Link4 iPonic 600 User manual

iPonic

™600

INTELLIGENT ENVIRONMENTAL CONTROLLER

Installation and User’s Guide

November 2011 Preliminary Edition

Copyright © 2011 Corporation

iPonic

™600

INTELLIGENT ENVIRONMENTAL CONTROLLER

Installation and User’s Guide

November 2011 Preliminary Edition

Copyright © 2011 Corporation

Table of Contents

Introduction .....................................................................................1

Link4 Corporation Contact Information........................................................................1

Terms and Conditions..................................................................................................2

Warranty.......................................................................................................................2

Installation .......................................................................................3

Content Inspection.......................................................................................................3

Mounting the iPonic 600............................................................................................4

Before you Begin ............................................................................5

Temperature Control....................................................................................................5

Deadbands..................................................................................................................5

Setpoint .......................................................................................................................5

Ramping......................................................................................................................6

Control Strategy...........................................................................................................7

Setpoint and Staging Worksheets ...............................................................................7

Internal Layout.............................................................................................................9

Connecting to the iPonic 600...................................................................................11

Indoor Sensor Module Installation.............................................................................11

Optional Ethernet Cable Installation..........................................................................11

Equipment Installation ...............................................................................................12

Low Voltage Output Installation.................................................................................13

Programming.................................................................................15

Before You Begin.......................................................................................................15

iPonic 600™ Main Status Screens ............................................................................15

Navigation..................................................................................................................15

Main Status Screen Entries ..............................................................................18

Programming Screens...............................................................................................20

1.0 CURRENT SETPOINT PROGRAMMING............................................................21

1.1 Temperature Setpoint...................................................................................22

1.1.1 Global Temperature Settings..............................................................23

1.2 Humidity Setpoint .........................................................................................23

1.2.1 Global Humidity Settings.....................................................................24

1.3 CO2 SetPoint................................................................................................25

1.3.1 CO2 Global Settings.............................................................................25

1.4 Light Settings................................................................................................27

1.4.1 Global Light Settings ............................................................................27

2.0 GROWTH SCHEDULE.........................................................................................28

3.0 REPORTS............................................................................................................31

3.1 Sensor Reports.............................................................................................31

3.2 Graphing.......................................................................................................31

3.2.1 Temperature........................................................................................32

3.2.2 Humidity ..............................................................................................33

3.2.3 Light ....................................................................................................33

3.2.4 CO2.....................................................................................................33

4.0 SYSTEM SETUP..................................................................................................34

4.1 Equipment Setup..........................................................................................35

4.1.1 Quick Setup..........................................................................................35

4.1.2 Advanced .............................................................................................35

4.1.2.1 Timed Override.........................................................................36

4.1.2.2 Initial Settings ...........................................................................37

4.2. Scheduling Setup (Growth Curve Setup).....................................................42

4.3. Sensor Setup...............................................................................................43

4.3.1 Advanced ............................................................................................43

4.3.1.1 Map Sensors............................................................................44

4.3.1.2 Calibrate Sensors....................................................................44

4.3.1.3 Self-Test Set Up ......................................................................44

4.3.1.4 Analog Sensor Mapping ..........................................................45

4.4 Alarms Setup................................................................................................46

4.5 Time/Date Setup...........................................................................................47

4.5.1 Set Time..............................................................................................47

4.5.2 Set Date..............................................................................................47

4.6 Advanced......................................................................................................48

4.6.1 Air Exchange Settings.........................................................................48

4.6.2 Diagnostics..........................................................................................49

4.6.3 Time Settings ......................................................................................49

4.6.4 Clear Data...........................................................................................49

4.7 Save/Restore................................................................................................50

4.7.1 Save/ Restore Configuration ...............................................................50

4.7.2 Save Log Files.....................................................................................51

4.7.3 Save/Restore Schedule.......................................................................51

4.8 Location Setup..............................................................................................52

4.9 Communication Setup ..................................................................................53

4.10 Measurement Units ....................................................................................54

5.0 SAVE/RESTORE CONFIG...................................................................................55

6.0 STAGES...............................................................................................................56

6.1 Temperature Stages.....................................................................................57

6.2 Humidity Stages ...........................................................................................57

960-0001-20 iGrowSeries 100 Installation Manual 1

Introduction

Welcome to iPonic 600TM, Link4‟s Intelligent Hydroponic Environmental Controller. The iPonic 600TM

represents the latest in indoor hydroponic environmental control automation. This UL and cUL procuct enables

you to control and integrate a variety of equipment in your hydroponic facility. Your heating, cooling, venting,

humidity, CO2, and lighting needs are linked together into one flexible, easy-to-use system.

Link4 can offer reliable service because we are staffed by the designer and engineers that developed the iPonic

600TM. In designing the iPonic 600TM it was our purpose to design a controller specifically for the unique

demands for the indoor growers. Your control system should improve the quality and efficiency of your

operation. iPonic 600TM offers quick installation, and dynamic programming flexibility for easier and more

accurate grow room management giving you the freedom for you to focus on plants and profits.

