Linhai T-Boss 550 User manual

SERVICE MANUAL

T-Boss 550

NOTICE

This manual was produced by the Linhai Group primarily for use by Linhai dealers

and their qualified mechanics. It is not possible to include all the knowledge of a

mechanic in one manual, so it is assumed that anyone who uses this book to perform

maintenance and repairs on Linhai vehicle has a basic understanding of the

mechanical ideas and the procedures of vehicle repair. Repairs attempted by anyone

without this knowledge are likely to render the vehicle unsafe and unfit for use.

Linhai Group is continually striving to improve all its models. Modifications and sig-

nificant changes in specifications or procedures will be forwarded to all authorized

Linhai dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following

notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe

injury or death to the vehicle operator, passenger, a bystander, or

a person checking or repairing the vehicle.

CAUTION: A CAUTION indicates special precautions that must be taken to

avoid damage to the vehicle.

NOTE: A NOTE provides key information to make procedures easier or

clearer.

CONTENTS

CHAPTER1 ……………………………………………………….General Information

CHAPTER2 ………………………………………….……………………Maintenance

CHAPTER3…………………………………….……….….…………………….Engine

CHAPTER4…………………………………………..…………………………Chassis

CHAPTER5………………………………………………….……………….Final Drive

CHAPTER6………………………………………………………………………Brakes

CHAPTER7………………………………………………….….……………..Electrical

Never run an engine in an enclosed area. Carbon monoxide exhaust gas is

poisonous and can cause severe injury or death. Always start engines outdoors.

Gasoline is extremely flammable and explosive under certain conditions. Battery

electrolyte is poisonous. It contains sulfuric acid. Serious burns can result from

contact with skin, eyes or clothing. Always keep alert and wear protection.

Exhaust system components are very hot during and after use of UTV. Never service

when the engine is warm or hot. Escaping steam from cooling system or hot oil from

the machine can cause severe burns. The engine must be cool before service.

Crate of the UTV and parts in the UTV maybe have sharp edge, always pay attention

and wear protection.

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

1

CHAPTER 1 GENERAL INFORMATION

The parts of different types/ variants/ versions maybe un-interchangeable, even some parts

have almost same appearance. Always refer to Parts Manual of each UTV model for spare

parts information and service.

1.1 IMPORTANT INFORMATION

1.2 V.I.N AND ENGINE SERIAL NUMBER

1.3 VEHICLE DIMENSIONS

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

2

1.1 IMPORTANT INFORMATION

PREPARATION FOR REMOVAL PROCEDURES

1. Remove all dirt, mud, dust and foreign material before removal and disassembly.

2. Use proper tools and cleaning equipment.

3. When disassembling the machine, always keep mated parts together. This includes gears,

cylinders, pistons and other parts that have been ”mated ”through normal wear. Mated part

must always be reused or replaced as an assembly.

4. During machine disassembly, clean all parts and place them in trays in the order of

disassembly. This will speed up assembly and allow for the correct installation of all parts.

5. Keep all parts away from any source of fire.

REPLACEMENT PARTS

Use only genuine parts for all replacements. Use recommended oil and grease for all

lubrication jobs. Other brands may be similar in function and appearance, but inferior in

quality.

GASKETS,OIL SEALS AND O-RINGS

1. Replace all gaskets seals and O-rings when overhauling the engine. All gasket surfaces,

oil seal lips and O-rings must be cleaned.

2. Properly oil all mating parts and bearings during reassembly. Apply grease to the oil seal

lips.

LOCK WASHERS/PLATES AND COTTER PINS

Replace all lock washers/plates and cotter

pins after removal. Bend lock tabs along the

bolt or nut flats after the bolt or nut has

been tightened to specification.

