Copyright © 1991-1997 by Linn Products Limited. All Rights Reserved. Page5

Revised Dec 97

Index

GENERALINFORMATION

Thiswillgivesomegeneralinformationonthefaults,(andabuse!)ofspeakerunits.

The most common cause of failure is over-driving which may result in:

Distortedsound,

Lowoutput,

And finally:No Sound

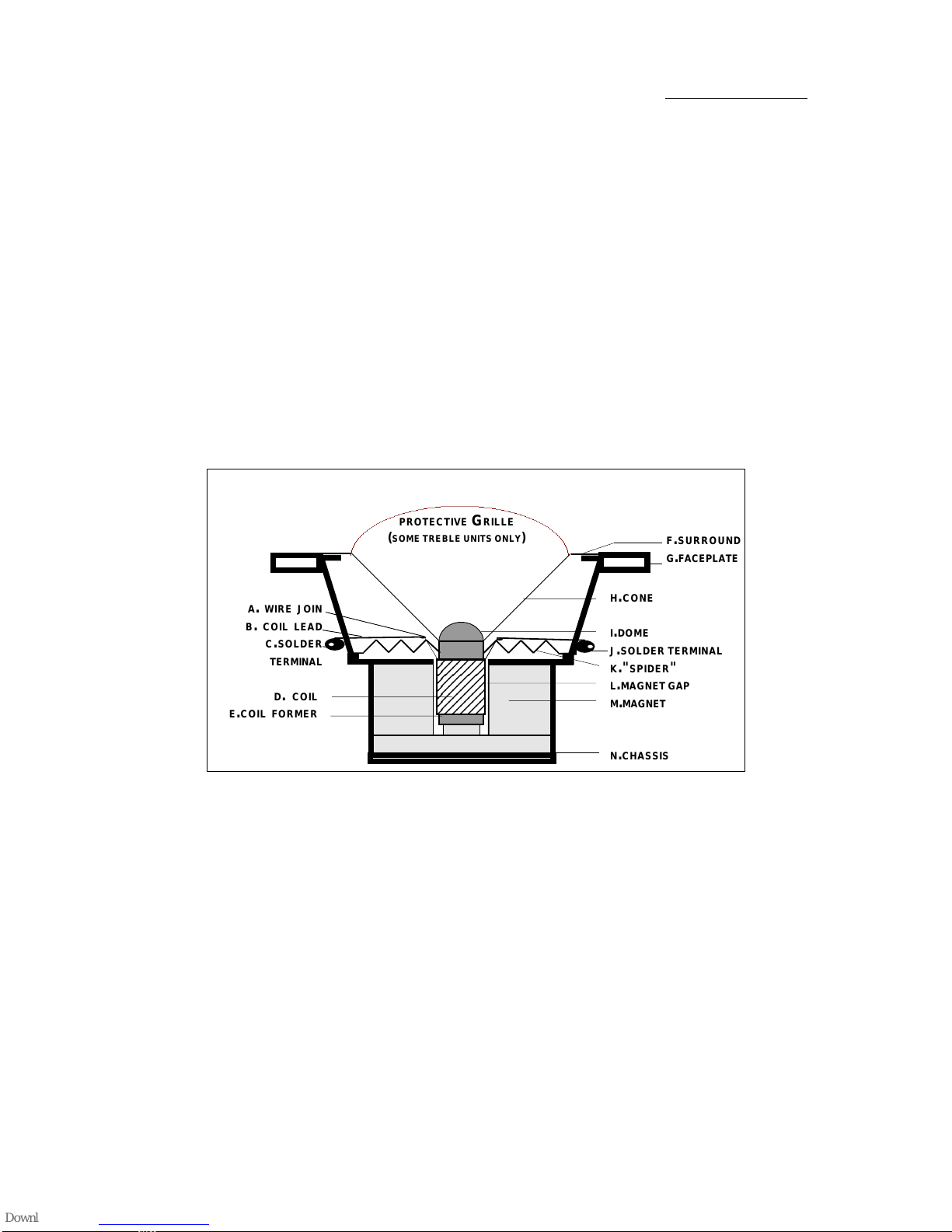

Allfaultscannormallybeconfirmedbyopeninguptheunitandexaminingthevoice

coil. Be warned that once a unit is opened it can not be reused and will have

to be replaced, so only do this if the unit is confirmed as being faulty.

DAMAGED UNITS

1. CURRENTOVERDRIVE:(Allunits)

Whenplayingthemusictoo loud (parties etc) or whendrivingalowpowered

amplifierintoclipping thecurrentacrossthevoicecoilcanbecome excessive

and cause the speaker voice coil to overheat.

First:

The enamel on the coil will start to blister and swell and this will cause

distortion as it will touch and rub the sides of the magnet gap as the voice

coilmovesforwardandbackward.

Next:

If the condition that is causing the blistering to occur continues, (the volume

isnotturneddown)theblisteringwillincreaseuntilitislargeenoughtorestrict

or stop the voice coil moving This will result in increased distortion, reduced

output and finally - no sound.

This can be seen by opening up the speaker and examining the voice

coil.

Remember, opening the unit is final and not reversible so the unit will

be need to be scrapped.

Finally:

The voice coil wire burns out and either goes open or short circuit. The unit

is now dead. This can be confirmed by checking with a multi-meter set on

ohms: Typical reading for a good unit is around 6- 8 Ohms.

2. HIGHFREQUENCYOSCILLATION:(Trebleunits)

Thiscanoccurwithunstableorfaultyamplifierswhichgeneratehighfrequency

signals (which may sometimes only be audible to the neighbourhood cat)

which will cause the unit to overheat due to the excessive High Frequency

current. - see point 1. These H/F signals can also occur where there are

earthingproblems.Somenamedamplifiersgonuts shouldyoudisconnectthe

earth while the volume is up, especially phono earths.

3. TRANSIENTDAMAGE:(Treble units)

Thiscanhappenwhenalargetransientsignalisappliedtothespeakersuch

aslettingthestylusfallontherecordwiththevolumesetveryhigh,fastcuing

(fast fwd or fast rev)of a tape recorder with the volume set high etc.

Thiswillcausethevoicecoil to"leap"forward(orbackword)beyondthelimit

ofitsnormal travelwhichmaybreakthevoice coilleadwireatthestart ofthe

coil.

4. DCVOLTAGEACROSSTHESPEAKER.(BassandMid-rangeunits)

Shoulda poweramplifierbecomefaulty andproduceDCacross thespeaker

outputthevoicecoil(s)willoverheatandbecomedamagedordestroyed(See

1). However as the treble units in passive speakers are driven through a by-

passfiltertheywillnotbedamagedunlessthevoltageissufficienttoburnout

the crossover, after which all the units may be destroyed.

SPEAKER UNITS