Edwards EPS 500 User manual

EPS 500 Power supply

INSTRUCTION MANUAL

B8J201880_B

300872814_002_C2

Original instrucons

edwardsvacuum.com

Copyright noce

©Edwards Limited 2020. All rights reserved.

Trademark credit

Edwards and the Edwards logo are trademarks of Edwards Limited, Innovaon Drive,

Burgess Hill, West Sussex RH15 9TW.

Disclaimer

The content of this manual may change from me to me without noce. We accept

no liability for any errors that may appear in this manual nor do we make any

expressed or implied warranes regarding the content. As far as praccal we have

ensured that the products have been designed and constructed to be safe and without

risks when properly installed and used in accordance with their operang instrucons.

We accept no liability for loss of prot, loss of market or any other indirect or

consequenal loss whatsoever.

Product warranty and limit of liability are dealt with in our standard terms and

condions of sale or negoated contract under which this document is supplied.

You must use this product as described in this manual. Read the manual before you

install, operate, or maintain the product.

P20010288A

CE Declaration of Conformity

The following product

B8J200811 EPS500 Power Supply for Turbomolecular Pumps

Is in conformity with the relevant requirements of European CE legislation:

2014/35/EU

Low voltage directive (LVD)

2014/30/EU

Electromagnetic compatibility (EMC) directive

2011/65/EU

Restriction of certain hazardous substances (RoHS) directive

as amended by Delegated Directive (EU) 2015/863

Based on the relevant requirements of harmonised standards:

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and laboratory

use. General requirements

EN 61326-1:2013

Electrical equipment for measurement, control and laboratory use. EMC requirements.

General requirements

Class A Emissions, Industrial Immunity

Documentation Officer:

Jelena Havelkova, Spielberk Office Centre, Holandska 10, Brno, 63900 Czech Republic,

: +42(0) 734 418 896, : [email protected]

This declaration, based on the requirements of the listed Directives and EN ISO/IEC 17050-1, covers all product

serial numbers from this date on: 13th February 2020.

Ian Keech – VP Engineering

Scientific Vacuum Division

Burgess Hill

Axel Guddas – General Manager

Cologne

Edwards Ltd

Innovation Drive

Burgess Hill

West Sussex

RH15 9TW

UK

This product has been manufactured under a quality management system certified to ISO 9001:2015

Additional Legislation and Compliance Information

EU EMC Directive: Class A/B Industrial equipment

Caution: This equipment is not intended for use in residential environments and may not provide adequate protection to

radio reception in such environments.

EU REACH Regulation Compliance

This product is a complex article which is not designed for intentional substance release. To the best of our knowledge

the materials used comply with the requirements of REACH. The product manual provides information and instruction to

ensure the safe storage, use, maintenance and disposal of the product including any substance based requirements.

Article 33.1 Declaration

This product does not knowingly or intentionally contain Candidate List Substances of Very High Concern above 0.1%ww

by article as clarified under the 2015 European Court of Justice ruling in case C-106/14.

Contents

1. Safety and compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Denion of Warnings and Cauons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Important safety informaon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Descripon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Design and funcon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Supplied equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Ordering data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. Installaon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Conforming use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Providing the connecons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 Changing the fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 Return the equipment or components for service . . . . . . . . . . . . . . . . . . . . . 11

Page 3

1. Safety and compliance

1.1 Denion of Warnings and Cauons

NOTICE:

For safe operaon from the start, read these instrucons carefully before you install

or commission the equipment.

Read all the safety instrucons in this secon and the rest of this manual carefully

and make sure that you obey these instrucons. The equipment must only be

operated and maintained by trained personnel in the proper condion and as

described in this instrucon manual.

Obey local and state requirements and regulaons. If you have any quesons about

safety, operaon or maintenance of the device, please contact our nearest subsidiary.

Important safety informaon is highlighted as warning and cauon instrucons. Obey

these instrucons.

WARNING:

If you do not obey a warning, there is a risk of injury or death. Dierent symbols are

used according to the type of hazard.

CAUTION:

If you do not obey a cauon, there is a risk of minor injury, damage to equipment,

related equipment or process.

NOTICE:

Informaon about properes or instrucons for an acon which, if ignored, will

cause damage to the pump or the system.