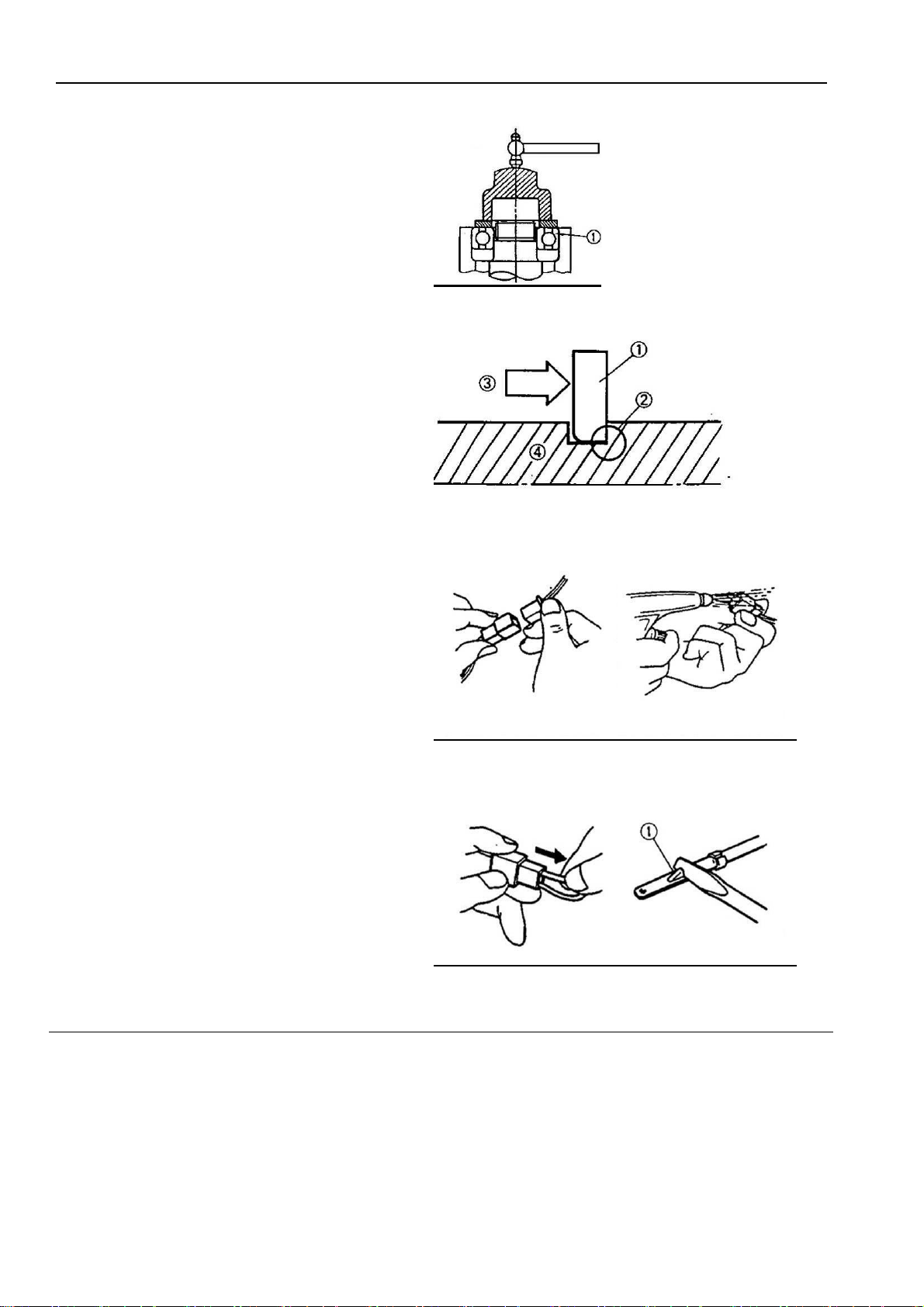

BEARINGS AND OIL SEALS

Install bearings and oil seals so that the

manufacturer’s marks or numbers are

visible. When installing oil seals, apply a

light coating of lightweight lithium base

grease to the seal lips. Oil bearings liberally

when installing, if appropriate.

①oil seal

CAUTION:

Do not use compressed air to spin the

bearings dry. This will damage the bearing

surfaces.

①Bearing

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

3

CIRCLIPS

1. Check all circlips carefully before

reassembly. Always replace piston pin

clips after one use. Replace distorted

circlips. When installing a circlip ①,

make sure that the sharp-edged corner

②is positioned opposite the thrust ③

it receives. See sectional view.

④Shaft

CHECKING OF CONNECTIONS

Dealing with stains, rust, moisture, etc. on

the connector.

1. Disconnect:

Connector

2. Dry each terminal with an air blower.

3. Connect and disconnect the connector

two or three.

4. Pull the lead to check that it will not

come off.

5. If the terminal comes off, bend up the

pin ①and reinset the terminal into the

connector.

6. Connect:

Connector

NOTE:

The two connectors ”click ”together.

7. Check for continuity with a tester.

NOTE:

If there is no continuity, clean the

terminals.

Be sure to perform the steps 1 to 7 listed

above when checking the wire harness.

Use the tester on the connector as

shown.

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

4

Never run an engine in an enclosed area. Carbon monoxide exhaust gas is poisonous and

can cause severe injury or death. Always start engines outdoors.

Gasoline is extremely flammable and explosive under certain conditions. Battery electrolyte is

poisonous. It contains sulfuric acid. Serious burns can result from contact with skin, eyes or

clothing. Always keep alert and wear protection..

Exhaust system components are very hot during and after use of UTV. Never service when

the engine is warm or hot. Escaping steam from cooling system or hot oil from the machine

can cause severe burns. The engine must be cool before service.