The reason why we stand out from others is because of our Link4 Promise: Our passion is to provide growers

with intelligent control solutions. We understandcontrolling your growing environmentis criticalto your success.

Therefore, our commitment is to build outstanding controllers and to provide excellent support so that you can

know with confidence that the iPonic 600TM system is right for you.

Customer Service

Link4 has a well-trained customer support staff that is ready to help. Our customer service center is committed

to your hydroponic facility business 24/7 through our website or service line for access to solutions for your

controller needs. Before you contact us, please write down the model number and serial number located inside

the iPonic 600TM enclosure so that we can serve you better.

Link4 Corporation

Contact Information

Address

22725 La Palma Ave.

Yorba Linda, CA 92887

Website

link4corp.com

iponic.link4corp.com

Additional support information

available to online registered

users.

Telephone

Service

Sales

866.755.5465

714.524.0004

Email

Service

Sales

support@link4corp.com

sales@link4corp.com

2 iGrowSeries 100 Installation Manual 960-0001-20

Terms and Conditions

Warranty

Link4 warrants that the iPonic 600 Controller with the exception of the sensor module sold under this contract

will be free from defects in material and workmanship for a period of 36 months after the date of purchase. The

sensor module is warranted for 12 months from the date of purchase. This warranty will be limited to the repair

and replacement of parts and the necessary labor and services required to repair the goods. IT IS

EXPRESSLY AGREED THAT THIS WARRANTY WILL BE IN LIEU OF ALL WARRANTIES OF FITNESS

AND IN LIEU OF THE WARRANTY OF MERCHANTABILITY

Moreover, any description of the goods contained in this contract is for the sole purpose of identifying them, is

not part of the basis of the bargain, and does not constitute a warranty that the goods will conform to that

description. The use of any sample or model in connection with this contract is for illustrative purposes only, is

not part of the basis of the bargain, and is not to be construed as a warranty that the goods will conform to the

sample or model. No affirmation of fact or promise made by Link4, whether or not in this contract, will constitute

a warranty that the goods will conform to the affirmation or promise.

Link4 shall not be responsible for replacement(s) or repair(s) which become defective from user negligence,

modification, abuse and/or any types of improper usage. Nonconformance to any of the specifications in the

product manual will void the warranty. Furthermore, our liability to the goods sold, whether on warranty,

contract, or negligence, will be released upon the expiration of the warranty period when all such liability shall

terminate.

Link4 shall not be responsible for any loss or claims due to consequential damages afford by the Buyer. Link4

also reserves the right to make anynecessarychanges to features and specifications to condition or warranty.

Returns

Merchandise cannot be returned without a Return Merchandise Authorization (RMA) number from

Link4. Requests for permission to return defective items must bemade within (14) fourteen days after receipt of

shipment. A Link4 RMA # for approved returns must appear on both the customer's shipping carton and the

related receipt memo. Parts under warranty will be repaired at no charge. Other returned items will be

subjected to the following restocking charges: 20% for no value added items, 40% for value added items, and

75% for custom designed or built to specification items.

Repair

A repair order must also have a Link4 Return Merchandise Authorization (RMA) number. Repairs that are not

covered by the warranty will be billed on a material and labor basis. Items returned for repair must be sent to

Link4 with prepaid return transportation Link4 will not be responsible for damage(s) due to improper packaging

or shipping and delivery of items returned for repair.

Additional Costs

It is expressly agreed that Buyer will reimburse Link4 for any additional costs attributable to changes in the

specifications, directions, or design of the items furnished which are requested or approved by Buyer at Link4‟s

listed retail prices in effect at the time such changes are ordered.

Governing Law

The validity of this contract and of any of its terms or provisions, as well as the rights and duties of the parties

under this contract, shall be construed pursuant to and in accordance with the law of California. The parties

specifically agree to submit to the jurisdiction of the courts of California.

960-0001-20 iGrowSeries 100 Installation Manual 3

Installation

Content Inspection

The package should come complete with an iPonic 600unit, a sensor module with 50‟ of cable attached,

and 4 –Self Drilling Screws. Upon arrival, check the contents with the packing list for damaged or missing

components (If you have the Integrated iPonic 600 Series Model, simply mount the panel using the two

holes on each side of the unit..

Make sure you have all items, all associated hardware, and necessary tools before you begin installation.

If there is any visible damage or missing parts, please contact our customer service at

support@Link4corp.com or 1-866-755-LINK or fax us at 714.558.9782.

1. iPonic 600unit

2. Sensor module with 16ft. cable (sensor is packed inside the controller)

3. Quick Start guide

4. Soft copies of

a. User Manual

b. Factory default configuration file (factory.icf)

c. Factory default growth curve (factory.tab)

d. Optional growth schedule (flower.tab)

Recommended tools and hardware

1. Drill

2. 3/8” socket drive drill bit with 3” extender

3. Adjustable Wrench

4. 1/8” high speed steel drill bit

5. Appropriate mounting screws

For example: 4 pcs –3/8” Drive, Hex Head Self Drilling Screws

6. Level (optional)

7. Pencil

4 iGrowSeries 100 Installation Manual 960-0001-20

Mounting the iPonic 600

1. First, find a secure location to mount the iPonic 600controller. The area should be away from

direct sunlight, condensing humidity, water, rain, or extreme temperatures. It should be

mounted in an easily accessible location at the user‟s eye level.

