Attention: before installing the system, read the safety instructions carefully:

Do not install the central unit (CPS) and the battery box near the water or in humid environments.

Do not install the central unit (CPS) and the battery box in places directly exposed to sunlight or heat

sources.

Do not obstruct the ventilation grills located in the rescuer's housing.

Do not connect devices that could overload the CPS.

Position the cables so that no one can step on or trip over them.

When installing the building's electrical system, it is necessary to provide an appropriate disconnection

device for short circuit protection.

The emergency system must be installed by qualified technical personnel.

The connection to earth is essential before the connection to the terminal of the building's electrical

system.

Do not disconnect the earth cable located on the BACK of the CPS or the terminals of the building's

electrical system as this could cause the cancellation of the protective earth of the CPS and of all the

connected loads.

The CPS output terminal block can be electrically active even if the rescuer is not connected to the

terminal of the building's electrical system, be careful.

To preserve battery life it is necessary to install the unit and the box with the batteries in a

ventilated place where the ambient temperature does not exceed 20-25 °C. A higher temperature

can lead to excessive stress on the accumulator causing irreversible damage.

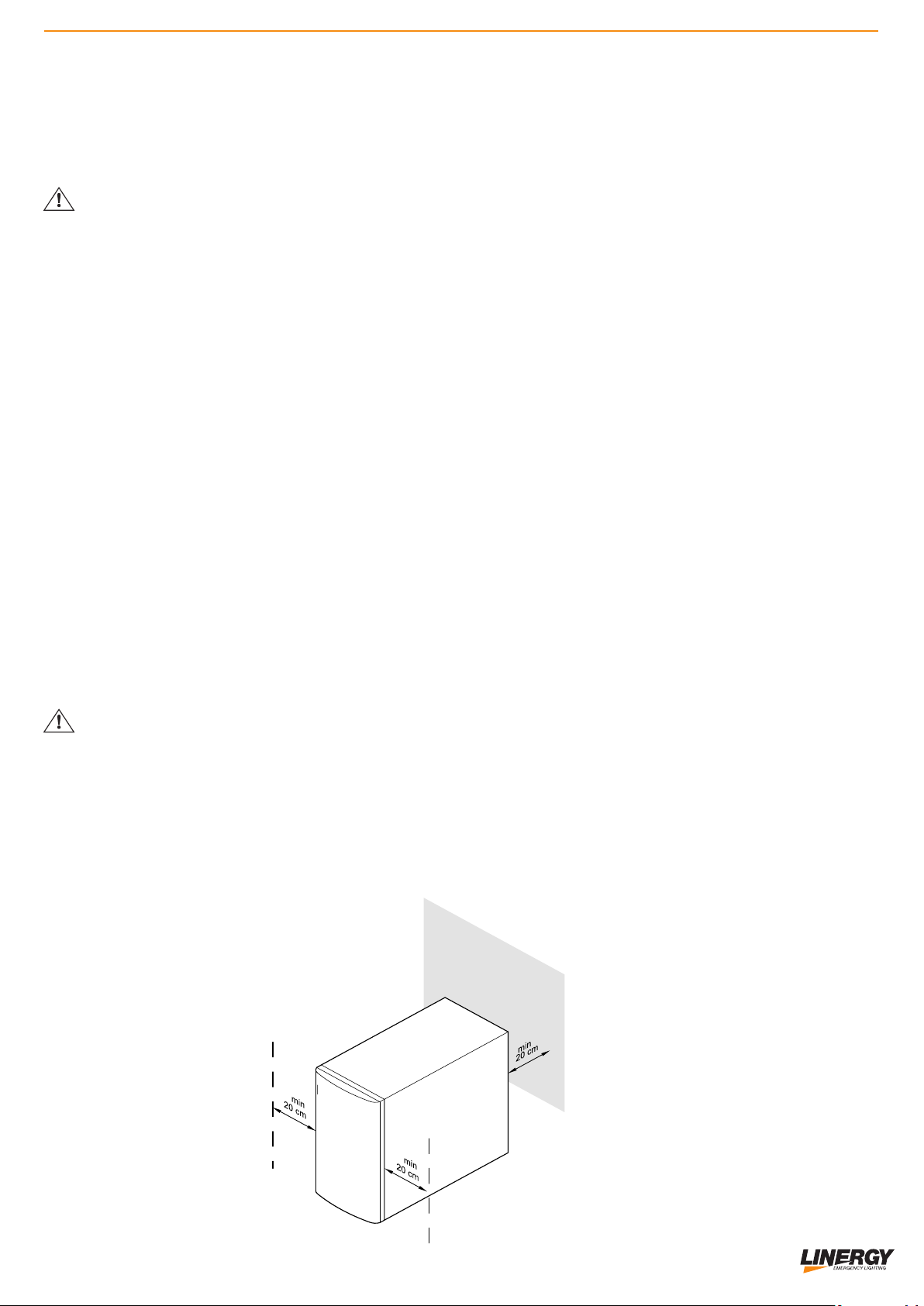

POSITION

ŸInstall in a dry and ventilated place

ŸDo not block the cooling fans.

ŸDo not expose to atmospheric agents (rain, wind etc.)

ŸDo not install and store the CPS in a way that is not protected from dust, dirt etc.

ŸEnsure ventilation by positioning the appliance at least 20 cm away from walls

ŸDo not cover the front, rear and side ventilation areas.

CHAPTER 2

7

REMOVAL CPS AND THE BATTERY BOX

WARNING: TO AVOID DAMAGE TO PERSONS AND / OR DAMAGE TO THE EQUIPMENT

CAREFULLY FOLLOW THE FOLLOWING INSTRUCTIONS.

SOME OF THE FOLLOWING OPERATIONS NEED THE WORK OF TWO PEOPLE.

§Cut the straps . Remove the packaging material.

§Remove the 2 brackets that secure the CPS to the pallet by unscrewing type A screws

§

The brackets removed previously also serve as slides. Fix the chutes to the pallet using the type A screws

and making sure to align them in correspondence with the wheels..

§ATTENTION :it is recommended to lower the CPS by pushing it from the rear,

with caution and accompanying its descent. Given the weight of the equipment, this operation requires the work .

of two people.

NOTE: It is advisable to keep all parts of the packaging for any future use.

1

3

1

3

8

TEMPERATURE