Crate of the UTV and parts in the UTV maybe have sharp edge, always pay attention and

wear protection.

CONVERSION TABLE

How to use the CONVERSION TABLE

Use this table to convert METRIC unit data to IMPERIAL unit data.

Ex.

METRIC MULIPLIER IMP

**mm x 0. 3937 = **in

**cm x 0.03937 = **in

CONVERSION TABLE

METRIC TO IMP

Known

Multiplier

Result

Torque

m·kg

m·kg

cm·kg

cm·kg

7.233

86.794

0.0723

0.8679

ft·lb

In·lb

ft·lb

In·lb

Weight

kg

g

2.205

0.03527

lb

oz

Distance

km/h

km

m

m

cm

mm

0.6214

0.6214

3.281

1.094

0.3927

0.03927

mph

mi

ft

yd

in

in

Volume/

Capacity

cc(cm3)

cc(cm3)

lit(liter)

lit(liter)

0.03527

0.06102

0.8799

0.2199

oz(IMP liq.)

cu·in

qt (IMP liq.)

gal(IMP liq.)

Miscellaneous

kg/mm

kg/cm2

Centigrade

55.997

14.2234

9/5(℃)+32

lb/in

psi(lb/in2 )

Fahrenheit(°F)

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

5

1.2 V.I.N AND ENGINE SERIAL NUMBER

The vehicle identification number ○

1is

stamped

into the rear right of the frame tube.

The engine serial number ②is stamped

into left side of engine crankcase.