We reserve the right to change the design and the stated data. The illustraons are not

binding.

Keep the instrucons for future use.

1.2 Safety symbols

Warning - Dangerous Voltage

Indicates hazards arising from dangerous voltages.

Warning - Hot Surfaces

Indicates that the marked item may be hot and should not be touched

without taking precauons.

Page 4

B8J201880_B - Safety and compliance

Warning - Dangerous Substances

Indicates hazards arising from operang the device in a chemically

aggressive environment.

Page 5

B8J201880_B - Safety and compliance

2. Important safety informaon

WARNING: ELECTRIC SHOCK

Failure to obey the informaon that follows this Warning could result in injury or

death by electric shock. Read and obey this safety informaon.

▪The electrical installaon must be done by a suciently qualied person. Obey

the naonal regulaons in the country of use (for example, EN 50110-1 for

Europe).

▪Lethal voltages are present at the mains connecons. Before you start

maintenance and service work, de-energise (lockout/tagout) the product rst.

▪Unplug any connectors only when the mains voltage is switched o and the pump

does no longer turn.

▪At speeds below 200 Hz, there is not enough power for the LEDs. The pump can

connue to operate without LED indicaon.

▪Unauthorized device conversion and modicaons are prohibited for safety

reasons.

▪Hazardous voltages are present within the converter. Contact with the converter

can cause death or injury. Aer the pump has stopped, disconnect the converter

from the mains power. Make sure that the pump cannot be accidentally switched

on (lockout/tagout) before you open it. There are no user serviceable parts in the

converter.

▪Put connecng lines so that they cannot be damaged. Protect the lines against

humidity and contact with water. Prevent any heat stress on the line due to

unfavourable condions.

▪ Support the connecng lines so that the pumps are not exposed to major

mechanical stress.

▪ Do not expose the converter and the connecons to dripping water. Read the

informaon on the IP type of protecon.

▪ When converter and connecng lines are stored in a humid atmosphere, they can

suer corrosion. Corrosion can cause conducve deposits which can cause short-

circuits and reduce the insulaon levels of electrical components

▪Transport the converter and connecng cables in their original packaging to avoid

mechanical damage. This can prevent air gaps and creepage distances.

▪Do not make electrical connecons unl the pump and accessories (e.g. air

cooler) have been installed mechanically.