The life expectancy for lead batteries is reduced by half for each 10 degree increase compared to the

design temperature of 20/25 °C.

Where possible, where an optimal useful cycle is necessary, it is preferable to choose controlled

temperature environments.

Proper ventilation will be provided, so that any potentially explosive mixtures of hydrogen and oxygen

are dispersed before reaching dangerous concentrations.

Ventilation will be designed according to EN 50272-2 "Safety regulations for batteries and

installations".

The EN 50272-2 standard, in section 2, deals with the topic of stationary accumulator batteries,

generally used in UPS applications. The standard describes the safety requirements, including

protections from the dangers generated by electricity, electrolytes and explosive gases. Other

provisions are also provided for the maintenance of the functional safety of batteries and installations.

VRLA (Valve Regulated Lead Acid) batteries, better known as sealed lead batteries with internal gas

recombination, can often be installed without particular safety requirements, since the air flow required

for these batteries is very low.

DO NOT TURN THE BATTERY BOX OVER

CORRECT

DO NOT TURN THE

BATTERY BOX IN ANY

CASE

9

BATTERY MAINTENANCE

ŸThis series of CPS requires minimal maintenance. The batteries used for the standard models are

normal VRLA AGM LEAD batteries with a 10-year life expectancy. These batteries require minimal

precautions. The only request is to keep the CPS regularly under the network in order to charge the

batteries and maximize their life. When the machine is switched on and under mains the CPS keeps

the batteries charged and also offers protection against overcharging or excessive discharging of

the batteries.

ŸThe CPS should be fed every 4 or 6 months if not used for a long time.

ŸIn countries with high temperatures, batteries should be recharged every 2 months. The standard

charging time is at least 12 hours.

ŸUnder normal conditions, the life of the batteries is approximately 10 years. If the batteries are not

found in good conditions, they must be replaced as soon as possible.

Batteries must be replaced by qualified personnel.

If necessary, replace the batteries with Linergy batteries of the same type.

Do not replace batteries individually. All batteries should be replaced at the same time following the

instructions of Linergy Srl.

Normally, batteries should be charged and discharged every 4-6 months. Charging should be done

after the CPS shuts down completely in battery mode, the standard full charge time is 12 hours.

Do not place the battery pack in a heat source, they could explode.

Do not open or cut the batteries in any way, the electrolyte is highly poisonous and harmful to the eyes

and skin.