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

6

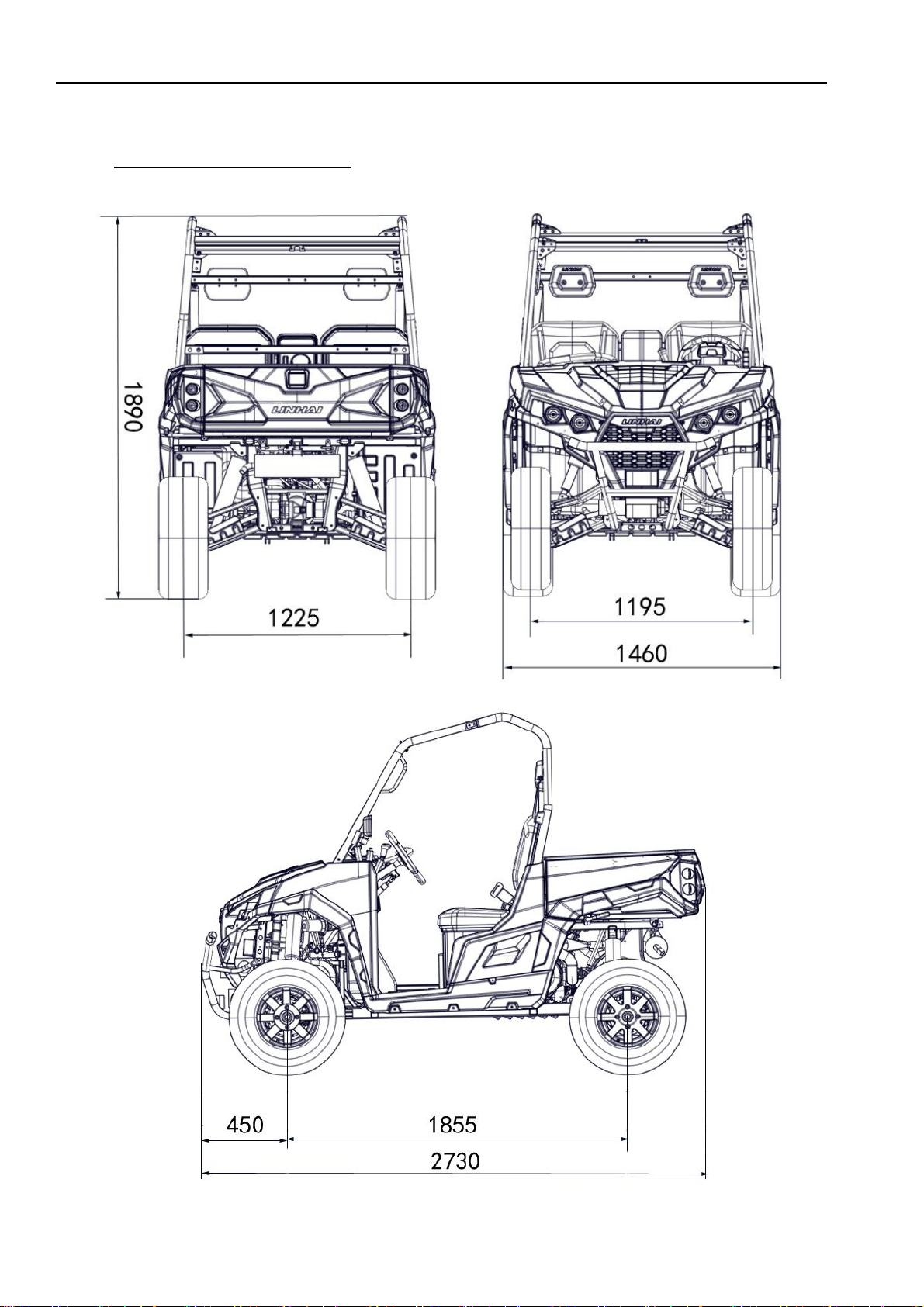

1.3 VEHICLE DIMENSIONS

CHAPTER 1 GENERALINFORMATION T-Boss550 SERVICE MANUAL 20.0

CHAPTER 1 GENERAL PAGE. 1-

7

NOTES

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

1

CHAPTER 2 MAINTENANCE

The parts of different types/ variants/ versions maybe un-interchangeable, even some parts

have almost same appearance. Always refer to Parts Manual of each UTV model for spare

parts information and service.

2.1 PERIODIC MAINTENANCE

2.2 THROTTLE PEDAL INSPECTION

2.3 CHOKE ADJUSTMETN

2.4 FUEL SYSTEM

2.5 TOE ALIGNMENT

2.6 BRAKING SYSTEM INSPECTION

2.7 SUSPENSION SPRING RPELOAD ADJUSTMENT

2.8 WHEELS

2.9 TIRE PRESSURE

3.0 FRAME, NUTS, BOLTS, FASTENERS

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

2

2.1 PERIODIC MAINTENANCE

GENARAL

CAUTION

Mark on the following chart

DL :Due to the nature of the adjustments marked with a DL on the following chart, it is

recommended that service be performed by an authorized dealer.

▲:Service/Inspect more frequently when operating in adverse conditions.

PERIODIC MAINTENANCE SCHEDULE

Careful periodic maintenance will help keep your vehicle in the safest, most reliable condition.

Inspection, adjustment and lubrication intervals of important components are explained in the

following chart on the following pages.

Maintenance intervals are based upon average riding conditions and an average vehicle

speed of approximately 16km/h (10 miles per hour). Vehicles subjected to severe use, such

as operation in wet or dusty areas, should be inspected and serviced more frequently.

Inspect, clean, lubricate, adjust or replace parts as necessary.

NOTE: Inspection may reveal the need for replacement parts. Always use genuine parts

available from your dealer.

Service and adjustments are critical. If you are not familiar with safe service and adjustment

procedures, have a qualified dealer perform these operations.

A = Adjust I = Inspect

C = Clean L = Lubricate

D = Drain R = Replace

T =Tighten to Correct Torque

Item

Hours

When

Remarks

Service (Main) Brake System

/

Pre-ride

I

Parking Brake

/

Pre-ride

I

Tires

/

Pre-ride

I

Wheels

/

Pre-ride

I

Frame nuts, bolts fasteners

/

Pre-ride

I

▲

Air Filter-Pre-Cleaner

/

Daily

I C

Coolant/Level

/

Daily

I

Coolant

150

Annually

R

Coolant strength

25

3 months

I Inspect strength seasonally

▲

Air Box Sediment Tube

/

Daily

D

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

3

Headlamp Inspection

/

Daily

C

apply dielectric grease to connector

when replaced

Tail lamp inspection

/

Daily

C

apply dielectric grease to socket when

replaced

▲

Air Filter-Main Element

2

Weekly

IC

Replace if necessary

▲

Transmission Oil Level

10

Monthly

I

change annually

Battery Terminals

10

Monthly

I C

DL

Brake pad wear

10

Monthly

I

▲

Gear case Oil

10

Monthly

C

150

annually

R

Engine Cylinder Head and

Cylinder Base Fasteners

25

3 months

I

(re-torque required at first service only)

▲

General Lubrication

all fittings, pivots, cables, etc.

25

3 months

L

Engine Oil-Level

/

Daily

I

Engine Oil Change

30

3 months

R

Break-in Service at 1 month. Change oil

more often in cold weather use.

▲

Oil Filter

50

6 months

IC

▲

Engine breather hose

100

6 months

I

Throttle Cable

/

Pre-ride

I

DL

Throttle Cable/Throttle pedal

50

6 months

A L (Grease M) R if necessary

Shift linkage

50

6 months

IA R if necessary

DL

Transmission belt

50

6 months

I

R if necessary

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

4

▲

Steering

50

6 months

I L T if necessary

▲

Front Suspension

50

6 months

IL

T if necessary

▲

Rear Suspension

50

6 months

I

T if necessary

Spark Plug

100

12 months

I

R if necessary

DL

Ignition Timing

100

12 months

I

Adjust as needed

DL

Fuel System

100

12 months

Check for leaks at tank, cap, lines, fuel

valve, and filter. Replace lines every 2

years.