3. Descripon

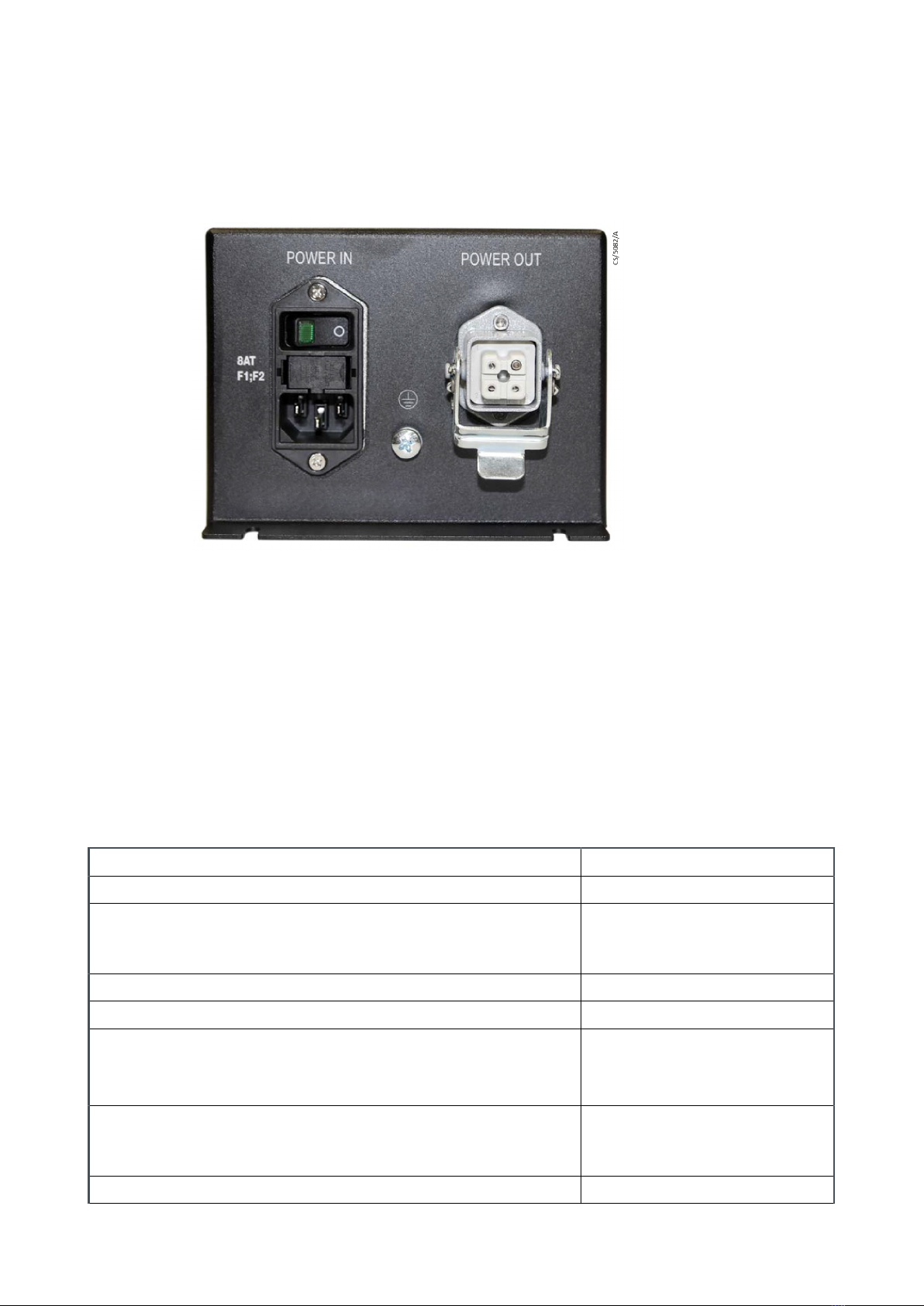

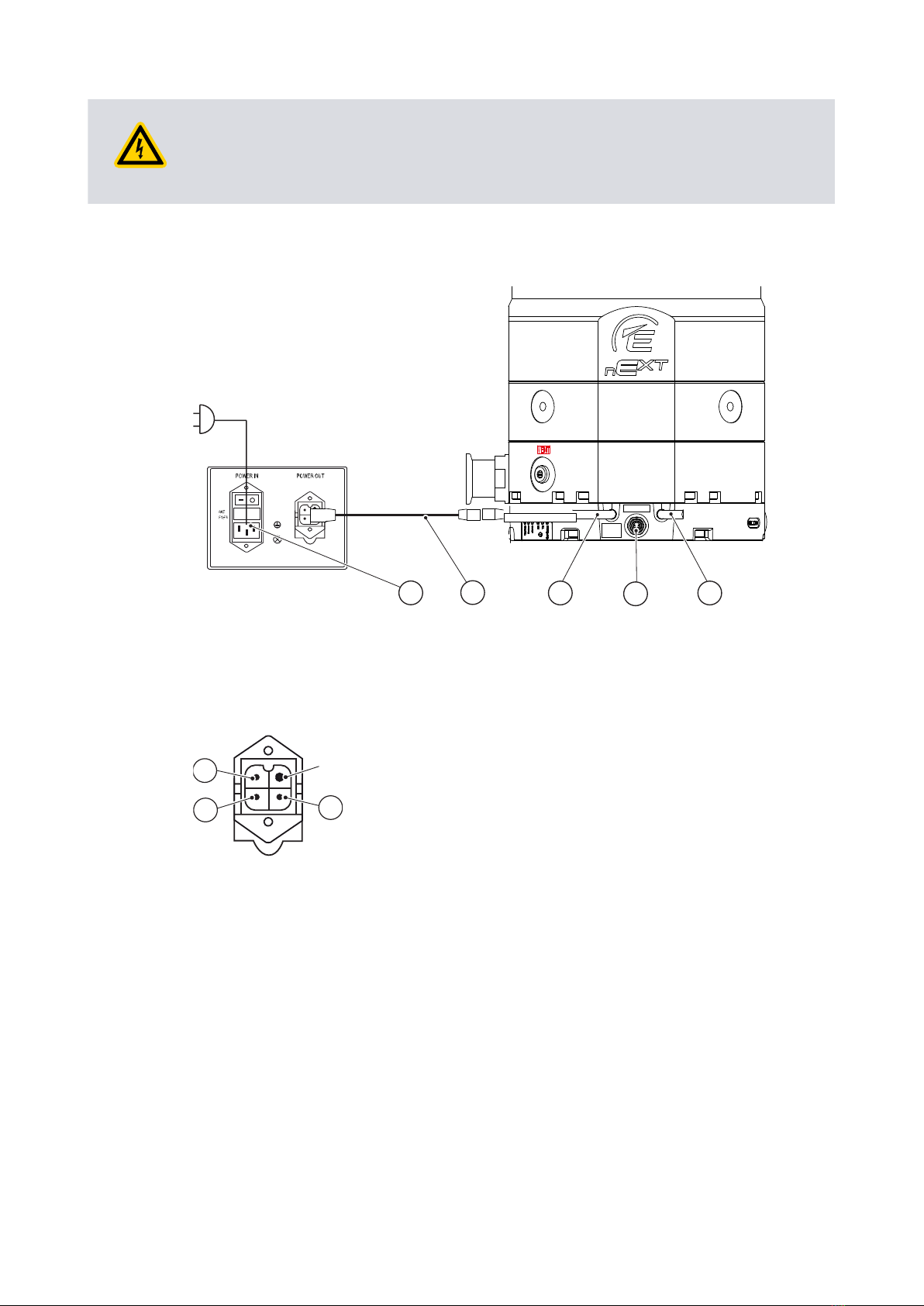

Figure 1 EPS 500, front side

3.1 Design and funcon

The power supply EPS 500 converts the mains voltage into a DC voltage for the

turbomolecular pumps nEXT 730D and 930D.

3.2 Supplied equipment

▪ Power supply

▪ 4 rubber feet

3.3 Technical data

Supply voltage (POWER IN) 100 - 240 V AC ± 10 %

Frequency 50/60 Hz

Power consumpon

maximum

at ulmate pressure operaon of the pump

650 VA

450 VA

DC power supply voltage (POWER OUT) 48 V DC

Maximum DC current consumpon 10 A

Max. length of the DC cable

at 3 x 1.5 mm2

at 3 x 2.5 mm2

5 m

20 m

Ambient temperature

during operaon

storage

10 - 40 °C

-10 - 70 °C

Relave air humidity; non condensing 5 to 85 %

Page 7

B8J201880_B - Descripon

Type of protecon IP 30

Overvoltage category II

Contaminaon grade 2

Weight, approx. 4 kg

Figure 2 Dimensions in mm

334

319

160

4.5

135

23

Ø 4

89

132

100

100

36

135

1

2

CS/5083/A

1. Countersink for M4 (4x) 2. Top view1. Countersink for M4 (4x) 2. Top view

3.4 Ordering data

Part No.

EPS 500 B8J200811

DC cable (connecon between EPS 500 and nEXT 730/930D 1 m

3 m

5 m

B8J200821

B8J200822

B8J200823

Page 8

B8J201880_B - Descripon

4. Installaon

4.1 Placement

Put the EPS 500 on a at, smooth surface or aach it with screws. If the EPS 500 is not

aached with screws, install the supplied rubber feet.

CAUTION

Do not block the heat dissipaon of the EPS 500. Make sure there is sucient

venlaon. The ambient temperature during operaon must not exceed 40 °C (104

°F).

WARNING

If the EPS 500 is built into a device, install a safety switch cut-o between the EPS 500

and the mains.

CAUTION

Do not operate the EPS 500 with the tested mains cable in a chemically aggressive

environment. If you operate the EPS 500 in a chemically aggressive environment

replace the mains cable with a resistant one.

Figure 3 Air ow paern; top view

CS/5084/A

4.2 Conforming use

The EPS 500 is used to operate the turbomolecular pumps. Other devices must not be

connected.

4.3 Providing the connecons

Aach the connecon line to the pump; see Fig. 4.

We recommend that you use the cables listed in Secon 3.4. If you decide use other

cables, use a shielded cable and obey the informaon given in Fig. 5.