Do not connect the positive and negative pole of the batteries, it could cause an electric shock or a fire.

Make sure there is no voltage before touching the batteries. The battery circuit is not isolated from the

input circuit. Dangerous voltage may occur between the battery poles and the earth.

10

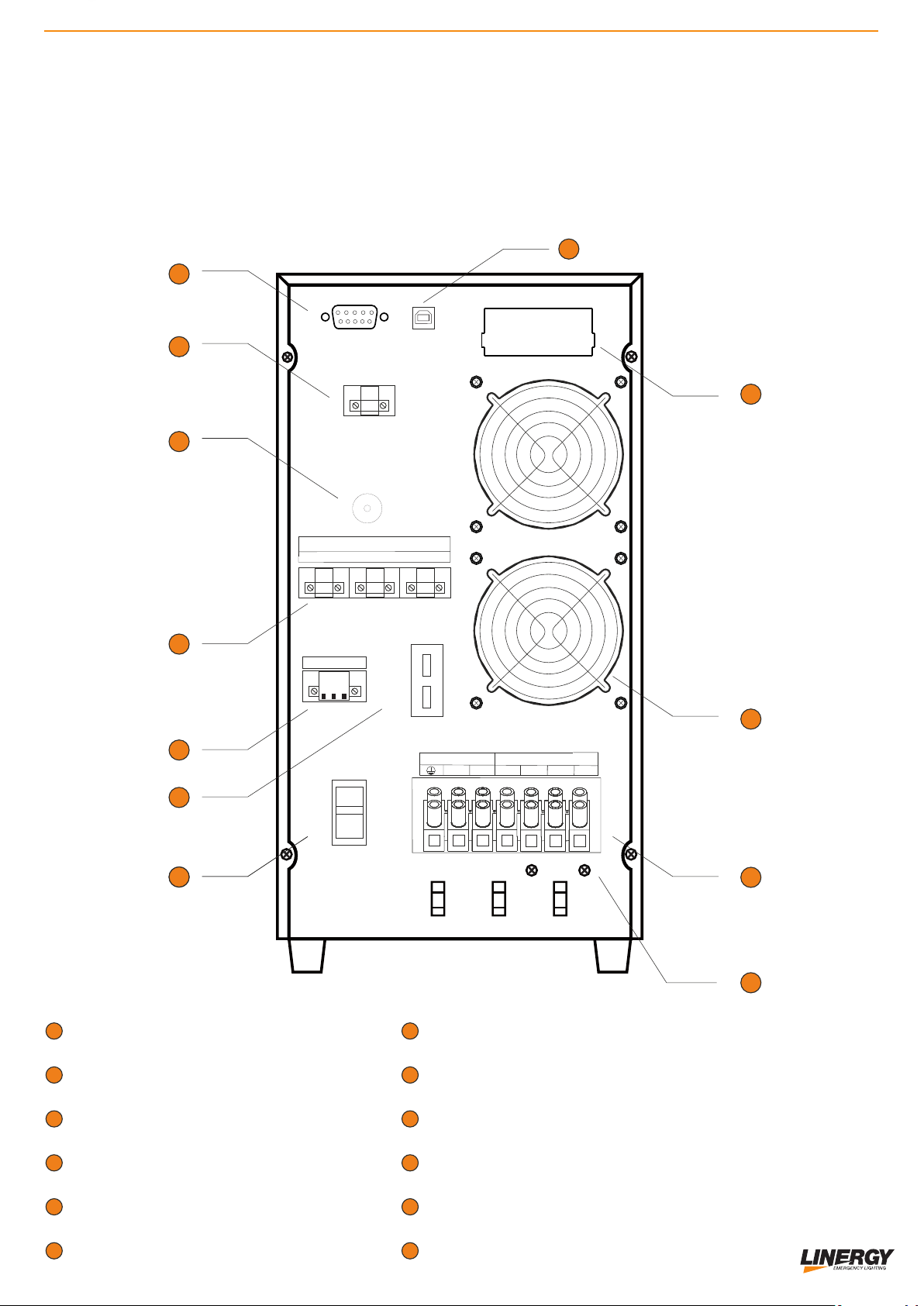

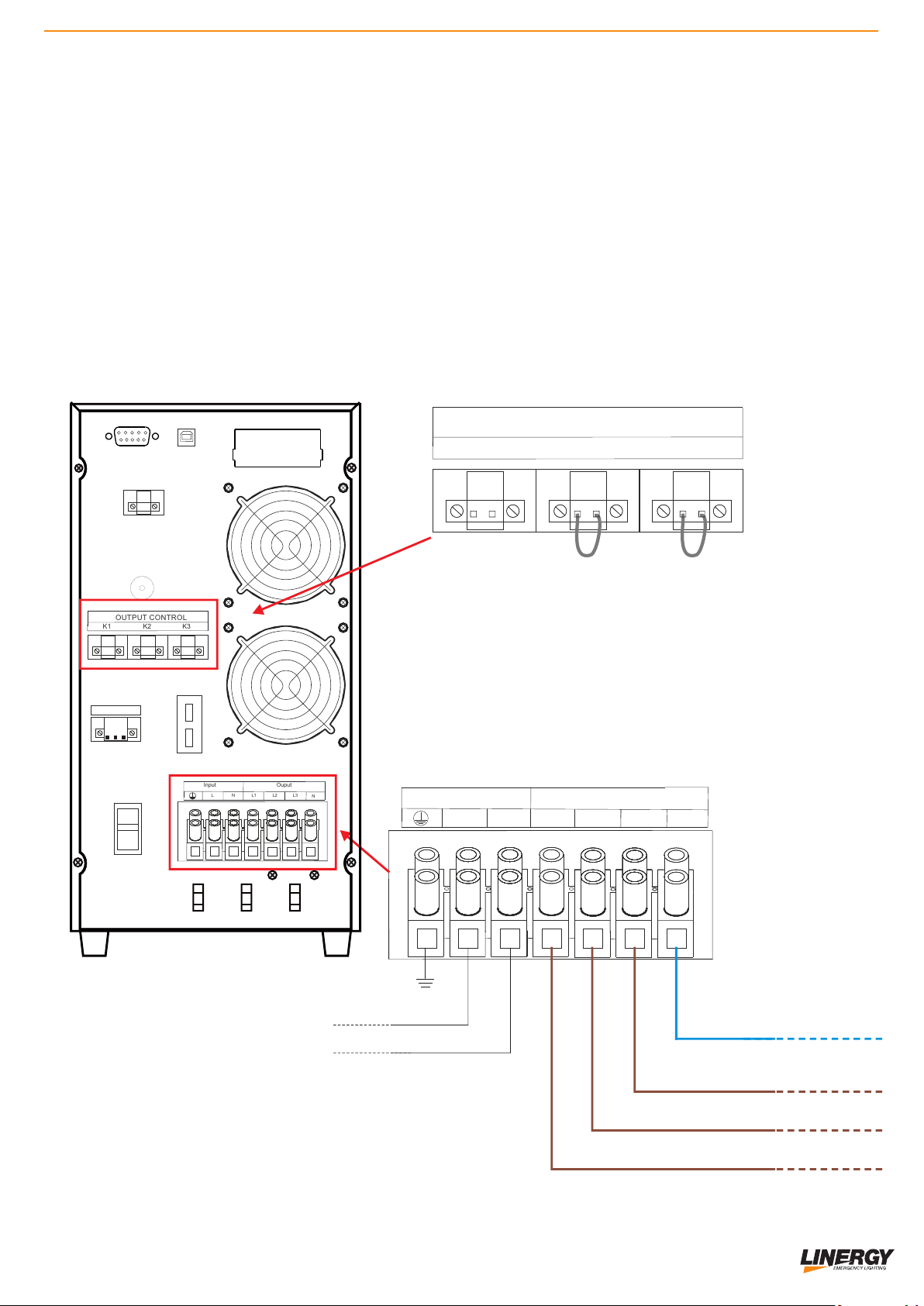

1 1 1

1

INPUT BATTERY BOX

OUTPUT 12V

OUTPUT DRY CONTACT

OUTPUT CONTROL