DL

Fuel Filter

100

12 months

R

Radiator

100

12 months

I R

Cooling System hoses

50

6 months

I

R if necessary

Spark arrestor

10

monthly

C

R if necessary

DL

Clutches (drive and Driven)

25

3 months

I R

R if necessary

Engine mounts

25

3 months

IT

DL

Valve clearance

100

12 months

IA

DL

Shift selector box

(R/N/ H/L)

200

24 months

Change grease every two years

Exhaust system

100

12 months

I

DL

Brake fluid Level

/

Pre-ride

I

Brake fluid

200

24 months

Change every two years

Idle Speed

/

As Required

A

DL

Toe adjustment

/

As Required

Periodic inspection, adjust when parts

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

5

are replaced

Headlight Aim

/

As Required

Adjust if necessary

▲

DL

Ball joint (A arm- strut)

10

monthly

I, (for damage, wear, and play)

R. Replace if necessary

LUBRICANT AND FLUID

Item

Lube Rec

Method

Frequency

1. Engine Oil

SAE15W/40

SG

Add to proper level on

dipstick

Check level daily

2.Brake Fluid

DOT 3 Only

Maintain level,Between

fill lines. See

“7.CONTROL”

As require;

change every

two years or 200

hours

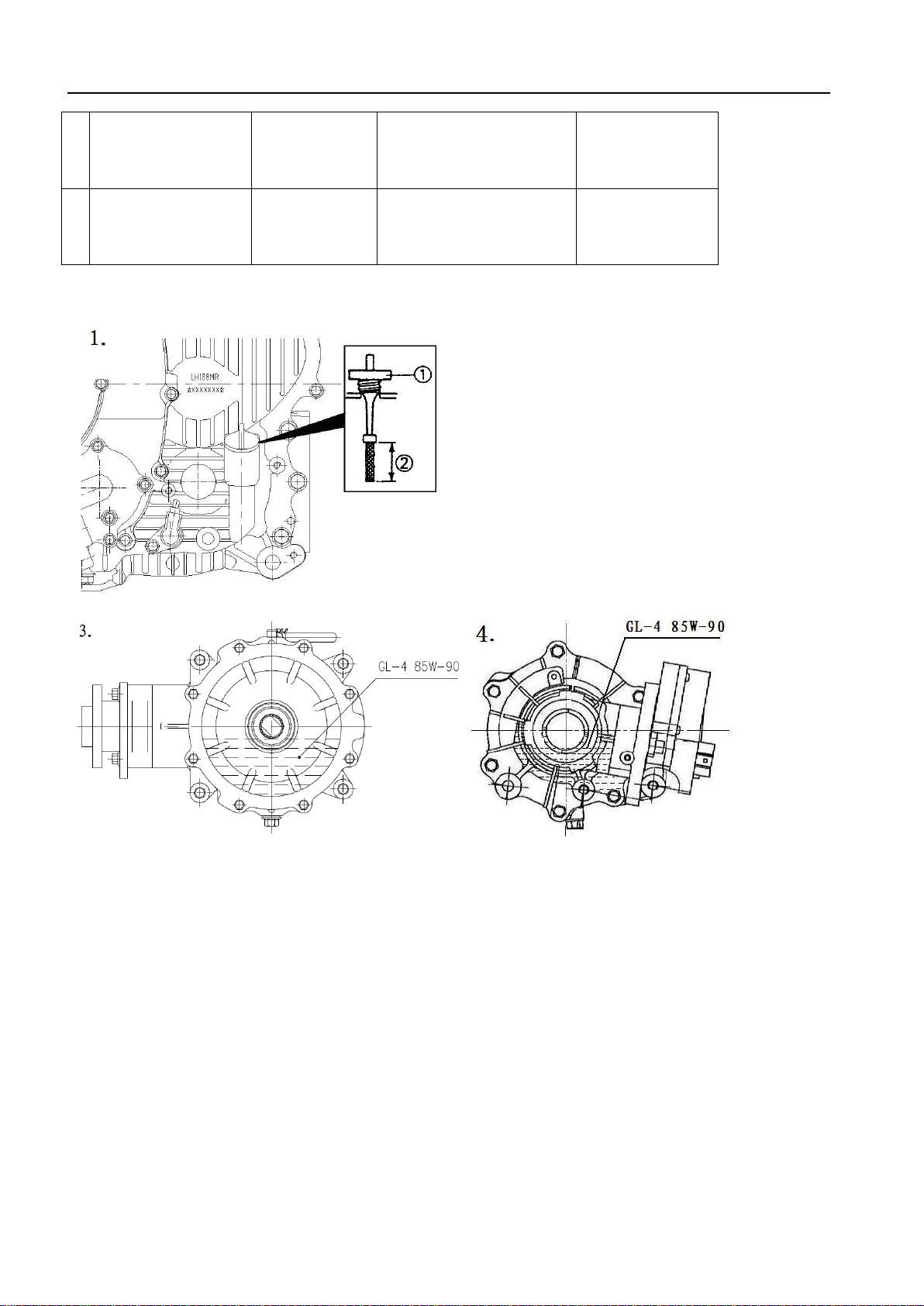

3.Rear Gear case

oil

SAE

GL-4 85W/90

See “16.MAI-

NTENANCE/ Rear

Gear Case Lubrication”

Change annually

or

at 100 hours

4.Front Gear case

oil

SAE

GL-4 85W/90

See “16.MAI-

NTENANCE/ Front

Gear Case Lubrication”

Change annually

or

at 100 hours

5.Steering system

Grease

Lubricate the pivoting

and sliding parts

Every 3 months

or 50 hours

6.Tie rods

Grease

Grease

Semi-annually

7.Shift

Linkages

Grease

Locate fittings

and Grease

Semi-annually

8.Front/Rear Wheel

bearings

Inspect

Inspect and replace

bearings if

necessary

Semi-annually

9.Ball joints

Grease

Inspect, Locate fittings

and Grease, or replace it

if necessary

Semi-annually

10.Prop Shaft &

Shaft Yoke, Spline

Joint

Grease

Locate fitting and Grease

Semi-annually

11. Front/Rear

A-arm

pivot Shaft

Grease

Locate fitting on pivot

shaft

and grease with grease

gun

Every 3 months

or 50 hours

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

6

12.Throttle

Cable

Grease M

Grease, inspect

and replace it if

necessary

Monthly or 20

hours

13. Accelerator

pedal and brake

pedal

Grease

Grease, inspect

Monthly or 20

hours

LUBRICATION RECOMMENDATIONS

NOTE:

1.More often under severe use, such as wet or dusty conditions.

2.Grease: Light weight lithium-soap grease.

3.Grease M:Molybdenum disulfide (MoS2 ) grease (water resistant).