Page 9

B8J201880_B - Installaon

WARNING

Use the ground bolt to connect the device to the protecve ground system.

Connect the mains cable.

Figure 4 Example of a connecon schemac

5

43

12

EPS 500

CS/5085/A

1. Mains connecon (100 - 240 V) 2. DC cable

3. 48 V DC pump power supply 4. Accessory connector

5. Control interface

1. Mains connecon (100 - 240 V) 2. DC cable

3. 48 V DC pump power supply 4. Accessory connector

5. Control interface

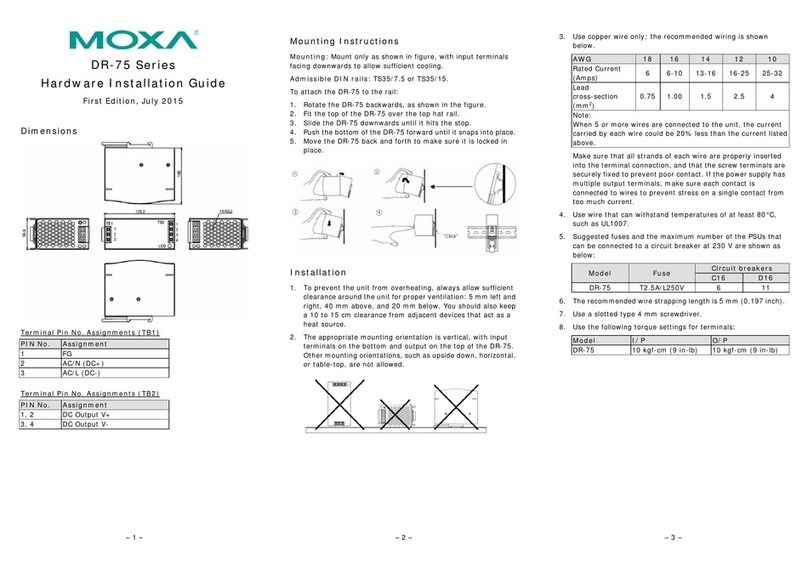

Figure 5 POWER OUT plug

PE

3

1

2

CS/5086/A

1. + 48 V DC 2. 0 V

3. not connected

1. + 48 V DC 2. 0 V

3. not connected

4.4 Changing the fuses

The device has mains fuses 8 A slow blow.

To change fuses, disconnect the mains cable and then remove the protecve cap below

the on/o switch.

Page 10

B8J201880_B - Installaon

5. Maintenance

Dust and moisture can cause contaminaon in the power supply. This contaminaon can

cause the power supply to overheat or short-circuit. We recommend that the power

supply is cleaned every 5 years.

5.1 Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send

us a completed Declaraon of Contaminaon of Vacuum Equipment and Components –

Form HS2. The HS2 form tells us if any substances found in the equipment are

hazardous, which is important for the safety of our employees and all other people

involved in the service of your equipment. The hazard informaon also lets us select the

correct procedures to service your equipment.

We provide instrucons for compleng the form in the Declaraon of Contaminaon of

Vacuum equipment and Components – Procedure HS1.

If you are returning a vacuum pump, note the following:

▪ If a pump is congured to suit the applicaon, make a record of the conguraon

before returning the pump. All replacement pumps will be supplied with default

factory sengs.

▪ Do not return a pump with accessories ed. Remove all accessories and retain

them for future use.

▪ The instrucon in the returns procedure to drain all uids does not apply to the

lubricant in pump oil reservoirs.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the

procedure in HS1, ll in the electronic HS2 form, print it, sign it, and return the signed

copy to us.

NOTICE:

If we do not receive a completed HS2 form, your equipment cannot be serviced.

Page 11

B8J201880_B - Maintenance

This page has been intentionally left blank.

This page has been intentionally left blank.

edwardsvacuum.com

Table of contents

Other Edwards Power Supply manuals

Popular Power Supply manuals by other brands

Moxa Technologies

Moxa Technologies DR-75 Series Hardware installation guide

Omron

Omron E3G-L1 instruction sheet

HB-THERM

HB-THERM M8098 Assembly instructions

Monacor

Monacor PSS-5000 quick start guide

Crestron

Crestron C2N-SPWS300 Specifications

Liebert

Liebert Ship-Ahead Input/Output Cabinet NXL installation manual