2. Since the iPonic 600is equipped with a hinged door and a hinged access panel for easy service and

installation, make sure there is adequate workspace, especially below the controller.

3. The iPonic 600comes with a 115 VAC power cord. Make sure there is a power outlet within

approximately 6 feet. It is recommended that the outlet is not switched and is on a circuit that is

independent of any noisy, high power equipment. The use of a sealed outlet is recommended if the

power output is exposed to moisture.

4. Identify what type of surface you will be mounting the iPonic 600and use appropriate hardware to

ensure proper mounting and load bearing. Consider the additional weight of the external equipment‟s

power cords.

5. There are 4 mounting holes on the outside of the iPonic 600. Use the appropriate tools and

hardware depending upon the surface which the unit will be mounted on to.

960-0001-20 iGrowSeries 100 Installation and User Manual 5

Before you Begin

Temperature Control

With the iPonic 600TM you can program a cooling temperature target called a “Cool Setpoint” and a heating

temperature target called a “Heat Setpoint”. The temperature range between these two targets is called the

“Normal” temperature range. If the hydroponic grow room temperature is within the Normal temperature band

usually none of the cooling or heating equipment is on. However, some circulation fans (often called horizontal

air flow (HAF) fans) may be active to maintain air movement within the hydroponic environment.

Whenever the temperature within the hydroponic facility moves above the cool setpoint, or below the heat

setpoint (falls outside the Normal temperature range) the iPonic 600TM will enter cooling or heating stages to

bring it back in line. With the iPonic 600TM you can program up to six cooling and two heating stages. These

stages go from Cool 1 to Cool 6 and Heat 1 to Heat 2. Cool 1 and Heat 1 are the least aggressive with Cool 6

and Heat 2 the most aggressive. In your program you will determine what equipment you want to be active in

each of the stages.

When the air temperature in the hydroponic facility rises above the Cool Setpoint, the system enters the first

stage of cooling, referred to as Cool 1. If the temperature continues to rise, the system will enter the second

stage, Cool 2, then the third stage, Cool 3 and so forth. At each increasing cooling stage, more cooling will be

brought to attempt to bring the air temperature below the cool setpoint and within the target “Normal”

temperature range. Heating works the same way.

In considering the difference between each heating and cooling stage there is a variable increment in the

program which is the number of degrees between each heating and cooling stage called the “Stage Separation”

or „Stage Width”. Whenever the temperature rises 1 degree above the cool setpoint (700) then the iPonic 600TM

will activate the appropriate equipment to bring the hydroponic facility to the normal temperature range. If the

temperature rises 2 degrees above the cool setpoint then the controller will be active in C2 cooling stage. The