4.When suspension action becomes stiff or after washing.

5.Hours are based on 10 mph(16Km/h) average.

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

7

2.2 THROTTLE PEDAL INSPECTION

THROTTLE FREEPLAY

If the throttle pedal has excessive play due to

cable

stretch or cable misadjustment, it will cause a

delay in throttle speed. Also, the throttle may

not open fully. If the throttle pedal has no play,

the throttle may be hard to control, and the idle

speed may be erratic. Check the throttle pedal

play periodically in accordance with the

Periodic Maintenance Chart and adjust the

play if necessary.

THROTTLE FREEPLAY INSPECTION

1. Apply the parking brake.

2. Put the gear shift lever in the N(Neutral) position.

3. Start the engine, and warm it up thoroughly.

4. Measure the distance the throttle pedal moves

before the engine begins to pick up speed. Free

play should be 1.5 –3 mm.

Adjustment

1. Slide the boot off inline cable adjuster sleeve.

Loosen adjuster locknut.

2. Turn adjuster until 1.5 to 3 mm, freeplay is

achieved pedal. NOTE: While adjusting freeplay,

it is important you flip the throttle lever back and

forth.

3. Tighten locknut.

2.3 CHOKE ADJUSTMETN

If the choke knob does not stay out when pulled,

adjust the choke tension by tightening (clockwise)

the chock cable boot until the choke slider freely but

stays out when pulled.

If smooth choke operation is not obtainable, inspect

choke cable for kinks or sharp bends in routing

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

8

2.4 FUEL SYSTEM

EFI

Always stop the engine and refuel

outdoors or in a well venltilated area.

Do not smoke or allow open flames or sparks in or near the area where refueling is

performed or where gasoline is stored.

Do not overfill the tank. Do not fill the tank neck.

If you get fuel in your eyes or if you swallow gasoline, see your doctor immediately.

If you spill fuel on your skin or clothing, immediately wash it off with soap and water and

change clothing.

Never start the engine or let it run in an enclosed area. Fuel powered engine exhaust

fumes are poisonous and can cause loss of consciousness and death in a short time.

Never drain the float bowl when the engine is hot. Severe burns may result.

FUEL LINES

1. Check fuel lines for signsof wear,

deterioration, damage or leakage.

Replace if necessary.

2. Be sure fuel lines are routed

properly and secured with cable

ties.

CAUTION:

Make sure lines are not kinked

orpinched.

Replace all fuel lines every two years.