EPO

RS 232

2

3

4

5

6

12

8

47

ON

OFF

1

3

1

3

Input Breaker

OUTPUT CONTROL

K1 K2 K3

NC COM NO +

-

N

LL3 N

Input Ouput

L1 L2

5

6

4

3

2

1

11

10

9

7

GROUND

INTELLIGENT SLOT

INPUT OUTPUT 230Vac

FAN

USB

INPUT SWITCH

8

9

10

11

12

EPO

OUTPUT 12Vdc

EXT BATTERY

REAR VIEW CPS

11

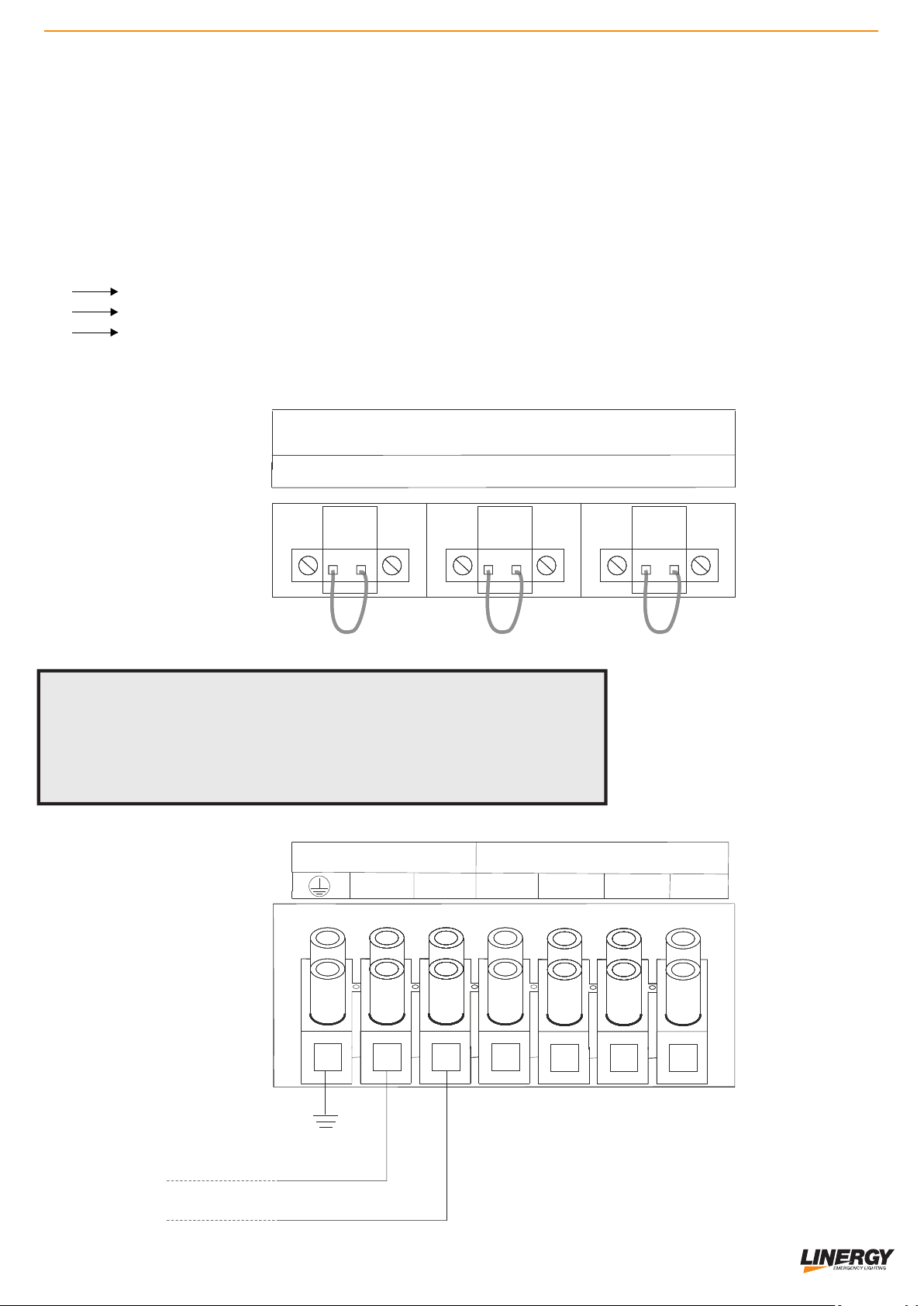

ELECTRICAL CONNECTIONS DIAGRAM

N

LL3 N

Input Ouput

L1 L2

OUTPUT CONTROL

K1 K2 K3

K closed = Not Maintained (NM) enabled relative output L

n n

K open = Maintained (M) enabled relative output L

n n

230 V~

The CPS is equipped with 3 single-phase outputs (L1-N; L2-N; L3-N) which can be managed

individually in Not Maintained (NM) or Maintained (M) through the Output control (K1; K2; K3) . By

jumpering the relevant terminal it is possible to configure the Not Maintained (NM), by opening the

circuit, we have the circuit Maintained (M).