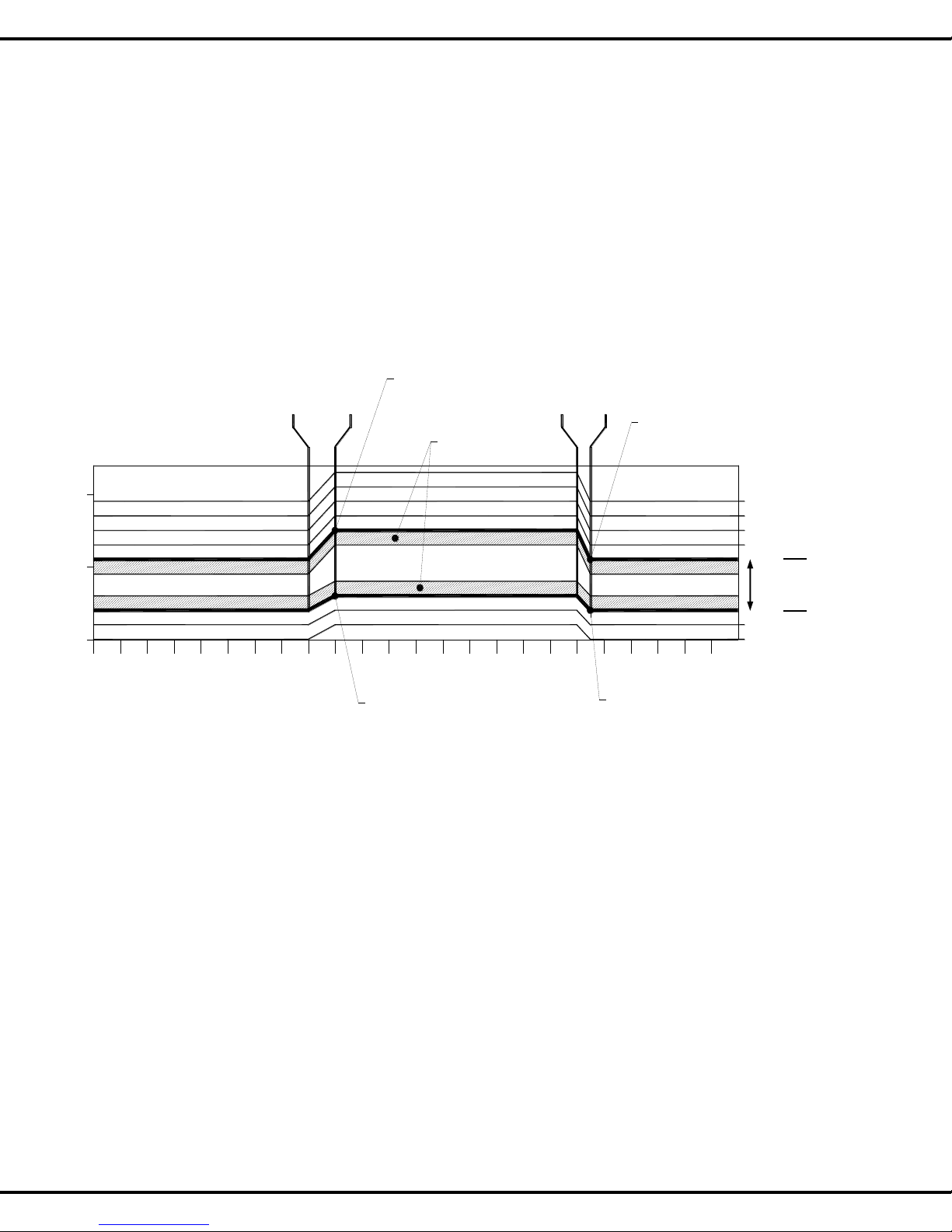

same goes for the heating stage when the temperature drops below the heating setpoints. In Figure 2.1, there

is an example with four cooling stages and two heating stages.

Deadbands

If the temperature is below the cool setpoint and rises into the first stage of cooling, some cooling equipment will

be turned on. This may then lower the temperature and bring it into the normal range. In order to keep the

equipment from oscillating, a “Deadband” is employed when the temperature is between stages. In Figure 2.1

the dead band is set at 1 degree so that when the hydroponic facility is attempting to return to Normal

temperature from C4 to C3 the controller will use a deadband of 1 degree to keep the equipment from oscillating

off and on. Now, when the temperature drops below the cool setpoint, the system remains in the Cool 1 stage

until the temperature drops below the Cool Deadband. The concepts that we described for cooling operate in

the same manner for heating.

Setpoint

You will be able to use up to 3 setpoints in a 24 hour time period. Within each day Setpoints are based on time

and temperature to produce an ideal environment. By placing setpoints during different times of the day you

can regulate the temperature within a range for target temperatures and humidity. When a setpoint is in effect

at a certain time length the controller will activate the necessary equipment in heating and cool stages to bring

the environment back to Norm. The same applies when the humidity rises or falls beyond the target low/high

setpoint. When one or more setpoints are used the second or subsequent setpoints will become the active

setpoint at the start time and the previous setpoint will end.

6 iGrowSeries 100 Installation Manual 960-0001-20

Ramping

In addition, you have the option of a temperature ramp between the setpoints. Each setpoint time period begins

with a Ramp time. The benefit of ramping allows for you to make smooth transitions within the hydroponic

facility so that the plants don‟t experience temperature shock. Ramping also saves energy, which translates

directly into lower operating costs.

In the example below, the start time is 8:00a with a 30-minute ramp time. The ramp time enables a smooth

transition of the target temperatures between the setpoint time periods. Of course, the ramp times can be set to

0 and in this case there will be an immediate step transition in the set points. This is best explained by the

illustration shown below.

12am 12 3 4 5 678 9 10 11 12pm 12 3 4 5 86 7910 11

65°F

70°F

75°F

Setpt 1

72.5°F

Setpt 1

68.0°F

Setpt 2

70.5°F

Beginning of

Ramp time

8:00am

End of

Ramp time

9:00am

Cool Stage 1

Cool Stage 2

Cool Stage 3

Cool Stage 4

Heat Stage 1

Heat Stage 2

Setpt 2

67.0°F

End of

Ramp time

6:30pm

Beginning of

Ramp time

6:00pm

1°F Deadbands

in this Example:

Setpoint 1 is set to 9:00am with a 60minute Ramp, Temp is set as 68 to 72.5F

Setpoint 2 is set to 6:00pm with a 30minute Ramp, Temp is set as 67 to 70.5F

Figure 2.1 Example of Setpoints, Staging, & Deadbands

Normal

Temp

Range

960-0001-20 iGrowSeries 100 Installation Manual 7

Control Strategy

Prior to installing and programming the iPonic 600it is important to determine an overall strategy to control

the environment in the hydroponic facility. The iPonic 600is an extremely flexible and powerful device,

thus additional care and planning are required.