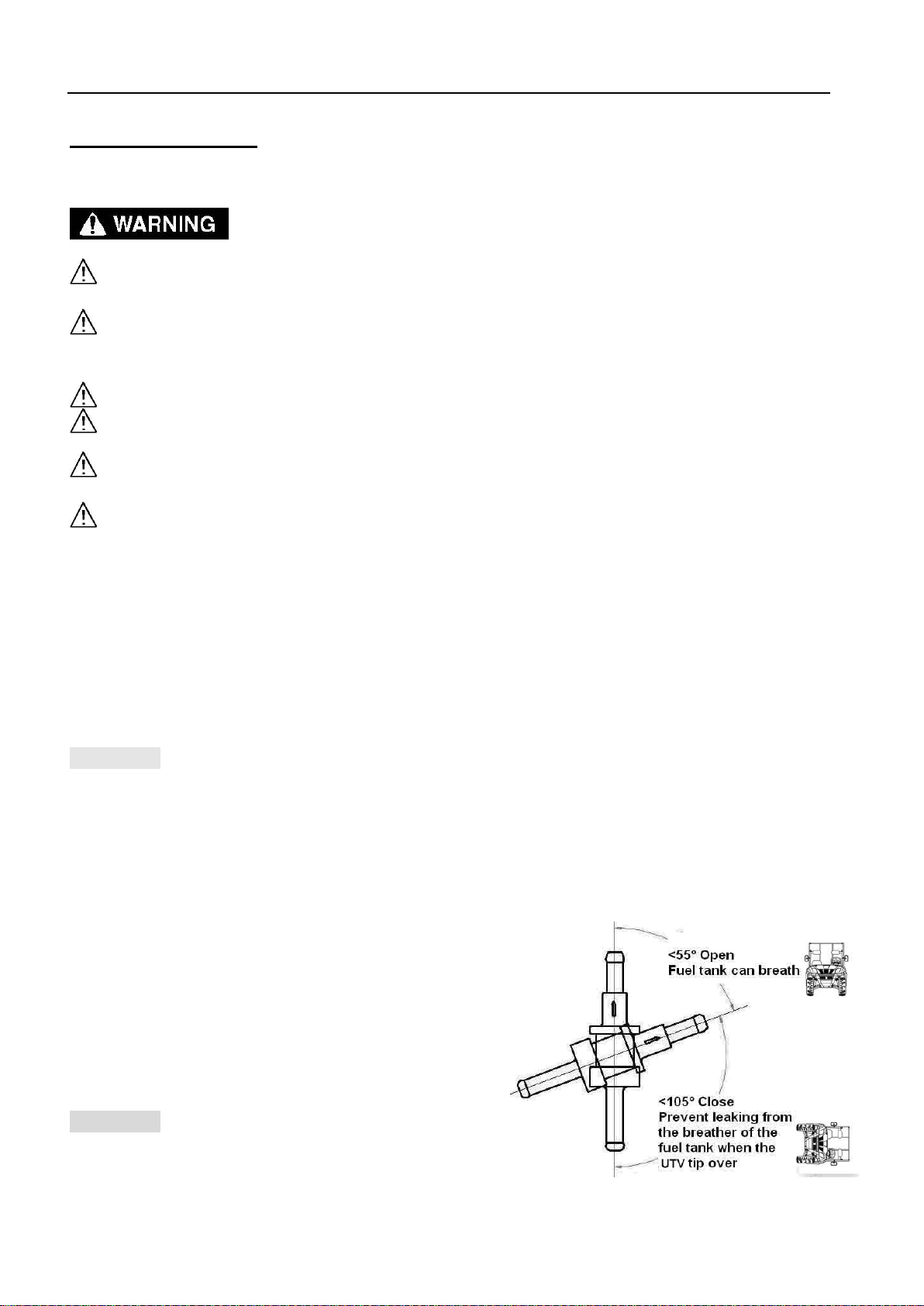

VENT LINES AND ROLL OVER VALVE

1. Check fuel tank, oil tank, battery and

transmission vent lines for signs of wear,

deterioration, damage of leakage. Replace every

two years.

2. Be sure vent lines are routed properly and

secured with cable ties.

CAUTION: Make sure lines are not kinked or

pinched.

NOTE: Make sure the↑mark on the roll over valve is

CHAPTER 2 MAINTENANCE T-Boss550 SERVICE MANUAL 20.0

CHAPTER 2 MAINTENANCE PAGE. 2-

9

upwards.