Each output Ln is associated with its own control terminal Kn:

L1 K1

L2 K2

L3 K3

OUTPUT CONTROL

K1 K2 K3

12

N

LL3 N

Input Ouput

L1 L2

OUTPUT CONTROL

K1 K2 K3

CONFIGURATION ‘’Ln’’

Jumper K1 open Circuit 1 ‘’M’’

Jumper K2 closed Circuit 2 ‘’NM’’

Jumper K3 closed Circuit 3 ‘’NM’’

230 V~

ON

OFF

Input Breaker

OUTPUT CONTROL

K1 K2 K3

NC COM NO +

-

N

LL3 N

Input Ouput

L1 L2

EPO

OUTPUT 12Vdc

EXT BATTERY

Example of configuration of the output circuits:

K1 jumper open the output circuit L1 is enabled in Maintained (M)

K2 jumper closed the output circuit L2 is enabled in Not Maintained (NM)

K3 jumper closed the output circuit L3 is enabled in Not Maintained (NM)

13

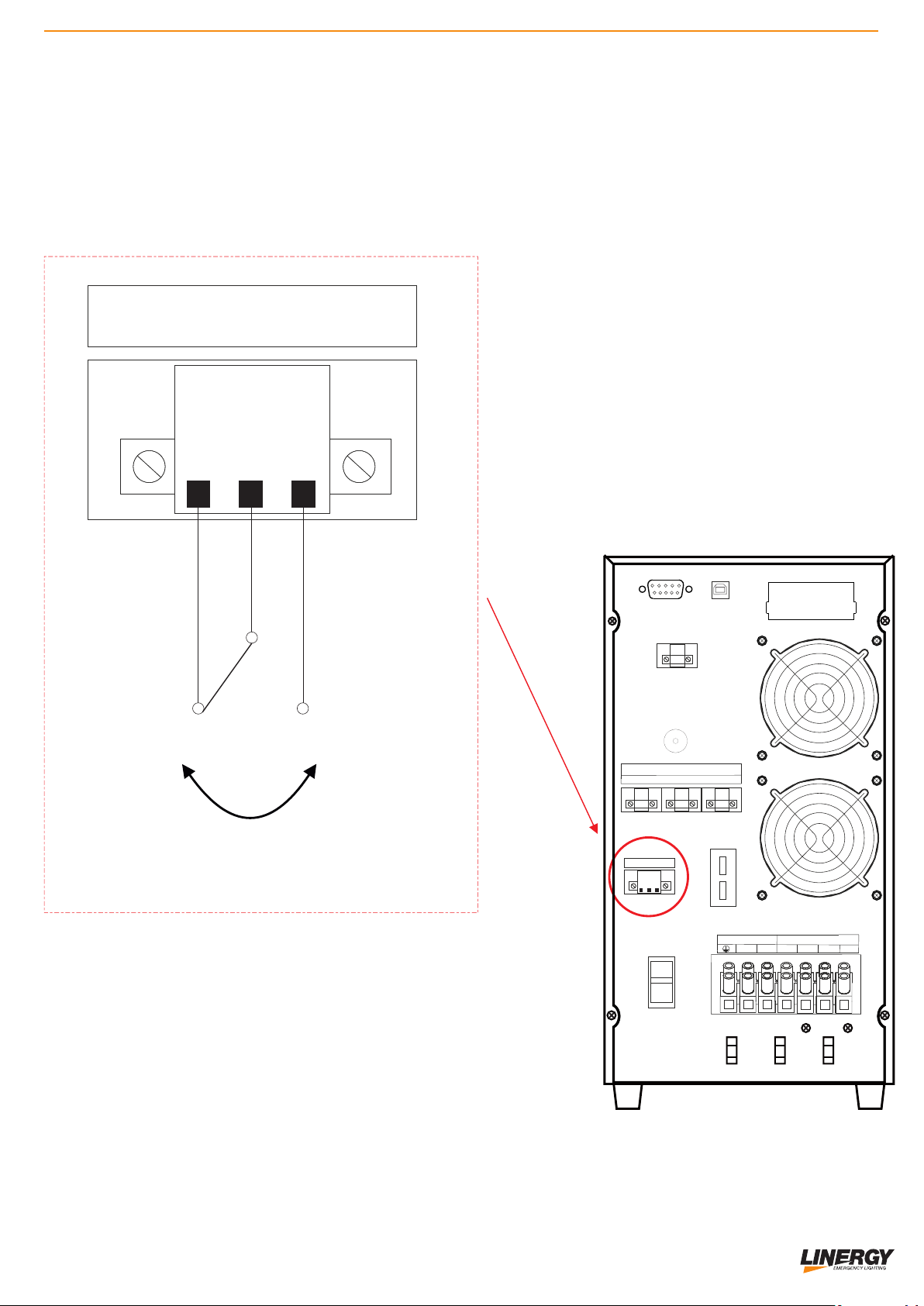

RELE’ NC/NO

The system is equipped as standard with an output for remote signaling dry contacts.

It is activated in the event of black out (230Vac), it signals the general emergency status.

ON

OFF

Input Breaker

OUTPUT CONTROL

K1 K2 K3

NC COM NO +

-

N

LL3 N

Input Ouput

L1 L2

EPO

OUTPUT 12Vdc

EXT BATTERY

NC COM NO

OPEN=OK

CLOSED=EMERGENCY

OPEN=EMERGENCY

CLOSED=OK

14

CONNECT THE BATTERY BOX

The battery BOX is supplied with the battery circuit already connected inside.

To connect the Battery BOX to the inverter, use the RED and BLACK CABLE with connector (supplied

in the KIT together with the fuses) connecting them to the EXT BATTERY terminal block respecting the

polarity as shown in the diagram

The inversion of polarity causes immediate and irreversible damage to the CPS.

Damages due to polarity inversion are in no case covered by the Linergy S.R.L.

Connecting the battery box to the CPS, close the circuit by inserting the fuses provided in the fuse

holder inside.

ON

OFF

Input Breaker

OUTPUT CONTROL

K1 K2 K3

NC COM NO +

-

N

LL3 N

Input Ouput

L1 L2

EPO

OUTPUT 12Vdc

EXT BATTERY

15

EPO CLAMP

EPO deactivated (Emergency enabled) EPO activated (Emergency disabled)

INT

11

12

EPO deactivated (Emergency enabled)

with display on external module*

INT

11

12

EPO deactivated (Emergency disabled)