In order to aid you with the process, Link4 has provided several worksheets in the following pages. It is

assumed that you already possess a general understanding of hydroponic growth room controls. If not,

please review this section carefully.

It is recommended that you make copies of these sheets before using them. They will be useful in the

future should your control needs change.

Setpoint and Staging Worksheets

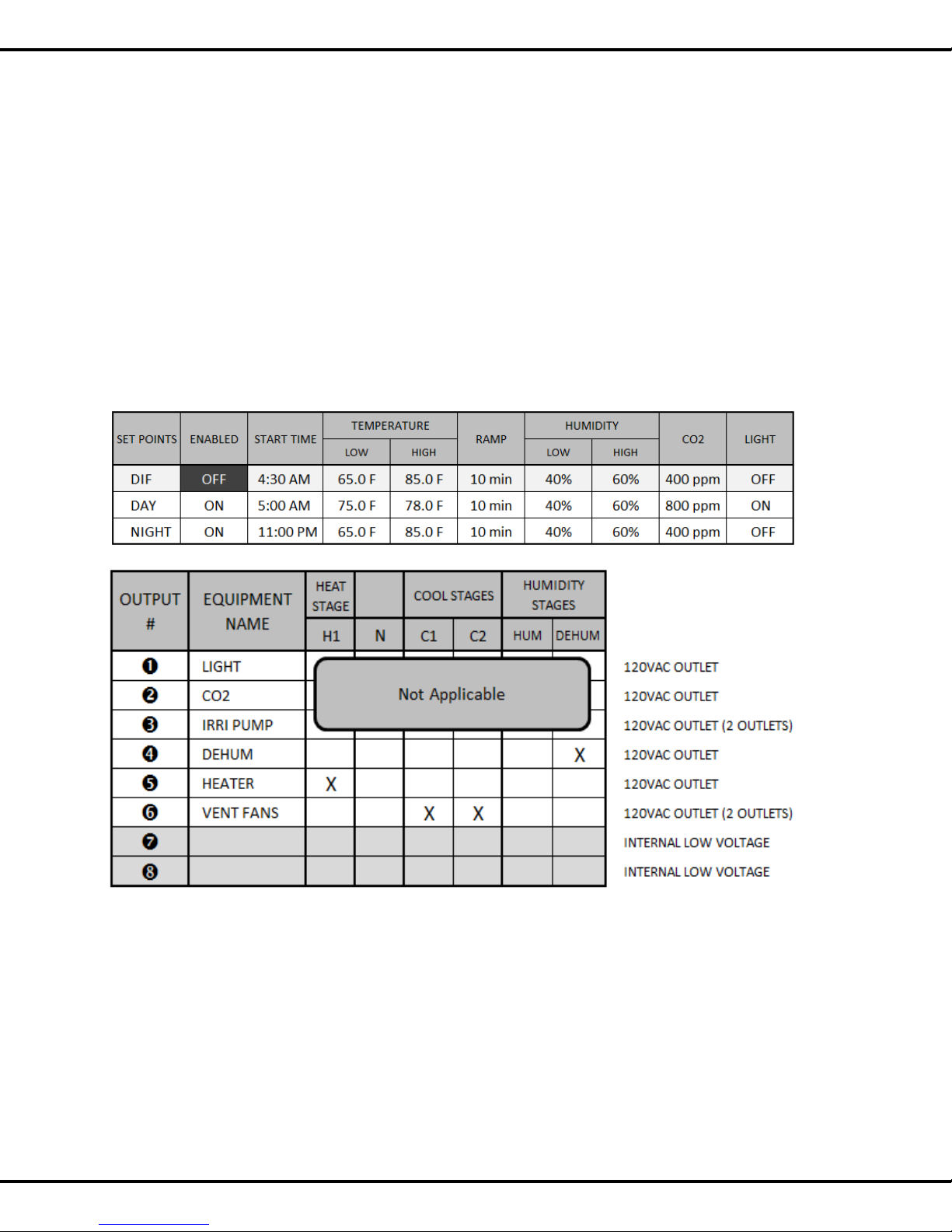

Figure 3.2 Factory default settings for setpoints and stages

8 iGrowSeries 100 Installation Manual 960-0001-20

Figure 3.3 Blank worksheet for setpoints and stages

960-0001-20 iGrowSeries 100 Installation and User Manual 9

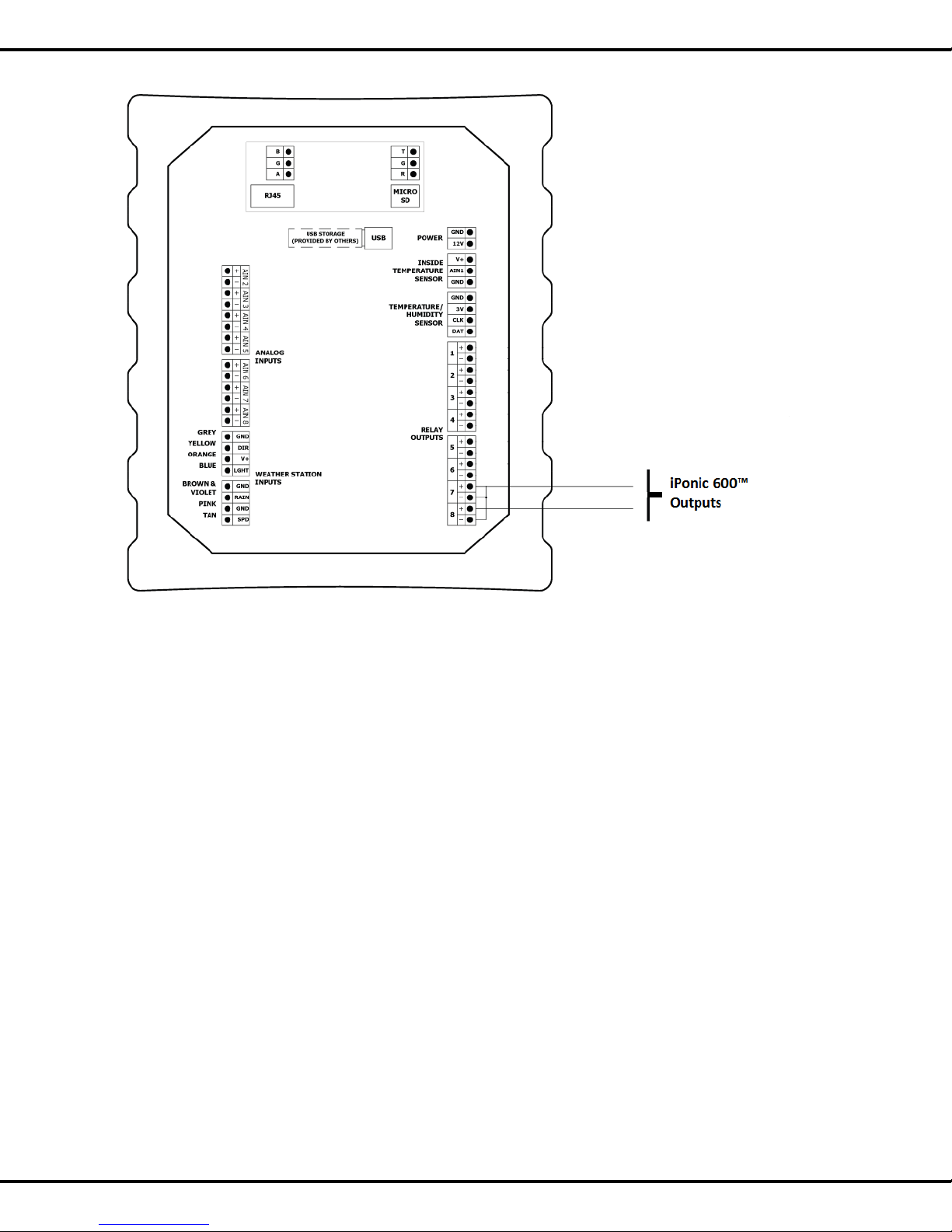

Internal Layout

Figure 4.2 shows how the iPonic 600looks on the inside. Although the unit is pre-wired it is good to have

some familiarity with the internal layout.

Figure 4.2 Board Layout of the iPonic 600PCB

Manual Override

Switches

Master Reset

Button

USB Storage

Input

Communication

Module

(OPTIONAL)

Screen contrast

adjustment

10 iGrowSeries 100 Installation Manual 960-0001-20

Figure 4.3 Electrical Connection Diagram of the iPonic 614

960-0001-20 iGrowSeries 100 Installation and User Manual 11

Connecting to the iPonic 600

Warning: Do Not Plug-in the power cord or any of the equipments into the iPonic 600without checking

to make sure all the manual override switches are in the OFF position.