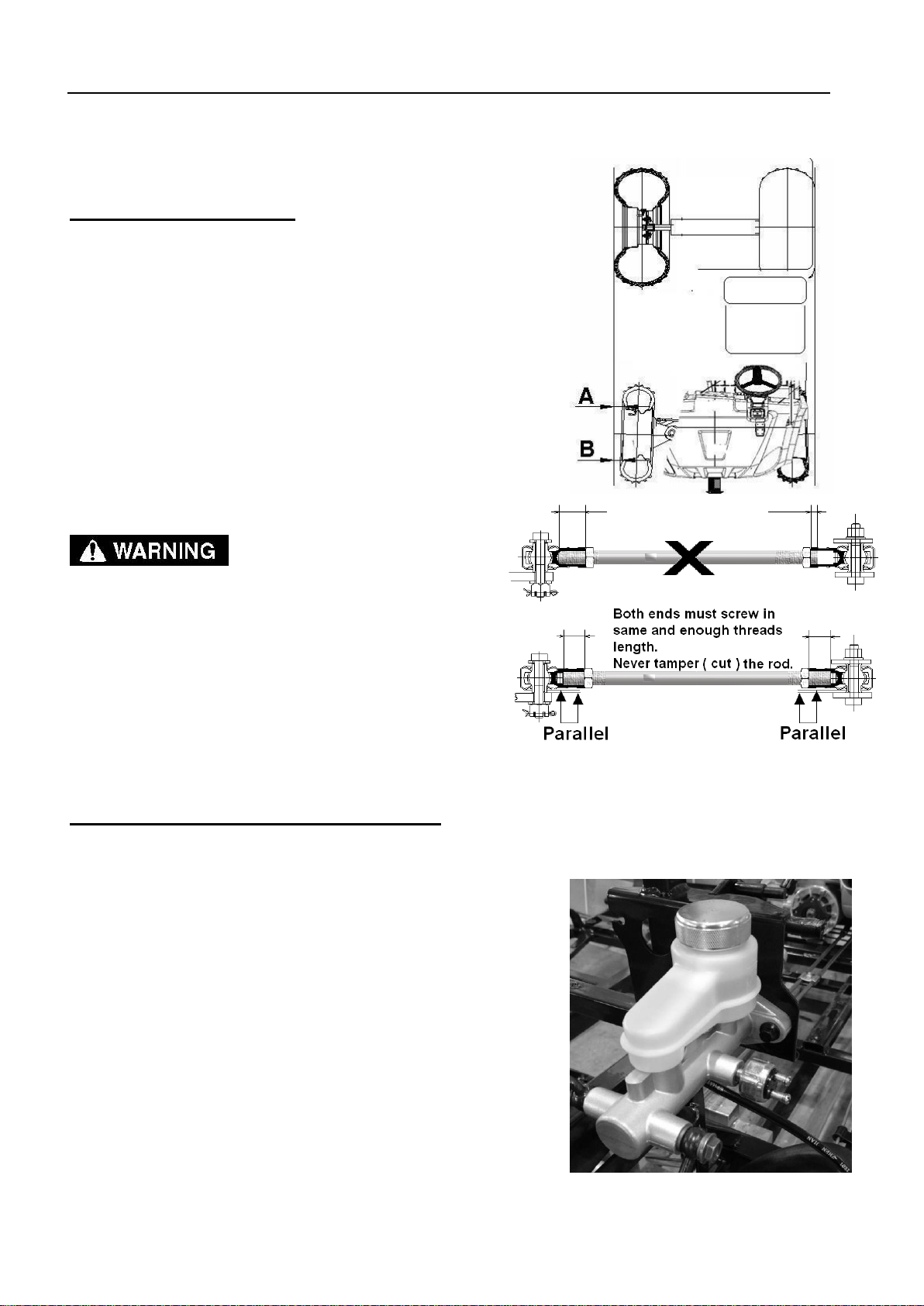

2.5 TOE ALIGNMENT

METHOD: STRAIGHTEDGE OR STRING

Be sure the steering wheel in a straight ahead position.

NOTE: String should just touch side surface of rear tire on

each side of the UTV.

Measure from string to rim at front and rear of rim.

Rear rim measurement (A) should be 1/8" to 1/4" (3 to 6

mm) more than front rim measurement (B).

Always pay attention to tie rods assembly, Both ends

must screw in same and enough threads length.

2.6 BRAKING SYSTEM INSPECTION

The following checks are recommended to keep the

braking system in good operating condition. Service life of

braking system components depends on operating

conditions. Inspect brakes in accordance with the

maintenance schedule and before each ride

Keep fluid level in the master cylinder reservoir to the

indicated level on reservoir.

Use DOT 3 brake fluid.

NOTE: Use new brake fluid or brake fluid from a sealed

container to avoid contamination to system.

Check brake system for fluid leaks.

Check brake for excessive travel or spongy feel.

Check friction pads for wear, damage and looseness.

Check surface condition of the disc.

Table of contents

Other Linhai Utility Vehicle manuals