with display on external module*

EPO CLAMP WITH OPTIONAL MODULE cod.SCBMOD

EMERGENCY POWER OFF (EPO)

The emergency stop function (EPO = Emergency Power-Off) is used for immediate remote shutdown

of the system and connected users. For this purpose it is necessary to remove the jumper from the

emergency stop plug (on the back of the system) and connect an external emergency stop switch.

Cross-section of the connection cable = 0.5 - 2.5mm2 (AWG 13 - 20)

Recommended section of the connection cable = 1.5mm2 (AWG 15)

16

SWITCHING ON THE CPS with the mains present. ( Line mode/

AC mode).

1) After making sure that the connections have been made correctly first place

the protection switch in the ON position. (fig.1)

2) To activate the CPS in operating mode, keep the keys pressed

simultaneously for 0.5 seconds.

3) When the CPS is turned on, the control unit starts a self-diagnosis, which

checks the battery charge and turns on the battery level scale indicating the

state of charge. After a few seconds, the machine runs in operating mode.

4) In the event that there is an interruption in the input network (signaled by an

audible warning via a beep), the CPS will switch to battery mode without

interrupting the direct supply to the Maintained (M) output load while the Not

Miantained (NM) output will be powered.

Attention it is recommended to turn off all the loads connected to the CPS before turning it off

both in battery mode and in mains present mode.

SWITCHING OFF THE CPS with the mains present.

1) Press simultaneously for more than 0.5 seconds to turn off the

INVERTER in operation.

2) The inverter shutdown and the system goes in standby mode.

3) To switch off the machine completely, disconnect the main power supply, after

a few seconds the display and the machine switch off completely.

(INPUT BREAKER)

OUTPUT CONTROL

K1 K2 K3

NC COM NO +

-

EPO

OUTPUT 12Vdc

EXT BATTERY

fig.1

Other manuals for SPY CENTER BASIC SCB050 Series

1

This manual suits for next models

1

Table of contents

Other Linergy Power Supply manuals