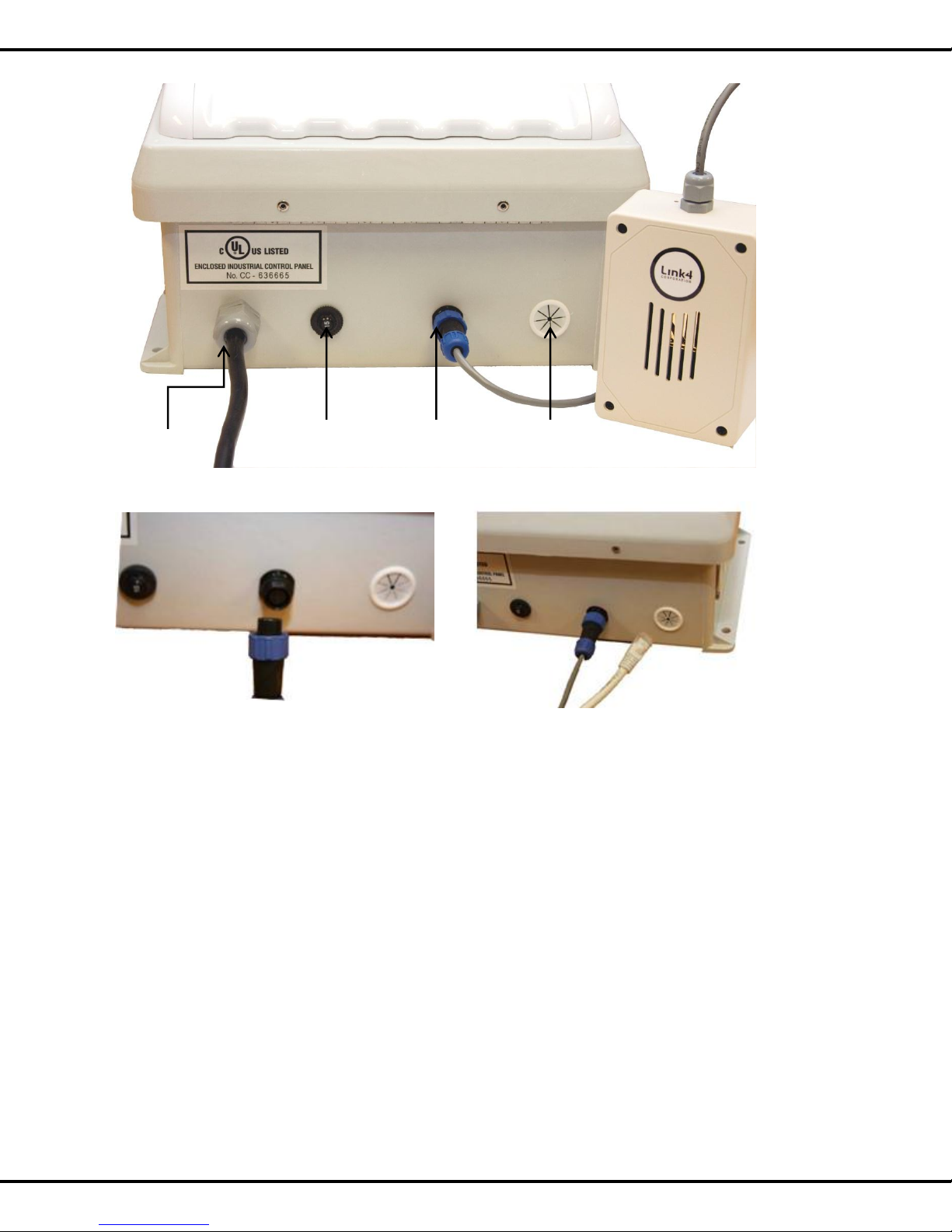

Indoor Sensor Module Installation

The iPonic 600ships with a sensor module. The module includes a 50-foot sensor cable. Normally

you will want to hang the module near the crop level close to the center of the controlled environment. It

is important to keep the module away from irrigation emitters, unit heaters, etc. that will affect the

accuracy of the sensor.

1. Connect the sensor module at the bottom of the iPonic 600as shown in Fig. 5.1 Make sure it is

screwed in tight.

2. You may extend the sensor cable as needed, but be sure to use an adapter and wire approved by

Link4 to make any extensions (the wire and adapter can be purchased from Link4). It should be noted

that the controller is calibrated for a 50 ft. temperature probe. If additional wires are added or

removed, software calibration will be necessary to ensure proper temperature measurement

accuracy.

Note: If any splices are needed to extend cable length, make certain they are WATERTIGHT. Water or

fertilizer infiltration WILL cause unstable sensor readings.

3. Keep sensor cables away from interference sources, including high voltage power wiring, inverters,

motor controllers, mercury arc, or sodium lamp circuits. Placing sensor cable near such wiring may

cause erratic sensor readings.

Optional Ethernet Cable Installation

If you want to connect to your local network or directly to the internet, you will need to connect an

Ethernet cable. Insert the cable through the socket as shown in the Fig 5.1. Plug in the cable to the

socket provided on the iPonic PCB board. For access to the internet, an optional communications

module is required and can be purchased from your dealer or distributor.

12 iGrowSeries 100 Installation Manual 960-0001-20

Equipment Installation

The iPonic 600has eight (8) 115 VAC electrical outlets, a resettable 15 ampere fuse and a six foot

power cord. On each side of the unit the bottom two outlets are ganged, as shown in the Fig.5.2 below,

whereas, the top two are independent. This gives a total of six outputs that can be controlled

independently. These outputs are numbered from 1-3 on the left side from top to bottom and 4-6 on the

right side, also from top to bottom. In a typical installation, the equipment are connected as follows:

Output 1 –Lights

Output 2 –CO2 injector

Output 3 –Irrigation pump

Output 4 –Dehumidifier

Output 5 –Heater

Output 6 –Vent Fan(s)

Power Cord

15A

Resettable

Breaker

Sensor

Module

Connector

Ethernet

Connection

(Optional)

Fig 5.1 Sensor Module and Ethernet Connections

960-0001-20 iGrowSeries 100 Installation and User Manual 13

Warning: The total amperage drawn from the iPonic 600must not exceed 15 amps.

Low Voltage Output Installation

Your iPonic 600™ has two (outputs #7 and #8) relays that are provided as dry contacts, i.e. switch

closures. If an output is activated to ON, the switch is “closed” (shorted); and if it is activated to OFF, the

switch is “open” (no continuity between the positive and negative terminals).

The board mounted relays are intended as “pilot” relays. For most loads you will want the iPonic 600™

outputs to control a load relay or contactor that is connected to the motor. However, in some cases such

as and alarm unit or irrigation valves that are 24 VAC, you can drive them directly assuming that you are

wiring only one or two valves per relay. The maximum current load recommended for each of the iPonic

600™ relays is 1.0 amp.

Warning –Do not exceed 1 Ampere or 24 Volts for outputs 7 and 8

Figure below shows the low voltage connection points for outputs 7 and 8.

5.2 Equipment Installation

14 iGrowSeries 100 Installation Manual 960-0001-20

960-0001-20 iGrowSeries 100 Installation and User Manual 15

Programming

Before You Begin

Before the iPonic 600™ is programmed, it is recommended that the following steps are followed:

Hardware is properlyinstalled and tested with manual switches.

All internal switches have been restored back to the OFF state.

All the templates from Chapter 3: Control Strategies that are relevant to your application are understood

and are completely filled out.

You can upgrade your controller to the latest firmware by going to iponic.link4corp.com. Follow the

provided instruction to upgrade your controller.

iPonic 600™ Main Status Screens

These are the status screens that you will see when you first power up the system. Pressing the HOME button

will let you toggle between the two screens.

Navigation

The following figures are designed to explain the features of these status screens.

Please review carefully.

Table of contents

Popular Network Router manuals by other brands

D-Link

D-Link DES-1210-52/ME Cli reference guide

Digisol

Digisol DG-BG4300NU/IS Faq

Nortel

Nortel Integrated Conference Bridge user guide

Nortel

Nortel Softphone 2050 installation guide

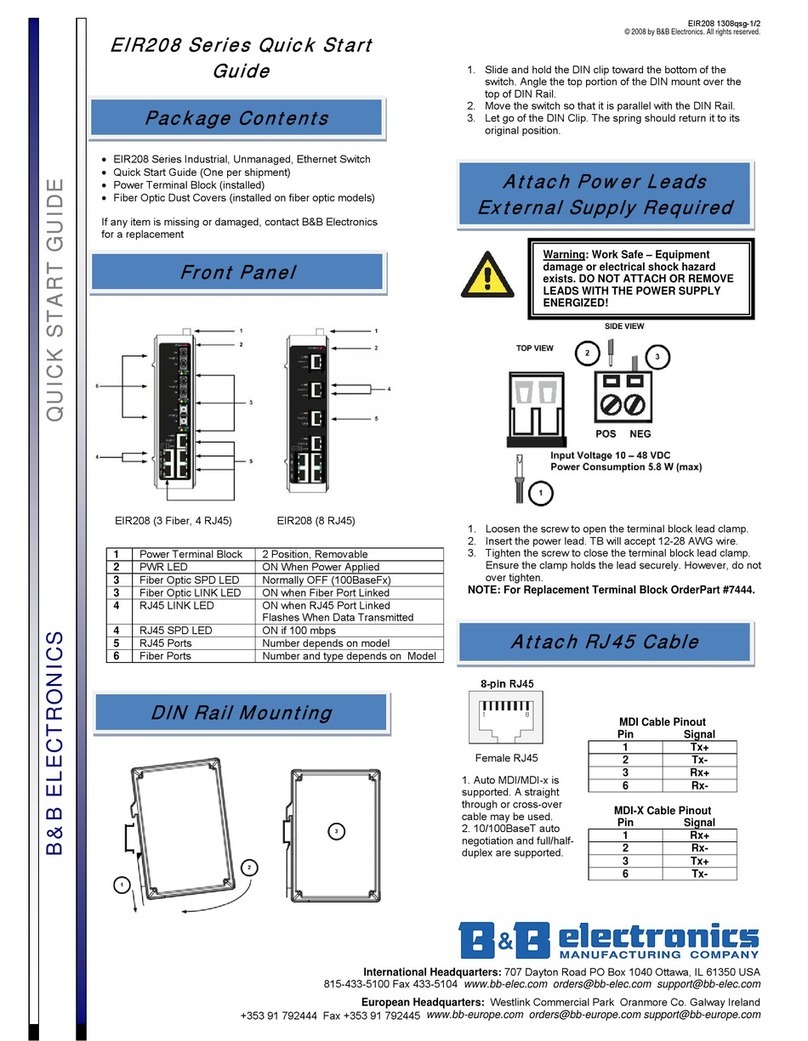

B&B Electronics

B&B Electronics EIR208 Series quick start guide

Digi

Digi TransPort WR21 Installation, operation and maintenance